Abstract

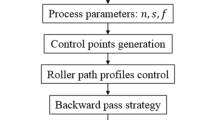

With the development of metal spinning, the limitation of producing axisymmetric shapes has been broken through by many researchers using the synchronous spinning method in which the motion of the roller is synchronized with the rotation of the mandrel. The thickness distribution on the product formed in synchronous spinning is usually non-uniform due to the irregular motion of the roller. A method of pass design for thickness control in synchronous multi-pass spinning is proposed in this study. The effects of different parameters on the circumferential distribution of the wall thickness on cylindrical cups in synchronous multi-pass spinning are investigated. The rotational direction of the mandrel is reversed under several schemes. The cross sections of the product during forming are adjusted to control the thickness distribution by changing the concavity of the pass λ and the roller-mandrel clearance δ at different circumferential positions. The thicknesses and strains were measured during the experiment to understand the material flow. Experiments are also conducted in conventional spinning for comparison. The results showed that the torsion in synchronous spinning with oblique shapes can be reduced by reversing the rotational direction of the mandrel; the circumferential distribution of the thickness can be controlled by changing the geometry of the roller pass circumferentially.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Shimizu I (2010) Asymmetric forming of aluminum sheets by synchronous spinning. J Mater Process Technol 210:585–592

Sugita Y, Arai H (2012) Development of synchronous multipath metal-spinning method for forming nonaxisymmetric shapes. Trans Jpn Soc Mech Eng 78(787):274–282 (in Japanese)

Sugita Y, Arai H (2015) Formability in synchronous multipass spinning using simple pass set. J Mater Process Technol 217:336–344

Arai H, Kanazawa T (2018) Synchronous multipass spinning of oblique-bottom shape. J Mater Process Technol 260:66–76

Xiao Y, Han ZR, Fan ZJ, Jia Z (2018) A study of asymmetric multi-pass spinning for angled-flange cylinder. J Mater Process Technol 256:202–215

Xiao Y, Han ZR, Zhou SY, Jia Z (2020) Experimental study of asymmetric multi-pass spinning. Int J Adv Manuf Technol 110:667–679

Xiao Y, Han ZR, Zhou SY, Jia Z (2020) Asymmetric spinning for offset blanks. Int J Adv Manuf Technol 107:2433–2448

Sekiguchi A, Arai H (2012) Control of wall thickness distribution by oblique shear spinning methods. J Mater Process Technol 212(4):786–793

Han ZR, Fan ZJ, Xiao Y, Jia Z (2016) A research on thickness distribution of oblique cone in dieless shear spinning. Int J Adv Manuf Technol 90:2901–2912

Hayama M, Kudo H, Shinokura T (1970) Study of the pass schedule in conventional simple spinning. Bulletin of the JSME 13(65):1358–1365

Takaishi K, Oosawa K, Yamada T (2004) Development of numerical control spinning technology for manufacture of axisymmetric cylindrical cup. Journal of the JSTP 45(516):55–59 (in Japanese)

Xia QX, Shima S, Kotera H, Yasuhuku D (2005) A study of the one-path deep drawing spinning of cups. J Mater Process Technol 159:397–400

Liu JH, Yang H, Li YQ (2002) A study of the stress and strain distribution of first-pass conventional spinning under different roller-traces. J Mater Process Technol 129(1–3):326–329

Wang L, Long H (2011) A study of effects of roller path profiles on tool forces and part wall thickness variation in conventional metal spinning. J Mater Process Technol 211:2140–2151

Polyblank JA, Allwood JM (2015) Parametric toolpath design in metal spinning. CIRP Ann 64(1):301–304

Funding

This work was financially supported by the Chinese Aeronautical Establishment [2018ZE54028].

Author information

Authors and Affiliations

Contributions

First author designed and conducted the experiments and wrote the paper. The corresponding helped designed the experiment and provided the experiment setups. The third and fourth authors helped with the experiments.

Corresponding author

Ethics declarations

Additional declarations for articles in life science journals that report the results of studies involving humans and/or animals

Not applicable.

Ethics approval

The work was original research that has not been published previously, and not under consideration for publication elsewhere, in whole or in part.

Consent to participate

The authors all approved to participate.

Consent for publication

It is approved by all authors for publication.

Conflict of interest

The authors declare No competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiao, Y., Han, Z., Zhou, S. et al. Control of wall thickness distribution in synchronous multi-pass spinning. Int J Adv Manuf Technol 114, 1457–1469 (2021). https://doi.org/10.1007/s00170-021-06946-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06946-2