Abstract

Wood is one of the most valuable and abundant renewable materials. Development of wood-based advanced products comprises an important and exciting area of research. In recent times, replacement of traditional technology for the improvement of wood preservation and drying has drawn substantial scientific interest. These technologies are important for improving the functional properties of wood. More accurate and rapid determination of wood properties adds value to the appropriate utilization of wood and its aesthetic value, which plays a significant role in the market. In this regard, lasers are a promising technology in wood science for architectural essence and furniture making to toys and fine crafts. Utilizing this technology ranges from simple incision to development of advanced wood-based products and ensured environmental sustainability. Better elucidation of the working principle and optimisation of lasers in wood science promotes opportunities for the development of industrial wood-based products. This review, critically presents various laser applications that improve wood functionality and have the potential to enhance sustainability of wood-based products and industries.

Highlights

Lasers are applied in different biological, industrial and commercial usages.

Wood science applications also benefit from the use of laser technology.

Integrating wood properties mapping using lasers supports efficient resource use.

Laser technology aids in forest conservation and mitigation of climate-change impacts.

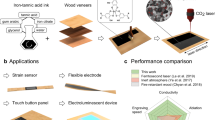

Lasers can produce advanced materials like graphene and detailed wooden artefacts.

Multifaceted Laser Applications for Wood – A Review from Properties Analysis to Advanced Products Manufacturing.

Similar content being viewed by others

Data Availability

Data sharing is not applicable to this article as no new data were created or analyzed in this study. The article has been written based on the secondary information.

References

Jiang, F., et al.: Wood-Based Nanotechnologies toward Sustainability.Advanced Materials, 30(1). (2018)

Ye, R.Q., et al.: Laser-Induced Graphene Formation on Wood.Advanced Materials, 29(37). (2017)

Chen, C.J., et al.: Structure-property-function relationships of natural and engineered wood.Nature Reviews Materials

Pappala, A.: Religion, Beliefs and Customs. SCL Publications (2015)

Palus, H., et al.: Projecting Climate Change Potential of Harvested Wood Products under Different Scenarios of Wood Production and Utilization: Study of Slovakia.Sustainability, 12(6). (2020)

Engineering, N.A.: Lasers: Invention to Application, ed. J.R. Whinnery, J.H. Ausubel, and H.D. Langford. Washington, DC: The National Academies Press. 144. (1987)

Tsai, H.C.: Effects of electromagnetic disturbance on light intensity signal of laser beam system. Progress In Electromagnetics Research M. 40, 167–178 (2014)

Chen, J., et al.: High-intensity and low-divergence THz laser with 1D autofocusing symmetric airy beams. Opt. Express. 27(16), 22877–22889 (2019)

Beckmann, L., Ehrlichmann, D.: Optical systems for high-power laser applications: principles and design aspects. Opt. Quant. Electron. 27(12), 1407–1425 (1995)

Affan Ahmed, S., Mohsin, M., Zubair, S.M., Ali: Survey and Technological Analysis of Laser and its Defense Applications. Defence Technology (2020)

Colin, F., Laborie, M.P., Fortin, M.: Wood properties: future needs, measurement and modelling. Ann. For. Sci. 72(6), 665–670 (2015)

Zobel, B.J., van Buijtenen, J.P.: Wood Variation: Its Causes and Control. Springer Series in Wood Science. Springer-Verlag Berlin Heidelberg, Springer-Verlag, New York (1989)

Tapia, C., Aicher, S.: Variation and serial correlation of modulus of elasticity between and within european oak boards (Quercus robur and Q. petraea). Holzforschung. 74(1), 33–46 (2020)

Le, T.S.D., et al.: Ultrafast Laser Pulses Enable One-Step Graphene Patterning on Woods and Leaves for Green Electronics.Advanced Functional Materials, 29(33). (2019)

Zhu, H., et al.: Wood-Derived materials for Green Electronics, Biological Devices, and Energy Applications. Chem. Rev. 116(16), 9305–9374 (2016)

Zhu, H.L., et al.: Wood-Derived Materials for Green Electronics, Biological Devices, and Energy Applications (vol 116, pg 9305, Chemical Reviews, 2016. 116(19): p. 12650–12650. (2016)

Solé, J.G., Bausá, L.E., Jaque, D.: An Introduction to the Optical Spectroscopy of Inorganic Solids. An Introduction to the Optical Spectroscopy of Inorganic Solids. 1-283. (2005)

Hattori, N., et al.: Microscopic observations of the solid products deposited on the edge of papers by co2-laser cutting. Mokuzai Gakkaishi. 34(5), 417–422 (1988)

Breck Hitz, C., JeffHecht, J.E.: Introduction to Laser Technology. Fourth Edition ed. Hoboken, New Jersey: A John Wiley & Sons, Inc., Publication, Ieee Press. (2012)

Kacik, F., Kubovsky, I.: Chemical changes of beech wood due to CO2 laser irradiation. J. Photochem. Photobiology a-Chemistry. 222(1), 105–110 (2011)

Kubovsky, I., Kacik, F.: Colour and chemical changes of the lime wood surface due to CO2 laser thermal modification. Appl. Surf. Sci. 321, 261–267 (2014)

Kubovsky, I., Kacik, F., Reinprecht, L.: The impact of UV radiation on the change of colour and composition of the surface of lime wood treated with a CO2 laser. J. Photochem. Photobiology a-Chemistry. 322, 60–66 (2016)

Ando, K., Hattori, N.: Effects of Laser Incising on Lumber Strength I. partial compression strength of lumber. Mokuzai Gakkaishi. 57(2), 81–87 (2011)

Giroud, G., et al.: Modeling black spruce wood fiber attributes with terrestrial laser scanning. Can. J. For. Res. 49(6), 661–669 (2019)

Jacobs, M., Rais, A., Pretzsch, H.: Analysis of stand density effects on the stem form of Norway spruce trees and volume miscalculation by traditional form factor equations using terrestrial laser scanning (TLS). Can. J. For. Res. 50(1), 51–64 (2020)

Oscarsson, J., Olsson, A., Enquist, B.: Localized modulus of elasticity in timber and its significance for the accuracy of machine strength grading. Wood Fiber Sci. 46(4), 489–501 (2014)

Wang, X.P., et al.: Defect detection and quality assessment of hardwood logs: part 2-combined acoustic and laser scanning system. Wood Fiber Sci. 50(3), 310–322 (2018)

Hattori, N., Yokoo, K.: Methods for preservation treatment of wood. (1991)

Islam, M.N., et al.: Impregnation of Preservative and Fire Retardants into japanese Cedar Lumber by Passive Impregnation. Bioresources. 8(1), 395–404 (2013)

Islam, M.N., et al.: Impregnation of laser incised wood of Douglas fir and japanese cedar by dipping (passive impregnation) in solutions of copper azole (CuAz- B) and a fire retardant (PPC). Holzforschung. 68(3), 353–360 (2014)

Islam, M.N., et al.: Passive impregnation of liquid in impermeable lumber incised by laser. J. Wood Sci. 53(5), 436–441 (2007)

Listyanto, T., et al.: Microwave and steam injection drying of CO2 laser incised Sugi lumber. J. Wood Sci. 59(4), 282–289 (2013)

Simpson, W.T.: Laser incising to increase drying rate of wood. Wood Fiber Sci. 19(1), 9–25 (1987)

Chryssolouris, G., Stavropoulos, P., Salonitis, K.: Process of Laser Machining, in Handbook of Manufacturing Engineering and Technology, A.Y.C. Nee, Editor. Springer London: London. p. 1601–1628. (2015)

Maiman, T.H.: Stimulated optical radiation in ruby. Nature. 187(4736), 493–494 (1960)

Weber, M.J.: Handbook of Lasers. CRC Press LLC (2001)

Powell, R.: Types of lasers. In: Springer Handbook of Atomic, Molecular, and Optical Physics, pp. 1035–1049. Springer, New York: New York, NY (2006). G. Drake, Editor

Skoog, D.A., Holler, F.J., Crouch, S.R.: Principles of Instrumental Analysis. Thomson Brooks/Cole (2007)

Lindlein, N., Leuchs, G.: Wave Optics. In: Springer Handbook of Lasers and Optics, pp. 87–156. Springer, New York: New York, NY (2007). F. Träger, Editor

Dubey, A.K., Yadava, V.: Laser beam machining - A review. Int. J. Mach. Tools Manuf. 48(6), 609–628 (2008)

Gautam, G.D., Pandey, A.K.: Pulsed nd:YAG laser beam drilling: a review. Opt. Laser Technol. 100, 183–215 (2018)

Wang, H.J., et al.: Laser drilling of structural ceramics-A review. J. Eur. Ceram. Soc. 37(4), 1157–1173 (2017)

Klimt, B.H.: State of the art in laser marking and engraving Proceedings of SPIE - The International Society for Optical Engineering, 744: p. 185–189. (1987)

Leone, C., Lopresto, V., De Iorio, I.: Wood engraving by Q-switched diode-pumped frequency-doubled nd:YAG green laser. Opt. Lasers Eng. 47(1), 161–168 (2009)

Zhou, B.H., Mahdavian, S.M.: Experimental and theoretical analyses of cutting nonmetallic materials by low power CO2-laser. J. Mater. Process. Technol. 146(2), 188–192 (2004)

Guo, X.L., et al.: Morphology, mechanism and kerf variation during CO2 laser cutting pine wood. J. Manuf. Process. 68, 13–22 (2021)

Pyorala, J., et al.: Assessing log geometry and wood quality in standing timber using terrestrial laser-scanning point clouds. Forestry. 92(2), 177–187 (2019)

Pyorala, J., et al.: Variability of wood Properties Using Airborne and Terrestrial Laser Scanning, p. 235. Remote Sensing of Environment (2019)

Daval, V., et al.: Automatic measurement of wood fiber orientation and knot detection using an optical system based on heating conduction. Opt. Express. 23(26), 33529–33539 (2015)

Nieminen, S., Heikkinen, J., Raty, J.: Laser transillumination imaging for determining wood defects and grain angle.Measurement Science and Technology, 24(12). (2013)

Simonaho, S.P., et al.: Determination of wood grain direction from laser light scattering pattern. Opt. Lasers Eng. 41(1), 95–103 (2004)

Aira-Zunzunegui, J.-R., et al.: Determination of wood moisture content with terrestrial laser scanner. Constr. Build. Mater. 350, 128834 (2022)

Muhammad, N.A., Isnaeni, Tahir, D.: Optical properties of wood by laser spectroscopy Journal of Physics: Conference Series, 1341: p. 082019. (2019)

Briggert, A., Olsson, A., Oscarsson, J.: Prediction of tensile strength of sawn timber: definitions and performance of indicating properties based on surface laser scanning and dynamic excitation.Materials and Structures, 53(3). (2020)

Olsson, A., Oscarsson, J.: Strength grading on the basis of high resolution laser scanning and dynamic excitation: a full scale investigation of performance. Eur. J. Wood Wood Product. 75(1), 17–31 (2017)

Wessels, C.B., Malan, F.S., Rypstra, T.: A review of measurement methods used on standing trees for the prediction of some mechanical properties of timber. Eur. J. For. Res. 130(6), 881–893 (2011)

Rudnicki, M., et al.: Measuring wood quality in standing trees–a review, in General Technical Report (GTR). : Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. p. 13. (2017)

Jakob, S., et al.: Femtosecond laser machining for characterization of local mechanical properties of biomaterials: a case study on wood. Sci. Technol. Adv. Mater. 18(1), 574–583 (2017)

Fischer, C., et al.: Predicting dynamic modulus of elasticity of Norway spruce structural timber by forest inventory, airborne laser scanning and harvester-derived data. Scand. J. For. Res. 33(6), 603–612 (2018)

Hilker, T., et al.: Prediction of Wood Fiber attributes from LiDAR-Derived Forest Canopy Indicators. For. Sci. 59(2), 231–242 (2013)

Luther, J.E., et al.: Predicting wood quantity and quality attributes of balsam fir and black spruce using airborne laser scanner data. Forestry. 87(2), 313–326 (2014)

Maltamo, M., et al.: Incorporating tree- and stand-level information on crown base height into multivariate forest management inventories based on airborne laser scanning.Silva Fennica, 52(3). (2018)

Liang, X.L., et al.: International benchmarking of terrestrial laser scanning approaches for forest inventories. Isprs J. Photogrammetry Remote Sens. 144, 137–179 (2018)

Liang, X.L., et al.: In-situ measurements from mobile platforms: an emerging approach to address the old challenges associated with forest inventories. Isprs J. Photogrammetry Remote Sens. 143, 97–107 (2018)

Liu, J.C., et al.: Extraction of Sample Plot Parameters from 3D Point Cloud Reconstruction Based on Combined RTK and CCD Continuous Photography.Remote Sensing, 10(8). (2018)

Liu, T.T., et al.: Ultrasmall Ru2P nanoparticles on graphene: a highly efficient hydrogen evolution reaction electrocatalyst in both acidic and alkaline media. Chem. Commun. 54(27), 3343–3346 (2018)

Dassot, M., Constant, T., Fournier, M.: The use of terrestrial LiDAR technology in forest science: application fields, benefits and challenges. Ann. For. Sci. 68(5), 959–974 (2011)

Liang, X.L., et al.: Terrestrial laser scanning in forest inventories. Isprs J. Photogrammetry Remote Sens. 115, 63–77 (2016)

Maas, H.G., et al.: Automatic forest inventory parameter determination from terrestrial laser scanner data. Int. J. Remote Sens. 29(5), 1579–1593 (2008)

Newnham, G.J., et al.: Terrestrial laser scanning for plot-scale forest measurement. Curr. Forestry Rep. 1(4), 239–251 (2015)

Barbeito, I., et al.: Terrestrial laser scanning reveals differences in crown structure of Fagus sylvatica in mixed vs. pure european forests. For. Ecol. Manag. 405, 381–390 (2017)

Howler, K., et al.: Competition improves quality-related external stem characteristics of Fagus sylvatica. Can. J. For. Res. 47(12), 1603–1613 (2017)

Kankare, V., et al.: Estimation of the timber quality of Scots Pine with Terrestrial Laser scanning. Forests. 5(8), 1879–1895 (2014)

Murphy, G.E., Acuna, M.A., Dumbrell, I.: Tree value and log product yield determination in radiata pine (Pinus radiata) plantations in Australia: comparisons of terrestrial laser scanning with a forest inventory system and manual measurements. Can. J. For. Res. 40(11), 2223–2233 (2010)

Pyorala, J., et al.: Comparison of terrestrial laser scanning and X-ray scanning in measuring Scots pine (Pinus sylvestris L.) branch structure. Scand. J. For. Res. 33(3), 291–298 (2018)

Blanchette, D., et al.: Predicting wood fiber attributes using local-scale metrics from terrestrial LiDAR data: a case study of Newfoundland conifer species. For. Ecol. Manag. 347, 116–129 (2015)

Nystrom, J.: Automatic measurement of fiber orientation in softwoods by using the tracheid effect. Comput. Electron. Agric. 41(1–3), 91–99 (2003)

van Wijk, K., Simpson, J., Hitchman, S.: A modified Hankinson equation for the wave speed of laser ultrasound in Radiata Pine. Wave Motion. 89, 57–64 (2019)

Chichkov, B.N., et al.: Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. a-Materials Sci. Process. 63(2), 109–115 (1996)

Ihlemann, J., et al.: Nanosecond and femtosecond excimer-laser ablation of oxide ceramics. Appl. Phys. a-Materials Sci. Process. 60(4), 411–417 (1995)

Wang, X.Z., et al.: Multi-Scale Evaluation of the Effect of Phenol Formaldehyde Resin Impregnation on the Dimensional Stability and Mechanical Properties of Pinus Massoniana Lamb.Forests, 10(8). (2019)

Pokharel, B., et al.: Predictive Modeling of Black Spruce (Picea mariana (Mill.) BSP) Wood Density Using Stand Structure Variables Derived from Airborne LiDAR Data in Boreal Forests of Ontario.Forests, 7(12). (2016)

van Leeuwen, M., et al.: Assessment of standing wood and fiber quality using ground and airborne laser scanning: a review. For. Ecol. Manag. 261(9), 1467–1478 (2011)

Bucur, V.: Nondestructive Characterization and Imaging of Wood. Springer Series in Wood Science, 1 edn. Springer-Verlag, Berlin Heidelberg (2003)

Wiedemann, G., et al.: Surface modification of wood by laser irradiation. Eclat - European Conference on Laser Treatment of Materials, ed. B.L. Mordike. 177–182. (1998)

Wust, H., et al.: Surface modification of wood by laser irradiation. Optics and Lasers in Biomedicine and Cultures Owls V, ed. C. Fotakis, T. Papazoglou, and C. Kalpouzos. Vol. 5. 151–154. (2000)

Wust, H., et al.: Laser cleaning applied in the restoration of a medieval wooden panel chamber at Pirna, in High-Power Lasers in Civil Engineering and Architecture, S. Nakai, L.A. Hackel, and W.C. Solomon, Editors. p. 240–249. (2000)

Ando, K., et al.: Drill and laser incising of lamina for fire-resistive glulam. Wood Mater. Sci. Eng. 11(3), 176–181 (2016)

Martin, M.Z., et al.: Analysis of preservative-treated wood by multivariate analysis of laser-induced breakdown spectroscopy spectra. Spectrochimica Acta Part B-Atomic Spectroscopy. 60(7–8), 1179–1185 (2005)

Ando, K., Hattori, N.: Effects of Laser Incising on Lumber Strength II. Bending strength of square lumber. Mokuzai Gakkaishi. 60(1), 23–27 (2014)

Ando, K., et al.: Development of one-hour fire-resistive building materials made of combustible japanese Cedar using laser incising. Int. J. Mater. Sci. 4(1), 31–34 (2014)

Kubovsky, I., Babiak, M.: Color changes induced by co2 laser irradiation of wood surface. Wood Res. 54(3), 61–66 (2009)

Lin, C.J., et al.: Effects of feed speed ratio and laser power on engraved depth and color difference of Moso bamboo lamina. J. Mater. Process. Technol. 198(1–3), 419–425 (2008)

Petru, A., Lunguleasa, A.: Effects of the laser power on wood colouration. (2015)

Petutschnigg, A., et al.: Laser Treatment of Wood Surfaces for Ski Cores: An Experimental Parameter Study Advances in Materials Science and Engineering, 2013. (2013)

Barcikowski, S., Koch, G., Odermatt, J.: Characterisation and modification of the heat affected zone during laser material processing of wood and wood composites. Holz Als Roh-Und Werkstoff. 64(2), 94–103 (2006)

Vidholdova, Z., Reinprecht, L., Igaz, R.: The impact of laser surface modification of Beech Wood on its color and occurrence of molds. Bioresources. 12(2), 4177–4186 (2017)

Rahman, K.S., et al.: Incising as an aid for the preservative treatment of wood - A review. Recent Pat. Mater. Sci. 4(3), 201–208 (2011)

Nath, S., et al.: Laser incising of Wood: a review. Lasers in Engineering. 45(4–6), 381–403 (2020)

Hattori, N., et al.: Laser incising of wood - impregnation of columns with water-soluble dye. Mokuzai Gakkaishi. 40(12), 1381–1388 (1994)

Ando, K., et al.: Effect of steam injection re-drying of japanese cedar on preservative leaching after passive impregnation. Wood Mater. Sci. Eng. 7(4), 196–201 (2012)

Goodell, B., Kamke, F.A., Liu, J.: Laser incising of spruce lumber for improved preservative penetration. For. Prod. J. 41(9), 48–52 (1991)

Islam, M.N., et al.: Effects of species and moisture content on penetration of liquid in laser incised lumber by the passive impregnation method. Eur. J. Wood Wood Product. 67(2), 129–133 (2009)

Islam, M.N., et al.: Preservative treatment of Douglas-fir lumber by the passive impregnation method with copper azole. Eur. J. Wood Wood Product. 67(1), 77–81 (2009)

Islam, M.N., et al.: Change of temperature and pressure in dry and green douglas-fir and sugi wood during passive impregnation method. Wood Fiber Sci. 43(3), 305–310 (2011)

Miyazaki, J., Nakano, T.: Effects of wood preservatives on adhesive properties IV - Effects of preservation and incising on shear strength and delamination. Mokuzai Gakkaishi. 49(3), 212–219 (2003)

Shalbafan, A., Nadali, A., Thoemen, H.: A Multifunctional Mineral Binder for Plywood Production: The Effect of Manufacturing Parameters on Bonding Quality.Materials, 13(10). (2020)

Hamid, S., et al.: The Effect of Incising Process on Copper-Chromium-Arsenic Retention in Scodocarpus Borneensis and Kokoona Spp Mathematical Models and Methods in Applied Sciences, 2009. 3: p. 123–128

Li, L.J., Mazumder, J.: A study of the mechanism of laser cutting of wood. For. Prod. J. 41(10), 53–59 (1991)

Hattori, N.: Laser processing of wood. Mokuzai Gakkaishi. 41(8), 703–709 (1995)

Hattori, N., et al.: Incising of wood with a 500 watt carbon-dioxide laser. Mokuzai Gakkaishi. 37(8), 766–768 (1991)

Ando, K., et al.: Preservative leaching from copper azole-treated Lumber: a comparison between the full-cell method and the Passive-Impregnation Method. For. Prod. J. 61(3), 270–272 (2011)

Kamke, F.A., Peralta, P.N.: Laser incising for lumber drying. For. Prod. J. 40(4), 48–54 (1990)

Lee, C.K., Chaiken, R.F., Singer, J.M.: Charring pyrolysis of wood in fires by laser simulation Symposium (International) on Combustion, 16(1): p. 1459–1470. (1977)

Paysepar, H., et al.: Production of phenolic chemicals from hydrolysis lignin via catalytic fast pyrolysis.Journal of Analytical and Applied Pyrolysis,149. (2020)

Du, B.Y., et al.: Catalytic Conversion of Lignin to bio-oil over PTA/MCM-41 Catalyst Assisted by Ultrasound Acoustic Cavitation, p. 206. Fuel Processing Technology (2020)

Ko, J.K., Lee, S.M.: Advances in cellulosic conversion to fuels: engineering yeasts for cellulosic bioethanol and biodiesel production. Curr. Opin. Biotechnol. 50, 72–80 (2018)

da Silva, J.C.G., et al.: Single-step and multi-step thermokinetic study - Deconvolution method as a simple pathway for describe properly the biomass pyrolysis for energy conversion.Energy Conversion and Management,209. (2020)

Quintero, F., et al.: Feasibility Study on Laser Cutting of Phenolic Resin Boards, in Lasers in Manufacturing 2011: Proceedings of the Sixth International Wlt Conference on Lasers in Manufacturing, Vol 12, Pt A, M. Schmidt, Editors. p. 578–583. (2011)

Cousin, J., et al.: Laser spectroscopic monitoring of gas emission and measurements of the C-13/C-12 isotope ratio in CO2 from a wood-based combustion. J. Quant. Spectrosc. Radiat. Transf. 109(1), 151–167 (2008)

Dieguez-Alonso, A., Anca-Couce, A., Zobel, N.: On-line tar characterization from pyrolysis of wood particles in a technical-scale fixed-bed reactor by applying Laser-Induced Fluorescence (LIF) Journal of Analytical and Applied Pyrolysis, 102: p. 33–46. (2013)

Lang, N., et al.: Pyrolysis behavior of thermally thick wood particles: time-resolved characterization with laser based in-situ diagnostics. Fuel. 210, 371–379 (2017)

Dieguez-Alonso, A., et al.: Understanding the primary and secondary slow pyrolysis mechanisms of holocellulose, lignin and wood with laser-induced fluorescence. Fuel. 153, 102–109 (2015)

Cooper, G.A., Erickson, R.W., Haygreen, J.G.: Drying behavior of prefrozen black walnut. For. Prod. J. 20(1), 30–35 (1970)

Erickson, R.W., Peterson, H.D.: The influence of pre-freezing and cold water extraction on the shrinkage of wood. For. Prod. J. 19, 53–58 (1969)

Chudnoff, M.: Void volume wood: an any tree-whole tree use concept. For. Prod. J. 22(6), 49–53 (1972)

Cech, M.Y.: Dynamic transverse compression treatment to improve drying behavior of yellow birch. For. Prod. J. 21(2), 41–50 (1971)

Alexiou, P.N., Wilkins, A.P., Hartley, J.: Effect of pre-steaming on drying rate, wood anatomy and shrinkage of regrowth eucalyptus-pilularis sm. Wood Sci. Technol. 24(1), 103–110 (1990)

Harris, R.A., Schroeder, J.G., Addis, S.C.: Steaming of red oak prior to kiln-drying - effects on moisture movement. For. Prod. J. 39(11–12), 70–72 (1989)

Simpson, W.T.: Steaming northern red oak to reduce kiln-drying time. For. Prod. J. 26(10), 35–36 (1976)

Ishiguri, F., et al.: Time-course changes of chemical and physical properties in sugi (Cryptomeria japonica D. Don) logs during smoke heating. Wood Fiber Sci. 35(4), 585–593 (2003)

Abubakari, A., Avramidis, S., Oliveira, L.C.: Impact of radio frequency heating pre-treatment on the kiln drying characteristics of sub-alpine fir. Eur. J. Wood Wood Product. 70(1–3), 245–251 (2012)

Miller, D.G.: Combining radio- frequency heating with kiln- drying to provide fast drying without degrade. For. Prod. J. 21(12), 17–21 (1971)

Torgovnikov, G., Vinden, P.: Microwave Wood Modification Technology and its applications. For. Prod. J. 60(2), 173–182 (2010)

Kobayashi, Y., et al.: Drying and anatomical characteristics of sugi wood attacked by bacteria during pond storage. J. Wood Sci. 44(6), 432–437 (1998)

Listyanto, T., et al.: CO2 laser incised Teak and Mahogany Lumber dried by microwave and steam injection. For. Prod. J. 66(7–8), 461–466 (2016)

Nakajima, K., et al.: Laser incising of Wood – Effect of wood density on hole shapes. Wood Ind. 54(8), 370–373 (1999)

Hattori, N., et al.: Application of laser incising to microwave drying of Sugi square lumber with black-heart. For. Resour. Environ. 35, 53–60 (1997)

Hasan, S.M., Hubeatir, K.A., Abd, D.S.: Effect of CO2 laser parameters on redwood engraving process complemented by Taguchi method. in 3rd International Conference on Materials Engineering and Science (IConMEAS). Electr Network. (2020)

Gochev, Z.: Laser wood Cutting and Modifications in its Structure, in International Furniture Congress, pp. 210–215. Mugla, Turkey (2016)

Eltawahni, H.A., Olabi, A.G., Benyounis, K.Y.: Investigating the CO2 laser cutting parameters of MDF wood composite material. Opt. Laser Technol. 43(3), 648–659 (2011)

Fukuta, S., et al.: Wavelength dependence of machining performance in UV-, VIS- and NIR-laser cutting of wood. J. Wood Sci. 62(4), 316–323 (2016)

Hattori, N., et al.: Trial ablation on a printed popular paper with pulsed Nd:YAG laser.International Forestry Review, 7(5). (2005)

Babenko, V.P., Tychinskii, V.P.: Gas-jet laser cutting. Sov J. Quantum Electron. 2(5), 399–410 (1973)

Sullivan, A.B., Houldcroft, P.T.: Gas-jet laser cutting. Br. Weld. J. 14(8), 443– (1967)

McMillin, C.W.: Application of automatic image-analysis to wood science. Wood Sci. 14(3), 97–105 (1982)

Lehner, C.: Drilling with light Industrial Laser Solutions for Manufacturing, : p. 30. (2004)

Nagai, K., Beckemper, S., Poprawe, R.: Laser Drilling of small holes in different kinds of concrete. Civil Eng. Journal-Tehran. 4(4), 766–775 (2018)

Kortsalioudakis, N., et al.: An application of laser drilling technique to fir and spruce wood specimens to improve their permeability, in The 7th International Scientific and Technical Conference, Innovations in Forest Industry and Engineering Design. : Sofia- Yundola, Bulgaria. (2014)

Grad, L., Mozina, J.: Optodynamic studies of Er: YAG laser interaction with wood. Appl. Surf. Sci. 127, 973–976 (1998)

Sandberg, D.: Additives in Wood Products-Today and Future Development, in Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts, A. Kutnar and S.S. Muthu, Editors. p. 105–172. (2016)

Baldan, A.: Adhesively-bonded joints and repairs in metallic alloys, polymers and composite materials: adhesives, adhesion theories and surface pretreatment. J. Mater. Sci. 39(1), 1–49 (2004)

Wu, Y.R., et al.: Effect of laser ablation surface treatment on performance of adhesive-bonded aluminum alloys. Surf. Coat. Technol. 304, 340–347 (2016)

Min, J., et al.: Application of laser ablation in adhesive bonding of metallic materials: A review.Optics and Laser Technology,128. (2020)

Panzner, M., et al.: Experimental investigation of the laser ablation process on wood surfaces. Appl. Surf. Sci. 127, 787–792 (1998)

Dobrev, T., Pham, D.T., Dimov, S.S.: Laser polishing. in Second International Conference on Multi-Material Micro Manufacture. Elsevier. (2006)

Marimuthu, S., Sezer, H.K., Kamara, A.M.: Chap. 7 - applications of laser cleaning process in high Value Manufacturing Industries. In: Developments in Surface Contamination and Cleaning: Applications of Cleaning Techniques, pp. 251–288. Elsevier (2019). R. Kohli and K.L. Mittal, Editors

Kim, D.-J., et al.: Dry Cleaning Technology of Silicon Wafer with a Line Beam for Semiconductor Fabrication by KrF Excimer laser. Jpn. J. Appl. Phys. 41, 4563–4570 (2002). Part 1, No. 7A)

Fekrsanati, F., et al.: Investigations regarding the behaviour of historic glass and its surface layers towards different wavelengths applied for laser cleaning. J. Cult. Herit. 2(4), 253–258 (2001)

Klein, S., et al.: Discoloration of marble during laser cleaning by nd:YAG laser wavelengths. Appl. Surf. Sci. 171(3), 242–251 (2001)

Klein, S., et al.: Comparative study of different wavelengths from IR to UV applied to clean sandstone. Appl. Surf. Sci. 157(1), 1–6 (2000)

Cooper, M., Larson, J.: Laser Cleaning in Conservation: An Introduction. Butter-worth Heineman, Oxford, United Kingdom: Taylor & Francis Ltd 120 (1998)

Fotakis, C., et al.: Laser technology in art conservation, in Resonance Ionization Spectroscopy 1996 - Eighth International Symposium, N. Winograd and J.E. Parks, Editors. p. 183–188. (1997)

Fotakis, C., et al.: Lasers in the conservation of painted artworks, in Second Gr-I International Conference on New Laser Technologies and Applications, A. Carabelas, Editors. p. 292–296. (1998)

Verges-Belmin, V.: Lasers in the Conservation of Artworks. in Proceedings of Lacona IV. Vienna, Austria: Springer, Berlin, Heidelberg. (2003)

Castellini, P., et al.: New applications of scanning laser Doppler Vibrometry (SLDV) to non-destructive diagnostics of artworks: mosaics, ceramics, inlaid wood and easel painting. J. Cult. Herit. 4, 321S–329S (2003)

Castillejo, M., et al.: Effect of wavelength on the laser cleaning of polychromes on wood. J. Cult. Herit. 4(3), 243–249 (2003)

Gaspar, P., et al.: A study of the effect of the wavelength in the Q-switched nd:YAG laser cleaning of gilded wood. J. Cult. Herit. 1(2), 133–144 (2000)

Cremers, D.A., Radziemski, L.J.: Handbook of Laser-Induced Breakdown Spectroscopy: Second Edition. Handbook of Laser-Induced Breakdown Spectroscopy: Second Edition. (2013)

Noll, R.: Laser-induced breakdown spectroscopy: Fundamentals and applications. Laser-Induced Breakdown Spectroscopy: Fundamentals and Applications. 1-543. (2012)

Holub, D., et al.: The Potential of Combining laser-induced Breakdown Spectroscopy and Raman Spectroscopy data for the Analysis of wood Samples, p. 195. Spectrochimica Acta Part B-Atomic Spectroscopy (2022)

Giakoumaki, A., Melessanaki, K., Anglos, D.: Laser-induced breakdown spectroscopy (LIBS) in archaeological science-applications and prospects. Anal. Bioanal. Chem. 387(3), 749–760 (2007)

Brech, F., Cross, L.: Optical microemission stimulated by a ruby maser. Appl. Spectrosc. 16, 5930 (1962)

Runge, E.F., Minck, R.W., Bryan, F.R.: Spectrochemical analysis using a pulsed laser source. Spectrochim. Acta. 20(4), 733–736 (1964)

Kearton, B., Mattley, Y.: Laser-induced breakdown spectroscopy - sparking new applications. Nat. Photonics. 2(9), 537–540 (2008)

Miziolek, A.W., Palleschi, V., Schechter, I.: Laser Induced Breakdown Spectroscopy. Cambridge: Cambridge University Press. (2006)

Anabitarte, F., Cobo, A., Lopez-Higuera, J.M.: Laser-Induced Breakdown Spectroscopy: Fundamentals, Applications, and Challenges ISRN Spectroscopy, 2012: p. 285240. (2012)

Moros, J., Laserna, J.: Laser-Induced Breakdown Spectroscopy (LIBS) of Organic Compounds: a review. Appl. Spectrosc. 73(9), 963–1011 (2019)

Trejos, T., et al.: Fast identification of inorganic and organic gunshot residues by LIBS and electrochemical methods. Forensic Chem. 8, 146–156 (2018)

Chen, Z.J., et al.: Fast and sensitive trace metal analysis in aqueous solutions by laser-induced breakdown spectroscopy using wood slice substrates. Spectrochimica Acta Part B-Atomic Spectroscopy. 63(1), 64–68 (2008)

Solo-Gabriele, H.M., et al.: Evaluation of XRF and LIBS technologies for on-line sorting of CCA-treated wood waste. Waste Manage. 24(4), 413–424 (2004)

Lu, Z.M., et al.: Feasibility study of gross calorific value, carbon content, volatile matter content and ash content of solid biomass fuel using laser-induced breakdown spectroscopy.Fuel,258. (2019)

Presser, C., Nazarian, A., Millo, A.: Laser-driven calorimetry measurements of petroleum and biodiesel fuels. Fuel. 214, 656–666 (2018)

Caetano, N.R., et al.: A comparison of experimental results of soot production in laminar premixed flames. Open Eng. 5(1), 213–219 (2015)

Vanderwal, R.L., Weiland, K.J.: Laser-induced incandescence - development and characterization towards a measurement of soot-volume fraction. Appl. Phys. B-Lasers Opt. 59(4), 445–452 (1994)

Ono, Y., Isogai, A.: Analysis of celluloses, plant holocelluloses, and wood pulps by size-exclusion chromatography/multi-angle laser-light scattering. Carbohydr. Polym. 251, 117045 (2021)

Brienen, R.J.W., et al.: Oxygen isotopes in tree rings are a good proxy for Amazon precipitation and El Nino-Southern Oscillation variability. Proc. Natl. Acad. Sci. U.S.A. 109(42), 16957–16962 (2012)

Heinrich, I., et al.: Winter-to-spring temperature dynamics in Turkey derived from tree rings since AD 1125. Clim. Dyn. 41(7–8), 1685–1701 (2013)

Hietz, P., et al.: Long-term change in the Nitrogen cycle of Tropical forests. Science. 334(6056), 664–666 (2011)

Pons, T.L., Helle, G.: Identification of anatomically non-distinct annual rings in tropical trees using stable isotopes. Trees-Structure and Function. 25(1), 83–93 (2011)

Schollaen, K., Heinrich, I., Helle, G.: UV-laser-based microscopic dissection of tree rings - a novel sampling tool for δ13C and δ18O studies. New Phytol. 201(3), 1045–1055 (2014)

Abbott, E., et al.: Laser Microdissection of Conifer stem Tissues: Isolation and Analysis of high Quality RNA, Terpene Synthase Enzyme Activity and Terpenoid Metabolites from Resin Ducts and Cambial zone Tissue of White Spruce (Picea glauca), p. 10. Bmc Plant Biology (2010)

Liang, W., et al.: Applying CLSM to increment core surfaces for histometric analyses: a novel advance in quantitative wood anatomy. Dendrochronologia. 31(2), 140–145 (2013)

Funada, R., et al.: The role of cytoskeleton in secondary xylem differentiation in conifers. Cell and Molecular Biology of Wood Formation, ed. R. Savidge, J.R. Barnett, and R. Napier. 255–264. (2000)

Ermel, F.F., et al.: Differential localization of arabinan and galactan side chains of rhamnogalacturonan 1 in cambial derivatives. Planta. 210(5), 732–740 (2000)

Prior, D.A.M., Oparka, K.J., Roberts, I.M.: En bloc optical sectioning of resin-embedded specimens using a confocal laser scanning microscope. J. Microscopy-Oxford. 193, 20–27 (1999)

Kim, Y.S., Singh, A.: Imaging degraded Wood by Confocal Microscopy. Microscopy Today. 6(4), 14–15 (1998)

Verbelen, J.P., Stickens, D.: IN-VIVO DETERMINATION OF FIBRIL ORIENTATION IN PLANT-CELL WALLS WITH POLARIZATION CSLM Journal of Microscopy, 177: p. 1–6. (1995)

Pritzkow, C., et al.: Relationship between wood anatomy, tree-ring widths and wood density of Pinus sylvestris L. and climate at high latitudes in northern Sweden. Dendrochronologia. 32(4), 295–302 (2014)

Bai, R.G., et al.: Graphene: a versatile platform for nanotheranostics and tissue engineering. Prog. Mater. Sci. 91, 24–69 (2018)

Chen, K.N., et al.: Graphene-based materials for flexible energy storage devices. J. Energy Chem. 27(1), 12–24 (2018)

Geim, A.K., Novoselov, K.S.: The rise of graphene. Nat. Mater. 6(3), 183–191 (2007)

Trusovas, R., et al.: Graphene layer formation in pinewood by nanosecond and picosecond laser irradiation. Appl. Surf. Sci. 471, 154–161 (2019)

Yuan, M., et al.: Laser direct writing O/N/S co-doped hierarchically porous graphene on carboxymethyl chitosan/lignin-reinforced wood for boosted microsupercapacitor. Carbon. 202, 296–304 (2023)

Kim, Y.J., et al.: Wood-based flexible graphene thermistor with an ultra-high sensitivity enabled by ultraviolet femtosecond laser pulses. CIRP Ann. Manuf. Technol. 70(1), 443–446 (2021)

Mao, J.J., et al.: Graphene aerogels for efficient energy storage and conversion. Energy Environ. Sci. 11(4), 772–799 (2018)

Peng, Z.W., et al.: Flexible and Stackable Laser-Induced Graphene Supercapacitorse. ACS Appl. Mater. Interfaces. 7(5), 3414–3419 (2015)

Zang, X.N., et al.: Graphene and carbon nanotube (CNT) in MEMS/NEMS applications. Microelectron. Eng. 132, 192–206 (2015)

Li, M.T., et al.: N-doped graphene as catalysts for oxygen reduction and oxygen evolution reactions: theoretical considerations. J. Catal. 314, 66–72 (2014)

Tan, J.B., et al.: Highly efficient oxygen evolution electrocatalysts prepared by using reduction-engraved ferrites on graphene oxide. Inorg. Chem. Front. 5(2), 310–318 (2018)

Thamaraiselvan, C., et al.: Laser-induced graphene and carbon nanotubes as conductive carbon-based materials in environmental technology. Mater. Today. 34, 115–131 (2020)

Palomar, T., et al.: Evaluation of laser cleaning for the restoration of tarnished silver artifacts. Appl. Surf. Sci. 387, 118–127 (2016)

Ciofini, D., et al.: Conservation of ethnographic artefacts: selective laser ablation of deposits from doum palm fibers. J. Cult. Herit. 27, 143–152 (2017)

Oliveira, G.L., de Oliveira, F.L., Brazolin, S., et al.: Wood preservation for preventing biodeterioration of Cross Laminated Timber (CLT) panels assembled in tropical locations, in Xiv International Conference on Building Pathology and Constructions Repair, G. Bartoli, Editors. p. 242–249. (2018)

Ando, K., Nakamura, A., Hattori, N.: Laser Incising of Wood - Application for preservative treatment of columns Wood Industry, 48(7): p.314–319(1993)

Aono, Y., Ando, K., Hattori, N.: Rapid identification of CCA-treated wood using laser-induced breakdown spectroscopy. J. Wood Sci. 58(4), 363–368 (2012)

Elnaggar, A., et al.: Viability of laser cleaning of papyrus: conservation and scientific assessment. Stud. Conserv. 60, S73–S81 (2015)

Proniewicz, L.M., et al.: FT-IR and FT-Raman study of hydrothermally degraded groundwood containing paper. J. Mol. Struct. 614(1–3), 345–353 (2002)

Rosati, C., et al.: Laser removal of mold growth from paper. Appl. Phys. a-Materials Sci. Process. 117(1), 253–259 (2014)

Elenga, R.G., et al.: Effects of Alkali Treatment on the microstructure, composition, and Properties of the Raffia textilis Fiber. Bioresources. 8(2), 2934–2949 (2013)

Lobb, M., et al.: A new approach to recording and monitoring wet-preserved archaeological wood using three-dimensional laser scanning. J. Archaeol. Sci. 37(12), 2995–2999 (2010)

Preklet, E., et al.: Changes in DRIFT spectra of wood irradiated by lasers of different wavelength. J. Photochem. Photobiology B-Biology. 112, 43–47 (2012)

Pandey, K.K., Vuorinen, T.: Comparative study of photodegradation of wood by a UV laser and a xenon light source. Polym. Degrad. Stab. 93(12), 2138–2146 (2008)

Hernandez-Castaneda, J.C., Sezer, H.K., Li, L.: The effect of moisture content in fibre laser cutting of pine wood. Opt. Lasers Eng. 49(9–10), 1139–1152 (2011)

Ye, X., et al.: Rapid growth mechanism of graphene fabricated by high-power laser irradiation.Materials Today Communications,24. (2020)

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Contributions

Md. Nazrul Islam: Conceptualization, Literature review, Writing – original draft, Writing - Review & Editing, Visualization, Atanu Kumar Das: Conceptualization, Writing – original draft, Writing - Review & Editing, Md Morsaline Billah: Conceptualization, Writing – original draft, Writing - Review & Editing, Khandkar-Siddikur Rahman: Writing - Review & Editing, Salim Hiziroglu: Writing - Review & Editing, Nobuaki Hattori: Conceptualization, Writing - Review & Editing, David A. Agar and Magnus Rudolfsson: Review and edited the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no known competing financial/non-financial interests or personal relationships that could have appeared to influence the work reported in this review article.

Ethical Approval

This article has been written based on the secondary data related to laser technology applied in wood for different applications. Information collected from the secondary sources has been cited properly.

I testify on behalf of all co-authors that our article submitted to this journal has not been published in whole or in part elsewhere, the manuscript is not currently being considered for publication in another journal, and all authors have been personally and actively involved in substantive work leading to the manuscript, and will hold themselves jointly and individually responsible for its content.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Islam, M.N., Das, A.K., Billah, M.M. et al. Multifaceted Laser Applications for Wood – A Review from Properties Analysis to Advanced Products Manufacturing. Lasers Manuf. Mater. Process. 10, 225–250 (2023). https://doi.org/10.1007/s40516-023-00204-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-023-00204-x