Abstract

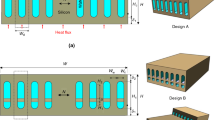

Maintaining the operating temperature within the allowable range for electronic components is crucial. This work aims to optimize the design of a heatsink manifold microchannel where the working fluid is MWCNT/water-nanofluid. The design parameters include inlet width \(({L}_{inlet})\), outlet width \(({L}_{outlet})\), heatsink height (\({h}_{f})\), and MWCNT nanoparticle volume fraction in the working fluid \((\varphi )\). Minimum pressure drop and minimum thermal resistance are selected as the objective functions. The finite volume method simulates the flow field and heat transfer at each design point. A regression model between the objective functions and the design variables is derived by utilizing the response surface method, and the sensitivity analysis of objective functions is performed by Pareto chart analysis. Finally, the response optimization method configures the optimal design points as \({L}_{inlet}\), \({L}_{outlet}\), \({h}_{f}\) being 85, 91, 245 \(\mu m\), respectively, and \(\varphi\) 0.016, corresponding to a pressure loss at 2677 Pa and thermal resistance at 0.8281 K/W. According to the results, the outlet width and heatsink height significantly affect the pressure drop and thermal resistance. Moreover, the physics of the flow field shows that the strength of the corner vortex and separation on the manifold can play a significant role in the thermal and hydraulic performance of the manifold microchannel heat sink. A numerical simulation has been performed to assess the regression model’s accuracy in predicting the thermal and fluid performance at the optimum point, showing a good agreement between the model prediction and the simulation results.

Similar content being viewed by others

Abbreviations

- \({c}_{p,f}\) :

-

Specific heat of the working flow (J kg−1 K−1)

- \({h}_{f}\) :

-

Height of the fin \((\mathrm{\mu m})\)

- \({\mathrm{h}}_{\mathrm{m}}\) :

-

Height of the manifold \((\mathrm{\mu m})\)

- \({\mathrm{h}}_{\mathrm{s}}\) :

-

Height of the heatsink \((\mathrm{\mu m})\)

- \({k}_{f}\) :

-

Thermal conductivity of the working flow (W m−1 K−1)

- \({k}_{s}\) :

-

Thermal conductivity of the manifold (W m−1 K−1)

- \({L}_{inlet}\) :

-

Inlet width \((\mathrm{\mu m})\)

- \({\mathrm{L}}_{\mathrm{m}}\) :

-

Manifold width \((\mathrm{\mu m})\)

- \({L}_{outlet}\) :

-

Outlet width \((\mathrm{\mu m})\)

- MMC:

-

Manifold Microchannel

- MWCNT:

-

Multi-walled carbon nanotubes

- \(n\) :

-

Normal to boundary

- \(nf\) :

-

Nanofluid

- \(P\) :

-

Pressure of the working flow (N m−2)

- \({P}_{in}\) :

-

Inlet pressure (N m−2)

- \({P}_{out}\) :

-

Outlet pressure (N m−2)

- \(Q\) :

-

Applied heat flux (W/cm2)

- RSM:

-

Response surface method

- \({\mathrm{R}}_{T}\) :

-

Thermal resistance (K/W)

- \(T\) :

-

Temperature of the working flow (K)

- \({T}_{inlet}\) :

-

Temperature of the coolant fluid (K)

- \({T}_{max}\) :

-

Maximum temperature of heated surface (K)

- \({T}_{s, interface}\) :

-

Solid–fluid interface, fluid side

- \({T}_{f, interface}\) :

-

Solid–fluid interface, solid side

- \(u\) :

-

Velocity of the working flow (m/s)

- \({\mathrm{w}}_{\mathrm{c}}\) :

-

Width of the heatsink \((\mathrm{\mu m})\)

- \({\mathrm{w}}_{\mathrm{f}}\) :

-

Width of the fin \((\mathrm{\mu m})\)

- \(\Delta \mathrm{P}\) :

-

Pressure drop (N m−2)

- \(\mu\) :

-

Viscosity of the working flow (kg/s)

- \({\rho }_{f}\) :

-

Density of the working flow (kg/m3)

- \({\rho }_{p}\) :

-

Density of the nanoparticle (kg/m3)

- \(\varphi\) :

-

Nanoparticle volume fraction

References

Yang X-H, Tan S-C, Ding Y-J, Liu J (2017) Flow and thermal modeling and optimization of micro/mini-channel heat sink. Appl Therm Eng 117:289–296. https://doi.org/10.1016/j.applthermaleng.2016.12.089

Chen Y, Li B, Wang X, Yan Y, Wang Y, Qi F (2019) Investigation of heat transfer and thermal stresses of novel thermal management system integrated with vapour chamber for IGBT power module. Thermal Sci Eng Progress 10:73–81. https://doi.org/10.1016/j.tsep.2019.01.007

Morozumi A, Yamada K, Miyasaka T, Sumi S, Seki Y (2003) Reliability of power cycling for IGBT power semiconductor modules. IEEE Trans Ind Appl 39:665–671. https://doi.org/10.1109/TIA.2003.810661

Wintrich A, Nicolai U, Tursky W (2011) Tobias reimann. Application Manual Power Semiconductors, SEMIKRON International GmbH

Raeisian L, Niazmand H, Ebrahimnia-Bajestan E, Werle P (2019) Thermal management of a distribution transformer: an optimization study of the cooling system using CFD and response surface methodology. Int J Electr Power Energy Syst 104:443–455. https://doi.org/10.1016/j.ijepes.2018.07.043

Sohel Murshed SM, Nieto de Castro CA (2017) A critical review of traditional and emerging techniques and fluids for electronics cooling. Renew Sustain Energ Rev 78:821–833. https://doi.org/10.1016/j.rser.2017.04.112

Tan H, Wu L, Wang M, Yang Z, Du P (2019) Heat transfer improvement in microchannel heat sink by topology design and optimization for high heat flux chip cooling. Int J Heat Mass Transf 129:681–689. https://doi.org/10.1016/J.IJHEATMASSTRANSFER.2018.09.092

Harpole GM, Eninger JE (1991) Micro-channel heat exchanger optimization. In: 1991 proceedings, seventh IEEE semiconductor thermal measurement and management symposium, Phoenix, AZ, USA, pp 59–63. https://ieeexplore.ieee.org/document/152913

Ryu JH, Choi DH, Kim SJ (2003) Three-dimensional numerical optimization of a manifold microchannel heat sink. Int J Heat Mass Transf 46:1553–1562. https://doi.org/10.1016/S0017-9310(02)00443-X

Adio SA, Olalere AE, Olagoke RO, Alo TA, Veeredhi VR, Ewim DRE, Olakoyejo OT (2021) Thermal and entropy analysis of a manifold microchannel heat sink operating on CuO–water nanofluid. J Braz Soc Mech Sci Eng 43:76. https://doi.org/10.1007/s40430-020-02772-x

Mohammadali R, Bayareh M, Sheikhzadeh GA (2021) Study of flow uniformity within convergent microchannels with a circular manifold. J Braz Soc Mech Sci Eng 43:74. https://doi.org/10.1007/s40430-020-02784-7

Gilmore N, Hassanzadeh-Barforoushi A, Timchenko V, Menictas C (2021) Manifold configurations for uniform flow via topology optimisation and flow visualisation. Appl Thermal Eng 183:116227. https://doi.org/10.1016/j.applthermaleng.2020.116227

Gilmore N, Timchenko V, Menictas C (2021) Manifold microchannel heat sink topology optimisation. Int J Heat Mass Transfer 170:121025. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121025

Kermani E (2008) Manifold microchannel cooling of photovoltaic cells for high efficiency solar energy conversion systems, Department of Mechanical Engineering, University of Maryland. https://drum.lib.umd.edu/handle/1903/8974?show=full

Luo Y, Li J, Zhou K, Zhang J, Li W (2019) A numerical study of subcooled flow boiling in a manifold microchannel heat sink with varying inlet-to-outlet width ratio. Int J Heat Mass Transf 139:554–563. https://doi.org/10.1016/j.ijheatmasstransfer.2019.05.030

Pourfattah F, Abbasian Arani AA, Babaie MR, Nguyen HM, Asadi A (2019) On the thermal characteristics of a manifold microchannel heat sink subjected to nanofluid using two-phase flow simulation. Int J Heat Mass Transf. 143:118518. https://doi.org/10.1016/J.IJHEATMASSTRANSFER.2019.118518

Sarangi S, Bodla KK, Garimella SV, Murthy JY (2014) Manifold microchannel heat sink design using optimization under uncertainty. Int J Heat Mass Transf 69:92–105. https://doi.org/10.1016/J.IJHEATMASSTRANSFER.2013.09.067

Bae D, Mandel R, Ohadi M (2017) Effect of bonding structure and heater design on performance enhancement of FEEDS embedded manifold-microchannel cooling https://doi.org/10.1115/IPACK2017-74158

Lin Y, Luo Y, Li W, Cao Y, Tao Z, Shih TI-P (2021) Single-phase and two-phase flow and heat transfer in microchannel heat sink with various manifold arrangements. Int J Heat Mass Transf. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121118

Yang M, Cao BY (2019) Numerical study on flow and heat transfer of a hybrid microchannel cooling scheme using manifold arrangement and secondary channels. Appl Therm Eng. 159:113896. https://doi.org/10.1016/j.applthermaleng.2019.113896

Yang M, Cao B-Y (2020) Multi-objective optimization of a hybrid microchannel heat sink combining manifold concept with secondary channels. Appl Therm Eng 181:115592. https://doi.org/10.1016/j.applthermaleng.2020.115592

Pan YH, Zhao R, Fan XH, Le Nian Y, Cheng WL (2020) Study on the effect of varying channel aspect ratio on heat transfer performance of manifold microchannel heat sink. Int J Heat Mass Transf. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120461

Parlak Z, Parlak N, İslamoğlu Y (2021) Optimal design of a converging diverging channel for convective heat transfer enhancement in fully developed turbulent air flow. Int J Thermal Sci 161:106732. https://doi.org/10.1016/j.ijthermalsci.2020.106732

Güngör S, Ceyhan U, Karadeniz ZH (2021) Optimization of heat transfer in a grooved pipe model by stochastic algorithms and DOE based RSM. Int J Thermal Sci 159:106634. https://doi.org/10.1016/j.ijthermalsci.2020.106634

Abo-Zahhad EM, Ookawara S, Radwan A, Elkady MF, El-Shazly AH (2020) Optimization of stepwise varying width microchannel heat sink for high heat flux applications. Case Stud Thermal Eng. https://doi.org/10.1016/j.csite.2020.100587

Pourfattah F, Sabzpooshani M, Toghraie D, Asadi A (2020) Correction to: On the optimization of a vertical twisted tape arrangement in a channel subjected to MWCNT–water nanofluid by coupling numerical simulation and genetic algorithm. J Therm Anal Calorim. https://doi.org/10.1007/s10973-020-09584-0

Ge Y, Lin Y, Tao S, He Q, Chen B, Huang S-M (2021) Shape optimization for a tube bank based on the numerical simulation and multi-objective genetic algorithm. Int J Thermal Sci 161:106787. https://doi.org/10.1016/j.ijthermalsci.2020.106787

Liu S, Huang W, Bao Z, Zeng T, Qiao M, Meng J (2021) Analysis, prediction and multi-objective optimization of helically coiled tube-in-tube heat exchanger with double cooling source using RSM. Int J Thermal Sci 159:106568. https://doi.org/10.1016/j.ijthermalsci.2020.106568

Hassan MA, Kassem MA, Kaood A (2022) Numerical investigation and multi-criteria optimization of the thermal–hydraulic characteristics of turbulent flow in conical tubes fitted with twisted tape insert. J Therm Anal Calorim 147:6847–6868. https://doi.org/10.1007/s10973-021-10998-7

He Z, Yan Y, Zhang L (2022) Thermal-hydraulic investigation on micro heat sinks with ribbed pin-fin arrays and single heating input: parametrical study. J Therm Anal Calorim 147:6489–6505. https://doi.org/10.1007/s10973-021-10977-y

Le HS, Galal AM, Alhamrouni I, Aly AA, Abbas M, Saidi AS, Truong TH, Dahari M, Wae-hayee M (2022) Heat transfer efficiency optimization of a multi-nozzle micro-channel heat sink utilizing response surface methodology. Case Stud Thermal Eng 37:102266. https://doi.org/10.1016/j.csite.2022.102266

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Siavashi M, Taylor RA, Niazmand H, Wongwises S, Hayat T, Kolanjiyil A, Kasaeian A, Pop I (2019) Recent advances in modeling and simulation of nanofluid flows-part I: fundamentals and theory. Phys Rep 790:1–48. https://doi.org/10.1016/J.PHYSREP.2018.11.004

Debnath P, Pradhan M (2022) A recent state of art review on heat transfer enhanced characteristics and material selection of SCTHX. Proc Instit Mech Eng Part E J Process Mech Eng. https://doi.org/10.1177/09544089221124463

Ahmadi AA, Arabbeiki M, Ali HM, Goodarzi M, Safaei MR (2020) Configuration and optimization of a minichannel using water–alumina nanofluid by non-dominated sorting genetic algorithm and response surface method. Nanomaterials 10(5):901. https://doi.org/10.3390/nano10050901

Ho CJ, Hsieh Y-J, Rashidi S, Orooji Y, Yan W-M (2020) Thermal-hydraulic analysis for alumina/water nanofluid inside a mini-channel heat sink with latent heat cooling ceiling—an experimental study. Int Commun Heat Mass Transfer 112:104477. https://doi.org/10.1016/j.icheatmasstransfer.2020.104477

Razeghi A, Mirzaee I, Abbasalizadeh M, Soltanipour H (2017) Al2O3/water nano-fluid forced convective flow in a rectangular curved micro-channel: first and second law analysis, single-phase and multi-phase approach. J Braz Soc Mech Sci Eng 39:2307–2318. https://doi.org/10.1007/s40430-016-0686-4

Asadi A, Rafizadeh S, Molana M, Ghasemiasl R, Armaghani T (2020) Two‐phase study of nanofluids mixed convection and entropy generation in an I‐shaped porous cavity with triangular hot block and different aspect ratios. Math Methods Appl Sci. https://doi.org/10.1002/mma.7006

Shajahan MI, Stephen C, Michael JJ, Arulprakasajothi M, Rathnakumar P, Parthasarathy M (2023) Heat transfer investigations of in-line conical strip inserts using MWCNT/water nanofluid under laminar flow condition. Int J Thermal Sci 183:107844. https://doi.org/10.1016/j.ijthermalsci.2022.107844

Ajeeb W, Oliveira MSA, Martins N, Murshed SMS (2021) Performance evaluation of convective heat transfer and laminar flow of non-newtonian MWCNTs in a circular tube. Thermal Sci Eng Progress 25:101029. https://doi.org/10.1016/j.tsep.2021.101029

Sarlak A, Ahmadpour A, Hajmohammadi MR (2019) Thermal design improvement of a double-layered microchannel heat sink by using multi-walled carbon nanotube (MWCNT) nanofluids with non-newtonian viscosity. Appl Therm Eng 147:205–215. https://doi.org/10.1016/j.applthermaleng.2018.10.084

Alnaqi AA, Alsarraf J, Al-Rashed AAAA, Afrand M (2021) Thermal-hydraulic analysis and irreversibility of the MWCNTs-SiO2/EG-H2O non-Newtonian hybrid nanofluids inside a zigzag micro-channels heat sink. Int Commun Heat Mass Transfer 122:105158. https://doi.org/10.1016/j.icheatmasstransfer.2021.105158

Wang S, Chen HH, Chen CL (2019) Enhanced flow boiling in silicon nanowire-coated manifold microchannels. Appl Therm Eng 148:1043–1057. https://doi.org/10.1016/j.applthermaleng.2018.11.125

Ghelich R, Jahannama MR, Abdizadeh H, Torknik FS, Vaezi MR (2019) Central composite design (CCD)-Response surface methodology (RSM) of effective electrospinning parameters on PVP-B-Hf hybrid nanofibrous composites for synthesis of HfB2-based composite nanofibers. Compos B Eng 166:527–541. https://doi.org/10.1016/j.compositesb.2019.01.094

Hone J (2007) Carbon nanotubes: thermal properties. Dekker Encyclopedia Nanosci Nanotechnol 10:987–1000. https://doi.org/10.1081/E-ENN

Brinkman HC (1952) The viscosity of concentrated suspensions and solutions. J Chem Phys 20:571. https://doi.org/10.1063/1.1700493

Pourfattah F, Sabzpooshani M (2020) Thermal management of a power electronic module employing a novel multi-micro nozzle liquid-based cooling system: a numerical study. Int J Heat Mass Transfer 147:118928. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118928

Wu R, Hong T, Cheng Q, Zou H, Fan Y, Luo X (2019) Thermal modeling and comparative analysis of jet impingement liquid cooling for high power electronics. Int J Heat Mass Transf 137:42–51. https://doi.org/10.1016/j.ijheatmasstransfer.2019.03.112

Diao YH, Li CZ, Zhang J, Zhao YH, Kang YM (2017) Experimental investigation of MWCNT–water nanofluids flow and convective heat transfer characteristics in multiport minichannels with smooth/micro-fin surface. Powder Technol 305:206–216. https://doi.org/10.1016/j.powtec.2016.10.011

Esfe MH, Mahian O, Hajmohammad MH, Wongwises S (2018) Design of a heat exchanger working with organic nanofluids using multi-objective particle swarm optimization algorithm and response surface method. Int J Heat Mass Transfer 119:922–930. https://doi.org/10.1016/j.ijheatmasstransfer.2017.12.009

Shirvan KM, Mirzakhanlari S, Mamourian M, Kalogirou SA (2017) Optimization of effective parameters on solar updraft tower to achieve potential maximum power output: a sensitivity analysis and numerical simulation. Appl Energ 195:725–737. https://doi.org/10.1016/j.apenergy.2017.03.057

Ighose BO, Adeleke IA, Damos M, Junaid HA, Okpalaeke KE, Betiku E (2017) Optimization of biodiesel production from thevetia peruviana seed oil by adaptive neuro-fuzzy inference system coupled with genetic algorithm and response surface methodology. Energ Conv Manag 132:231–240. https://doi.org/10.1016/j.enconman.2016.11.030

Xie Y, Hu P, Zhu N, Lei F, Xing L, Xu L (2020) Collaborative optimization of ground source heat pump-radiant ceiling air conditioning system based on response surface method and NSGA-II. Renew Energ 147:249–264. https://doi.org/10.1016/j.renene.2019.08.109

Pasandideh SHR, Niaki STA (2006) Multi-response simulation optimization using genetic algorithm within desirability function framework. Appl Math Comput 175(1):366–382. https://doi.org/10.1016/j.amc.2005.07.023

Derringer G, Suich R (1980) Simultaneous optimization of several response variables. J Qual Technol 12:214–219. https://doi.org/10.1080/00224065.1980.11980968

Shirvan KM, Ellahi R, Mirzakhanlari S, Mamourian M (2016) Enhancement of heat transfer and heat exchanger effectiveness in a double pipe heat exchanger filled with porous media: numerical simulation and sensitivity analysis of turbulent fluid flow. Appl Thermal Eng 109:761–774. https://doi.org/10.1016/j.applthermaleng.2016.08.116

Author information

Authors and Affiliations

Contributions

F.P was involved in literature reviewing, validation, data curation, post-processing, writing, and revising. M.F was involved in simulation, optimization and writing. LP.W was involved in conceptualization, methodology, formal analysis, and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Technical Editor: Ahmad Arabkoohsar.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pourfattah, F., Kheryrabadi, M.F. & Wang, LP. Coupling CFD and RSM to optimize the flow and heat transfer performance of a manifold microchannel heat sink. J Braz. Soc. Mech. Sci. Eng. 45, 178 (2023). https://doi.org/10.1007/s40430-023-04097-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04097-x