Abstract

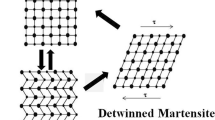

In this paper, a systematic literature review (SLR) approach has been implemented to show up the research progress on the joining of Nitinol (NiTi) Shape Memory Alloy (SMA) using laser. The properties of NiTi alloy, like the shape memory effect (SME), super-elasticity and biocompatibility, endure it as a desirable material in several high-performance applications. Owing to the extensive use of NiTi SMAs in medical devices, micro-electrical components, aerospace industries etc. joining of this alloy has been a subject of investigation and attracted the attention of the scientific community. Considering its unique characteristics, getting a proper joining of NiTi alloys with self as well as other materials is not only tough but also challenging. Therefore, literature on the advancements in the joining of NiTi alloys is reviewed systematically. Various challenges and ranges of the scope of research during similar and dissimilar joining are addressed and summarized. The weld joint characteristics such as the tensile strength, microhardness, corrosion resistance and microstructural properties are also outlined. Different optimization techniques implemented to obtain the optimum parameter setting during welding and/or machining of these distinctive materials are appraised. The research gaps referred to the domain are identified and deliberated.

Similar content being viewed by others

Data Availability Statement

The authors declare that the data supporting the findings of this study are available within the article.

References

DeepanBharathiKannan, T., Sathiya, P., Ramesh, T.: Experimental investigation and characterization of laser welded NiTinol shape memory alloys. J. Manuf. Processes 25, 253–261 (2017). https://doi.org/10.1016/j.jmapro.2016.12.006

Shayanfard, P., et al.: Stress raisers and fracture in shape memory alloys: review and ongoing challenges. Crit. Rev. Solid State Mater. Sci. 0(0), 1–59 (2021). https://doi.org/10.1080/10408436.2021.1896475

Kramár, T., Tauer, J., Vondrous, P.: Welding of nitinol by selected technologies. Acta Polytech. 59, 42–50 (2019). https://doi.org/10.14311/AP.2019.59.0042

Mehrpouya, M., Gisario, A., Lavvafi, H., Dehghanghadikolaei, A., Darafsheh, A.: Chapter 8 - Laser welding of nickel-titanium (NiTi) shape memory alloys. In: Paulo Davim, J., Gupta, K., Gupta, K., Paulo Davim, J. (eds.) Advanced Welding and Deforming, pp. 203–230. Elsevier (2021). https://doi.org/10.1016/B978-0-12-822049-8.00008-6

Mehrpouya, M., Gisario, A., Barletta, M., Natali, S., Veniali, F.: Dissimilar laser welding of NiTi wires. Lasers Manuf. Mater. Process. 6(2), 99–112 (2019). https://doi.org/10.1007/s40516-019-00084-0

Lee, J., Shin, Y.C.: Effects of composition and post heat treatment on shape memory characteristics and mechanical properties for laser direct deposited nitinol. Lasers Manuf. Mater. Process. 6(1), 41–58 (2019). https://doi.org/10.1007/s40516-019-0079-5

Shamsolhodaei, A., Oliveira, J.P., Panton, B., Ballesteros, B., Schell, N., Zhou, Y.N.: Superelasticity preservation in dissimilar joint of NiTi shape memory alloy to biomedical PtIr. Materialia 16, 101090 (2021). https://doi.org/10.1016/j.mtla.2021.101090

Mehrpouya, M., Shahedin, A.M., Daood Salman Dawood, S., Kamal Ariffin, A.: An investigation on the optimum machinability of NiTi based shape memory alloy. Mater. Manuf. Processes 32(13), 1497–1504 (2017). https://doi.org/10.1080/10426914.2017.1279290

Shehab, A.A., et al.: Laser welding of titanium grade 2 and aluminium AA 3105-O using a New AlScZr filler metal. Lasers Manuf. Mater. Process. (2022). https://doi.org/10.1007/s40516-021-00159-x

Mehrpouya, M., Gisario, A., Huang, H., Rahimzadeh, A., Elahinia, M.: Numerical study for prediction of optimum operational parameters in laser welding of NiTi alloy. Opt. Laser Technol. 118, 159–169 (2019). https://doi.org/10.1016/j.optlastec.2019.05.010

Chan, C.-W., Man, H.C., Yue, T.: Parameter optimization for laser welding of NiTi wires by the Taguchi method. Lasers Eng. 30, 247–265 (2015)

Pattanayak, S., Panda, S.: Laser beam micro drilling – a review. Lasers Manuf. Mater. Process. 5(4), 366–394 (2018). https://doi.org/10.1007/s40516-018-0072-4

Thorpe, R., Holt, R.: The SAGE dictionary of qualitative management research. SAGE (2007)

Mengist, W., Soromessa, T., Legese, G.: Method for conducting systematic literature review and meta-analysis for environmental science research. MethodsX 7, 100777 (2020). https://doi.org/10.1016/j.mex.2019.100777

Siksnelyte-Butkiene, I.: A systematic literature review of indices for energy poverty assessment: a household perspective. Sustainability 13(19), 19 (2021). https://doi.org/10.3390/su131910900

Wang, Y. et al.: Numerical simulation of ultrasonic spot welding of superelastic NiTi alloys: temperature distribution and deformation behavior. J. Manuf. Sci. Eng. 144(8) (2022). https://doi.org/10.1115/1.4053523

Yao, R., Dong, P., Liaw, P.K., Zhou, J., Wang, W.: Microstructure and shape memory effect of laser welded Nitinol wires. Mater. Lett. 238, 1–5 (2019). https://doi.org/10.1016/j.matlet.2018.11.141

Dong, P., Li, H., Wang, W., Zhou, J.: Microstructural characterization of laser micro-welded Nitinol wires. Mater. Charact. 135 (2017). https://doi.org/10.1016/j.matchar.2017.11.022

Ikai, A., Kimura, K., Tobushi, H.: TIG welding and shape memory effect of TiNi shape memory alloy. J. Intell. Mater. Syst. Struct. 7(6), 646–655 (1996). https://doi.org/10.1177/1045389X9600700604

Oliveira, J.P., Barbosa, D., BrazFernandes, F., Miranda, R.M.: Tungsten inert gas (TIG) welding of Ni-rich NiTi plates: Functional behavior. Smart Mater. Struct. 25, 03LT01 (2016). https://doi.org/10.1088/0964-1726/25/3/03LT01

Quazi, M.M., et al.: A comprehensive assessment of laser welding of biomedical devices and implant materials: recent research, development and applications. Crit. Rev. Solid State Mater. Sci. 46(2), 109–151 (2021). https://doi.org/10.1080/10408436.2019.1708701

Oliveira, J.P., Miranda, R.M., BrazFernandes, F.M.: Welding and joining of NiTi shape memory alloys: a review. Progress Mater. Sci. 88, 412–466 (2017). https://doi.org/10.1016/j.pmatsci.2017.04.008

Mirshekari, G.R., Saatchi, A., Kermanpur, A., Sadrnezhaad, S.K.: Laser welding of NiTi shape memory alloy: Comparison of the similar and dissimilar joints to AISI 304 stainless steel. Opt. Laser Technol. 54, 151–158 (2013). https://doi.org/10.1016/j.optlastec.2013.05.014

Tam, B., Khan, M.I., Zhou, Y.: Mechanical and Functional Properties of Laser-Welded Ti-55.8 Wt Pct Ni Nitinol Wires. Metall. Mater. Trans. A 42(8), 2166–2175 (2011). https://doi.org/10.1007/s11661-011-0639-6

Naffakh-Moosavy, H., Rasouli, A.: Similar Joining of NiTi Shape Memory Alloy using Nd:YAG Pulsed Laser Welding. J Welding Sci. Technol. Iran 7(2), 89–101 (2022)

Gugel, H., Schuermann, A., Theisen, W.: Laser welding of NiTi wires. Mater. Sci. Eng., A 481–482, 668–671 (2008). https://doi.org/10.1016/j.msea.2006.11.179

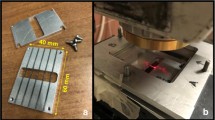

Datta, S., Raza, M.S., Saha, P., Pratihar, D.K.: Effects of process parameters on the quality aspects of weld-bead in laser welding of NiTinol sheets. Mater. Manuf. Processes 34(6), 648–659 (2019). https://doi.org/10.1080/10426914.2019.1566608

Dong, P., et al.: Microstructure and corrosion resistance of laser-welded crossed nitinol wires. Materials (Basel) 11(5), E842 (2018). https://doi.org/10.3390/ma11050842

Chan, C.W., Man, H.C.: Reduction of environmentally induced cracking of laser-welded shape memory NiTi wires via post-weld heat-treatment. Mater. Sci. Eng., A 588, 388–394 (2013). https://doi.org/10.1016/j.msea.2013.09.051

Song, Y.G., Li, W.S., Li, L., Zheng, Y.F.: The influence of laser welding parameters on the microstructure and mechanical property of the as-jointed NiTi alloy wires. Mater. Lett. 62(15), 2325–2328 (2008). https://doi.org/10.1016/j.matlet.2007.11.082

Chan, C.W., Man, H.C., Yue, T.M.: Effects of process parameters upon the shape memory and pseudo-elastic behaviors of laser-welded NiTi thin foil. Metall. Mater. Trans. A 42(8), 2264–2270 (2011). https://doi.org/10.1007/s11661-011-0623-1

ShojaeiZoeram, A., Rahmani, A., Akbari Mousavi, S.A.A.: Microstructure and properties analysis of laser-welded Ni–Ti and 316l sheets using copper interlayer”. J. Manuf. Processes 26, 355–363 (2017). https://doi.org/10.1016/j.jmapro.2017.02.005

Sun, Q., et al.: Study on weld formation and segregation mechanism for dissimilar pulse laser welding of NiTi and Cu wires. Opt. Laser Technol. 140, 107071 (2021). https://doi.org/10.1016/j.optlastec.2021.107071

Shamsolhodaei, A., Sun, Q., Wang, X., Panton, B., Di, H., Zhou, Y.N.: Effect of Laser Positioning on the Microstructure and Properties of NiTi-Copper Dissimilar Laser Welds. J. Mater. Eng. Perform 29(2), 849–857 (2020). https://doi.org/10.1007/s11665-020-04637-9

Xie, J., Chen, Y., Yin, L., Zhang, T., Wang, S., Wang, L.: Microstructure and mechanical properties of ultrasonic spot welding TiNi/Ti6Al4V dissimilar materials using pure Al coating. J. Manuf. Process 64, 473–480 (2021). https://doi.org/10.1016/j.jmapro.2021.02.009

Deng, H., et al.: Microstructure and mechanical properties of dissimilar NiTi/Ti6Al4V joints via back-heating assisted friction stir welding. J. Manuf. Process. 64, 379–391 (2021). https://doi.org/10.1016/j.jmapro.2021.01.024

Rodrigues, L.F.A., Amorim, F.A., Grassi, E.N.D., dos Santos, P.L.L., de Araújo, C.J.: TIG spot welding applied to NiTi shape memory wires optimized by factorial design. Int. J. Adv. Manuf. Technol. 121(11), 7749–7762 (2022). https://doi.org/10.1007/s00170-022-09848-z

Chen, Y., Sun, S., Zhang, T., Zhou, X., Li, S.: Effects of post-weld heat treatment on the microstructure and mechanical properties of laser-welded NiTi/304SS joint with Ni filler. Mater. Sci. Eng., A 771, 138545 (2020). https://doi.org/10.1016/j.msea.2019.138545

Zeng, Z., Oliveira, J.P., Yang, M., Song, D., Peng, B.: Functional fatigue behavior of NiTi-Cu dissimilar laser welds. Mater. Des. 114, 282–287 (2017). https://doi.org/10.1016/j.matdes.2016.11.023

Huang, G.Q., Yan, Y.F., Wu, J., Shen, Y.F., Gerlich, A.P.: Microstructure and mechanical properties of fine-grained aluminum matrix composite reinforced with nitinol shape memory alloy particulates produced by underwater friction stir processing. J. Alloy. Compd. 786, 257–271 (2019). https://doi.org/10.1016/j.jallcom.2019.01.364

Costa, J.D., et al.: Obtaining and characterization of Ni-Ti/Ti-Mo joints welded by TIG process. Vacuum 133, 58–69 (2016). https://doi.org/10.1016/J.VACUUM.2016.08.016

Fox, G., Hahnlen, R., Dapino, M.J.: Fusion welding of nickel–titanium and 304 stainless steel tubes: Part II: tungsten inert gas welding. J. Intell. Mater. Syst. Struct. 24(8), 962–972 (2013). https://doi.org/10.1177/1045389X12461076

Fukumoto, S., Inoue, T., Mizuno, S., Okita, K., Tomita, T., Yamamoto, A.: Friction welding of TiNi alloy to stainless steel using Ni interlayer. Sci. Technol. Weld. Joining 15(2), 124–130 (2010). https://doi.org/10.1179/136217109X12577814486692

Yuhua, C., Yuqing, M., Weiwei, L., Peng, H.: Investigation of welding crack in micro laser welded NiTiNb shape memory alloy and Ti6Al4V alloy dissimilar metals joints. Opt. Laser Technol. 91, 197–202 (2017). https://doi.org/10.1016/j.optlastec.2016.12.028

Cheng, Q., Guo, N., Zhang, D., Fu, Y., Zhang, S., He, J.: Study on interface and mechanical property of laser welding of NiTi shape memory alloy and 2A12 aluminum alloy joint with a TC4 wire. Smart Mater. Struct. 31(1), 015032 (2021). https://doi.org/10.1088/1361-665X/ac3d71

Zhong, Y., Xie, J., Chen, Y., Yin, L., He, P., Lu, W.: Microstructure and mechanical properties of micro laser welding NiTiNb/Ti6Al4V dissimilar alloys lap joints with nickel interlayer. Mater. Lett. 306, 130896 (2022). https://doi.org/10.1016/j.matlet.2021.130896

Teshome, F.B., et al.: Microstructure, macrosegregation, and mechanical properties of NiTi to Ti6Al4V dissimilar laser welds using Co interlayer. J. Mater. Eng. Perform (2022). https://doi.org/10.1007/s11665-022-07064-0

Li, H.M., Sun, D.Q., Cai, X.L., Dong, P., Wang, W.Q.: Laser welding of TiNi shape memory alloy and stainless steel using Ni interlayer. Mater. Des. 39, 285–293 (2012). https://doi.org/10.1016/j.matdes.2012.02.031

Pouquet, J., Miranda, R.M., Quintino, L., Williams, S.: Dissimilar laser welding of NiTi to stainless steel. Int. J. Adv. Manuf. Technol. 61 (2011). https://doi.org/10.1007/s00170-011-3694-7

Oliveira, J.P., et al.: Laser joining of NiTi to Ti6Al4V using a Niobium interlayer. Acta Mater. 105, 9–15 (2016). https://doi.org/10.1016/j.actamat.2015.12.021

Wang, H., Xie, J., Chen, Y., Liu, W., Zhong, W.: Effect of CoCrFeNiMn high entropy alloy interlayer on microstructure and mechanical properties of laser-welded NiTi/304 SS joint. J. Market. Res. 18, 1028–1037 (2022). https://doi.org/10.1016/j.jmrt.2022.03.022

Mehrpouya, M., Gisario, A., Broggiato, G.B., Puopolo, M., Vesco, S., Barletta, M.: Effect of welding parameters on functionality of dissimilar laser-welded NiTi superelastic (SE) to shape memory effect (SME) wires. Int. J. Adv. Manuf. Technol. 103(1), 1593–1601 (2019). https://doi.org/10.1007/s00170-019-03514-7

Krishnakumari, A., Saravanan, M., Sarvesh, J.: Application of Nd: YAG laser in Nano WC surface alloying with low carbon austenitic steel in predicting the microstructure and hardness. Lasers Manuf. Mater. Process. 8(2), 201–215 (2021). https://doi.org/10.1007/s40516-021-00145-3

Shamsolhodaei, A., Razmpoosh, M.H., Maletta, C., Magaro, P., Zhou, Y.N.: A comprehensive insight into the superelasticity measurement of laser welded NiTi shape memory alloys. Mater. Lett. 287, 129310 (2021). https://doi.org/10.1016/j.matlet.2021.129310

Ge, F., et al.: Dissimilar laser welding of a NiTi shape memory alloy to Ti2AlNb. Metals 11(10), 10 (2021). https://doi.org/10.3390/met11101578

Shamsolhodaei, A., Oliveira, J.P., Schell, N., Maawad, E., Panton, B., Zhou, Y.N.: Controlling intermetallic compounds formation during laser welding of NiTi to 316L stainless steel. Intermetallics 116, 106656 (2020). https://doi.org/10.1016/j.intermet.2019.106656

Oliveira, J.P., et al.: Dissimilar laser welding of superelastic NiTi and CuAlMn shape memory alloys. Mater. Des. 128, 166–175 (2017). https://doi.org/10.1016/j.matdes.2017.05.011

Mehrpouya, M., Gisario, A., Brotzu, A., Natali, S.: Laser welding of NiTi shape memory sheets using a diode laser. Opt. Laser Technol. 108, 142–149 (2018). https://doi.org/10.1016/j.optlastec.2018.06.038

Mehrpouya, M., Gisario, A., Barletta, M., Broggiato, G.B.: Welding strength of dissimilar laser-welded NiTi and NiTiCu shape memory wires. Manuf. Lett. 22, 25–27 (2019). https://doi.org/10.1016/j.mfglet.2019.10.003

Panton, B., Pequegnat, A., Zhou, Y.N.: Dissimilar laser joining of NiTi SMA and MP35N wires. Metall. Mater. Trans. A. 45(8), 3533–3544 (2014)

Li, J., Panton, B., Mao, Y., Vivek, A., Daehn, G.: High-strength micro impact welding of NiTi wire to brass sheet. Weld World 66(9), 1799–1809 (2022). https://doi.org/10.1007/s40194-022-01336-y

Asadi, S., Saeid, T., Valanezhad, A., Watanabe, I., Khalil-Allafi, J.: Effects of Ni powder addition on microstructure and mechanical properties of NiTi to AISI 304 stainless steel archwire dissimilar laser welds. J. Manuf. Process. 55, 13–21 (2020). https://doi.org/10.1016/j.jmapro.2020.03.041

Michael, A., Pequegnat, A., Wang, J., Zhou, Y.N., Khan, M.I.: Corrosion performance of medical grade NiTi after laser processing. Surf. Coat. Technol. 324, 478–485 (2017). https://doi.org/10.1016/j.surfcoat.2017.05.092

Chan, C.W., Man, H.C., Yue, T.M.: Effect of post-weld heat-treatment on the oxide film and corrosion behaviour of laser-welded shape memory NiTi wires. Corros. Sci. 56, 158–167 (2012). https://doi.org/10.1016/j.corsci.2011.11.020

Mirshekari, G.R., Kermanpur, A., Saatchi, A., Sadrnezhaad, S.K., Soleymani, A.P.: Microstructure, cyclic deformation and corrosion behavior of laser welded NiTi shape memory wires. J. Mater. Eng. Perform 24(9), 3356–3364 (2015). https://doi.org/10.1007/s11665-015-1614-y

Mandal, M., Patra, S., Chakraborty, R., Saha, P., Shome, M.: Microstructural evolution and nanoindentation study of magnetic pulse welded Nitinol and Aluminium sheets. Mater. Charact. 184, 111690 (2022). https://doi.org/10.1016/j.matchar.2021.111690

Pequegnat, A., Michael, A., Wang, J., Lian, K., Zhou, Y., Khan, M.I.: Surface characterizations of laser modified biomedical grade NiTi shape memory alloys. Mater. Sci. Eng. C 50, 367–378 (2015). https://doi.org/10.1016/j.msec.2015.01.085

Michael, A., Zhou, Y.N., Yavuz, M., Khan, M.I.: Deconvolution of overlapping peaks from differential scanning calorimetry analysis for multi-phase NiTi alloys. Thermochim. Acta 665, 53–59 (2018). https://doi.org/10.1016/j.tca.2018.05.014

Mehrpouya, M., Gisario, A., Barletta, M., Veniali, F.: Investigation on the functionality of laser-welded NiTi to NiTiCu shape memory wires. J. Intell. Mater. Syst. Struct. 31(9), 1171–1175 (2020). https://doi.org/10.1177/1045389X20914401

Gao, X.-L., Wang, X.-Q., Liu, J., Li, L.: A novel laser welding method for the reliable joining of NiTi/301SS. Mater. Lett. 268, 127573 (2020)

Zhou, X., Chen, Y., Huang, Y., Mao, Y., Yu, Y.: Effects of niobium addition on the microstructure and mechanical properties of laser-welded joints of NiTiNb and Ti6Al4V alloys. J. Alloy. Compd. 735, 2616–2624 (2018). https://doi.org/10.1016/j.jallcom.2017.11.307

Kannan, T.D.B., Ramesh, T., Sathiya, P.: Application of Artificial Neural Network Modelling for Optimization of Yb: YAG Laser Welding of Nitinol. Trans. Indian Inst. Met. 70(7), 1763–1771 (2017). https://doi.org/10.1007/s12666-016-0973-x

Zhang, K., Liu, F., Tan, C., Zhou, Y.N., Peng, P.: Effect of heat input modes on microstructure, mechanical properties and porosity of laser welded NiTi-316L joints: A comparative study. Mater. Sci. Eng. A 848, 143426 (2022). https://doi.org/10.1016/j.msea.2022.143426

Tam, B., Pequegnat, A., Khan, M.I., Zhou, Y.: Resistance microwelding of Ti-55.8 wt pct Ni nitinol wires and the effects of pseudoelasticity. Metall. Mater. Trans. A 43(8), 2969–2978 (2012). https://doi.org/10.1007/s11661-012-1115-7

Zhang, K., Peng, P., Zhou, Y.N.: Laser welding-brazing of NiTi/304 stainless steel wires with beam defocus and large offset. Mater. Sci. Eng. A 835, 142660 (2022). https://doi.org/10.1016/j.msea.2022.142660

Shamsolhodaei, A., Zhou, Y.N., Michael, A.: Enhancement of mechanical and functional properties of welded NiTi by controlling nickel vapourisation. Sci. Technol. Weld. Joining 24(8), 706–712 (2019). https://doi.org/10.1080/13621718.2019.1595926

Tuissi, A., Besseghini, S., Ranucci, T., Squatrito, F., Pozzi, M.: Effect of Nd-YAG laser welding on the functional properties of the Ni–49.6at.%Ti. Mater. Sci. Eng. A 273–275, 813–817 (1999). https://doi.org/10.1016/S0921-5093(99)00422-0

Gaikwad, V., Jatti, V.S.: Optimization of material removal rate during electrical discharge machining of cryo-treated NiTi alloys using Taguchi’s method. J. King Saud Univ. Eng. Sci. 30(3), 266–272 (2018). https://doi.org/10.1016/j.jksues.2016.04.003

Mohammed, M.K., Al-Ahmari, A.: Laser-machining of microchannels in NiTi-based shape-memory alloys: experimental analysis and process optimization. Materials 13(13), 13 (2020). https://doi.org/10.3390/ma13132945

Chaudhari, R., Vora, J.J., Prabu, S.S.M., Palani, I.A., Patel, V.K., Parikh, D.M.: Pareto optimization of WEDM process parameters for machining a NiTi shape memory alloy using a combined approach of RSM and heat transfer search algorithm. Adv. Manuf. 9(1), 64–80 (2021). https://doi.org/10.1007/s40436-019-00267-0

Otibar, D., Rathmann, C., Lygin, K., Kreimeier, D., Szymansky, P.: Analyzing laser-welded NiTi-NiTi-joints for actuator applications using design of experiments. JMEA 5(2) (2015). https://doi.org/10.17265/2159-5275/2015.02.003

Daneshmand, S., Kahrizi, E.F., LotfiNeyestanak, A.A., Monfared, V.: Optimization of electrical discharge machining parameters for Niti shape memory alloy by using the taguchi method. J. Mar. Sci. Technol. Taiwan 22(4), 506–512 (2014). https://doi.org/10.6119/JMST-013-0624-1

Das, B., Parimanik, S.R., Mahapatra, T.R., Mishra, D.: Machinability assessment of NiTinol shape memory alloy in electrochemical machining. Int. J. Mach. Mach. Mater. 24(3–4), 280–313 (2022). https://doi.org/10.1504/IJMMM.2022.125200

Sadeghi, A., Babakhani, A., Zebarjad, S.M., Mostajabodaveh, H.: Use of grey relational analysis for multi-objective optimisation of NiTiCu shape memory alloy produced by powder metallurgy process. J. Intell. Mater. Syst. Struct. 25(16), 2093–2101 (2014). https://doi.org/10.1177/1045389X13517312

Parimanik, S.R., Mahapatra, T.R., Mishra, D., Rout, A.K.: Optimisation of performance characteristics in laser welding of Nitinol wires using Taguchi and grey relation analysis. Adv. Mater. Process. Technol. 0(0), 1–10 (2022). https://doi.org/10.1080/2374068X.2022.2088653

Mishra, L., Mahapatra, T.R., Mishra, D., Pattanaik, S.K.: Machinability analysis and multiple performance optimization during laser micro-drilling of CNT reinforced polymer nanocomposite. Lasers Manuf. Mater. Process. 9(2), 151–172 (2022). https://doi.org/10.1007/s40516-022-00171-9

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Parimanik, S.R., Mahapatra, T.R. & Mishra, D. A Systematic Literature Review on Laser Welding of NiTi SMA. Lasers Manuf. Mater. Process. 10, 77–117 (2023). https://doi.org/10.1007/s40516-022-00200-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-022-00200-7