Abstract

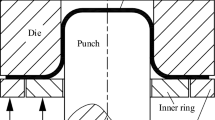

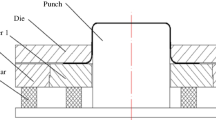

In this paper, a novel multi-ring blank holder technique is developed. The blank holding force (BHF) provided by each ring can be independently and effectively applied on all radial regions. The principles and advantages of the multi-ring technique are first explained and analyzed by theoretical derivation, stress analysis, and forming simulation. The results indicate that the distribution of the blank holder force per unit area (FUA) applied by the new blank holder technique is more reasonable than using the conventional single blank holder and can better suppress the wrinkles. Finally, the effectiveness of the multi-ring blank holder technique is proven by a deep drawing experiment of the 08Al plate. It was verified that due to the reasonable FUA distribution, the use of the blank holder technique can suppress the wrinkles on the flange very well.

Similar content being viewed by others

Data availability

The data sets supporting the results of this article are included within the article.

Materials availability

The data sets supporting the results of this article are included within the article.

References

El-Sebaie MG, Mellor PB (1972) Plastic instability conditions in the deep drawing of a circular blank of sheet metal. Int J Mech Sci 14:535–542

Obermeyer EJ, Majlessi SA (1998) A review of recent advances in the application of blank-holder force towards improving the forming limits of sheet metal parts. J Mater Process Technol 75(1/3):222–234

Hardt DE, Lee CGY (1986) Real-time control of sheet stability during stamping, Proceedings of the 13th North American Manufacturing Research Conference, Society of Manufacturing Engineers, Dearborn, MI pp 315–322

Maslennikov NA (1957) Russian developed punchless drawing. Metal-work Prod 16:1417–1420

Kergen R, Jodogne P (1992) Computerized control of the blank holder pressure on deep drawing process. SAE paper No. 920433, Warrendale, PA

Cao J, Boyce MC (1997) A predictive tool for delaying wrinkling and tearing failures in sheet metal forming, ASME. J Eng Mater Technol 119:354–365

Gunnarsson L, Asnafi N, Schedin E (1998) In-process control of blank holder force in axi-symmetric deep drawing with degressive gas springs. J Mater Process Technol 73(1/3):89–96

Seo YR (2008) Electromagnetic blank restrainer in sheet metal forming processes. Int J Mech Sci 50(4):743–751

Lai ZP, Cao QL, Zhang B, Han XT, Zhou ZY, Xiong Q, Zhang X, Chen Q, Li L (2015) Radial Lorentz force augmented deep drawing for large drawing ratio using a novel dual-coil electromagnetic forming system. J Mater Process Technol 222:13–20

Siegert K, Doege E (1993) CNC hydraulic multipoint blankholder system for sheet metal forming presses. CIRP Ann-manuf Technol 42(1):319–322

Hassan MA, Suenaga R, Takakura N, Yamaguchi K (2005) A novel process on friction aided deep drawing using tapered blank holder divided into four segments. J Mater Process Technol 159(3):418–425

Murata A, Matsui M (1994) Effects of control of local blank holding forces on deep drawability of square shell. Proceedings of the 18th biennial congress IDDRG. International Deep Drawing Research Group Working Group, Lisbon, Portugal 207–216

Manabe K, Yang M, Teramae T et al (1996) Development of a square-drawing simulator with cellularly divided blank holder control system. Proceedings of the 19th biennial congress IDDRG, International Deep Drawing Research Group Working Group, Eger, Hungary 101–108

Li MZ, Cai ZY, Liu CG (2007) Flexible manufacturing of sheet metal parts based on digitized-die. Robot Cim-int Manuf 23(1):107–115

Qu E, Li M, Li R (2019) Investigation of forming accuracy in multipoint forming with composite elastic pads. Int J Adv Manuf Technol 05:4401–4413

Qin SJ, Xiong BQ, Lu H, Zhang TT (2012) Critical blank-holder force in axisymmetric deep drawing. T Nonferr Metal Soc 22(S2):239–246

Liu ZM, Xing SM, Bao PW et al (2013) A new equation of load curve of critical wrinkles variable blank holder force in the warm deep-drawing of twin-roll cast Mg sheets. Lecture Notes Elec Eng 199:11–22

Morovvati MR, Mollaei-Dariani B, Asadian-Ardakani MH (2010) A theoretical, numerical, and experimental investigation of plastic wrinkling of circular two-layer sheet metal in the deep drawing. J Mater Process Technol 210(13):1738–1747

Funding

The work is supported by the National Natural Science Foundation of China (no. 51675466) and the Natural Science Foundation of Hebei Province of China (no. E2021203043). The work is also supported by the Science and Technology Research and Development Program of Qinhuangdao city (no. 202004A005).

Author information

Authors and Affiliations

Contributions

HS Zhang contributed significantly to analysis and manuscript preparation. SJ Qin and LY Meng performed the experiment and contributed to the conception of the study.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

All authors agree to be signed in the manuscript.

Consent for publication

Manuscript is approved by all authors for publication.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, H., Qin, S. & Meng, L. Research on deep drawing with multi-ring blank holder technique. Int J Adv Manuf Technol 122, 4115–4126 (2022). https://doi.org/10.1007/s00170-022-10142-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10142-1