Abstract

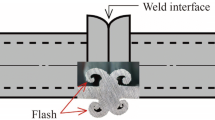

In this study, the effect of core bar inserted into weld faying part to obtain an ideal pipe joint with non-generating inner flash via friction welding is described. A steel pipe with inner and outer diameters corresponding to 8.0 mm and 13.5 mm was used, and the weld faying surface was machined to a groove shape of a flat (butt) type. The core bar of various materials was inserted in the weld faying part of the pipes, and those pipes were welded with a friction speed of 27.5 s−1 and friction pressure of 30 MPa. The core bars did not decrease inner flash when joints were fabricated with a core bar of some metallic materials with melting points below that of steel; thus, they were melted during the welding process. The joint with an alumina core bar did not decrease inner flash and was crushed by generating an inner flash. However, a commercially pure tungsten (CP-W) core bar was successfully achieved for decreasing the inner flash. Additionally, all joints with a CP-W core bar did not exhibit the tensile strength of the base metal and a fracture in the base metal, when they were fabricated during the same time, the friction torque reached the initial peak. The joint exhibited a fracture in the base metal when it was fabricated with a CP-W core bar and a taper groove shape that was proposed in the previous study. Furthermore, the core bars were easily removed from the joints; thus the joint with almost no inner flash was successfully obtained. To reduce the inner flash of pipe joints, they should be fabricated with a CP-W core bar inserted into the weld faying part with a taper groove shape.

Similar content being viewed by others

References

Wang KK (1975) Friction welding, vol 204. Welding Research Council Bulletin, New York, pp 1–12

Maalekian M (2007) Friction welding-critical assessment of literature. Sci Technol Weld Join 12(8):738–759

Aurich JC, Dornfeld D, Arrazola PJ et al (2009) Burrs-analysis, control and removal. CIRP Ann 58(2):519–542

Palanivel R, Laubscher RF, Dinaharan I et al (2017) Microstructure and mechanical characterization of continuous drive friction welded grade 2 seamless titanium tubes at different rotational speeds. Int J Press Ves Pip 154:17–28

Luo J, Ye YH, Xu JJ et al (2009) A new mixed-integrated approach to control welded flashes forming process of damping-tube-gland in continuous drive friction welding. Mater Des 30:353–358

Rovere CAD, Ribeiro CR, Silva R et al (2014) Local mechanical properties of radial friction welded supermartensitic stainless steel pipes. Mater Des 56:423–427

Faes K, Dhooge A, De Baets P et al (2008) Influence of deceleration phase on properties of friction welded pipelines using intermediate ring. Sci Technol Weld Join 13(2):136–145

Pissanti DR, Scheid A, Kanan LF et al (2019) Pipeline girth friction welding of the UNS S32205 duplex stainless steel. Mater Des 162:198–209

Shi L, Song R, Tian X (2017) Plasma beam radius compensation-integrated torch path planning for CNC pipe hole cutting with welding groove. Int J Adv Manuf Technol 88(5/8):1971–1981

Li X, Ma H, Shen Z (2015) Research on explosive welding of aluminum alloy to steel with dovetail grooves. Mater Des 87:815–824

Wan L, Huang Y (2018) Friction welding of AA6061 to AISI 316L steel: characteristic analysis and novel design equipment. Int J Adv Manuf Technol 95(9/12):4117–4128

Ashfaq M, Sajja N, Rafi HK et al (2013) Improving strength of stainless steel/aluminum alloy friction welds by modifying faying surface design. J Mater Eng Perform 22(2):376–383

Kimura M, Iwamoto S, Kusaka M et al (2019) Effect of weld faying part groove shape on reduction of inner flash in steel pipe joints fabricated by friction welding. Adv Manuf 7(4):411–422

Kimura M, Yukawa T, Kusaka M et al (2013) Possibility of direct friction welding between type 7075 aluminum alloy and low carbon steel. In: Proceedings of the 1st international joint symposium on joining and welding (IJS- JW2013), Osaka, Japan, Woodhead Pub, pp 267–273

Kimura M, Kasuya K, Kusaka M et al (2009) Effect of friction welding condition on joining phenomena and joint strength of friction welded joint between brass and low carbon steel. Sci Technol Weld Join 14(5):404–412

Kimura M, Ichihara A, Kusaka M et al (2012) Joint properties and their improvement of AISI 310S austenitic stainless steel thin walled circular pipe friction welded joint. Mater Des 38:38–46

Kimura M, Kusaka M, Kaizu K et al (2016) Friction welding technique and joint properties of thin-walled pipe friction welded joint between type 6063 aluminum alloy and AISI 304 austenitic stainless steel. Int J Adv Manuf Technol 82(1):489–499

Kimura M, Kusaka M, Seo K et al (2002) Relationship between the friction time, friction torque, and joint properties of friction welding for the low heat input friction welding method. Q J Jpn Weld Soc 20(4):559–565

Kimura M, Kusaka M, Seo K et al (2004) Properties of low carbon steel joint by low heat input friction welding method. In: Proceedings of the 57th assembly of international institute of welding, Osaka, Japan, pp 139–149

Heo NH, Chang JC, Kim SJ (2013) Elevated temperature intergranular cracking in heat-resistant steels. Mater Sci Eng A 559:665–677

Zhang W, Zhao G, Fu Q (2018) Study on the effects and mechanisms of induction heat treatment cycles on toughness of high frequency welded pipe welds. Mater Sci Eng A 736:276–287

Yamazaki M, Watanabe T, Hongo H et al (2008) Creep rupture properties of welded joints of heat resistant steels. J Power Energy Syst 2(4):1140–1149

Wang W, Zhao W, Qu J (2013) Effect of heat treatment on microstructure and mechanical properties of 2.25Cr-1Mo steel. Steel Res 84(2):178–183

Zhang Q, Zhang J, Zhao P et al (2015) Microstructure of 10% Cr martensitic heat-resistant steel welded joints and type IV cracking behavior during creep rupture at 650 °C. Mater Sci Eng A 638:30–37

Sklenicka V, Kucharová K, Svobodová M et al (2016) Creep properties in similar weld joint of a thick-walled P92 steel pipe. Mater Charact 119:1–12

Taniguchi G, Yamashita K (2013) Effects of post weld heat treatment (PWHT) temperature on mechanical properties of weld metals for high-Cr ferritic heat-resistant steel. Kobelco Tech Rev 32:33–39

Fu H, Nagasaka T, Muroga T et al (2015) Weldability of 9Cr-ODS and JLF-1 steels for dissimilar joining with hot isostatic pressing and electron beam welding. Plasma Fusion Res 10:3405015

Li Y, Liu Y, Liu C et al (2018) Microstructure evolution and mechanical properties of liner friction welded S31042 heat-resistant steel. J Mater Sci Technol 34(4):653–659

Imgram AG, Swift RA (1985) Pressure vessel, piping, and welding needs for coal conversion systems. J Mater Energy Sys 7(3):212–222

Acknowledgements

We thank the staff members of the Machine and Workshop Engineering at the Graduate School of Engineering, University of Hyogo. We also thank Dr. Yujiro Nakatani and Mr. Shigekazu Miyashita in Toshiba Energy Systems & Solutions Corporation as well as Dr. Masashi Takahashi in Nishinippon Institute of Technology for their assistance in the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kimura, M., Iwamoto, S., Kusaka, M. et al. Effect of core bar inserted into weld faying part to obtain an ideal pipe joint with non-generating inner flash via friction welding. Adv. Manuf. 8, 418–428 (2020). https://doi.org/10.1007/s40436-020-00319-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-020-00319-w