Abstract

The aim of this paper is to propose and validate a numerical methodology for optimizing the Waterjet Peening (WJP) parameters on the surface integrity and High-Cycle Fatigue (HCF) strength of metallic materials. This methodology is composed of four principal steps: (i) the prediction of WJP surface integrity (residual stresses, plastic deformations, surface roughness and superficial damage) by using Finite Element (FE) simulation and considering different process conditions defined by the design-of-experiment method, (ii) the multi-objective optimization of the process parameters, (iii) the FE simulation of the elasto-plastic behavior of the peened surface under a cyclic loading and the determination of the quasi-stabilized surface integrity, and (iv) the prediction of the optimal S–N curve of the peened surface in the HCF regime by using the DangVan’s fatigue criterion. The proposed methodology is developed and validated for an Al 7075-T6 aluminum alloy peened at a given condition and subjected to 4-point rotative bending fatigue tests. Little discrepancy between experimental and theoretical fatigue lives is observed. In addition, the optimal WJP process parameters lead to about a 23% increase in the material fatigue limit in the range of 105–108 cycles.

Similar content being viewed by others

References

Srivastava M, Tripathi R, Hloch S, Chattopadhyaya S, Rai Dixit A (2016) Potential of using water jet peening as a surface treatment process for welded joints. Int Conf Manuf Eng Mater 149:472–480. https://doi.org/10.1016/j.proeng.2016.06.694

Mochizuki M, Enomoto K, Sakata S, Saito H, Ichie K (1993) A study on residual stress improvement by water jet peening. In: Proceedings of 5th international conference on shot peening, Oxford University, Christ Church, pp 247–256

Grinspan SA, Gnanamoorthy R (2006) A novel surface modification technique for the introduction of compressive residual stress and preliminary studies on Al alloy AA6063. Surf Coat Technol 201:1768–1775. https://doi.org/10.1016/j.surfcoat.2006.03.002

Zhanshu H, Huixin Y, Shusen Z, Jiaqi X, Dalei L, Chao LC, Shuai W (2020) An experimental and numerical analysis of water jet peening of Al6061-T6. Int J Adv Manuf Technol 107:3833–3845. https://doi.org/10.1007/s00170-020-05282-1

Mahmoudi AH, Salahi F, Ghasemi A (2016) Comparison between residual stress induced by waterjet peening and shot peening. In: International conference on surface modification technologies (SMT30), Milan; Italy.

Krull P, Nitschke-Pagel T, Wohlfahrt H (1999) Influence of shot peening and high pressure water peening on near surface microstructure of 316 Ti stainless steel. Trans Eng Sci 25:292–300

Kong MC, Axinte D, Voice W (2010) Aspects of material removal mechanism in plain waterjet milling on gamma titanium aluminide. J Mater Process Technol 210:573–584. https://doi.org/10.1016/j.jmatprotec.2009.11.009

Huang L, Folkes J, Kinnell P, Shipway PH (2012) Mechanisms of damage initiation in a titanium alloy subjected to water droplet impact during ultra-high. J Mater Process Technol 212:1906–1915. https://doi.org/10.1016/j.jmatprotec.2012.04.013

Colosimos BM, Monno M, Semeraro Q (2000) Process parameters control in water jet peening. Int J Mater Prod Technol 15:10–19. https://doi.org/10.1504/IJMPT.2000.001232

Daniewicz SR, Cummings SD (1999) Characterization of water peening process. ASME J Eng Mater Technol 121:336–340. https://doi.org/10.1115/1.2812383

Azmir A, Christian S, Eberhardb K, Jhislain N (2014) Surface Erosion of Carbon Steel 1045 during waterjet peening. J Mater Eng Perform 23(5):1870–1880. https://doi.org/10.1007/s11665-014-0932-9

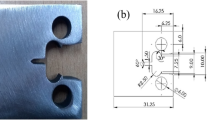

Kunaporn S, Ramulu M (2002) An experimental and numerical analysis of waterjet peening of 7075-T6 aluminum alloy. Ph.D. thesis, University of Washington

Hashish M, Hopkins J, Kunaporn S, Ramulu M (2001) Ultra high-pressure water jet peening, Part I: surface texture. In: WJTA American Waterjet conference, pp 18–21

Chillman A, Ramulu M, Hashish M (2007) Waterjet peening and surface preparation at 600 MPa: a preliminary experimental study. J Fluids Eng 129:485–490. https://doi.org/10.1115/1.2436580

Ramulu M, Kunaporn S, Arola D, Hashish M, Hopkins J (2000) Water jet machining and peening of metals. J Pressure Vessel Technol 2000(122):90–95. https://doi.org/10.1115/1.556155

Epp J, Zoch HW (2016) Comparison of alternative peening methods for the improvement of fatigue properties of case-hardened steel parts. HTM J Heat Treat Mater 71:109–116. https://doi.org/10.3139/105.110288

Rajesh N, Ramesh BN (2005) Empirical modelling of water-jet peening of 6063–T6 aluminium alloy. J Produc Eng 86:22–26

Macodiyo DO, Soyama H (2006) Optimization of cavitation peening parameters for fatigue performance of carburized steel using Taguchi methods. J Mater Process Technol 178:234–240. https://doi.org/10.1016/j.jmatprotec.2006.03.172

Azmir A, Christian S, Bo L (2013) Effect of waterjet peening on aluminum alloy 5005. Int J Adv Manuf Technol 67:785–795. https://doi.org/10.1007/s00170-012-4522-4

Ayeb M, Frija M, Fathallah R (2019) Prediction of residual stress profile and optimization of surface conditions induced by laser shock peening process using artificial neural networks. Int J Adv Manuf Technol 100:2455–2471. https://doi.org/10.1007/s00170-018-2883-z

Maleki E, Farrahi GH (2018) Modelling of conventional and severe shot peening influence on properties of high carbon steel via artificial neural network. Int J Eng 31:382–393. https://doi.org/10.5829/ije.2017.30.11b.00

Daoud M, Kubler R, Bemou A, Osmond P, Polette A (2021) Prediction of residual stress fields after shot peening of TRIP780 steel with second-order and artificial neural network models based on multiimpact finite element simulations. J Manuf Process Soc Manuf Eng 72:529–543. https://doi.org/10.1016/j.jmapro.2021.10.034

Manual MU (2019) USA. MINITAB Inc. State College, PA

Derringer G, Suich R (1980) Simultaneous optimization of several response variables. J Qual Technol. https://doi.org/10.1080/00224065.1980.11980968

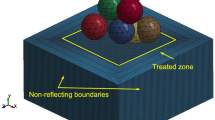

Amri R, Laamouri A, Fathallah R (2020) Finite element simulation of waterjet-peened Al 7075–T6 aluminum alloy surface by using multiple droplet impacts. J Mater Eng Perform 29:7336–7351. https://doi.org/10.1007/s11665-020-05208-8

Hibbitt, Karlsson, Sorensen, Inc (2014) ABAQUS Standard User’s manual, version 6.14, USA

Amri R, Laamouri A, Manchoul S, Fathallah R (2019) Transient dynamic finite element simulation for prediction of surface integrity induced by waterjet peening. Proc Inst Mech Eng L J Mater Design Appl. https://doi.org/10.1177/1464420719874389

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In: Proceedings of the 7th international symposium on ballistics, vol 54, pp 541–547

Gregory Kay (2003) Failure modeling of titanium 6Al-4Vand aluminum 2024-T3 with the Johnson Cook material model, Office of Aviation Research Washington, DC 20591, September.

Brar NS, Joshi VS, Harris BW (2009) Constitutive model constants for Al 7075T651 and Al 7075T6. AIP Conf Proc. https://doi.org/10.1063/1.3295300

Hsu C-Y, Liang C-C, Teng T-L, Nguyen A-T (2013) A numerical study on high-speed water jet impact. Ocean Eng 72:98–106. https://doi.org/10.1016/j.oceaneng.2013.06.012

Chizari M, Al Hassani STS, Barrett LM, Wang B (2007) 3-D finite element modelling of water jet spot welding. In: Proceedings of the world congress on engineering

Myers RH, Montgomery DC (2002) Response surface methodology, 2nd edn. Wiley, New York

Kartal ME, Basaga HB, Bayraktar A (2011) Probabilistic nonlinear analysis of CFR dams by MCS using response surface method. Appl Math Model 35:2752–2770. https://doi.org/10.1016/j.apm.2010.12.003

Chi G, Hu S, Yang Y, Chen T (2012) Response surface methodology with prediction uncertainty: a multi-objective optimization approach. Chem Eng Res Des. https://doi.org/10.1016/j.cherd.2011.12.012

Montgomery DC, Peck EA, Vining GG (2001) Introduction to linear regression analysis. Wiley, New York

Mattson RL, Coleman WS (1954) Effect of shot peening variables and residual stresses on fatigue life of leaf spring specimens. Trans Soc Autom Eng 62:546–556. https://doi.org/10.4271/540262

Zhuang WZ, Halford GR (2001) Investigation of residual stress relaxation under cyclic load. Int J Fatigue 23:S31–S37. https://doi.org/10.1016/S0142-1123(01)00132-3

Omar SZ, Aidy A, Sahari BB, Rizal Z (2009) Modelling of residual stress relaxation: a review. Pertanika J Sci Technol 17:325–336

Wick A, Schulze V, V¨ ohringer, O. (2000) Effects of warm peening on fatigue life and relaxation behavior of residual stresses in AISI 4140 steel. Mater Sci Eng A 293:191–197. https://doi.org/10.1016/S0921-5093(00)01035-2

Dang Van K, Douaron A, Lieurade HP (1984) Multiaxial fatigue limit: a new approach. In: Advances in fracture research, 6th Int. Conf. Fracture, pp 1879–1885

Fathallah R, Laamouri A, Sidhom H, Braham C (2004) High cycle fatigue behavior prediction of shot-peened parts. Int J Fatigue 26:1053–1067. https://doi.org/10.1016/j.ijfatigue.2004.03.007

Sidhom N, Laamouri A, Fathallah R, Braham C, Lieurade HP (2005) Fatigue strength improvement of 5083 H11 Al-alloy T-welded joints by shot peening experimental characterization and predictive approach. Int J Fatigue 27:729–745. https://doi.org/10.1016/j.ijfatigue.2005.02.001

Laamouri A, Ghanem F, Braham C, Sidhom H (2019) Influences of up-milling and down-milling on surface integrity and fatigue strength of X160CrMoV12 steel. Int J Adv Manuf Technol 105:1209–1228. https://doi.org/10.1007/s00170-019-04280-2

Laamouri A, Sidhom H, Braham C (2022) A predictive methodology for high-cycle fatigue behavior of machined metallic parts. J Mater Eng Perform. https://doi.org/10.1007/s11665-022-06594-x

MATLAB (2020) Version (R2020a). The MathWorks Inc, Natick

Taira S, Murakami Y (1960) On the changes in residual stresses due to repeated stressing. In: Proceedings of the 3rd Japan congress on testing materials, Kyoto, Japan, pp 52–55

Kodama S (1972) The behaviour of residual stress during fatigue stress cycles. In: Proceedings of the international conference of mechanical behaviour of materials, vol II, pp 111–118

Qui Q, Wang R (1987) Changes in the state of the material by shot peening. In: H Wohlfahrt, R Kopp, OV¨ Ohringer (eds) Proceedings of the 3rd international conference on shot peening (ICSP3), pp 231–238

Basquin OH (1910) The exponential law of endurance tests. Am Soc Test Mater 10:625–630

Surajit Kumar P, Sivaprasad S, Dhar S, Tarafder S (2010) Ratcheting and low cycle fatigue behavior of SA333 steel and their life prediction. J Nucl Mater 401:17–24. https://doi.org/10.1016/j.jnucmat.2010.03.014

Funding

The authors received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Technical Editor: Izabel Fernanda Machado.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Amri, R., Laamouri, A. & Fathallah, R. Multiobjective optimization of waterjet peening effects on high-cycle fatigue life of Al-7075-T6 alloy. J Braz. Soc. Mech. Sci. Eng. 46, 31 (2024). https://doi.org/10.1007/s40430-023-04613-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04613-z