Abstract

Purpose of Review

Advances in zirconia ceramics have expanded their application in dentistry, necessitating faster delivery of zirconia-based restorations. With the introduction of high translucency grades of zirconia ceramics, the rapid sintering strategies that aim to reduce processing times can have a central impact on clinically relevant properties. The present review has surveyed the available literature evaluating the properties of rapidly sintered dental zirconia ceramics.

Recent Findings

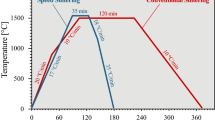

Recent studies emphasize the evolution of sintering protocols for zirconia ceramics, especially highlighting differences between conventional sintering (CS) and rapid methods like speed (SS) and high-speed sintering (HSS). These modern rapid sintering techniques transform the microstructure of zirconia ceramics, impacting its translucency, flexural strength, and aging resistance. These properties exhibit variability based on zirconia type and chosen sintering process, with HSS showing particular promise.

Summary

Rapid sintering protocols offer efficient alternatives to traditional zirconia ceramic processing, with benefits in cost and time. Despite the recent findings, discrepancies persist within zirconia generations, calling for further standardization and investigation.

Similar content being viewed by others

References

Papers of particular interest, published recently, have been highlighted as: • Of importance

Kocjan A, Mirt T, Kohal R-J, Shen Z, Jevnikar P. Zirconia ceramics: clinical and biological aspects in dentistry. In: Pomeroy M, editor. Encycl Mater Tech Ceram. Glas., Oxford: Elsevier; 2021. p. 817–32. https://doi.org/10.1016/B978-0-12-818542-1.00051-5.

Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials. 1999;20:1–25. https://doi.org/10.1016/S0142-9612(98)00010-6.

Kosmač T, Oblak Č, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999;15:426–33. https://doi.org/10.1016/0038-1101(68)90151-2.

Güth JF, Stawarczyk B, Edelhoff D, Liebermann A. Zirconia and its novel compositions: what do clinicians need to know? Quintessence Int. 2019;50:512–20. https://doi.org/10.3290/j.qi.a42653.

Camposilvan E, Leone R, Gremillard L, Sorrentino R, Zarone F, Ferrari M, et al. Aging resistance, mechanical properties and translucency of different yttria-stabilized zirconia ceramics for monolithic dental crown applications. Dent Mater. 2018;34:879–90. https://doi.org/10.1016/j.dental.2018.03.006.

Zhang F, Inokoshi M, Batuk M, Hadermann J, Naert I, Van Meerbeek B, et al. Strength, toughness and aging stability of highly-translucent Y-TZP ceramics for dental restorations. Dent Mater. 2016;32:e327–37. https://doi.org/10.1016/j.dental.2016.09.025.

Swain MV. Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomater. 2010;5:1668–77. https://doi.org/10.1016/j.actbio.2008.12.016.

Chevalier J. What future for zirconia as a biomaterial? Biomaterials. 2006;27:535–43. https://doi.org/10.1016/j.biomaterials.2005.07.034.

Cotič J, Jevnikar P, Kocjan A. Ageing kinetics and strength of airborne-particle abraded 3Y-TZP ceramics. Dent Mater. 2017;33:847–56. https://doi.org/10.1016/j.dental.2017.04.014.

Kocjan A, Cotič J, Kosmač T, Jevnikar P. In vivo aging of zirconia dental ceramics – Part I: Biomedical grade 3Y-TZP. Dent Mater. 2020; https://doi.org/10.1016/j.dental.2020.11.023.

Pereira GKR, Guilardi LF, Dapieve KS, Kleverlaan CJ, Rippe MP, Valandro LF. Mechanical reliability, fatigue strength and survival analysis of new polycrystalline translucent zirconia ceramics for monolithic restorations. J Mech Behav Biomed Mater. 2018;85:57–65. https://doi.org/10.1016/j.jmbbm.2018.05.029.

Harada A, Shishido S, Barkarmo S, Inagaki R, Kanno T, Örtengren U, et al. Mechanical and microstructural properties of ultra-translucent dental zirconia ceramic stabilized with 5 mol% yttria. J Mech Behav Biomed Mater. 2020;111:103974. https://doi.org/10.1016/j.jmbbm.2020.103974.

Malgaj T, Plut A, Eberlinc A, Drevenšek M, Jevnikar P. Anterior esthetic rehabilitation of an alveolar cleft using novel minimally invasive prosthodontic techniques: a case report. Cleft Palate-Craniofacial J. 2020:1055665620964709. https://doi.org/10.1177/1055665620964709.

Zhang F, Reveron H, Spies BC, Van Meerbeek B, Chevalier J. Trade-off between fracture resistance and translucency of zirconia and lithium-disilicate glass ceramics for monolithic restorations. Acta Biomater. 2019;91:24–34. https://doi.org/10.1016/j.actbio.2019.04.043.

Mirt T, Abram A, van del Velde N, Jerman I, Bermejo R, Kocjan A, et al. Effect of airborne-particle abrasion of yttria-containing zirconia dental ceramics on mechanical properties before and after regeneration firing. J Eur Ceram Soc. 2022;42:5035–44. https://doi.org/10.1016/j.jeurceramsoc.2022.05.010.

Guazzato M, Albakry M, Ringer SP, Swain MV. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent Mater. 2004;20:449–56. https://doi.org/10.1016/j.dental.2003.05.002.

De Jonghe LC, Rahaman MN. Sintering of ceramics. In: Somiya S, Aldinger F, Spriggs RM, editors. Handb. Adv. Ceram. Mater. Appl. Process. Prop., vol. 2, Elsevier Academic Press California; 2003, p. 187.

Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008;24:299–307. https://doi.org/10.1016/j.dental.2007.05.007.

Lohbauer U, Belli R. Chemistry and microstructure BT - dental ceramics: fracture mechanics and engineering design. In: Lohbauer U, Belli R, editors. Cham: Springer International Publishing; 2022. p. 3–37. https://doi.org/10.1007/978-3-030-94687-6_2.

Jansen JU, Lümkemann N, Letz I, Pfefferle R, Sener B, Stawarczyk B. Impact of high-speed sintering on translucency, phase content, grain sizes, and flexural strength of 3Y-TZP and 4Y-TZP zirconia materials. J Prosthet Dent. 2019;122:396–403. https://doi.org/10.1016/j.prosdent.2019.02.005.

Kang S-JL. Sintering densification, grain growth, and microstructure. Oxford: Butterworth-Heinemann; 2005. https://doi.org/10.1016/B978-075066385-4/50000-5.

Liu H, Inokoshi M, Nozaki K, Shimizubata M, Nakai H, Cho Too T Di, et al. Influence of high-speed sintering protocols on translucency, mechanical properties, microstructure, crystallography, and low-temperature degradation of highly translucent zirconia. Dent Mater. 2022;38:451–468. https://doi.org/10.1016/j.dental.2021.12.028.

Chen I-W, Wang X-H. Sintering dense nanocrystalline ceramics without final-stage grain growth. Nature. 2000;404:168–71. https://doi.org/10.1038/35004548.

Darvell BW. Chapter 7 - Flexible impression materials. In: Darvell BWBT-MS for D (Ninth E, editor. Woodhead Publ. Ser. Biomater., Woodhead Publishing; 2009, p. 163–96. https://doi.org/10.1533/9781845696672.163.

Gómez SY, da Silva AL, Gouvêa D, Castro RHR, Hotza D. Nanocrystalline yttria-doped zirconia sintered by fast firing. Mater Lett. 2016;166:196–200. https://doi.org/10.1016/j.matlet.2015.12.042.

Zhang H, Xu Y, Wang B, Zhang XL, Yang J, Niihara K. Effects of heating rate on the microstructure and mechanical properties of rapid vacuum sintered translucent alumina. Ceram Int. 2015;41:12499–503.

Chen D-J, Mayo MJ. Rapid rate sintering of nanocrystalline ZrO2−3 mol% Y2O3. J Am Ceram Soc. 1996;79:906–12. https://doi.org/10.1111/j.1151-2916.1996.tb08524.x.

Lawson NC, Maharishi A. Strength and translucency of zirconia after high-speed sintering. J Esth Restor Dent. 2020;32:219–25. https://doi.org/10.1111/jerd.12524.

Adolfsson E, Shen JZ. Chapter 17 - defect minimization in prosthetic ceramics. In: Shen JZ, Kosmač TBT-AC for D, editors., Oxford: Butterworth-Heinemann; 2014, p. 359–373. https://doi.org/10.1016/B978-0-12-394619-5.00017-1.

• Cokic SM, Vleugels J, Van Meerbeek B, Camargo B, Willems E, Li M, et al. Mechanical properties, aging stability and translucency of speed-sintered zirconia for chairside restorations. Dent Mater. 2020;36:959–72. https://doi.org/10.1016/j.dental.2020.04.026. This article presented important findings on translucency of speed-sintered of different types of zirconia ceramics.

Öztürk C, Çelik E. Influence of heating rate on the flexural strength of monolithic zirconia. J Adv Prosthodont. 2019;11:202–8.

Yang C-C, Ding S-J, Lin T-H, Yan M. Mechanical and optical properties evaluation of rapid sintered dental zirconia. Ceram Int. 2020;46:26668–74. https://doi.org/10.1016/j.ceramint.2020.07.137.

Kaizer MR, Gierthmuehlen PC, dos Santos MB, Cava SS, Zhang Y. Speed sintering translucent zirconia for chairside one-visit dental restorations: optical, mechanical, and wear characteristics. Ceram Int. 2017;43:10999–1005. https://doi.org/10.1016/j.ceramint.2017.05.141.

Miura S, Shinya A, Koizumi H, Fujisawa M. Effect of speed sintering of monolithic zirconia with different yttria contents on color and crystal phase. Eur J Oral Sci. 2022;130:e12898. https://doi.org/10.1111/eos.12898.

Ebeid K, Wille S, Hamdy A, Salah T, El-Etreby A, Kern M. Effect of changes in sintering parameters on monolithic translucent zirconia. Dent Mater. 2014;30:e419–24. https://doi.org/10.1016/j.dental.2014.09.003.

Scott HG. Phase relationships in the zirconia-yttria system. J Mater Sci. 1975;10:1527–35. https://doi.org/10.1007/BF01031853.

Inokoshi M, Zhang F, De Munck J, Minakuchi S, Naert I, Vleugels J, et al. Influence of sintering conditions on low-temperature degradation of dental zirconia. Dent Mater. 2014;30:669–78. https://doi.org/10.1016/j.dental.2014.03.005.

Jiang L, Liao Y, Wan Q, Li W. Effects of sintering temperature and particle size on the translucency of zirconium dioxide dental ceramic. J Mater Sci Mater Med. 2011;22:2429–35. https://doi.org/10.1007/s10856-011-4438-9.

Stawarczyk B, Özcan M, Hallmann L, Ender A, Mehl A, Hämmerlet CHF, et al. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investig. 2013;17:269–74. https://doi.org/10.1007/s00784-012-0692-6.

Bučevac D, Kosmač T, Kocjan A. The influence of yttrium-segregation-dependent phase partitioning and residual stresses on the aging and fracture behaviour of 3Y-TZP ceramics. Acta Biomater. 2017;62:306–16. https://doi.org/10.1016/j.actbio.2017.08.014.

Zhang F, Van Meerbeek B, Vleugels J. Importance of tetragonal phase in high-translucent partially stabilized zirconia for dental restorations. Dent Mater. 2020;36:491–500. https://doi.org/10.1016/j.dental.2020.01.017.

Apetz R, van Bruggen MPBB. Transparent alumina: a light-scattering model. J Am Ceram Soc. 2003;86:480–6. https://doi.org/10.1111/j.1151-2916.2003.tb03325.x.

Klimke J, Trunec M, Krell A. Transparent tetragonal yttria-stabilized zirconia ceramics: influence of scattering caused by birefringence. J Am Ceram Soc. 2011;94:1850–8. https://doi.org/10.1111/j.1551-2916.2010.04322.x.

Yamashita I, Tsukuma K. Light scattering by residual pores in transparent zirconia ceramics. J Ceram Soc Japan. 2011;119:133–5.

Zhang H, Li Z, Kim B-N, Morita K, Yoshida H, Hiraga K, et al. Effect of alumina dopant on transparency of tetragonal zirconia. J Nanomater. 2012;2012:1–5. https://doi.org/10.1155/2012/269064.

Zhang Y. Making yttria-stabilized tetragonal zirconia translucent. Dent Mater. 2014;30:1195–203. https://doi.org/10.1016/j.dental.2014.08.375.

• Jerman E, Wiedenmann F, Eichberger M, Reichert A, Stawarczyk B. Effect of high-speed sintering on the flexural strength of hydrothermal and thermo-mechanically aged zirconia materials. Dent Mater. 2020;36:1144–50. https://doi.org/10.1016/j.dental.2020.05.013. This paper presented first findings on mechanical properties of aged zirconia ceramics sintered by high-speed sintering protocol.

• Presenda Á, Salvador MD, Peñaranda-Foix FL, Moreno R, Borrell A. Effect of microwave sintering on microstructure and mechanical properties in Y-TZP materials used for dental applications. Ceram Int. 2015;41:7125–32. https://doi.org/10.1016/j.ceramint.2015.02.025. Highlighted article presents the first attempt to sinter zirconia materials by microwave sintering for dental application.

Ersoy NM, Aydoğdu HM, Değirmenci BÜ, Çökük N, Sevimay M. The effects of sintering temperature and duration on the flexural strength and grain size of zirconia. Acta Biomater Odontol Scand. 2015;1:43–50. https://doi.org/10.3109/23337931.2015.1068126.

• Kong M-C, Park M-G. Effect of sintering condition and low-temperature degradation on the flexural strength and phase transformation of zirconia. J Prosthet Dent. 2021;126:692.e1–692.e14. https://doi.org/10.1016/j.prosdent.2021.07.027. This article focuses on the effects of low temperature degradation of zirconia ceramics sintered by different protocols.

Cotič J, Kocjan A, Panchevska S, Kosmač T, Jevnikar P. In vivo ageing of zirconia dental ceramics — Part II: Highly-translucent and rapid-sintered 3Y-TZP. Dent Mater. 2020; https://doi.org/10.1016/j.dental.2020.11.019.

Luz JN, Kaizer M d R, Ramos N d C, Anami LC, Thompson VP, de SFA SG, et al. Novel speed sintered zirconia by microwave technology. Dent Mater. 2021;37:875–81. https://doi.org/10.1016/j.dental.2021.02.026.

Funding

This work was supported by the Slovenian Research Agency funding through research projects towards reliable implementation of monolithic zirconia dental restorations (J2–9222) and Preclinical and clinical investigations of zirconia dental ceramics fabricated by additive manufacturing technologies (J3–3064), and research program Ceramics and complementary materials for advanced engineering and biomedical applications (P2–0087).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Human and Animal Rights and Informed Consent

N/A.

Ethics Declarations

The Section Editors for the topical collection Dental Restorative Materials are Mutlu Özcan and Paulo Cesar. Please note that Mutlu Özcan was not involved in the editorial process of this article as she is a co-author.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mirt, T., Bhootpur, N., Malgaj, T. et al. Sintering Strategies for Dental Zirconia Ceramics: Slow Versus Rapid?. Curr Oral Health Rep 10, 233–242 (2023). https://doi.org/10.1007/s40496-023-00355-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40496-023-00355-y