Abstract

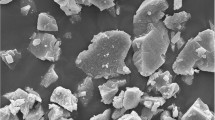

Scale formation is one of the many challenges for flow assurance in the oil and gas industry in deep water oilfields. This work focuses on the development of a new technique for inorganic scale monitoring based on electrical measurements. Experiments were carried out using synthetic water with the composition of a pre-salt Brazilian oilfield. Two different methodologies were applied for fouling formation. The results showed that the multiple-batch methodology increased the content of inorganic deposits on the electrodes, improving the output signal decay analysis of the system. Scanning electron microscopy with energy-dispersive spectroscopy (SEM–EDS) studies was used to validate the presence of fouling deposits, corroborating the sensor's detection efficiency. The spatial distribution of the main scaling chemical elements was also demonstrated by SEM–EDS analysis across the batches. In addition, the effects of temperature and electrode surface orientation were determined. The decay of the sensor output signal increased for higher temperatures (80 °C and 60 °C) compared to 40 °C due to the reduced solubility of CaCO3. For the horizontal position of the electrodes, measurements of the sensor and SEM analysis revealed a greater accumulation of fouling compared to the vertical position.

Similar content being viewed by others

Data availability

Data sharing does not apply to this article as no datasets were generated or analyzed during the current study.

References

Qazvini S, Golkari A, Azdarpour A, Santos RM, Safavi MS, Norouzpour M (2021) Experimental and modelling approach to investigate the mechanisms of formation damage due to calcium carbonate precipitation in carbonate reservoirs. J Pet Sci Eng 205:108801. https://doi.org/10.1016/j.petrol.2021.108801

World Bank (2022) Commodity Markets Outlook: The Impact of the War in Ukraine on Commodity Markets, April 2022. World Bank, Washington, DC. License: Creative Commons Attribution CC BY 3.0 IGO.

Valbuena G (2010) Challenges of deepwater development. Offshore Mag.

Bader MSH (2007) Sulfate removal technologies for oil fields seawater injection operations. J Pet Sci Eng 55:93–110. https://doi.org/10.1016/j.petrol.2006.04.010

Liu J, Zhou F, Dai Q, Gao H (2021) Effect of Ca2+, Mg2+, Ba2+ and Sr2+ cations on calcium carbonate scaling formation in oil-gas well: based on density functional theory study and molecular dynamics simulation. J Cryst Growth 563:126089. https://doi.org/10.1016/j.jcrysgro.2021.126089

Feng C, Zhang P (2022) Control of composite oilfield scales and deposits. Water-Form Depos. https://doi.org/10.1016/j.jcrysgro.2018.07.037

Kamal MS, Hussein I, Mahmoud M, Sultan AS, Saad MAS (2018) Oilfield scale formation and chemical removal: a review. J Pet Sci Eng 171:127–139. https://doi.org/10.1016/j.petrol.2018.07.037

Kelland MA (2014) Production chemicals for the oil and gas industry, 2nd edn. CRC Press/Taylor & Francis, Boca Raton, FL

Thant MMM, Sallehud-Din MTM, Hewitt GFF, Hale CPP, Quarini GLL (2011) Mitigating flow assurance challenges in deepwater fields using active heating methods. OnePetro. https://doi.org/10.2118/140997-MS

Rostron P (2018) Critical review of pipeline scale measurement technologies. Indian J Sci Technol 11:1–18. https://doi.org/10.17485/ijst/2018/v11i17/121459

Zuo Z, Yang W, Zhang K, Chen Y, Li M, Zuo Y, Yin X, Liu Y (2020) Effect of scale inhibitors on the structure and morphology of CaCO3 crystal electrochemically deposited on TA1 alloy. J Colloid Interface Sci 562:558–566. https://doi.org/10.1016/j.jcis.2019.11.078

Feasey ND, Freiter E, Jordan MM, Wintle R (2000) Field Experiences with a Novel Near Real Time Monitor for Scale Deposition in Oilfield Systems. OnePetro

Emmons DH, Graham GC, Holt SP, Jordan MM, Locardel LP, Locardel B (1999) On-Site. OnePetro, Near-Real-Time Monitoring of Scale Deposition. https://doi.org/10.2118/56776-MS

de Souza AVA, Rosário F, Cajaiba J (2019) Evaluation of calcium carbonate inhibitors using sintered metal filter in a pressurized dynamic system. Materials 12:1849. https://doi.org/10.3390/ma12111849

Christidis K, Gunarathne GP, Peteineri K (2013) Intelligent instrumentation for identification of scales in petroleum pipelines in situ. Trans Inst Meas Control 35:457–463. https://doi.org/10.1177/0142331212453598

Salgado CM, Salgado WL, de Freitas Dam RS, Conti CC (2021) Calculation of scales in oil pipeline using gamma-ray scattering and artificial intelligence. Measurement 179:109455. https://doi.org/10.1016/j.measurement.2021.109455

Wong P-Z (1999) 4. Conductivity, Permeability, and Electrokinetics. In: Wong P (ed) Experimental Methods in the Physical Sciences. Academic Press. https://doi.org/10.1016/S0076-695X(08)60415-9

Frias MAR, Yang W, (2016) Electrical resistance tomography with voltage excitation, I: 2016 IEEE International Instrumentation and Measurement Technology Conference Proceedings, https://doi.org/10.1109/I2MTC.2016.7520444.

Haddad PR, Jackson PE (1990) Chapter 9 Conductivity Detection. In: Ion chromatography: principles and applications. Elsevier, Kensington, https://doi.org/10.1016/S0301-4770(08)61141-0

Edvardsen L, Gawel K, Wenner S, Gawel B, Torsaeter M (2020) Electrochemical enhancement and inhibition of calcium carbonate deposition. J Environ Chem Eng 8:104239. https://doi.org/10.1016/j.jece.2020.104239

Dervos CT, Mergos JA, Iosifides AA (2005) Characterization of insulating particles by dielectric spectroscopy: case study for CaCO3 powders. Mater Lett 59:2842–2849. https://doi.org/10.1016/j.matlet.2005.03.066

Schmidt MP, Ilott AJ, Phillips BL, Reeder RJ (2014) Structural changes upon dehydration of amorphous calcium carbonate. Cryst Growth Des 14:938–951. https://doi.org/10.1021/cg401073n

Ihli J, Wong WC, Noel EH, Kim Y, Kulak AN, Christenson HK, Duer MJ, Meldrum FC (2014) Dehydration and crystallization of amorphous calcium carbonate in solution and in air. Nat Commun 5:3169. https://doi.org/10.1038/ncomms4169

Han Y, Zhang C, Wu L, Zhang Q, Zhu L, Zhao R (2018) Influence of alternating electromagnetic field and ultrasonic on calcium carbonate crystallization in the presence of magnesium ions. J Cryst Growth 499:67–76. https://doi.org/10.1016/j.jcrysgro.2018.07.037

Desarnaud J, Bertrand F, Shahidzadeh-Bonn N (2013) Impact of the kinetics of salt crystallization on stone damage during rewetting/drying and humidity cycling. J Appl Mech 80:020911–020998. https://doi.org/10.1115/1.4007924

Shahidzadeh-Bonn N, Desarnaud J, Bertrand F, Chateau X, Bonn D (2010) Damage in porous media due to salt crystallization. Phys Rev E 81:066110. https://doi.org/10.1103/PhysRevE.81.066110

Steiger M (2005) Crystal growth in porous materials—I: the crystallization pressure of large crystals. J Cryst Growth 282:455–469. https://doi.org/10.1016/j.jcrysgro.2005.05.007

MacAdam J, Parsons SA (2004) Calcium carbonate scale formation and control. Rev Environ Sci Biotechnol 3:159–169

Zhao J, Wang M, Lababidi HMS, Al-Adwani H, Gleason KK (2018) A review of heterogeneous nucleation of calcium carbonate and control strategies for scale formation in multi-stage flash (MSF) desalination plants. Desalination 442:75–88. https://doi.org/10.1016/j.desal.2018.05.008

Wang H, Alfredsson V, Tropsch J, Ettl R, Nylander T (2013) Formation of CaCO3 deposits on hard surfaces—effect of bulk solution conditions and surface properties. ACS Appl Mater Interfaces 5:4035–4045. https://doi.org/10.1021/am401348v

Serpa FS, Silva GM, Freitas LFL, Filho EBM, Nascimento JF, Pereira LS, Salazar-Banda GR, Borges GR, Dariva C, Franceschi E (2022) An experimental study of calcium carbonate precipitation with hydrate inhibitor in MEG recovery unit. Upstream Oil Gas Technol 8:100061. https://doi.org/10.1016/j.upstre.2021.100061

Acknowledgements

The authors thank the Brazilian agencies Conselho Nacional de Desenvolvimento Científico e Tecnológico—CNPq (grant: 305438/2018-2), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—CAPES (Cod. 001), and ANP/Petrobras for the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no potential conflicts of interest.

Human or animal rights

Not applicable to this study.

Informed consent

For this type of analysis, formal consent is not needed.

Additional information

Technical Editor: Marcelo Castro.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cruz, A.A., Dossi, F.C.A., Salazar-Banda, G.R. et al. A new measurement technique for monitoring inorganic scale deposition. J Braz. Soc. Mech. Sci. Eng. 45, 438 (2023). https://doi.org/10.1007/s40430-023-04361-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04361-0