Abstract

In order to reduce the dynamic load of cutting transmission system and maintain the coal productivity under sudden-changing load conditions, the drum speed control strategy and traction-drum speed combined control strategy were proposed to adapt to different sudden-changing load conditions based on analyzing the influence factors of drum load and productivity. When sudden-changing load is small, the drum speed control strategy is adopted; when sudden-changing load is large, the traction-drum speed combined control strategy is adopted. The model of cutting transmission system has been established and analyzed, and the results show that the proposed strategies can not only reduce the dynamic load effectively, but also maintain the highly coal productivity under sudden-changing load conditions. Aiming at the overshoot of system load in the variable speed process, the speed variation rate of cutting motor of the two control strategies was optimized, respectively, and the load overshoot can be reduced effectively. The conclusions have been verified by building the test bench.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

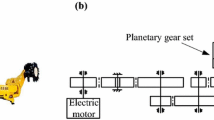

At present, coal accounts for 64% of China’s energy consumption, and in the next decades, coal will still be the main energy source in China [1]. So the improvement in coal production can guarantee the national energy security. In the coal mining process, shearer has been one of the key coal mining machines, which is mainly composed of cutting unit, intermediate box and traction unit, as shown in Fig. 1a. The load on cutting unit has the characteristics of strong randomness, high fluctuation and strong impact. Moreover, the drum speed of existing shearers can’t be adjusted, so these shearers have the shortages of high failure rate, bad adaptability and low coal productivity. And the trend of unmanned coal mining in deep coal bed has made strict requirements on the reliability and adaptability of shearer [2,3,4]. So it is of great significance to improve the reliability and adaptive capacity of cutting unit.

In the existing research, the references [5,6,7,8] analyzed the influence factors such as traction speed and shearing media by establishing drum load model, and results show that the drum load can be adjusted by adjusting drum speed and traction speed. The references [9, 10] achieved better coal productivity and lump coal rate through matching drum speed and traction speed. However, most researches haven’t considered the load of transmission system and coal productivity synthetically when studying on how to reduce drum load. Besides, there is few theoretical research combined with experimental testing.

Therefore, based on the analysis of influence factors of drum load and coal productivity, this paper aims to improve the reliability of cutting transmission system and to ensure the productivity when the cutting resistance changes suddenly. According to the different operation conditions of shearer and the change of cutting resistance, the drum speed control strategy and traction-drum speed combined control strategy are put forward. The effectiveness of the control strategies has been proved by building simulation model and test bench.

2 Analysis of influence factors for cutting unit load and coal productivity and speed control strategy

2.1 Analysis of influence factors for cutting unit load and coal productivity

The cutting unit is mainly composed of driving motor, ranging arm reducer and drum, as shown in Fig. 1b. And there is a long transmission chain in rocker arm reducer, which is composed of the parallel shaft reducing mechanism in high-speed end and the planetary gear reducing mechanism in low-speed end.

The cutting unit reliability is closely related to the load condition. The existing shearers usually lower the traction speed to reduce drum load when meeting hard coal seam, which will decrease coal productivity and load adaptability. In order to improve the reliability of cutting unit and ensure the coal productivity, this paper firstly analyzes the influence factors of cutting unit load and coal productivity.

When working, the biggest factor affecting the cutting transmission system is the cutting resistance torque Mdm (N m) along the drum circumferential direction. It is the superposition of the average load of all working pick:

where Zmi is the average cutting force of picks in the ith (i = 1, 2, … 12, as shown in Fig. 2) transversal line, N; Di is the turning circle diameter of picks in the ith transversal line, m; Nci is the number of working picks in the ith transversal line; and Ncl is the total number of transversal line.

The cutting resistance Zm of single pick can be obtained by Eq. (2) [11]:

where Ap is the average cutting resistance of coal seam, N mm−1; Vq is the traction speed of shearer, m min−1; nd is the drum speed, r min−1; Sj is the intercept of cutting picks, mm; m is the number of cutting picks of each cutting line; ky is the coefficient influenced by mine pressure; km is the bare coefficient of coal; kα is the coefficient influenced by cutting angle; ky is the coefficient influenced by tool face shape; kp is the pick arrangement coefficient; kØ is the coefficient influenced by crack angle; bp is the width of working part of pick; β is the installing angle of picks, rad; and Øb is the avalanche angle of coal debris, rad.

Analyzing Eqs. (1) and (2), we can draw the following conclusions: In addition to the two established factors of coal physical properties and drum parameters, the cutting resistance Mdm of drum is mainly affected by traction speed and drum speed; the cutting resistance increases with increase in traction speed, but decreases with increase in drum speed, as shown in Fig. 3.

Actual productivity of shearer can be expressed by Eq. (3):

where k is the actual continuous working factor, which takes the value of 0.8; B is the average cutting depth of drum, mm; L is the width of cutting mechanism, mm; and ρ is the average density of coal, kg m−3.

It can be seen from Eq. (3) that coal productivity of shearer is only related to traction speed, and the higher the speed, the greater the productivity. However, the traction speed is limited by the power of cutting motor [12]. It has to meet the following relationship:

where Pi is the total cutting power of single drum, kW; Q is the designed productivity of shearer, m3 min−1; k1 and k2 are the coefficients influenced by power; k3 is the coefficient influenced by working condition; ηi is the total transmission efficiency of cutting unit; m is the number of cutting picks in each cutting line.

2.2 Speed regulation control strategies under sudden-changing load

When shearer is working, in order to make the cutting motor operating under rated load, the drum target load is determined by the motor rated torque Te [13]:

where Te is the rated torque of cutting motor, N m; η is the efficiency of cutting transmission system; and ia is the total reduction ratio of cutting unit.

Combining Eqs. (2) and (5), when the cutting motor works at rated torque Te, the relationship between cutting resistance Ap and drum speed nd can be obtained as:

The above equation proves that the cutting resistance Ap which the drum can overcome increases with the rise of drum speed nd when the traction speed Vq is an invariant. When the cutting motor speed equals to the rated speed, the drum speed is maximum ndmax. At the same time, when the traction speed Vq is constant and the cutting motor works at rated torque Te, the maximum cutting resistance the drum can overcome Ap0 can be expressed as Eq. (7):

In conclusion, in order to reduce the load of cutting transmission system and ensure the coal productivity as far as possible when cutting resistance changes, the following speed regulation control strategies have been proposed in this paper: When the cutting motor can overcome cutting resistance from coal seam, namely Ap < Ap0, the traction speed remains unchanged and the cutting motor speed should increase; when the cutting motor cannot overcome cutting resistance, namely Ap > Ap0, the only adjustment on drum speed cannot achieve the reduction in load. Therefore, the traction speed should be reduced firstly, then the cutting motor speed increases to the target value, and the traction speed is recovered at last.

3 Modeling and simulation analysis of dynamic characteristics of cutting transmission system

3.1 Modeling of cutting transmission system

A purely torsional dynamic model of cutting transmission system has been established to analyze the proposed speed regulation control strategies. The rotary inertia of fixed axis gear train of cutting unit except gear 1 and gear 2 is equivalent to the gear 2. The connecting shaft between motor and fixed axis gear train, the connecting shaft between fixed axis gear train and planetary gear train, the connecting shaft between planetary gear train and drum are simplified to the spring-damp system, respectively [14, 15]. Because planetary gear train is an important component of cutting transmission system, furthermore, it’s at the end of the driving system, has heavy load and likely occurs destruction [16], it’s necessary to analyze the internal meshing force in planetary gear. The cutting unit model is mainly composed of motor model based on direct torque control (DTC), transmission system model of ranging arm and load model of drum. The transmission system model of cutting unit and the coupling relationship of each part are shown in Figs. 4 and 5, respectively:

Equation 8 is the purely torsional dynamic equation of transmission system of cutting unit:

where Mm and Md are the electromagnetic torque of cutting motor and drum load, respectively, N m; Jm, J1, J2, Js, Jc, Jr, Jd and Jpn are the rotary inertia of motor rotor, gear 1, gear 2, sun wheel, planet carrier, internal ring, drum and nth planetary gear, respectively, kg m2; θm, θ1, θ2, θs, θc, θr, θd and θpn are the angular displacement of motor rotor, gear 1, gear 2, sun wheel, planet carrier, internal ring, drum and nth planetary gear, respectively, rad; N is the number of planetary gear; i is the reduction ratio of fixed axis gear train except gear 1 and gear 2; αs is the pressure angle of planetary gear and sun gear, rad; αr is the pressure angle of internal ring and planetary gear, rad; c1 and k1 are the torsional damping and stiffness between motor and gear 1, respectively, N m rad−1 s, N m rad−1; cmp and kmp are the torsional damping and stiffness between gear 2 and following drive system, N m rad−1 s, N m rad−1; cpd and kpd are the torsional damping and stiffness between output shaft of planetary gear and drum, respectively, N m rad−1 s, N m rad−1; cm1 and km1 are the mesh damping and stiffness between gear 1 and gear 2, respectively, N m−1 s, N m−1; rb1, rb2, rbs, rc, rbr and rbp are the basic circle radius of gear 1, gear 2, sun gear, planetary carrier, internal ring and planetary gear, m; and Tr is the torque of rocker box acting on the ring, N m. These parameters also should meet the following:

where rbpn is the basic radius of nth planetary gear, m; KSP and CSP are the mesh stiffness and damping between sun gear and planetary gear, respectively, N m−1, N m−1 s; and KPR and CPR are the mesh stiffness and damping between planetary gear and ring, respectively, N m−1, N m−1 s.

3.2 Simulation analysis of dynamic characteristics of cutting unit under sudden-changing load

Based on the established model, the following simulation analysis has been carried out. The simulation conditions are as follows: Cutting motor speed is set to 1200r min−1; traction speed is set to 4 m min−1; initial cutting resistance of coal is 200 N mm−1; and the cutting resistance suddenly changes to 300 N mm−1 at 3 s.

(1) Simulation analysis of traditional traction speed regulation

From Fig. 6, we can see that, after the cutting resistance suddenly changes, the drum load suddenly rises from 0.76 × 105 to 1.18 × 105 N m. Then, after reducing traction speed, electromagnetic torque of cutting motor, input torque of ranging arm and mesh force of gear ring are reduced from 2714 to 2207 N m, from 2683 to 2167 N m and from 7.74 × 105 to 6.36 × 105 N, respectively. The results show that it is effective to reduce the cutting load by reducing traction speed. However, due to the decline of traction speed, the coal productivity drops dramatically.

(2) Simulation analysis of drum speed control strategy when Ap < Ap0

The rotation speed of cutting motor increases from 1200 to 1400r min−1 when time is set to 3.5 s.

From Fig. 7, the following conclusions can be drawn: After adopting drum speed regulation, compared to the non-regulation, drum load has declined to 1.05 × 105N m. At the same time, electromagnetic torque of cutting motor, input torque of ranging arm and mesh force of gear ring are reduced to 2410 N m, 2420 N m and 7.06 × 105 N, respectively. The results have proved the effectiveness of drum speed regulation under low sudden-changing load. However, the maximum values of electromagnetic torque of cutting motor, input torque of ranging arm and mesh force of gear ring have reached to 3210 N m, 2744 N m and 7.96 × 105 N, respectively, in variable speed process, which are higher than the corresponding values of non-regulation. Thus, it’s necessary to optimize the speed change rate of cutting motor.

(3) Simulation analysis of traction-drum speed combined control strategy when Ap > Ap0

When simulation time is at 3.2 s, traction speed drops from 4 to 3 m min−1 within 0.5 s, and within the next 0.5 s, the cutting motor speed increases to 1400r min−1. In the end, the traction speed recovers to 4 m min−1 within 0.5 s.

From Fig. 8, the following conclusions can be drawn: After adopting traction-drum speed combined control strategy, drum load, mesh force of gear ring, electromagnetic torque of cutting motor and input torque of ranging arm are reduced to 1.05 × 105 N m, 7.06 × 105 N, 2410 N m and 2420 N m, respectively. The results have proved the effectiveness of the combined control strategy to decrease cutting transmission system’s load under high sudden-changing load. At the same time, observing the system force situation in the process of increasing cutting motor speed, the maximum values of electromagnetic torque of cutting motor, input torque of ranging arm and mesh force of gear ring are 2675 N m, 2239 N m and 6.49 × 105 N, respectively, which have not exceeded the corresponding value of non-regulation. It is obvious that the combined control strategy can avoid load overshoot of transmission system effectively. But in the variable speed process, the system is subjected to the impact load from inertia moment, so it’s necessary to optimize the combined control strategy.

4 Optimization and experimental verification of speed control strategies considering cutting unit inertia

4.1 Optimization of speed regulation control strategies

Analysis shows that the real shearer’s cutting unit is a large inertia system, and the speed regulation has been affected by cutting motor torque and inertia moment. Therefore, when cutting resistance changes suddenly, in the variable speed process, the electromagnetic torque of cutting motor shouldn’t exceed the corresponding value of non-regulation.

where Tem is the electromagnetic torque of cutting motor, N m; Je is the equivalent rotary inertia on cutting motor shaft, kg m2; iA is the total reduction ratio of ranging arm; and θm is the angular displacement of cutting motor, rad. And Eq. (11) can be derived by integrating and processing Eq. (10) with replacing Tem0 with Tem:

So the real-time rotation speed of cutting motor in the variable speed process should meet Eq. (12) after optimization:

where \(\dot{\theta }_{\text{m0}}\), \(\dot{\theta }_{\text{mt}}\) and \(\dot{\theta }_{\text{mT}}\) are the initial rotation speed, real-time rotation speed and target rotation speed, respectively, r/min. Because the drum load is related to the traction speed, cutting resistance and cutting motor speed, the permissible target speed of cutting motor differs from different conditions. Taking 300 N mm−1 cutting resistance as an example, at different cutting motor speeds, the permissible target speed of cutting motor increases with increasing traction speed, which is shown in Fig. 9.

4.2 Simulation analysis of the optimized drum speed control strategy

The simulation conditions are the same as Sect. 2.2(2); the loaded conditions of cutting transmission system have been compared under three types control strategies: non-regulation, the drum speed control strategy and the optimized drum speed control strategy.

From Fig. 10, we can see that, using the optimized drum speed control strategy, the mesh force of gear ring, electromagnetic torque of cutting motor and input torque of ranging arm are reduced from 7.96 × 105 to 7.73 × 105 N, from 3210 to 2700 N m and from 2744 to 2668 N m, respectively, compared to the drum speed control strategy. The values decreased by 2.89, 15.89 and 2.77%, respectively, which means that the optimized control strategy can effectively reduce the load overshoot of the cutting transmission system.

4.3 Simulation analysis of the optimized traction-drum speed combined control strategy

The simulation conditions are the same as Sect. 2.2(3); the loaded conditions of cutting transmission system have been compared under three types control strategies: non-regulation, the traction-drum speed combined control strategy and the optimized traction-drum speed combined control strategy.

From Fig. 11, we can see that, using the optimized combination control strategy compared to the non-optimized control strategy, the mesh force of gear ring, electromagnetic torque of cutting motor and input torque of ranging arm are reduced from 6.49 × 105 N, 2675 and 2239 N m to 6.24 × 105 N, 2450 and 2153 N m, respectively, in the process of cutting motor speed regulation. The values decreased by 3.85, 8.41 and 3.84%, respectively, which means that the optimized combination control strategy can effectively reduce the load overshoot of the cutting transmission system.

To summarize, compared to the non-optimized control strategies, the optimized control strategies not only can reduce the drum load under sudden-changing load, but also can restrain the load deterioration of cutting transmission system caused by cutting unit inertia in variable speed process, and the expected objects have been achieved.

4.4 Experimental verification of speed regulation control strategies

The test bench has been built to prove the effectiveness of the proposed control strategies. The cutting motor in simulation study is MG300/700 with rated power of 300 kW, so the test bench has been built using similarity theory as shown in Fig. 12. The test bench adopts DTC motor with rated power of 15 kW to simulate cutting motor and, at the same time, adopts two-stage parallel shaft reducer and single-stage planetary reducer to simulate transmission system of ranging arm, whose total reduction ratio is 41.5. The flywheel is used to simulate drum inertia. The loading system is composed of AC electrical dynamometer and hydraulic brake. The brake is mainly used to assist the dynamometer in producing high-frequency sudden-changing load. As the maximum speed of flywheel is 40r min−1, the speed increase gearbox has been designed between flywheel and loading system. A real-time measurement and control system based on dSPACE is developed. During the experiment, the control system of test bench selects the control strategies of the shearer automatically according to the simulated target cutting resistance of the loading system.

The speed regulation experiment of shearer has been carried out based on the test bench, and the experimental results are shown as the following:

(1) Experimental comparison of drum speed control strategy before and after optimization when Ap < Ap0

During the experiment, the traction speed maintains 3 m min−1, and the cutting motor increases from 1200 to 1300r min−1 within 1 s. The experimental results are shown in Fig. 13.

The results show that the drum speed control strategy can reduce the load of cutting transmission system after completing speed regulation, and in the variable speed process, there is a sudden increase in the system load. When using the optimized drum speed control strategy, the load fluctuation can be reduced significantly.

(2) Experimental comparison of traction-drum speed combined control strategy before and after optimization when Ap > Ap0

During the experiment, the initial speed of cutting motor is 1200r min−1. The traction speed reduces from 3 to 2 m min−1 within 1 s, then the cutting motor speed increases to 1300r min−1, and at last, the traction speed should be back to 3 m min−1. The experimental results are shown in Fig. 14.

The results show that the traction-drum speed combined control strategy can significantly reduce the load of cutting transmission system after completing speed regulation, and in the variable speed process, there is also a sudden increase in the system load. When using the optimized combination control strategy, the load fluctuation can be reduced significantly.

5 Conclusions

-

1.

Based on analyzing the influence factors of drum load and coal productivity, the drum speed control strategy and traction-drum speed combined control strategy were proposed. When the sudden-changing load is small, the drum speed control strategy can reduce cutting unit load effectively and maintain the coal productivity; when the sudden-changing load is large, the traction-drum speed control strategy can reduce cutting unit load significantly and have a minor effect on coal productivity.

-

2.

Aiming at the load overshoot of cutting transmission system in the variable speed process, the electromagnetic torque of cutting motor in non-regulation has been set as the upper limit. Based on the upper limit values, the speed change rate of cutting motor of the tow control strategies is optimized. The simulation results show that the load overshoot can be decreased with the optimized control strategies.

-

3.

Based on the established shearer test bench and its measurement and control system, the experiments have been carried out to verify the conclusions. The effectiveness of the two control strategies has been proved, and the experimental results also demonstrate that the optimized control strategies can reduce the load overshoot of cutting transmission system effectively.

References

Qian Y (2016) China’s coal consumption accounted for half of the world. Beijing Business Today, 25 May

Fang XQ, Zhao JJ, Hu Y (2010) Tests and error analysis of a self-positioning shearer operating at a manless working face. Min Sci Technol 20(1):53–58

Sahoo R, Mazid AM (2009) Application of opto-tactile sensor in shearer machine design to recognise rock surfaces in underground coal mining. In: IEEE international conference on industrial technology Victoria, pp 1–6

Hoseinie SH, Ataie M, Khalookakaei R et al (2011) Reliability modeling of hydraulic system of drum shearer machine. J Coal Sci Eng 17(4):450–456

Wang DY, Wang H (2016) Experimental study on the roadheader cutting load at different coal and rock properties. J Mach Des 33(5):75–79

Liu SY, Du CL, Zhang JJ et al (2011) Parameters analysis of shearer drum loading performance. Min Sci Technol 21(5):621–624

Li XY, Huang BB, Li CC et al (2012) Dynamics analysis on roadheader cutting head based on LS-DYNA. J Converg Inf Technol 7(23):333–340

Ma ZL (2012) Modelling and simulation on shearer self-adaptive memory cutting. Procedia Eng 37(4):37–41

Ma ZL (2009) Study on key technology of shearer with variable speed cutting. Ph.D. Dissertation, China University of Mining and Technology

Qin DT, Wang Z, Hu MH et al (2015) Dynamic matching of optimal drum movement parameters of shearer based on multi-objective optimization. J China Coal Soc 40(2):532–539

Liu SY (2009) Research on cutting performance of shearer drum and cutting system dynamics. Ph.D. Dissertation, China University of Mining and Technology

Liu CS, Yu XW, Ren CY (2010) The drum shearer working bodies. Harbin Engineering University Press, Harbin

Ge SS, Qin DT, Hu MH (2015) Research on drum shearer speed control strategies under impact conditions. J China Coal Soc 40(11):2569–2578

Liu CZ, Qin DT, Liao YH (2016) Dynamic analysis for the cutting electromechanical transmission system in the long-wall shearer. J Mech Eng 52(7):14–22

Shu RZ, Liu ZJ, Liu CZ et al (2015) Load sharing characteristic analysis of short driving system in the long-wall shearer. J Vibroeng 17(7):3572–3585

Li J (2013) Reliability study of new shearer cutting unit working in thin coal seam. B.S. Dissertation, Liaoning Technical University

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Victor Juliano De Negri.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Hu, J., Zha, J., Liu, C. et al. Research on drum shearer speed control strategies under sudden-changing load. J Braz. Soc. Mech. Sci. Eng. 40, 323 (2018). https://doi.org/10.1007/s40430-018-1252-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1252-z