Abstract

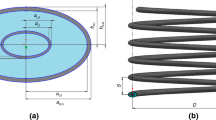

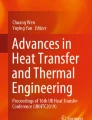

In the present study, the thermal attributes and hydrodynamic characteristics of a finned double-tube heat exchanger involving six design variables (\(\mathrm{Re}, (\frac{H}{D}),(\frac{p}{D}),(\frac{t}{D}),{\varnothing }_{p},(\frac{{T}_{c}}{{T}_{h}}))\) were numerically investigated and optimized by simultaneous use of computational fluid dynamics and response surface methodology. Ninety numerical designs proposed based on the face-centered central composite design (FCCD) technique were utilized to generate mathematical regression models of response functions. The accuracy and reliability of the obtained regression models including \({\eta }_{\left(t-h\right)}, {\eta }_{\mathrm{II}}, \frac{\mathrm{Nu}}{{\mathrm{Nu}}_{s}}\) and \(\Delta p\) were investigated through analysis of variance (ANOVA). Furthermore, the significance of model terms was also analyzed by considering F values larger than the critical F value for each response functions and a P value smaller than the selected level of significance (i.e. 0.05). Multi-objective shape and flow optimization of the finned double-tube counter-flow heat exchanger was carried out using the composite desirability function approach to maximize the thermo-hydrodynamic performance index, exergetic efficiency and Nusselt number and to minimize the pressure drop across the heat exchanger. The optimum design variables resulting in the highest desirability function (i.e. 0.8886) were found to be \(\mathrm{Re}=4000,(\frac{H}{D})=0.154, (\frac{p}{D})=9.840, (\frac{t}{D})=8.610, {\varnothing }_{p}=0\%, ( \frac{{T}_{c}}{{T}_{h}})= 0.968\), which correspond to the maximum predicted value of \({\eta }_{(t-h)}=1.193, {\eta }_{\mathrm{II}}=8.367\%, \frac{\text{Nu}}{{\mathrm{Nu}}_{s}}=1.771,\Delta p=7461.1 (\mathrm{Pa})\). The value of \({\eta }_{(t-h)}\) can be further increased up to 1.261 where the composite desirability function reaches to 0.8514.

Similar content being viewed by others

Abbreviations

- A :

-

Heat transfer surface area (m2)

- C 2 :

-

Model constant

- C p :

-

Specific heat at constant pressure (J/kg K)

- C µ :

-

Model parameter

- D i :

-

Inner tube diameter (m)

- D o :

-

Outer tube diameter (m)

- D h :

-

Hydraulic diameter (m)

- f :

-

Friction factor

- h :

-

Heat transfer coefficient (W/m2 K), fin height (m)

- H:

-

Fin height (m)

- k :

-

Turbulent kinetic energy (m2/s2), thermal conductivity (W/mK)

- L :

-

Length of tube (m)

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- Nu:

-

Nusselt number \((hD_{{\text{h}}} /{\mathrm{K}})\)

- p :

-

Pressure Pa, Fin pitch (m)

- Pr:

-

Prandtl number \(\left( {C_{{\text{p}}} \mu /{\mathrm{K}}} \right)\)

- q :

-

Heat flux (W/m2)

- Q :

-

Heat transfer rate (W)

- Re:

-

Reynolds number \(\left( {\rho uD_{h} /\mu } \right)\)

- s :

-

Specific entropy (J/K)

- t :

-

Fin thickness (m)

- T :

-

Temperature (K)

- u :

-

Velocity component in flow direction (m/s)

- W :

-

Work (J)

- \(Y^{+}\) :

-

Dimensionless distance from wall

- Δ:

-

Difference operator

- \(\delta_{ij}\) :

-

Kronecker delta

- \(\varepsilon\) :

-

Turbulent energy dissipation rate (m2/s3)

- \(\mu\) :

-

Dynamic viscosity (kg/m s)

- \(\nu\) :

-

Kinematic viscosity (m2/s)

- \(\rho\) :

-

Density (kg/m3)

- \(\alpha\) :

-

Thermal diffusivity (m2/s)

- \(\nu\) :

-

Kinematic viscosity (m2/s), Specific volume (1/m3)

- \(\sigma_{\tau }\) :

-

Turbulent Prandtl number in energy equation

- \(\sigma_{k}\) :

-

Diffusion Prandtl number for \(k\)

- \(\sigma_{\varepsilon }\) :

-

Diffusion Prandtl number for \(\varepsilon\)

- \(\emptyset\) :

-

Nanoparticle volume concentration

- \(\psi\) :

-

Specific flow exergy

- \(\dot{X}\) :

-

Exergy rate

- \(\eta_{\text{II}}\) :

-

Second-law efficiency

- \(\eta_{t - h}\) :

-

Thermo-hydrodynamic performance index

- Avg:

-

Average

- hw:

-

Hot water

- b:

-

Bulk quantity

- bf:

-

Base fluid

- fr:

-

Freezing

- in:

-

Inlet

- IT:

-

Inner tube

- i, j, k :

-

Spatial indices

- l:

-

Laminar property

- m:

-

Mean value

- nf:

-

Nanofluid

- out:

-

Outlet

- p:

-

Nanoparticle

- s:

-

Smooth, surface area

- t:

-

Turbulent quantity

- t-h:

-

Thermo-hydrodynamic

- w:

-

Wall

- CFD:

-

Computational fluid dynamics

- DTCHEX:

-

Double-tube counter-flow heat exchanger

- RSM:

-

Response surface methodology

References

Agarwal P, Sikand A, Shanthi V (2014) Application of heat exchangers in bioprocess industry: a review. Int J Pharm Pharm Sci 6(1):24–28

Akbarzadeh M, Rashidi S, Keshmiri A, Shokri N (2020) The optimum position of porous insert for a double-pipe heat exchanger based on entropy generation and thermal analysis. J Therm Anal Calorim 139(1):411–426

Aslan N (2007) Application of response surface methodology and central composite rotatable design for modeling the influence of some operating variables of a Multi-Gravity Separator for coal cleaning. Fuel 86(5–6):769–776

Atashafrooz M, Sheikholeslami M, Sajjadi H, Delouei AA (2019) Interaction effects of an inclined magnetic field and nanofluid on forced convection heat transfer and flow irreversibility in a duct with an abrupt contraction. J Magn Magn Mater 478:216–226

Atashafrooz M, Sajjadi H, Delouei AA (2020) Interacting influences of Lorentz force and bleeding on the hydrothermal behaviors of nanofluid flow in a trapezoidal recess with the second law of thermodynamics analysis. Int Commun Heat Mass Transfer 110:104411

Atashafrooz M, Sajjadi H, Delouei AA, Yang TF, Yan WM (2021) Three-dimensional analysis of entropy generation for forced convection over an inclined step with presence of solid nanoparticles and magnetic force. Numer Heat Transf Part A Appl 80(6):318–335

Bahiraei M, Mazaheri N, Hanooni M (2021) Performance enhancement of a triple-tube heat exchanger through heat transfer intensification using novel crimped-spiral ribs and nanofluid: a two-phase analysis. Chem Eng Process Process Intensif 160:108289

Bashtani I, Esfahani JA, Kim KC (2021) Effects of water-aluminum oxide nanofluid on double pipe heat exchanger with gear disc turbulators: a numerical investigation. J Taiwan Inst Chem Eng 124:63–74

Bergman TL, Incropera FP, DeWitt DP, Lavine AS (2011) Fundamentals of heat and mass transfer. Wiley, New York

Cengel YA (2002) Heat transfer: a practical approach, 2nd edn. McGraw-Hill, New York

Cengel YA, Boles MA (2011) Thermodynamics: an engineering approach, 7th edn. McGraw-Hill Education, New York

Chen H, Ding Y, He Y, Tan C (2007) Rheological behavior of ethylene glycol based titania nanofluids. Chem Phys Lett 444(4–6):333–337

Chen T, Xu M, Tu J, Wang H, Niu X (2018) Relationship between Omnibus and Post-hoc Tests: An Investigation of performance of the F test in ANOVA. Shanghai Arch Psychiatry 30(1):60

Corcione M (2011) Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers Manag 52(1):789–793

Delouei AA, Sajjadi H, Mohebbi R, Izadi M (2019) Experimental study on inlet turbulent flow under ultrasonic vibration: Pressure drop and heat transfer enhancement. Ultrason Sonochem 51:151–159

Delouei AA, Atashafrooz M, Sajjadi H, Karimnejad S (2022a) The thermal effects of multi-walled carbon nanotube concentration on an ultrasonic vibrating finned tube heat exchanger. Int Commun Heat Mass Transfer 135:106098

Delouei AA, Sajjadi H, Ahmadi G (2022b) Ultrasonic vibration technology to improve the thermal performance of CPU water-cooling systems: experimental investigation. Water 14(24):4000

Duangthongsuk W, Wongwises S (2010) An experimental study on the heat transfer performance and pressure drop of TiO2-water nanofluids flowing under a turbulent flow regime. Int J Heat Mass Transf 53(1–3):334–344

Esfe MH, Hajmohammad H, Toghraie D, Rostamian H, Mahian O, Wongwises S (2017) Multi-objective optimization of nanofluid flow in double tube heat exchangers for applications in energy systems. Energy 137:160–171

Etghani MM, Baboli SAH (2017) Numerical investigation and optimization of heat transfer and exergy loss in shell and helical tube heat exchanger. Appl Therm Eng 121:294–301

Gnielinski V (1976) New equations for heat and mass transfer in turbulent pipe and channel flow. Int Chem Eng 16(2):359–368

Han HZ, Li BX, Wu H, Shao W (2015) Multi-objective shape optimization of double pipe heat exchanger with inner corrugated tube using RSM method. Int J Therm Sci 90:173–186

Hangi M, Rahbari A, Lipiński W (2021) Design improvement of compact double-pipe heat exchangers equipped with tube-side helical insert and annulus-side helical strip: Hydrothermal and exergy analyses. Appl Therm Eng 190:116805

Hatami M, Jafaryar M, Ganji DD, Gorji-Bandpy M (2014) Optimization of finned-tube heat exchangers for diesel exhaust waste heat recovery using CFD and CCD techniques. Int Commun Heat Mass Transfer 57:254–263

Hatami M, Ganji DD, Gorji-Bandpy M (2015) Experimental and numerical analysis of the optimized finned-tube heat exchanger for OM314 diesel exhaust exergy recovery. Energy Convers Manage 97:26–41

Khanafer K, Vafai K (2011) A critical synthesis of thermophysical characteristics of nanofluids. Int J Heat Mass Transf 54(19–20):4410–4428

Kokoska S, Nevison C (2012) Statistical tables and formulae. Springer, Berlin

Kola PVKV, Pisipaty SK, Mendu SS, Ghosh R (2021) Optimization of performance parameters of a double pipe heat exchanger with cut twisted tapes using CFD and RSM. Chem Eng Process Process Intensif 163:108362

Li X, Wang L, Feng R, Wang Z, Liu S, Zhu D (2021) Study on shell side heat transport enhancement of double tube heat exchangers by twisted oval tubes. Int Commun Heat Mass Transfer 124:105273

Liu S, Huang W, Bao Z, Zeng T, Qiao M, Meng J (2021) Analysis, prediction and multi-objective optimization of helically coiled tube-in-tube heat exchanger with double cooling source using RSM. Int J Therm Sci 159:106568

Maddah H, Aghayari R, Mirzaee M, Ahmadi MH, Sadeghzadeh M, Chamkha AJ (2018) Factorial experimental design for the thermal performance of a double pipe heat exchanger using Al2O3-TiO2 hybrid nanofluid. Int Commun Heat Mass Transfer 97:92–102

Mahian O, Kianifar A, Kalogirou SA, Pop I, Wongwises S (2013) A review of the applications of nanofluids in solar energy. Int J Heat Mass Transf 57(2):582–594

Mohapatra T, Sahoo SS, Padhi BN (2019) Analysis, prediction and multi-response optimization of heat transfer characteristics of a three fluid heat exchanger using response surface methodology and desirability function approach. Appl Therm Eng 151:536–555

Montgomery DC (2017) Design and analysis of experiments. Wiley, New York

Mozafarie SS, Javaherdeh K, Ghanbari O (2021) Numerical simulation of nanofluid turbulent flow in a double-pipe heat exchanger equipped with circular fins. J Therm Anal Calorim 143(6):4299–4311

Nakhchi ME, Hatami M, Rahmati M (2021) Effects of CuO nano powder on performance improvement and entropy production of double-pipe heat exchanger with innovative perforated turbulators. Adv Powder Technol 32(8):3063–3074

Noorbakhsh M, Mousavi Ajarostaghi SS, Zaboli M, Kiani B (2022) Thermal analysis of nanofluids flow in a double pipe heat exchanger with twisted tapes insert in both sides. J Therm Anal Calorim 147(5):3965–3976

Pak BC, Cho YI (1998) Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf Int J 11(2):151–170

Petukhov BS, Irvine TF, Hartnett JP (1970) Advances in heat transfer. Academic, New York 6:503–564

Sheikholeslami M, Gorji-Bandpy M, Ganji DD (2016) Experimental study on turbulent flow and heat transfer in an air to water heat exchanger using perforated circular-ring. Exp Thermal Fluid Sci 70:185–195

Shih T, Liou WW, Shabbir A, Yang Z, Zhu J (1995) A new k-ϵ eddy viscosity model for high Reynolds number turbulent flows. Comput Fluids 24(3):227–238

Siavashi M, Miri Joibary SM (2019) Numerical performance analysis of a counter-flow double-pipe heat exchanger with using nanofluid and both sides partly filled with porous media. J Therm Anal Calorim 135(2):1595–1610

Tiwari AK, Javed S, Oztop HF, Said Z, Pandya NS (2021) Experimental and numerical investigation on the thermal performance of triple tube heat exchanger equipped with different inserts with WO3/water nanofluid under turbulent condition. Int J Therm Sci 164:106861

Wael WIA (2014) Numerical study on turbulent heat transfer and pressure drop of nanofluid in coiled tube-in-tube heat exchangers. Energy Convers Manage 79:304–316

Wang X, Xu X, Choi SUS (1999) Thermal conductivity of nanoparticle-fluid mixture. J Thermophys Heat Transf 13(4):474–480

Wang Q, Yanzhong L, Xi C (2005) Exergy analysis of liquefied natural gas cold energy recovering cycles. Int J Energy Res 29(1):65–78

Xuan Y, Roetzel W (2000) Conceptions for heat transfer correlation of nanofluids. Int J Heat Mass Transf 43(19):3701–3707

Yang L, Hu Y (2017) Toward TiO2 nanofluids—part 1: preparation and properties. Nanoscale Res Lett 12(1):1–21

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no competing financial interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohammadi, M. Multi-objective Shape and Flow Optimization of Finned Double-Tube Heat Exchanger Filled with Nanofluid: A CFD and RSM Study. Iran J Sci Technol Trans Mech Eng 48, 1–27 (2024). https://doi.org/10.1007/s40997-023-00641-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-023-00641-1