Abstract

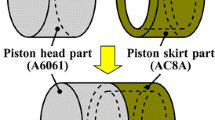

This paper describes the joint properties of the friction welded joint between 6061 (AA6061) Al alloy pipe and Al-Si12CuNi (AC8A) Al cast alloy pipe. When joints were made with a friction pressure of 25 MPa, a friction speed of 27.5 rps, and a forge pressure of 30 MPa, the joint strength increased with increasing friction time, and it was approximately 40 % of the ultimate tensile strength of the AC8A base metal at a friction time of 2.0 s. However, all joints fractured at the weld interface between the AA6061 side and the AC8A side, which had an AC8A adhering to the weld interface on the AA6061 side (mixed-mode fracture). When joints were made at a friction time of 0.3 s with the same friction pressure and friction speed, the joint strength increased with increasing forge pressure, and it was approximately 60 % of the AC8A base metal at a forge pressure of 175 MPa. Many joints had the fracture at the AC8A side although one of the joints had at the mixed-mode fracture. On the other hand, when joints were made at friction times of 0.7 and 2.0 s, the joint strength was approximately 60 % of the AC8A base metal at a forge pressure of 75 MPa. Those joints fractured on the AC8A side, because the adjacent region of the weld interface was softened. In addition, the flash of the joint with a friction time of 0.7 s was fewer than that of 2.0 s. To obtain the joint with the fracture from the AC8A side, the joint should be made with the opportune friction time such as 0.7 s and the opportune forge pressure such as 75 MPa because this joint had no cracks at the weld interface.

Similar content being viewed by others

References

Ohuchi H, Kanayama Y, Irisawa T (1996) Influence of Cu, Mg contents on cyclic thermal shock properties of Al-12%Si alloy castings. J Jpn Inst Light Met 46(3):144–149 (in Japanese)

Cha SW, Ha EJ, Lee KW, Chang H (2009) Development of fatigue durability analysis techniques for engine piston using CAE. SAE Int J Mater Manuf 2(1):403–408

Takahashi T, Iwabuchi Y, Nagasawa T, Kimura M (2013) Development of evaluation method for a joining part by friction welding which subjected to thermo-mechanical cyclic loading under sever environment. Res Rep Kushiro Natl Coll Tech 47:105–108 (in Japanese)

Shiozawa K, Nishino S, Tohda Y, Sun SM (1994) Small fatigue crack growth behavior and fatigue strength of squeeze-cast aluminum alloys, AC8A-T6 and AC4C-T6. Trans Jpn Soc Mech Eng A 60(571):663–670 (in Japanese)

Moffat AJ, Mellor BG, Sinclair I, Reed PAS (2007) The mechanisms of long fatigue crack growth behaviour in Al-Si casting alloys at room and elevated temperature. Mater Sci Technol 23(12):1396–1401

Asghar Z, Requena G, Boller E (2011) Three- dimensional rigid multiphase networks providing high-temperature strength to cast AlSi10Cu5Ni1-2 piston alloys. Acta Mater 59:6420–6432

Mbuya TO, Sinclair I, Moffat AJ, Reed PAS (2011) Analysis of fatigue crack initiation and S-N response of model cast aluminium piston alloys. Mater Sci Eng A 528:7331–7340

Huang X, Liu C, Lv X, Li G, Li F (2011) Aluminum alloy pistons reinforced with Sic fabricated by centrifugal casting. J Mater Process Technol 211(9):1540–1546

Moizumi K, Tezuka H, Sato T (2003) Influence of Cu and Mg addition on mechanical properties and thermal fatigue life of Al-Si-Mg cast alloys for cylinder head. J Jpn Foundry Eng Soc 75(6):397–402 (in Japanese)

Kimura M, Sakaguchi H, Kusaka M, Kaizu K, Takahashi T (2015) Characteristics of friction welding between solid bar of 6061 Al alloy and pipe of Al-Si12CuNi Al cast alloy. J Mater Eng Perform 24(11):4551–4560

Fuji A, Ameyama K, Futamata M, Shimaki Y (1994) Effects of post-weld heat treatment on the properties of commercially pure titanium/pure aluminium friction welds. Q J Jpn Weld Soc 12(1):101–107 (in Japanese)

Kimura M, Choji M, Kusaka M, Seo K, Fuji A (2005) Effect of friction welding conditions and aging treatment on mechanical properties of A7075-T6 aluminum alloy friction joint. Sci Technol Weld Join 10(4):406–412

Mizuno M, Takada T, Katoh S (1967) Weldability of high strength Al-Zn-Mg alloy (report 1) -Aging characteristics of heat-affected zone-. J Jpn Weld Soc 36(8):854–861 (in Japanese)

Mizuno M, Matsumura Y, Ogihara A (1970) Weldability of high strength Al-Zn-Mg Alloy (report 2) -Aging characteristics of pure Al-Zn-Mg ternary alloys-. J Jpn Weld Soc 39(1):73–82 (in Japanese)

Aval HJ, Serajzadeh S (2014) A study on natural aging behavior and mechanical properties of friction stir-welded AA6061-T6 plates. Int J Adv Manuf Technol 71(5):933–941

Wang D, He C, Wang H, Zhao X, Zuo L (2014) Effects of post-weld heat treatment on microstructure and mechanical properties of Al-12.7Si-0.7Mg alloy welded joints by GMAW. Acta Metall Sin (Engl Lett) 27(2):245–252

Kimura M, Ishii H, Kusaka M, Kaizu K, Fuji A (2009) Joining phenomena and joint strength of friction welded joint between aluminium-magnesium alloy (AA5052) and low carbon steel. Sci Technol Weld Join 14(7):655–661

Zeren M (2007) The effect of heat-treatment on aluminum-based piston alloys. Mater Des 28:2511–2517

Taylor JA (2012) Iron-containing intermetallic phases in Al-Si based casting alloys. Procedia Mater Sci 1:19–33

Eisaabadi BG, Davami P, Varahram N, Kim SK (2013) On the effect of hydrogen and Fe on reproducibility of tensile properties in cast Al-Si-Mg alloys. Mater Sci Eng A 565:278–284

Tzeng YC, Wu CT, Bor HY, Horng JL, Tsai ML, Lee SL (2014) Effects of scandium addition on iron-bearing phases and tensile properties of Al-7Si-0.6Mg alloys. Mater Sci Eng A 593:103–110

Morinaga T, Zaima S, Aono Y, Shimizu T (1964) On the strength of the aluminium castings specified in Japanese Industrial Standard (JIS) (part 1): on the mechanical properties of miniature lader parabolic reflector made from Al-7% Si alloy. J Jpn Inst Light Met 14(3):172–181 (in Japanese)

Japan Light Metal Association (2007) Aluminium handbook, 7th edn. Japan Light Metal Association, Tokyo, pp 212–223 (in Japanese)

Avalle M, Belingardi G, Cavatorta MP, Doglione R (2002) Casting defects and fatigue strength of a die cast aluminium alloy: a comparison between standard specimens and production components. Int J Fatigue 24:1–9

Yoshida M, Taki K, Fukunaga H (2000) Effect of hydrogen in molten aluminum on the growth of micro-porosity and mechanical properties of squeeze cast material. J Jpn Inst Light Met 50(7):325–329 (in Japanese)

Nentwig AWE, Jenicek A (1994) Research into the possible applications of friction stud welding. Weld Res Abroad 42(2):36–40

Shinoda T, Takegami H (2005) Friction stud welding of small diameter aluminum alloy for automobile use. Proc Int Symp Join Tech Adv Automobile Assembly 2005, 13–14 October 2005, Tokyo, Technical Commission on Joining and Materials Processing for Light Structures, Japan Welding Society 27–35

Nishida T, Ogura T, Fujimoto M, Hirose A (2011) Microstructure and mechanical property of 5000 series aluminum stud joint with zinc insert using friction welding. J Jpn Inst Light Met 61(7):322–327 (in Japanese)

Okita K, Aritoshi M, Kishimoto W, Yamada K, Hira H (1981) Study on the friction welding of different diameter bars (report 1) -Effect of relative difference of bar diameter on the friction welding phenomenon-. J Jpn Weld Soc 50(2):189–195 (in Japanese)

Fukakusa K, Satoh T (1981) Travelling phenomena of rotational plane during friction welding -Experimental results and travelling mechanism-. J Jpn Weld Soc 50(10):953–958 (in Japanese)

Kato K, Tokisue H (1991) Friction welding of an aluminum alloy with different shape. J Jpn Inst Light Met 41(12):809–814 (in Japanese)

Fukakusa K (1996) On real rotational contact plane in friction welding of different diameter materials and dissimilar materials -Fundamental study of friction welding-. Q J Jpn Weld Soc 14(3):483–488 (in Japanese)

Shinoda T, Mizuno Y, Li J, Saito T (1999) Friction welding phenomena of aluminum. J Light Met Weld Constr 37(8):345–350 (in Japanese)

Deng L, Wang X, Xia J, Li J (2011) Effect of isothermal extrusion parameters on mechanical properties of Al-Si eutectic alloy. Mater Sci Eng A 528:6504–6509

Fernández-Gutiérrez R, Requena GC (2011) The effect of spheroidisation heat treatment on the creep resistance of a cast AlSi12CuMgNi piston alloy. Mater Sci Eng A 598:147–153

Nelson TW, Steel RJ, Arbegast WJ (2003) In site thermal studies and post-weld mechanical properties of friction stir welds in age hardenable aluminium alloys. Sci Technol Weld Join 8(4):283–288

Takaya K, Harada Y, Kumai S, Kitayama K (2012) Microstructure of joint interface and mechanical properties in high-speed solid-state welded 2024 aluminum alloy stud and 6N01 aluminum alloy plate. J Jpn Inst Light Met 62(10):376 (in Japanese)

İpekoğlu G, Erim S, Çam G (2014) Effects of temper condition and post weld heat treatment on the microstructure and mechanical properties of friction stir butt-welded AA7075 Al alloy plates. Int J Adv Manuf Technol 70(1):201–213

Malarvizhi S, Raghukandan K, Viswanathan N (2008) Effect of post weld aging treatment on tensile properties of electron beam welded AA2219 aluminum alloy. Int J Adv Manuf Technol 37(3):294–301

Katayama S, Ogawa K (2010) Laser weldability and aging characteristics of Welds -Laser weldability of commercially available A7N01 alloy (1)-. J Light Met Weld 48(12):463–474 (in Japanese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kimura, M., Sakaguchi, H., Kusaka, M. et al. Joint properties of friction welded joint between 6061 Al alloy pipe and Al-Si12CuNi (AC8A) Al cast alloy pipe. Int J Adv Manuf Technol 86, 2603–2614 (2016). https://doi.org/10.1007/s00170-016-8348-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8348-3