Abstract

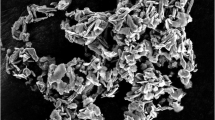

As an effective method to improve the load capacity of the oil-film bearing, a kind of nano-scale magnetic fluid (MF) by taking silicon oil as carrier fluid was prepared using the chemical coprecipitation method. The microstructure and magnetism of the magnetic particles (MPs) were analyzed based on SEM, VSM, and TGA. It is shown that the MPs are spherical particles with an average diameter of 20 nm, and the MPs behave superparamagnetism. A natural sedimentation control group was developed to investigate the sedimentation stability of the MF. The results indicated that the prepared MF presents good sedimentation stability. The viscosity of MF was measured from temperature and magnetic field by a single factor experiment, and the data was regressed according to the Herschel-Bulkley (H-B) model. According to the regression results, the effects of temperature and magnetic field intensity on the properties of MF were investigated. It is found that the yield stress τ0, viscosity coefficient K, and the shear thinning effect n of the MF were increased by 38–54%, 7–11%, and 6–9%, respectively, as the current increased from 0 to 2.0 A. The increase in temperature (from 20 to 80 ℃) reduces the yield stress and viscosity coefficient of MF by 3–6.85% and 1.13–1.36% and aggravates the shear thinning effect by 1.03–1.06%. Furthermore, the regression analysis of the H-B model parameters vs. temperature was carried out, and the equation of viscosity, η = f(T, γ), was obtained, which can be directly used to predict the lubrication state of MF.

Similar content being viewed by others

References

Engel, T., Lechler, A., Verl, A.: Sliding bearing with adjustable friction properties. CIRP Ann. Manuf. Technol. 65, 353–356 (2016). https://doi.org/10.1016/j.cirp.2016.04.084

Chun, S.M., Khonsari, M.M.: Wear simulation for the journal bearings operating under aligned shaft and steady load during start-up and coast-down conditions. Tribol. Int. 97, 440–466 (2016). https://doi.org/10.1016/j.triboint.2016.01.042

Huang, Q.X., Wang, J.M., Ma, L.F., Zhao, C.J.: Fatigue damage mechanism of oil film bearing sleeve. J. Iron. Steel Res. Int. 14, 60–63 (2007). https://doi.org/10.1016/S1006-706X(07)60013-2

Nakata, K., Hu, Y., Uzun, O., Bakr, O., Stellacci, F.: Chains of superparamagnetic nanoparticles. Adv. Mater. 20, 4294–4299 (2008). https://doi.org/10.1002/adma.200800022

Xia, J., Qiao, Q., Zhou, G.: Controllable gap in microsphere resonator integrated with a deformable ferrofluid droplet for magnetic field sensing. Opt. Fiber Technol. 58, 102292 (2020). https://doi.org/10.1016/j.yofte.2020.102292

Zhang, W., Peng, J., Li, S.: Damping force modeling and suppression of self-excited vibration due to magnetic fluids applied in the torque motor of a hydraulic servovalve. Energies. 10, (2017). https://doi.org/10.3390/en10060749

Zhang, H., Li, Y.Q., Yuan, B.Y., Cheng, F.Y., Yang, Z., Yuan, Z., Xue, H.L.: Modeling and experimental studies of optical power cable current sensing based on the optical transmission properties of magnetic fluids. Opt. Lett. 16, 12–16 (2020). https://doi.org/10.1007/s11801-020-9097-y

Daoush, W.M.: Co-precipitation and magnetic properties of magnetite nanoparticles for potential biomedical applications. J. Nanomed. Res. (2017). https://doi.org/10.15406/jnmr.2017.05.00118

Reinert, L., Green, I., Gimmler, S., Lechthaler, B., Mücklich, F., Suàrez, S.: Tribological behavior of self-lubricating carbon nanoparticle reinforced metal matrix composites. Wear 408–409, 72–85 (2018). https://doi.org/10.1016/j.wear.2018.05.003

Zhang, Y., Li, C., Jia, D., Li, B., Wang, Y., Yang, M., Hou, Y., Zhang, X.: Experimental study on the effect of nanoparticle concentration on the lubricating property of nanofluids for MQL grinding of Ni-based alloy. J. Mater. Process. Technol. 232, 100–115 (2016). https://doi.org/10.1016/j.jmatprotec.2016.01.031

Zin, V., Agresti, F., Barison, S., Litti, L., Fedele, L., Meneghetti, M., Fabrizio, M.: Effect of external magnetic field on tribological properties of goethite (a-FeOOH) based nanofluids. Tribol. Int. 127, 341–350 (2018). https://doi.org/10.1016/j.triboint.2018.06.023

Trivedi, K., Kothari, A., Parekh, K., Upadhyay, R.V.: Effect of particle concentration on lubricating properties of magnetic fluid. J. Nanofluids 7, 420–427 (2018). https://doi.org/10.1166/jon.2018.1472

Bolotov, A.N., Gorlov, I.V., Novikov, V.V.: Nanodispersed ferrofluid oil lubricity improvement with processing methods. In: Procedia Engineering. pp. 606–610. Elsevier Ltd (2017). https://doi.org/10.1016/j.proeng.2017.10.524

Pop, L.M., Odenbach, S.: Investigation of the microscopic reason for the magnetoviscous effect in ferrofluids studied by small angle neutron scattering. J. Phys. Condens. Matter. 18, (2006). https://doi.org/10.1088/0953-8984/18/38/S17

Zhu, Z., Wu, S., Zhang, C., Zhou, J.: Length measurement of chain-like structure of micron magnetic particles dispersing in carrier fluid effected by magnetic field. J. Supercond. Novel Magn. 34, 805–816 (2021). https://doi.org/10.1007/s10948-020-05779-6

Liu, Y., Liu, X., Liu, H.: The Monte Carlo simulation to magnetic particles of magnetorheological fluids. Procedia Eng. 15, 3896–3900 (2011). https://doi.org/10.1016/j.proeng.2011.08.729

Andablo-Reyes, E., De Vicente, J., Hidalgo-Álvarez, R., Myant, C., Reddyhoff, T., Spikes, H.A.: Soft elasto-hydrodynamic lubrication. Tribol. Lett. 39, 109–114 (2010). https://doi.org/10.1007/s11249-010-9623-3

Xu, M., Dai, Q., Huang, W., Wang, X.: Using magnetic fluids to improve the behavior of ball bearings under starved lubrication. Tribol. Int. 141, 105950 (2020). https://doi.org/10.1016/j.triboint.2019.105950

Engler, H., Borin, D., Odenbach, S.: Thermomagnetic convection influenced by the magnetoviscous effect. J. Phys: Conf. Ser. 149, 012105 (2009). https://doi.org/10.1088/1742-6596/149/1/012105

Wang, J., Li, Z., Mohammadkazem, S., Cai, M., Kang, J., Zhang, Y.: Stability characteristics of lubricating film in mill oil-film bearings. Ind. Lubr. Tribol. 70, 201–211 (2018). https://doi.org/10.1108/ILT-12-2016-0318

Quinci, F., Litwin, W., Wodtke, M., van den Nieuwendijk, R.: A comparative performance assessment of a hydrodynamic journal bearing lubricated with oil and magnetorheological fluid. Tribol. Int. 162, 107143 (2021). https://doi.org/10.1016/j.triboint.2021.107143

Zhang, Q., Song, H., Wu, B., Feng, W., Li, X., Jiao, Y., Hu, X.: Effect of magnetic field on the tribological behaviors of Fe3O4@MoS2 as polyalphaolefin additive in the steel/steel friction interface. Wear. 466–467, (2021). https://doi.org/10.1016/j.wear.2020.203586

Zhou, G., Zhu, Y., Wang, X., Xia, M., Zhang, Y., Ding, H.: Sliding tribological properties of 0.45% carbon steel lubricated with Fe3O4 magnetic nano-particle additives in baseoil. Wear. 301, 753–757 (2013). https://doi.org/10.1016/j.wear.2013.01.027

Lampaert, S.G.E., van Ostayen, R.A.J.: Experimental results on a hydrostatic bearing lubricated with a magnetorheological fluid. Curr. Appl. Phys. 19, 1441–1448 (2019). https://doi.org/10.1016/j.cap.2019.09.004

Jang, K.I., Min, B.K., Seok, J.: A behavior model of a magnetorheological fluid in direct shear mode. J. Magn. Magn. Mater. pp. 1324–1329 (2011)

Jung, I.D., Kim, M., Park, S.J.: A comprehensive viscosity model for micro magnetic particle dispersed in silicone oil. J. Magn. Magn. Mater. 404, 40–44 (2016). https://doi.org/10.1016/j.jmmm.2015.12.024

Wang, J., Zuo, Z., Zhao, Y., Hou, D., Li, Z.: Preparation and viscosity characteristics of nano-scale magnetic fluid oil-film bearing oil. J. Nanosci. Nanotechnol. 19, 2688–2694 (2018). https://doi.org/10.1166/jnn.2019.15897

Dong, X.F., Ma, N., Qi, M., Li, J.H., Guan, X.C., Ou, J.P.: Properties of magneto-rheological fluids based on amorphous micro-particles. Trans. Nonferrous Met. Soc. Chin. (English Edition). 22, 2979–2983 (2012). https://doi.org/10.1016/S1003-6326(11)61559-8

Xu, Y., Gong, X., Xuan, S., Zhang, W., Fan, Y.: A high-performance magnetorheological material: preparation, characterization and magnetic-mechanic coupling properties. Soft Matter 7, 5246–5254 (2011). https://doi.org/10.1039/c1sm05301a

Hu, Z., Wang, Z., Huang, W., Wang, X.: Supporting and friction properties of magnetic fluids bearings. Tribol. Int. 130, 334–338 (2019). https://doi.org/10.1016/j.triboint.2018.10.006

Chin, A.B., Yaacob, I.I.: Synthesis and characterization of magnetic iron oxide nanoparticles via w/o microemulsion and Massart’s procedure. J. Mater. Process. Technol. 191, 235–237 (2007). https://doi.org/10.1016/j.jmatprotec.2007.03.011

Vidal-Vidal, J., Rivas, J., López-Quintela, M.A.: Synthesis of monodisperse maghemite nanoparticles by the microemulsion method. Colloids Surf. A 288, 44–51 (2006). https://doi.org/10.1016/j.colsurfa.2006.04.027

Shao, H., Zhou, Y., Qi, J., Hu, P., He, J.: Characterization of Fe3O4/γ-Fe2O3@SiO2 core-shell structure composite magnetic fluid by microemulsion method. J. Supercond. Novel Magn. 32, 247–252 (2019). https://doi.org/10.1007/s10948-018-4910-6

Pereira, A.S., Soares, E.J.: Polymer degradation of dilute solutions in turbulent drag reducing flows in a cylindrical double gap rheometer device. J. Nonnewton. Fluid Mech. 179–180, 9–22 (2012). https://doi.org/10.1016/j.jnnfm.2012.05.001

Cross, M.M.: Rheology of non-Newtonian fluids: a new flow equation for pseudoplastic systems. J. Colloid Sci. 20, 417–437 (1965). https://doi.org/10.1016/0095-8522(65)90022-X

Tichy, J.A.: Hydrodynamic lubrication theory for the Bingham plastic flow model. J. Rheol. 35, 477–496 (1991). https://doi.org/10.1122/1.550231

Gershel, V.B.: Consistency measurement for rubber-benzene solutions. I am. Soc. Test Proc. 621–623 (1926). https://doi.org/10.1021/ie50177a019

Quitian, G., Saldarriaga, W., Rojas, N.: Steady rheological properties of a magnetorheological fluid from mining waste. Appl. Phys. A Mater. Sci. Process. 127, 1–11 (2021). https://doi.org/10.1007/s00339-020-04221-x

Tian, F., Zhou, J.F., Shao, C.L., Wu, H.B., Hao, L.: Effective recovery of oil slick using the prepared high hydrophobic and oleophilic Fe3O4 magnetorheological fluid. Colloids Surf. A Physicochem. Eng. Asp. 591, (2020). https://doi.org/10.1016/j.colsurfa.2020.124531

Zou, H., Weder, C., Simon, Y.C.: Shape-memory polyurethane nanocomposites with single layer or bilayer oleic acid-coated Fe3O4 nanoparticles. Macromol. Mater. Eng. 300, 885–892 (2015). https://doi.org/10.1002/mame.201500079

Wu, H., Hao, L., Chen, C., Zhou, J.: Superhydrophobic Fe3O4/OA magnetorheological fluid for removing oil slick from water surfaces effectively and quickly. ACS Omega 5, 27425–27432 (2020). https://doi.org/10.1021/acsomega.0c03857

Wang, G., Ma, Y., Tong, Y., Dong, X.: Development of manganese ferrite/graphene oxide nanocomposites for magnetorheological fluid with enhanced sedimentation stability. J. Ind. Eng. Chem. 48, 142–150 (2017). https://doi.org/10.1016/j.jiec.2016.12.032

Wang, X., Li, H., Meng, G.: Rotordynamic coefficients of a controllable magnetorheological fluid lubricated floating ring bearing. Tribol. Int. 114, 1–14 (2017). https://doi.org/10.1016/j.triboint.2017.04.002

Funding

This work was supported by the National Natural Science Foundation of China [grant number 52175171].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

This article does not contain any studies with human participants or animals performed by any of the authors. Informed consent was obtained from all individual participants included in the study.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hao, L., Zhou, J. Experimental Study on the Rheological Properties of MF Lubricant Based on the Herschel-Bulkley Model. J Supercond Nov Magn 35, 3333–3346 (2022). https://doi.org/10.1007/s10948-022-06386-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-022-06386-3