Abstract

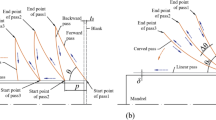

In our previous studies, numerical simulations and experiments were carried out to understand the mechanism of asymmetric spinning for square cone shape. However, the geometry of the products does not coincide well with the geometry in theory. Therefore, in this study, the relationship between the roller and the product is analyzed and a modified roller path is deduced through geometric approach. The result shows the geometry has improved a lot. The relative error of the wall straightness λ drops from 15.9 to 4.1% after modifying. The modified roller path does not have much effect on the wall angle and the wall thickness.

Similar content being viewed by others

References

Music O, Allwood JM, Kawai K (2010) A review of the mechanics of metal spinning. J Mater Process Technol 210:3–23

Arai H, Kanazawa T (2018) Synchronous multipass spinning of oblique-bottom shape. J Mater Process Technol 260:66–76

Awiszus B, Meyer F (2005) Metal spinning of non-circular hollow parts. In: Proceedings of 8th ICTP. Verona, Italy, pp 353–355

Arai H (2005) Robotic metal spinning—forming asymmetric products using force control. In: Proceedings of 2005 IEEE international conference on robotics and automation. Barcelona, Spain, pp 2702–2707

Arai H (2006) Force-controlled metal spinning machine using linear motors. In: Proceedings of the 2006 IEEE international conference on robotics and automation. Orlando, Florida, pp 4031–4036

Amano T, Tamura K (1984) The study of an elliptical cone spinning by the trial equipment. In: Proceedings of the 3rd international conference on rotary metalworking processes. Kyoto, Japan, pp 213–224

Gao XC, Kang DC, Meng XF, Wu HJ (1999) Experimental research on a new technology—ellipse spinning. J Mater Process Technol 94(2–3):197–200

Xia QX, Lai ZY, Zhan XX, Cheng XQ (2010) Research on spinning method of hollow part with triangle arc-type cross section based on profiling driving. Steel Res Int (Spec Ed) 81(9):994–997

Shimizu I (2010) Asymmetric forming of aluminum sheets by synchronous spinning. J Mater Process Technol 210:585–592

Härtel S, Laue R (2016) An optimization approach in non-circular spinning. J Mater Process Technol 229:417–430

Han ZR, Xu Q, Jia Z, Li XB (2015) Experimental research on oblique cone die-less shear spinning. Proc Inst Mech Eng Part B J Eng Manuf 78(23):11772–11782

Han ZR, Fan ZJ, Xiao Y, Jia Z (2016) A research on thickness distribution of oblique cone in dieless shear spinning. Int J Adv Manuf Technol 90:2901–2912

Russo IM, Cleaver CJ, Allwood JM, Loukaides EG (2020) The influence of part asymmetry on the achievable forming height in multipass spinning. J Mater Process Technol 275:116350

Jia Z, Han ZR, Xu Q, Peng WF (2014) Numerical simulation and experiment study on hollow spinning process for square cross-section cone. Int J Adv Manuf Technol 75:1605–1612

Jia Z, Han ZR, Xu Q (2015) Effects of processing parameters on the surface quality of square section die-less spinning. Int J Adv Manuf Technol 80:1689–1700

Jia Z, Han ZR, Xu Q, Peng WF (2016) Precision forming of the straight edge of square section by die-less spinning. J Manufacturing Sci Eng 138:011006

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Lincoln Cardoso Brandao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Han, Z., Xiao, Y., Zhou, S. et al. Modification of roller path for square cone by die-less asymmetric spinning. J Braz. Soc. Mech. Sci. Eng. 42, 269 (2020). https://doi.org/10.1007/s40430-020-02356-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02356-9