Abstract

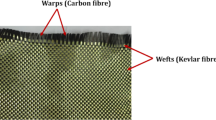

Adhesive bonded joints of fiber-reinforced polymer structural components provide countless benefits; these include great strength and large hardness-to-weight ratios, good fatigue and corrosion resistance, and high energy absorption capability, all of which make them more influential in comparison with other types of fasteners. In this study, the effect of various contents of graphene nanoparticle (GNP) in the epoxy adhesive on the shear and flexural behaviors of glass fiber-reinforced polymer plates (GFRP) bonded joints are investigated. Based on the weight content of epoxy graphene, nanoparticles were added by 0.1, 0.2, 0.3, 0.4, and 0.5 wt.%. GFRP were used as adherents. Failure mechanisms were analyzed by taking photos over the front and rear sides of the samples after tests. The obtained results showed that 0.3 wt.% graphene nanoparticle addition exhibiting the better load transferring between adherents had 145% improvements in shear strength. Furthermore, the samples containing 0.2 wt.% GNP resulted in an increase in flexural strength by 100%.

Similar content being viewed by others

References

Banea MD, Da Silva LF (2009) Adhesively bonded joints in composite materials: an overview. Proc Inst Mech Eng Part L J Mater Des Appl 223(1):1–18. https://doi.org/10.1243/14644207JMDA219

Tsai MY, Morton J (2010) An investigation into the stresses in double-lap adhesive joints with laminated composite adherends. Int J Solids Struct 47(24):3317–3325. https://doi.org/10.1016/j.ijsolstr.2010.08.011

Arenas JM, Alía C, Narbón JJ, Ocaña R, Recio; M.M. (2012) Considerations for application of structural adhesives for joining aluminum with compound materials in the manufacturing of competition motorcycles. AIP Conf Proc 1431:959. https://doi.org/10.1063/1.4707656

Wahab MMA (2012) Fatigue in adhesively bonded joints: a review. ISRN Mater Sci. https://doi.org/10.5402/2012/746308

Adams RD (2005) Adhesive bonding: science, technology and applications. Elsevier, Cambridge

Yuan J, Zhou S, Gu G, Wu L (2005) Effect of the particle size of nanosilica on the performance of epoxy/silica composite coatings. J Mater Sci 40:3927–3932. https://doi.org/10.1007/s10853-005-0714-8

Hartwig A, Sebald M, Pütz D, Aberle L (2005) Preparation, characterization and properties of nanocomposites based on epoxy resins—an overview. Macromol Symp. https://doi.org/10.1002/masy.200550313

Zheng Y, Zheng Y, Ning R (2003) Effects of nanoparticles SiO2 on the performance of nanocomposites. Mater Lett 57(19):2940–2944. https://doi.org/10.1016/S0167-577X(02)01401-5

Akpinar IA, Gültekin K, Akpinar S, Akbulut H, Ozel A (2017) Experimental analysis on the single-lap joints bonded by a nanocomposite adhesive which obtained by adding nanostructures. Compos B 110:420–428

Akpinar IA, Gürses A, Akpinar S, Gültekin K, Akbulut H, Ozel A (2018) Investigation of mechanical and thermal properties of nanostructure-doped bulk nanocomposite adhesives. J Adhes 94(11):847–866. https://doi.org/10.1080/00218464.2017.1415809

Kazaz I, Akpinar S, Ozel A (2020) The effects of thermal cycle and nanostructure reinforcement on the shear load in adhesively bonded joints. Mech Adv Mater Struct 27(19):1627–1638. https://doi.org/10.1080/15376494.2018.1522560

Zhai L, Ling G, Li J, Wang Y (2006) The effect of nanoparticles on the adhesion of epoxy adhesive. Mater Lett 60(25):3031–3033. https://doi.org/10.1016/j.matlet.2006.02.038

Evans AG (1972) The strength of brittle materials containing second phase dispersions. Philos Mag J Theor Exp Appl Phys 26(6):1327–1344. https://doi.org/10.1080/14786437208220346

Lange FF (1970) The interaction of a crack front with a second-phase dispersion. Philos Mag J Theor Exp Appl Phys 22(179):0983–0992. https://doi.org/10.1080/14786437008221068

Kanar B, Akpinar S, Akpinar IA, Akbulut H, Ozel A (2018) The fracture behaviour of nanostructure added adhesives under ambient temperature and thermal cyclic conditions. Theoret Appl Fract Mech 97:120–130

Dean D, Abdalla M, Ganguli S (2003) Big things in small packages-Opportunities and challenges await nano-engineered adhesives, sealants and coatings. Adhes Age 46(3):12–19

Kahraman R, Sunar M, Yilbas B (2008) Influence of adhesive thickness and filler content on the mechanical performance of aluminum single-lap joints bonded with aluminum powder filled epoxy adhesive. J Mater Process Technol 205(1–3):183–189

Hussan F, Hojjayi M, Okamoto M, Gorga RE (2006) Review article: Polymer-matrix nanocomposites, processing, manufacturing and application. J Compos Mater 40(17):1511–1575. https://doi.org/10.1177/0021998306067321

Ezzine MC, Amiri A, Tarfaoui M (2018) Experimental and numerical investigation of the fracture behavior of adhesive shear tests single lap joints. J Braz Soc Mech Sci Eng 40:382. https://doi.org/10.1007/s40430-018-1303-5

Gilbert EN, Hayes BS, Seferis JC (2003) Nano-alumina modified epoxy-based film adhesives. Polym Eng Sci 43(5):1096–1104. https://doi.org/10.1002/pen.10093

Akpinar S, Ozel A (2019) Experimental and numerical determination of the thermal cycle performance of joints obtained with nanostructure-doped nanocomposite adhesives. Compos B 174:106959

Darwish SM, Niazi A, Ghania A, Kassem ME (1991) Improving the electrical properties of structural epoxy resin adhesives. Int J Adhes Adhes 11(1):37–42. https://doi.org/10.1016/0143-7496(91)90059-Q

Gude MR, Prolongo SG, Gómez-del Río T, Urena A (2011) Mode-I adhesive fracture energy of carbon fibre composite joints with nanoreinforced epoxy adhesives. Int J Adhes Adhes 31(7):695–703. https://doi.org/10.1016/j.ijadhadh.2011.06.016

Hsiao KT, Alms J, Advani SG (2003) Use of epoxy/multiwalled carbon nanotubes as adhesives to join graphite fibre reinforced polymer composites. Nanotechnology 14(7):791–793. https://doi.org/10.1088/0957-4484/14/7/316

Gojny FH, Wichmann MH, Fiedler B, Schulte K (2005) Influence of different carbon nanotubes on the mechanical properties of epoxy matrix composites—a comparative study. Compos Sci Technol 65(15–16):2300–2313. https://doi.org/10.1016/j.compscitech.2005.04.021

Prolongo SG, Gude MR, Ureña A (2010) Rheological behaviour of nanoreinforced epoxy adhesives of low electrical resistivity for joining carbon fiber/epoxy laminates. J Adhes Sci Technol 24(6):1097–1112. https://doi.org/10.1163/016942409X12584625925060

Kim YJ, Shin TS, Do Choi H, Kwon JH, Chung YC, Yoon HG (2005) Electrical conductivity of chemically modified multiwalled carbon nanotube/epoxy composites. Carbon 43(1):23–30. https://doi.org/10.1016/j.carbon.2004.08.015

Saeed MB, Zhan MS (2007) Adhesive strength of nano-size particles filled thermoplastic polyimides. Part-I: multi-walled carbon nano-tubes (MWNT)–polyimide composite films. Int J Adhes Adhes 27(4):306–318. https://doi.org/10.1016/j.ijadhadh.2006.06.001

Jojibabu P, Jagannatham M, Haridoss P, Ram GJ, Deshpande AP, Bakshi SR (2016) Effect of different carbon nano-fillers on rheological properties and lap shear strength of epoxy adhesive joints. Compos A Appl Sci Manuf 82:53–64. https://doi.org/10.1016/j.compositesa.2015.12.003

Garg AC, Mai YW (1988) Failure mechanisms in toughened epoxy resins—a review. Compos Sci Technol 31(3):179–223. https://doi.org/10.1016/0266-3538(88)90009-7

Vaidya UK, Gautam AR, Hosur M, Dutta P (2006) Experimental–numerical studies of transverse impact response of adhesively bonded lap joints in composite structures. Int J Adhes Adhes 26(3):184–198. https://doi.org/10.1016/j.ijadhadh.2005.03.013

Doğan NF, Bulut M, Erkliğ A, Bozkurt ÖY (2019) Mechanical and low velocity impact characterization of carbon/glass hybrid composites with graphene nanoplatelets. Mater Res Express. https://doi.org/10.1088/2053-1591/ab1c03

ASTM(D5868–01) (2014) Standard test method for lap shear adhesion for fiber reinforced plastic (FRP) bonding

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Çakır, M.V., Erkliğ, A. & Ahmed, B.F. Graphene nanoparticle effect on flexural and shear behaviors of adhesively bonded single lap joints of GFRP composites. J Braz. Soc. Mech. Sci. Eng. 43, 211 (2021). https://doi.org/10.1007/s40430-021-02920-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-02920-x