Abstract

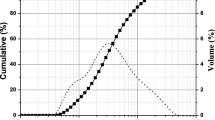

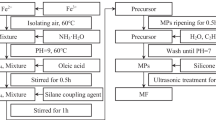

In the present study, the magnetorheological fluid (MRF) samples are prepared using pure carbonyl iron particles (CIPs), CIPs/Claytone APA/Molyvan 855 additive, and friction reducer dispersed in poly-alpha-olefin oil. The scanning electron microscopy reveals that the Claytone additive morphology looks like a surface abundant in small folds, which connect the gaps between the spherical pure CIPs and prevent sedimentation in the MRF. The magnetic saturation properties are investigated through the vibrating sample magnetometer. The pure CIPs MRF shows (Ms) value as 146.12 emu/g, and the CIPs/Claytone APA/Molyvan indicates (Ms) as 55.12 emu/g. The magnetorheological flow curves, such as shear stress and viscosity as a function of shear rate, are investigated for the MRF samples through the magnetorheometer. The sedimentation analysis of the MRF is observed by visual inspection and shows that the CIPs/Claytone APA/Molyvan improved the sedimentation rate than the pure CIPs MRF. Finally, the experimental characterization of the prototype monotube MR damper is carried out using the hydraulic dynamic testing machine at 1.5 Hz frequency for damper peak–peak displacement length of ± 5 mm at three intervals of 0 h, 24 h, and 72 h in damper to know the effect on damping force for the prepared MRF samples against the sedimentation rate.

Similar content being viewed by others

References

Dyke SJ, Spencer BF, Sain MK, Carlson JD (1996) Modeling and control of magnetorheological dampers for seismic response reduction. Smart Mater Struct 5:565–575. https://doi.org/10.1088/0964-1726/5/5/006

Carlson JD (2008) Magnetorheological fluids. Smart Mater 252:17-1–17-8

Rabinow J (1948) The magnetic fluid clutch. Trans Am Inst Electr Eng 67:1308–1315. https://doi.org/10.1109/T-AIEE.1948.5059821

Yang Y, Li L, Chen G (2009) Static yield stress of ferrofluid-based magnetorheological fluids. Rheol Acta 48:457–466. https://doi.org/10.1007/s00397-009-0346-z

De Vicente J, Klingenberg DJ, Hidalgo-Alvarez R (2011) Magnetorheological fluids: a review. Soft Matter 7:3701–3710. https://doi.org/10.1039/c0sm01221a

Olabi AG, Grunwald A (2007) Design and application of magneto-rheological fluid. Mater Des 28:2658–2664. https://doi.org/10.1016/j.matdes.2006.10.009

Carlson JD, Catanzarite DM (1995) Commerciale magneto-rheological fluid devices. In: 5th International conference on electro-rheological, magneto-rheological suspensions and associated technology, Sheffield, pp 10–14

Wang DH, Liao WH (2011) Magnetorheological fluid dampers: a review of parametric modelling. Smart Mater Struct 20:023001. https://doi.org/10.1088/0964-1726/20/2/023001

Park JH, Chin BD, Park OO (2001) Rheological properties and stabilization of magnetorheological fluids in a water-in-oil emulsion. J Colloid Interface Sci 240:349–354. https://doi.org/10.1006/jcis.2001.7622

Park BJ, Fang FF, Choi HJ (2010) Magnetorheology: materials and application. Soft Matter 6:5246–5253. https://doi.org/10.1039/c0sm00014k

Ashtiani M, Hashemabadi SH, Ghaffari A (2015) A review on the magnetorheological fluid preparation and stabilization. J Magn Magn Mater 374:711–715. https://doi.org/10.1016/j.jmmm.2014.09.020

Pu H-T, Jiang FJ, Yang ZL (2006) Preparation and properties of soft magnetic particles based on Fe3O4 and hollow polystyrene microsphere composite. Mater Chem Phys 100:10–14. https://doi.org/10.1016/j.matchemphys.2005.11.032

Wu WP, Zhao BY, Wu Q et al (2006) The strengthening effect of guar gum on the yield stress of magnetorheological fluid. Smart Mater Struct 15:N94. https://doi.org/10.1088/0964-1726/15/4/N04

Piao SH, Bhaumik M, Maity A, Choi HJ (2015) Polyaniline/Fe composite nanofiber added softmagnetic carbonyl iron microsphere suspension and its magnetorheology. J Mater Chem C 3:1861–1868. https://doi.org/10.1039/c4tc02491e

Kim MS, Cho MS, Choi HJ (2007) PMMA coated carbonyl iron microbeads and their magnetic characteristics. Phys Status Solidi Appl Mater Sci 204:4198–4201. https://doi.org/10.1002/pssa.200777351

Iglesias GR, López-López MT, Durán JDG et al (2012) Dynamic characterization of extremely bidisperse magnetorheological fluids. J Colloid Interface Sci 377:153–159. https://doi.org/10.1016/j.jcis.2012.03.077

Lim ST, Cho MS, Jang IB, Choi HJ (2004) Magnetorheological characterization of carbonyl iron based suspension stabilized by fumed silica. J Magn Magn Mater 282:170–173. https://doi.org/10.1016/j.jmmm.2004.04.040

Chen K, Zhang WL, Shan L et al (2014) Magnetorheology of suspensions based on graphene oxide coated or added carbonyl iron microspheres and sunflower oil. J Appl Phys 116:153508. https://doi.org/10.1063/1.4898678

Fang FF, Choi HJ, Jhon MS (2009) Magnetorheology of soft magnetic carbonyl iron suspension with single-walled carbon nanotube additive and its yield stress scaling function. Colloids Surf A Physicochem Eng Asp 351:46–51. https://doi.org/10.1016/j.colsurfa.2009.09.032

Chae HS, Piao SH, Maity A, Choi HJ (2014) Additive role of attapulgite nanoclay on carbonyl iron-based magnetorheological suspension. Colloid Polym Sci 293:89–95. https://doi.org/10.1007/s00396-014-3389-3

Piao SH, Zhang WL, Choi HJ (2014) Magnetic carbonyl iron suspension with sepiolite additive and its magnetorheological property. IEEE Trans Magn 50:1–4. https://doi.org/10.1109/TMAG.2013.2278694

Lim ST, Choi HJ, Jhon MS (2005) Magnetorheological characterization of carbonyl iron-organoclay suspensions. IEEE Trans Magn 41:3745–3747. https://doi.org/10.1109/TMAG.2005.854759

Hong CH, Liu YD, Choi HJ (2013) Carbonyl iron suspension with halloysite additive and its magnetorheology. Appl Clay Sci 80–81:366–371. https://doi.org/10.1016/j.clay.2013.06.033

Liu YD, Lee J, Choi SB, Choi HJ (2013) Silica-coated carbonyl iron microsphere based magnetorheological fluid and its damping force characteristics. Smart Mater Struct 22:065022. https://doi.org/10.1088/0964-1726/22/6/065022

Shah K, Phu DX, Seong MS et al (2014) A low sedimentation magnetorheological fluid based on plate-like iron particles, and verification using a damper test. Smart Mater Struct 23:027001. https://doi.org/10.1088/0964-1726/23/2/027001

Additives-organo NR, Baragel B, Rheological N, Cited R (2001) (12) United States Patent, 1

Emett CJ, Hagemeister MP, Harrington BA, Matsunaga PT, Nandapurkar PJ, Ruff CJ, Stavens KB (2016) U.S. Patent No. 9,399,746. U.S. Patent and Trademark Office, Washington, DC

Tanaka, N., Fukushima, A., Tatsumi, Y., & Saito, Y. (1997). U.S. Patent No. 5,627,146. Washington, DC: U.S. Patent and Trademark Office

Rowan EV, Farmer HH (1970) U.S. Patent No. 3,494,866. U.S. Patent and Trademark Office, Washington, DC

Zhang H, Zhou J, Muhammad Y, Tang R, Liu K, Zhu Y, Tong Z (2019) Citric acid modified bentonite for Congo Red adsorption. Front Mater 6:5. https://doi.org/10.3389/fmats

Nguyen QH, Choi SB (2009) Optimal design of a vehicle magnetorheological damper considering the damping force and dynamic range. Smart Mater Struct 18:015013. https://doi.org/10.1088/0964-1726/18/1/015013

Xu ZD, Jia DH, Zhang XC (2012) Performance tests and mathematical model considering magnetic saturation for magnetorheological damper. J Intell Mater Syst Struct 23:1331–1349. https://doi.org/10.1177/1045389X12445629

Gurubasavaraju TM, Kumar H, Arun M (2017) Evaluation of optimal parameters of MR fluids for damper application using particle swarm and response surface optimisation. J Braz Soc Mech Sci Eng 39:3683–3694. https://doi.org/10.1007/s40430-017-0875-9

Yu M, Ju B, Fu J et al (2014) Magnetoresistance characteristics of magnetorheological gel under a magnetic field. Ind Eng Chem Res 53:4704–4710. https://doi.org/10.1021/ie4040237

Aruna MN, Rahman MR, Joladarashi S, Kumar H (2019) Influence of additives on the synthesis of carbonyl iron suspension on rheological and sedimentation properties of magnetorheological (MR) fluids. Mater Res Express 6:086105. https://doi.org/10.1088/2053-1591/ab1e03

Boekelheide Z, Dennis CL (2016) Artifacts in magnetic measurements of fluid samples. AIP Adv 6(8):085201. https://doi.org/10.1063/1.4960457

Sidpara A, Das M, Jain VK (2009) Rheological characterization of magnetorheological finishing fluid. Mater Manuf Process 24:1467–1478. https://doi.org/10.1080/10426910903367410

Kim MW, Han WJ, Kim YH, Choi HJ (2016) Effect of a hard magnetic particle additive on rheological characteristics of microspherical carbonyl iron-based magnetorheological fluid. Colloids Surf A Physicochem Eng Asp 506:812–820. https://doi.org/10.1016/j.colsurfa.2016.07.070

Kim YH, Sim B, Choi HJ (2016) Fabrication of magnetite-coated attapulgite magnetic composite nanoparticles and their magnetorheology. Colloids Surf A Physicochem Eng Asp 507:103–109. https://doi.org/10.1016/j.colsurfa.2016.07.095

Kwon SH, Choi HJ, Lee JW et al (2013) Magnetorheology of xanthan-gum-coated soft magnetic carbonyl iron microspheres and their polishing characteristics. J Korean Phys Soc 62:2118–2122. https://doi.org/10.3938/jkps.62.2118

Bae DH, Choi HJ, Choi K et al (2017) Microcrystalline cellulose added carbonyl iron suspension and its magnetorheology. Colloids Surf A Physicochem Eng Asp 514:161–167. https://doi.org/10.1016/j.colsurfa.2016.11.052

Nguyen QH, Choi SB (2008) Optimal design of a vehicle magnetorheological damper considering the damping force and dynamic range. Smart Mater Struct 18(1):015013. https://doi.org/10.1088/0964-1726/18/1/015013

Tharehalli Mata G, Kumar H, Mahalingam A (2019) Performance analysis of a semi- active suspension system using coupled CFD-FEA based non-parametric modeling of low capacity shear mode monotube MR damper. Proc Inst Mech Eng Part D J Automob Eng 233:1214–1231. https://doi.org/10.1177/0954407018765899

Chand M, Kumar S, Shankar A et al (2013) The size induced effect on rheological properties of Co-ferrite based ferrofluid. J Non Cryst Solids 361:38–42. https://doi.org/10.1016/j.jnoncrysol.2012.10.003

Chand M, Shankar A, Jain K et al (2014) Improved properties of bidispersed magnetorheological fluids. RSC Adv 4:53960–53966. https://doi.org/10.1039/c4ra07431a

Yang P, Yu M, Fu J, Luo H (2018) Rheological properties of dimorphic magnetorheological gels mixed dendritic carbonyl iron powder. J Intell Mater Syst Struct 29(1):12–23. https://doi.org/10.1177/1045389X17692050

Wang G, Ma Y, Tong Y, Dong X (2016) Synthesis, characterization and magnetorheological study of 3-aminopropyltriethoxysilane-modified Fe3O4 nanoparticles. Smart Mater Struct 25(3):035028. https://doi.org/10.1088/0964-1726/25/3/035028

Arief I, Mukhopadhyay PK (2017) Yielding behavior and temperature-induced on-field oscillatory rheological studies in a novel MR suspension containing polymer-capped Fe3Ni alloy microspheres. J Magn Magn Mater 429:236–240. https://doi.org/10.1016/j.jmmm.2017.01.048

Wang G, Ma Y, Li M et al (2017) Magnesium ferrite nanocrystal clusters for magnetorheological fluid with enhanced sedimentation stability. Solid State Sci 63:70–75. https://doi.org/10.1016/j.solidstatesciences.2016.11.015

Shah K, Xuan Phu D, Choi SB (2014) Rheological properties of bi-dispersed magnetorheological fluids based on plate-like iron particles with application to a small-sized damper. J Appl Phys 115:203907. https://doi.org/10.1063/1.4879681

Hemanth K, Kumar H, Gangadharan KV (2017) Vertical dynamic analysis of a quarter car suspension system with MR damper. J Braz Soc Mech Sci Eng 39:41–51. https://doi.org/10.1007/s40430-015-0481-7

Snyder RA, Kamath GM, Wereley NM (2001) Characterization and analysis of magnetorheological damper behavior under sinusoidal loading. AIAA J 39:1240–1253. https://doi.org/10.2514/2.1466

Kwon SH, Hong CH, Do PX et al (2015) Magnetorheology of a carbonyliron microsphere suspension with a halloysite additive and its damping force characteristics. Ind Eng Chem Res 54:4655–4663. https://doi.org/10.1021/acs.iecr.5b00233

Acknowledgements

This project was funded by IMPRINT India, Ministry of Human Resources Development, under the Government of India. The Project (No: 7330) is entitled “Development of Cost-Effective Magneto-Rheological (MR) Fluid Damper in Two Wheeler and Four Wheeler Automobiles to Improve Ride Comfort and Stability.”

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Edson José Soares, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aruna, M.N., Rahman, M.R., Joladarashi, S. et al. Investigation of sedimentation, rheological, and damping force characteristics of carbonyl iron magnetorheological fluid with/without additives. J Braz. Soc. Mech. Sci. Eng. 42, 228 (2020). https://doi.org/10.1007/s40430-020-02322-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02322-5