Abstract

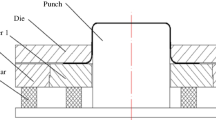

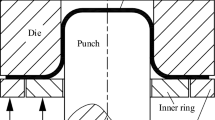

In this paper, an independent blank holder technique is proposed for the deep drawing of the conical cup. The blank holding force (BHF) can be applied on all radial flange regions independently in a more convenient way. The principles and advantages of the new blank holder technique are first expatiated and analyzed by theoretical derivation and numerical simulation. The results show that the forming quality can be significantly improved by the independent blank holders. Finally, the effectiveness of the new blank holder technique is proven by forming simulations and experiments with galvanized sheets. Because BHF applied on all radial areas are more reasonable, the wrinkles of the drawn cups are better eliminated using the new blank holder.

Similar content being viewed by others

References

Lee CK, Lee M, Yun JW (2021) A study of the domed drawing displacement characteristics of a high-tension steel plate (SGAFC980). J Braz Soc Mech Sci Eng 43(11):1–14

Kitayama S, Shimizu K, Kawamoto K (2021) Numerical optimization of blank shape and sloped variable blank holder force trajectory for an automotive part. J Adv Mech Des Syst Manuf 15(3):1–10

Guo ZF, Men QY, Kang XY, Jun LA (2021) A stress analysis model of a cup-shaped part in a secondary deep drawing process. Int J Adv Manuf Technol 16(1–2):473–486

He P, Zhou L, Wu P, Huang M (2021) Experimental determination of the Hosford yield function exponential parameter for metal plates. J Brazilian Soc Mech Sci Eng 43(5):1–11

Kergen R, Jodogne P (1992) Computerized control of the blank holder pressure on deep drawing process. SAE paper No.920433, Warrendale, PA

Lee JH, Jung WJ, Kim JH (2012) Influence of drawing speed and blank holding force in rectangular drawing of ultra-thin sheet metal. J Korean Soc Technol Plast 21(6):348–353

Qu E, Li M, Li R (2019) Investigation of forming accuracy in multipoint forming with composite elastic pads. Int J Adv Manuf Technol 105:4401–4413

Mirza HA, Lang L, Tabasum MN, Meng Z, Alexandrov S, Jiang J (2022). An investigation into the forming of fiber metal laminates with different thickness metal skins using hydromechanical deep drawing. Appl Compos Mater. (0123456789)

Huang YJ, Han XT, Cao QL, Lai ZP, Cai H, Liu N et al (2017) Design and analysis of a pulsed electromagnetic blank holder system for electromagnetic forming. Procedia Eng 207:347–352

Qin SJ, Zhang HS, Mao YB, Yang L, Li XB, Hu ZH, Cheng X (2020) Electropermanent magnet blank holder technique in sheet metal deep drawing. Int J Adv Manuf Technol 106(11–12):5497–5507

Zhao SD, Zhang ZY, Zhang Y, Yuan JH (2007) The study on forming principle in the process of hydro-mechanical reverse deep drawing with axial pushing force for cylindrical cups. J Mater Process Technol 187–188:300–303

Kriechenbauer S, Mauermann R, Muller P (2014) Deep drawing with superimposed low-frequency vibrations on servo-screw presses. Proc Eng 81:905–913

Li H, Wang Q, Fang H, Zheng YY, Sun YQ (2019) Design, numerical simulation, and experimental validation of a novel electro- magnetic blank holding system for conventional drawing process. Int J Adv ManufTechnol 102:2183–2193

Balla VK, Deckers E, Jonckheere S, Pluymers B, Desmet W (2021) Incommensurate vibroacoustic performance due to in-process blank holder force variation during deep drawing process. Appl Acoust 2021:172

Obermeyer EJ, Majlessi SA (1998) A review of recent advances in the application of blank-holder force towards improving the forming limits of sheet metal parts. J Mater Process Technol 75(1/3):222–234

Gong F, Yang Z, Chen Q, Xie Z, Shu D, Yang J (2015) Influences of lubrication conditions and blank holder force on micro deep drawing of C1100 micro conical-cylindrical cup. Precis Eng 42:224–230

Lai Z, Cao Q, Zhang B et al (2015) Radial Lorentz force augmented deep drawing for large drawing ratio using a novel dual-coil electromagnetic forming system. J Mater Process Technol 222:13–20

Wang H, Shen X (2021) A novel hydrodynamic deep drawing utilizing a combined floating and static die cavity. Int J Adv Manuf Technol 114(3–4):829–839

Hardt D, Fenn R (1993) Real-time control of sheet stability during forming. ASME J Eng Ind 115:299–308

Irthiea IK, Green G (2017) Evaluation of micro deep drawing technique using soft die-simulation and experiments. Int J Adv Manuf Technol 89:2363–2374

Li MZ, Cai ZY, Liu CG (2007) Flexible manufacturing of sheet metal parts based on digitized-die. Robot Cim-int Manuf 23(1):107–115

Murata A, Matsui M (1994) Effects of control of local blank hold- ing forces on deep drawability of square shell. In: Proceedings of the 18th biennial congress IDDRG. International Deep Drawing Research Group Working Group, Lisbon, Portugal, pp 207–216

Zhang HS, Qin SJ, Cao LQ (2021) Investigation of the effect of blank holder force distribution on deep drawing using developed blank holder divided into double rings. J Braz Soc Mech Sci Eng 43(284):1–10

Hassan MA, Suenaga R, Takakura N, Yamaguchi K (2005) A novel process on friction aided deep drawing using tapered blank holder divided into four segments. J Mater Process Tech 159(3):418–425

Zhang HS, Qin SJ (2022) A novel process of deep drawing based on electro-permanent magnet combined segmental blank holder technique. Int J Adv Manuf Technol 118(11–12):3883–3896

Qin SJ, Bin GB, Kong XH, Deng C (2015) Analytical solutions of strain of axisymmetric curved part in sheet metal forming process using direct integral method. Int J Mech Sci 101–102:49–58

Liang BW, Hu SG (1987) Theory of sheet forming plasticity. China Machine Press, Beijing

Senior BW (1956) Flange wrinkling in deep-drawing operations. J Mech Phys Solids 4(4):235–246

Qin SJ, Xiong BQ, Lu H, Zhang TT (2012) Critical blank-holder force in axisymmetric deep drawing. Trans Nonferr Metal Soc 22(S2):239–246

Tseng HC, Hung CH, Huang CC (2010) An analysis of the formability of aluminum/copper clad metals with different thicknesses by the finite element method and experiment. Int J Adv Manuf Technol 49:1029–1036

Funding

The authors are pleased to acknowledge the financial support of National Natural Science Foundation of China (No. 51675466), and the Natural Science Foundation of Hebei Province of China (No. E2021203043). The work is also supported by the Science and Technology Research and Development Program of Qinhuangdao city (No. 202004A005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Technical Editor: Lincoln Cardoso Brandao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, H., Qin, S. Forming of conical cup using independent blank holders. J Braz. Soc. Mech. Sci. Eng. 44, 454 (2022). https://doi.org/10.1007/s40430-022-03747-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03747-w