Abstract

A structural model of a soft/hard composite-coated textured (SHCCT) tool was proposed and substantiated by a three-dimensional numerical simulation. Its dry turning performance as applied to AISI-1045 steel was analyzed via three-factor five-level orthogonal experiments for different coating parameters, including coating thickness, coating material, and thickness ratio of the soft and hard coatings. In addition, the cutting performance of the proposed SHCCT tool was compared with those of uncoated non-textured, coated non-textured, and uncoated textured tools, and its superiority was proved by the significant reductions in the cutting force, and specifically, the cutting temperature. The optimal results were provided by the SHCCT tool with a WS2/ZrN soft/hard composite coating, a 0.9:0.1 thickness ratio of the above ingredients, and a total coating thickness of 0.5 μm.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cutting fluids are vital during the conventional cutting process for the lubrication and cooling of tools and workpieces [1, 2]. However, the cutting fluid application increases not only the processing costs but also the environmental pollution risks [3, 4]. Therefore, green processing technology (without cutting fluids) is a sustainable development trend, which has become increasingly topical [5, 6]. However, dry cutting exposes the tool to more heavy-duty conditions because of the inevitably increased cutting forces, cutting temperatures, and tool wear [7]. Hence, the development of innovative dry cutting tools is a research hotspot, which covers two primary types of tools including micro-textured tools [8, 9], and coated tools [10, 11].

Xie et al. [12] performed an experimental study on cutting temperatures and cutting forces in the dry turning of a titanium alloy using a non-coated micro-grooved tool. They reported that micro-grooves patterned on the tool rake surface contributed to the reduction of cutting chip friction and heat. Kümmel et al. [13] investigated the microtexturing of uncoated cemented carbide cutting tools for wear improvement and built-up edge stabilization. They reported that the adhesion of workpiece material to the rake face could be modified by applying specific textures produced by laser texturing. Deng et al. [14] reported an experiment where MoS2/Zr composite coating was deposited on the surface of YT15-cemented carbide and a dry cutting test was conducted on hardened steel. The results indicated that, in the case of low-speed cutting, MoS2/Zr-coated tools exhibited superior cutting performance as compared to the uncoated ones. The coatings on the rake face acted as lubricating additives between the tool-chip sliding couple during the cutting process and contributed to the tool wear reduction. In the high-speed cutting process, there were numerous cracks in the coating because of the elevated cutting temperature, which initiated coating delamination from the tool face and accelerated the tool wear. Aslantas et al. [15] reported the wear behavior of TiN-coated and uncoated ceramic Al2O3-TiCN mixed inserts on the dry machining of hardened AISI 52100 steel (with a hardness of 63HRC). The results indicated that the dominant wear type for both the coated and uncoated cutting tools was crater wear. In addition, TiN coating significantly increased the wear resistance of ceramic tools but rendered them more inclined to the formation of built-up edges.

According to the available results from previous studies, surface textures can reduce cutting forces [16, 17], soft coatings can significantly reduce the friction coefficient [18], while hard layers render the tool more wear-resistant [19]. In this study, therefore, a fusion of micro-textured and coating technologies into a new green cutting tool technique is proposed. However, it is necessary to have a theoretical basis for the preparation of a soft/hard composite-coated textured (SHCCT) tool, which should also reduce the actual experimental workload. Numerous scholars have simulated cutting performance using finite element analysis. Arulkirubakaran et al. [20] performed a numerical simulation, using the deform 3D software, of the machining of a Ti-6Al-4V alloy with surface-textured tools. Kim et al. [21] conducted the finite element modeling of hard turning bearing steel (AISI 52100) via micro-textured tools.

In this study, a combination of theoretical analysis and numerical simulation is used for the substantiation of the feasibility of different soft/hard composite coatings deposited on the surface of the textured tool during dry cutting, as well as the optimization of their parameters.

2 Experimental

2.1 Design ideas of SHCCT tool

In this study, the concept of a tool combining soft/hard composite coatings and textures is proposed. Firstly, orderly arranged micro-grooves of specific shape and size were produced on the rake face of the tool using surface-processing technology. Hard and soft coatings were then deposited on the rake face of the tool, sequentially, using surface coating deposition technology. These measures were aimed at producing a cutting tool with low friction, high wear resistance, and extended service life of its substrate. The cutting schematic of the SHCCT tool is shown in Fig. 1.

2.2 Theoretical substantiation of expected reduction in cutting force and cutting temperature

In actual machining, oblique cutting is the commonest. Based on the straight feed direction and the applied combinations of cutting depth, feed rate, and tool edge radius used in the oblique cutting process, it can be reduced to orthogonal cutting. A simplified model of orthogonal cutting is shown in Fig. 2.

The cutting flow direction in this approximately orthogonal cutting coincides with the direction of cutting force resistance. When the cutting resistance of the orthogonal cutting is decomposed into an axial force Fx, radial force Fy, and main cutting force Fz, these components can be respectively expressed as [22]

where lf is the tool-chip contact length, \(a_{\text{w}}\) the cutting width, \(\overline{{\tau_{\text{c}} }}\) the average shear stress on the tool rake face, γo the rake angle, β the friction angle, ψr the approach angle, and \(\psi_{\uplambda}\) the chip flow angle.

From Eqs. (1)–(3), it follows that the three cutting force components are proportional to the tool-chip contact length lf and the average shear stress on the tool rake face \(\overline{{\tau_{\text{c}} }}\).

In the cutting process, the primary heat generation contributions are the chip deformation work and the friction work on the rake face and flank face. The latter increases the temperature in the tool-chip zone, which is referred to as the cutting temperature. The cutting heat distribution in dry cutting is shown in Fig. 3. It is typically assumed that the cutting temperature \(\overline{\theta }_{\text{t}}\) can be derived as a superposition of the shear surface temperature \(\overline{\theta }_{\text{s}}\) and the tool-chip contact surface temperature \(\overline{\theta }_{\text{f}}\), according to Ref. [23]

where \(\bar{\theta }_{\text{t}}\) is the cutting temperature at the tool-chip interface on the rake face of the cutting tool, \(\bar{\theta }_{\text{s}}\) the shear surface temperature, \(\bar{\theta }_{\text{f}}\) the tool-chip contact surface temperature, \(\theta_{0}\) the ambient temperature, \(R_{1}\) the ratio of the heat generated at the shear plane and transferred into the chip, \(R_{2}\) the ratio of the heat generated at the rake face and transferred into the chip, \(v\) the cutting speed, \(v_{\text{s}}\) the shear speed, \(\tau_{\text{s}}\) the shear strength of the workpiece material, \(c_{1}\) the specific heat capacity of workpiece material at the average temperature of \(\theta_{0} {-}\bar{\theta }_{\text{s}}\), \(c_{2}\) the specific heat capacity of chip at the temperature of \((\bar{\theta }_{\text{s}} + \bar{\theta }_{\text{f}} )\), \(\rho_{1}\) the density of workpiece material, \(\rho_{2}\) the density of chip at the temperature of \((\bar{\theta }_{\text{s}} + \bar{\theta }_{\text{f}} )\), \(k_{2}\) the thermal conductivity of chip at the temperature of \((\bar{\theta }_{\text{s}} + \bar{\theta }_{\text{f}} )\), \(\xi\) the chip deformation coefficient, and \(\phi\) the shear angle.

It is noteworthy that the cutting temperature is positively correlated to the square root of the tool-chip contact length \(\sqrt {l_{\text{f}} }\) and the average shear stress \(\overline{{\tau_{\text{c}} }}\) on the rake face of the tool. A more detailed analysis of Eq. (4) can be found in Ref. [24].

2.3 Effects of texture on cutting forces and cutting temperature

The profile of a textured tool during cutting is shown in Fig. 4. In the tool-chip zone, the actual contact distance between the chip and the tool rake face is reduced because of the texture. As can be seen in Eqs. (1)–(3), the cutting force components are proportional to the tool-chip contact length. Equation (4) implies that the cutting temperature is positively correlated to the square root of the tool-chip contact length. Therefore, we can conclude that the presence of textures can effectively reduce the cutting forces and the cutting temperature.

2.4 Effect of soft/hard composite coating on cutting forces and cutting temperature

A soft/hard composite coating is fabricated by hard coating deposition over the substrate, with further depositing of a soft coating layer. Insofar as the external soft coating is directly in contact with cutting workpieces, it plays a significant role in the reduction of cutting forces and temperatures. The shear strength of a soft coating is significantly lower than that of common tool materials, which makes a substantial reduction of the average shear stresses on the rake face feasible. As follows from Eqs. (1)–(3), the cutting force components are directly proportional to the average shear stress on the tool rake face. In addition, as seen in Eq. (4), the cutting temperature is positively correlated to the average shear stress on the tool rake face. Therefore, the soft coating application can reduce the cutting force components and the cutting temperature.

2.5 Orthogonal experiments design

Tungsten disulfide (WS2) and molybdenum disulfide (MoS2) find an increasingly broad use as soft coatings. They both have a hexagonal crystal layered structure, a low friction coefficient, and produce interface films in the process of friction. Therefore, WS2 and MoS2 soft coatings were used for the SHCCT tool preparation in this study.

The hard coating in the soft/hard composite coating is primarily used to improve the hardness and wear resistance of the tool substrate. Hard coatings such as TiN, ZrN, and TiAlN have high hardness, excellent wear resistance, and high-temperature resistance. Therefore, these three materials were used for the preparation of the hard coatings in this study. The physical and thermal properties of the coating materials are presented in Table 1.

Numerous researchers have reported that a combination of certain soft and hard coatings could significantly improve the conventional cutting performance. However, to the best of our knowledge, the combined application of soft and hard coatings to dry cutting has not yet been reported. To obtain the best combination of soft and hard coatings from known materials, three-factor five-level (L2556) orthogonal experiments were designed. The three factors were the coating thickness, coating material, and thickness ratio of soft and hard coatings, and the five levels of each factor are described in detail in Table 2. As reference samples, three additional experiments were conducted, which involved tools without texturing and coating (group 26), textured tools without coating (group 27), and coated tools without texturing (group 28). The orthogonal experimental scheme is summarized in Table 3.

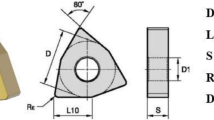

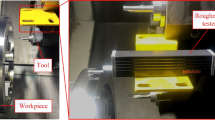

2.6 Cutting simulation

The AISI-1045 steel, which is quenched and tempered #45 steel, was selected as the workpiece material, and cemented carbide was selected as the tool substrate. The physical and thermal properties of the tool and the workpiece materials are presented in Table 4. The simplified model for turning is shown in Fig. 5, where the size of the textured area on the rake face is 1 mm × 1 mm. The structural parameters of the texture are a diameter of 50 μm, a depth of 40 μm, and a spacing of 150 μm, as presented in Table 5. After repeated verification, a suitable calculation efficiency and accuracy was obtained when the number of grids of the tool and workpiece was 70 000. During the cutting process, the highest stress, strain, and temperature were observed at the tool rake face, which contacted with the workpiece. Thus, on the premise of ensuring the accuracy of the calculation, it was found expedient to reduce the calculation time by increasing the grid density of the tool nose. The tool and workpiece after re-meshing are shown in Fig. 6. The depth of cut was set to 0.3 mm; the feed rate was 0.1 mm/r; the cutting speed was 150 m/min; and the ambient temperature was 20 °C.

3 Results and discussion

3.1 Cutting temperature

The cutting temperatures of groups 18 and 26 are shown in Figs. 7a, b, respectively, while those of four different tools are shown in Fig. 8. As can be seen in Fig. 8, under the same cutting parameters, the cutting temperature of the tool without coating and texturing was the highest, reaching 428.0 °C. The cutting temperature of the SHCCT tool (group 18) was the lowest, namely 62.9 °C. By comparing the cutting temperature of the four types of tools, we can see that both coated and textured tools can reduce the cutting temperature, however, their combination provides a synergetic effect.

3.2 Main cutting force

The main cutting forces of groups 2 and 26 are shown in Figs. 9a, b, respectively, while those of four different tools are plotted in Fig. 10. A comparative analysis of Figs. 9 and 10 reveals no significant differences in the main cutting force values for different tools. Among them, the highest main cutting force of 97.4 N was observed in the tool without the coating and texturing. In addition, it can be seen in Fig. 10 that the effect of coating or textures on the reduction of the main cutting force is not significant. However, the main cutting force of the SHCCT tool (group 2) was 79.1 N, i.e., 18.8% lower than that of tools without the coating and texturing. This indicates that the combination of coating and textures is more conducive to the reduction of the main cutting force.

3.3 Results of orthogonal experiments

The results of orthogonal experiments are presented in Table 6. According to the test results on group 25, the processing of textures or depositing of a coating on the tool rake face can reduce the main cutting force, and specifically, the cutting temperature. The effects of coating thickness, coating material, and thickness ratio of the soft and hard coating on the cutting temperature are shown in Figs. 11a–c, respectively. As can be seen in Fig. 11a, with an increase in the coating thickness, the cutting temperature increases rapidly and then stabilizes. When the coating thickness is 0.5 μm, the cutting temperature is the lowest. As can be seen in Fig. 11b, the cutting temperature of the WS2/ZrN SHCCT tool is the lowest. As can be seen in Fig. 11c, with a decrease in the thickness ratio of the soft coating, the cutting temperature gradually increases, and is approximately directly proportional to the soft coating thickness. This complies with the primary function of the soft coating to lubricate the tool-chip contact area and reduce the friction coefficient, thereby reducing the generated heat. Figure 11d shows the effect of three parameters on the cutting temperature. It can be seen that the effect of the thickness ratio of soft and hard coatings on the cutting temperature is the most obvious, followed by the coating material factor, while the coating thickness is the least important factor. Therefore, group A1B2C1 is the most conducive to reduce the cutting temperature.

The effects of coating thickness, coating material, and thickness ratio of soft and hard coatings on the main cutting force are shown in Figs. 12a–c, respectively. As can be seen in Fig. 12a, with an increase in the coating thickness, the main cutting force exhibits a slight upward trend and then stabilizes. At a coating thickness of 0.5 μm, the main cutting force is the smallest. As can be seen in Fig. 12b, the main cutting force of the WS2/ZrN SHCCT tool is the lowest, while that of the MoS2/ZrN SHCCT tool is the greatest. In addition, it was found that all SHCCT tools with WS2 soft coating exhibited lower values of the main cutting force than those with the MoS2 soft coating. As can be seen in Fig. 12c, with a decrease in the thickness ratio of soft/hard coatings, the main cutting force exhibits an initial increasing trend, followed by a decline and a final marginal increase. When the thickness ratio of the soft and hard coatings is 0.9:0.1, the main cutting force is the lowest. Figure 12d shows the effects of three parameters on the main cutting force. In decreasing order of their impact on the main cutting force, the parameters are thickness ratio, coating material, and coating thickness. Therefore, tools from group A1B2C1 were found to be the most efficient in the main cutting force reduction.

In summary, the optimal cutting performance is exhibited by the SHCCT tools (group A1B2C1) with a coating thickness of 0.5 μm, WS2/ZrN coating materials, and a soft-to-hard coatings thickness ratio of 0.9:0.1, which ensures the lowest cutting temperature and smallest main cutting force.

4 Conclusions

The following conclusions were drawn

-

(i)

A joint application of micro-textures and soft/hard composite coating was proposed for the dry turning SHCCT tool. Its FEM model was implemented, and three-factor five-level orthogonal cutting experiments of the tool with different coating parameters were conducted. Using numerical simulation, the effects of varying coating parameters on the cutting temperature and the main cutting force were analyzed, and the optimal coating parameters were identified.

-

(ii)

The cutting temperature of the SHCCT tool is significantly lower than that of the soft/hard composite-coated tool with no textures, the uncoated textured tool, and the uncoated non-textured tool.

-

(iii)

The effect of coating and textures on the main cutting force reduction is not significant. The force of the SHCCT tool group 2 was 18.8% lower than that of the uncoated non-textured tool, which was used as a reference.

-

(iv)

In decreasing order of their impact on the cutting temperature and the main cutting force, the influencing factors are thickness ratio, coating material, and coating thickness. The optimal combination of these parameters, which ensured the lowest cutting temperature and smallest main cutting force in the dry turning of AISI-1045 steel, was a coating thickness of 0.5 μm, WS2/ZrN coating materials, and a soft-to-hard coatings thickness ratio of 0.9:0.1.

References

Debnath S, Reddy MM, Yi QS (2016) Influence of cutting fluid conditions and cutting parameters on surface roughness and tool wear in turning process using Taguchi method. Measurement 78:111–119

Yasar HS, Heris SZ, Shanbedi M et al (2017) Experimental investigation of thermal properties of cutting fluid using soluble oil-based TiO2 nanofluid. Powder Technol 310:213–220

Paul PS, Varadarajan AS, Gnanadurai RR (2016) Study on the influence of fluid application parameters on tool vibration and cutting performance during turning of hardened steel. Eng Sci Technol Int J 19(1):241–253

Feng WL, Yin Y, Mendoza ML et al (2018) Oil recovery from waste cutting fluid via the combination of suspension crystallization and freeze-thaw processes. J Clean Prod 172:481–487

Uddin MS, Pham B, Sarhan A et al (2017) Comparative study between wear of uncoated and TiAlN-coated carbide tools in milling of Ti6Al4V. Adv Manuf 5(1):83–91

Ma JF, Duong NH, Chang S et al (2015) Assessment of microgrooved cutting tool in dry machining of AISI 1045 steel. ASME J Manuf Sci Eng 137(3):031001

Sugihara T, Singh P, Enomoto T (2017) Development of novel cutting tools with dimple textured surfaces for dry machining of aluminum alloys. Procedia Manuf 14:111–117

Azarhoushang B, Zahedi A (2017) Laser conditioning and structuring of grinding tools—a review. Adv Manuf 5(1):35–49

Kumar CS, Patel SK (2018) Effect of WEDM surface texturing on Al2O3/TiCN composite ceramic tools in dry cutting of hardened steel. Ceram Int 44(2):2510–2523

Kumar R, Sahoo AK, Mishra PC et al (2018) Comparative investigation towards machinability improvement in hard turning using coated and uncoated carbide inserts: part I. Experimental investigation. Adv Manuf 6(1):52–70

Prengel HG, Jindal PC, Wendt KH et al (2001) A new class of high performance PVD coatings for carbide cutting tools. Surf Coat Technol 139(1):25–34

Xie J, Luo MJ, Wu KK et al (2013) Experimental study on cutting temperature and cutting force in dry turning of titanium alloy using a non-coated micro-grooved tool. Int J Mach Tools Manuf 73:25–36

Kümmel J, Braun D, Gibmeier J et al (2015) Study on micro texturing of uncoated cemented carbide cutting tools for wear improvement and built-up edge stabilisation. J Mater Process Technol 215:62–70

Deng JX, Song WL, Zhang H et al (2008) Performance of PVD MoS2/Zr-coated carbide in cutting processes. Int J Mach Tools Manuf 48(14):1546–1552

Aslantas K, Ucun İ, Çicek A (2012) Tool life and wear mechanism of coated and uncoated Al2O3/TiCN mixed ceramic tools in turning hardened alloy steel. Wear 274–275:442–451

Vasumathy D, Meena A (2017) Influence of micro scale textured tools on tribological properties at tool-chip interface in turning AISI 316 austenitic stainless steel. Wear 376–377:1747–1758

Kawasegi N, Sugimori H, Morimoto H et al (2009) Development of cutting tools with microscale and nanoscale textures to improve frictional behaviour. Precis Eng 33(3):248–254

Lian YS, Deng JX, Li SP et al (2013) Preparation and cutting performance of WS2 soft-coated tools. Int J Adv Manuf Technol 67(5–8):1027–1033

Nouari M, Ginting A (2006) Wear characteristics and performance of multi-layer CVD-coated alloyed carbide tool in dry end milling of titanium alloy. Surf Coat Technol 200(18–19):5663–5676

Arulkirubakaran D, Senthilkumar V, Kumawat V (2016) Effect of micro-textured tools on machining of Ti-6Al-4V alloy: an experimental and numerical approach. Int J Refract Metals Hard Mater 54:165–177

Kim DM, Bajpai V, Kim BH et al (2015) Finite element modeling of hard turning process via a micro-textured tool. Int J Adv Manuf Technol 78(9–12):1393–1405

Chen RY (1993) Metal-cutting principles. China Machine Press, Beijing

Loewen E, Shaw M (1954) On the analysis of cutting tool temperatures. Trans ASME 76(2):217–225

Bono M, Ni J (2006) The location of the maximum temperature on the cutting edges of a drill. Int J Mach Tools Manuf 46(7–8):901–907

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 51505399), the Natural Science Foundation of Fujian Province of China (Grant No. 2017J05088), and the Fundamental Research Funds for the Central Universities, Xiamen University (Grant No. 20720160078).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Lian, YS., Mu, CL., Liu, M. et al. Three-dimensional numerical simulation of soft/hard composite-coated textured tools in dry turning of AISI 1045 steel. Adv. Manuf. 7, 133–141 (2019). https://doi.org/10.1007/s40436-019-00249-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-019-00249-2