Abstract

Salt crystallization is the most important weathering processes that causes problems for rocks used as building stones. Therefore, assessment of the physico-mechanical properties of stones against cyclic salt crystallization is a critical issue for rock engineering applications in salty environmental conditions especially prone to abrasion. This research aims at investigating the relationship between the degradation of various physico-mechanical properties including apparent porosity, point load index, unconfined compression strength and abrasion loss rate for rocks during salt weathering process. For showing rock weathering in the salt crystallization process, five kinds of carbonate rocks were sampled from different areas of Egypt and subject to cyclic salt crystallization, up to twenty cycles. The variation rates of their physico-mechanical characteristics and abrasion loss values were calculated after each five cycles of salt weathering. The results showed that the studied rocks are suitable for use as building and decorative stones in areas prone to crystallization of salts, but attention must be paid to rocks with high porosity and low strength characteristics such as El-Minia limestone specimens. It was also found that there are strong linear correlations between the physico-mechanical degradation parameters and the abrasion loss rate of the studied rock samples at the end of the twentieth cycle of salt weathering. These relationships may be used to estimate the abrasion loss rate of the studied rock types against the cyclic salt weathering conditions and hence to make a rapid evaluation of the stone durability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Carbonate rocks have been used as building stones in ancient and modern buildings from ancient times until present day (Garcia-del-Cura et al. 2012; Bell 1993). The physico-mechanical and petrographic characteristics of rocks are significant for selecting stones for different applications (Bayram 2012). Unconfined compression strength and point load strength are one of the most significant mechanical characteristics to evaluate the rock durability under weathering agents (Jamshidi et al. 2016). The abrasion loss is the most significant mechanical parameter for the rocks used as building stones in the floors and in areas that are exposed to heavy traffic (Iphar and Goktan 2006). Therefore, the variation in the rock characteristics under weathering conditions can cause problems for their durability over time (Jamshidi et al. 2013).

The environmental conditions are very significant factor in the weathering of rocks. For instance, in salty environment conditions, for selecting the most appropriate stone for the places that are subject to traffic, the abrasion loss value after the salt aging process is determined. Salt crystallization is one of the most significant physical weathering processes in the deterioration of rocks, especially in marine environmental conditions (Doehne and Price 2010). Crystallization pressure is the most significant degradation mechanism that occurs due to the salt weathering process, which depends on the porosity and water absorption capacity (Benavente et al. 1999). Growth of salt crystals in pores can exert a stress enough to reach the rock strength and new microcracks are formed and the existing ones are widened. As a result, their porosity, physico-mechanical characteristics and durability are altered (Coussy 2006; La Iglesia et al. 1997). Consequently, it is needed to understand the variation of the rock characteristics during the cyclic salt crystallization.

Many studies used the salt crystallization weathering process for evaluating the durability of rocks used as building and construction stones (e.g. Abdelhamid et al. 2022; Ruffolo et al. 2017; Jamshidi et al. 2016; Menendez and Petranova 2016; Barone et al. 2015). Cultrone et al. (2012) studied the petro-physical and durability characteristics of sedimentary rocks used as construction materials for evaluating their quality. Yavuz et al. (2008) investigated tests on eleven various carbonate rocks for determining abrasion properties of some carbonate stones under three-body abrasion and relations between abrasion and stone characteristics. They found that correlation between abrasion and rock hardness is logarithmic. The variations in the values of Bohme abrasion of the specimens during the salt weathering process are also investigated by Yavuz et al. (2006). They showed that the loss of Bohme abrasion of aged tuffs was 60%. The weight variations of sedimentary rocks used as building stones against the salt crystallization are determined by Vazquez et al. (2013 ). Yavuz et al. (2005) studied the abrasion behavior of some marble rock specimens. They found important relationships between abrasion and hardness and grain size of marble samples. Ghobadi et al. (2014) studied the petro-physical and the durability experiments on sandstone rocks used as construction stones to assess their quality by using Analytical Hierarchy Process (AHP). MacGregor and Chiu (2000) carried out experiments on two granitic rock samples and two marble samples to determine their abrasion resistance in flooring tiles.

Deterioration of rocks under the impact of the salt crystallization process has been investigated by many studies (e.g. Khodabandeh and Rozgonyi-Boissinot 2022; Lezzerini et al. 2022; Çeli and İbrahimoglu 2021; Çelik and Sert 2020; Benavente et al. 2018; Çelik and Tigli 2018; Bozdag et al. 2016; Temraz and Khallaf 2016; Barone et al. 2015; Ludovico-Marques and Chastre 2012; Akin and Ozsan 2011). However, there is a lack in determining the change in the strength properties regarding abrasion loss value of rocks due to the cyclic salt crystallization process (e.g. Yavuz et al. 2008; Vazquez et al. 2013; Yavuz et al. 2006; Eren and Bahali 2005; Mac-Gregor and Chiu 2000). Therefore, this study is an attempt to predict the abrasion loss rate with the help of the physico-mechanical degradation parameters such as apparent porosity, point load strength, and uniaxial compression strength of some Egyptian carbonate rocks used as building and ornamental stones due to the cyclic salt crystallization. It also aims to investigate the effect of salt crystallization action on the physico-mechanical characteristics of the studied rock samples and to assess the relationships between the changes in the physico-mechanical characteristics and abrasion loss parameter. Overall, this work contributes to the preliminary stage of design, construction and safety evaluation of rock engineering in salty or marine environments.

2 Materials and methods

2.1 Materials

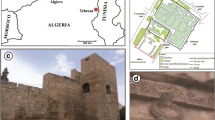

In this work, five types of carbonate rocks were quarried from different provinces in Egypt such as; El Minia limestone-LEM; North Sinai limestone-LNS; Cairo limestone-LC; Red Sea marble-MRS; and South Sinai marble-MSS (Fig. 1). These stones are used for construction and decorative purposes. Large blocks were chosen for each rock type, which had a size of 25 cm × 30 cm × 30 cm to 30 cm × 35 cm × 35 cm. Cylindrical samples of 5.4 cm in diameter were obtained (Fig. 2). The selected samples were free from cracks and /or joints to avoid the anisotropy influence. In this work, two sets of specimens were prepared for each rock type for determining the physico-mechanical characteristics prior and after the salt weathering action. The first set was used to determine the main characteristics of the studied rock samples (untreated). The second set were subjected to salt crystallization aging cycles (treated) and then the variation rates of rock properties such as; apparent porosity; abrasion loss; uniaxial compression strength; and point load index strength were determined at the end of each five cycles of salt weathering.

2.2 Petrographical properties

Rock petrographical features provide information about their mineralogical composition and provenance (Jamshidi et al. 2013). For the mineralogical composition and texture properties, thin sections of the studied rock samples were examined under polarized optical microscope (POM) analysis. Thin section studies indicate that the major mineral constituent of the selected samples is calcite associated with some accessory minerals. The major petrographical features of the selected samples are presented in Table 1.

2.3 Chemical analysis

In this work, X-ray Fluorescence (XRF) analysis was carried out to investigate the chemical composition of stone samples. Representative specimens were analyzed to determine the weight percentage of significant major element oxides (Table 2).

2.4 Physical characteristics

The physical characteristics are the critical parameters for determining the durability of natural rocks used as building and construction material (Shakoor and Bonelli 1991). Presence of water in the rock is a critical factor for most of the weathering tests (De Kock et al. 2017; Stuck et al. 2013). Therefore, in this work, the physical properties of the studied samples including; the bulk density; water absorption; effective porosity were determined. The physical parameters were determined according to the test methods outlined by ASTM (2001) and ISRM (1981) by using the saturation technique. Therefore, the mass of the oven dried specimens (Mdry), the mass of the saturated specimens (Msat), and the bulk volume (V) of rock samples were recorded and then the bulk density (ρb), the water absorption (Wabs), and the apparent porosity (ne) were calculated using Eqs. 1, 2, and 3 respectively:

Where, ρw is the water density.

The number of samples tested for each stone type was five and the average values of the mentioned physical parameters were determined.

2.5 Mechanical characteristics

The impact of weathering on the mechanical characteristics of natural rocks used as building stones cause durability problems. Therefore, in this study, the mechanical characterization of the rock samples were investigated by using the abrasion loss, uniaxial compression strength, and point load index strength tests.

2.5.1 Abrasion test

The studied rock samples were prepared and tested according to the procedures outlined by Ulusay and Hudson (2007); Selim (2016); and EN 14,157 (2004). The cross sectional area of the tested specimens was 7 × 7 cm2. The rock sample was placed in the holders of the abrasion machine and rotated 352 revolutions at a speed of 38 r.p.m (88 revolutions for each side of the specimen). Quartz sand (25–36 mesh) was utilized as an abrasive material at a rate of feed of 750 g per test. Rock samples were rotated in the reverse direction to that of the specimen surface during the tests according to the Egyptian Code 2010. During this experiment, the device rotated a grinding wheel while the sample was placed under 5 kg constant loads. The weight of each test specimen was determined before and after abrasion. The abrasion loss (loss in thickness of surface layer) was calculated by using the following Equation (Selim 2016):

Where, AL is the abrasion loss (mm), M1 is the weight of specimen before abrasion process (g), M2 is the mass weight of specimen after abrasion (g), ρ is the sample density (g/cm3), and A is the sample cross sectional area (cm2).

2.5.2 Uniaxial compression strength test

The uniaxial compressive strength of rocks is an important property for selecting rocks as building materials and ornamental stones as well as evaluating the stability of rock engineering against environmental conditions (Diamantis et al. 2009). This test provides also useful information for the rock durability assessment during different weathering processes. The unconfined compression strength test was performed on core specimens of 5.4 cm and a length of 10.2 cm according to the test methods proposed by standards NF EN 1926 (2007) and ISRM (1981). The uniaxial compression strength test was carried out by using a universal testing machine, with a maximum capacity of 200 Tons and loading stress rate between 0.1 and 0.2 kN/s. The rock sample surfaces were flattened, parallel to each other and perpendicular to the sample axis. The loading path has been carried out from bottom to top. For determining the uniaxial compression strength, five samples from each stone type were tested and their mean values were obtained.

2.5.3 Point load index strength test

The point load method is an indirect test used to determine the strength of rock materials in the field and in the laboratory (ASTM 2008; Franklin 1985). The point load index strength was applied according to the test methods procedures outlined by ASTM D 5731 (2005) and ISRM (1985). The axial point load test methods were conducted on cylindrical samples with a diameter of 5.4 cm and the ratio between the length and the diameter of the samples was 0.9. The rock specimen is placed so that the loading platens are parallel to its core axis. The number of tested rock samples for each stone type was five and the mean values of the point load strength were determined.

2.6 Salt crystallization aging process

The salt-crystallization weathering test (S-C) was carried out according to the test procedures outlined by Rothert et al. 2007. This test was conducted on cylindrical samples of 5.4 cm by total immersion in a solution of sodium chloride (10%) to study their resistance to disintegration experimentally and determine the physico-mechanical characteristics and their change rates. In this study, all rock samples were subjected to salt-crystallization weathering test, up to twenty cycles. The salt-crystallization process was consisted of three stages (Fig. 3). In the first stage (immersion), the clean and dried rock specimens were placed in a container and covered with the solution of sodium chloride above the top of the specimens to soak for a period of 4 h and the container was covered for reducing evaporation. In the second stage (drying), the specimens were taken out from the solution and dried in an air-ventilated oven at 60 °C for 16 h. In the third stage (cooling), the specimens are cooled at room conditions 20 °C for a period of 4 h. Each S-C cycle requires 24 h to be completed. In this study, two series of the rock specimens were prepared; one set of these specimens was used to determine the initial physico-mechanical characteristics before salt-crystallization process (fresh specimens). The second set of the specimens was subjected to salt-crystallization process (weathered samples). At the end of every five cycles, the physical and mechanical characteristics of rock specimens and the variation rates were determined and evaluated.

3 Results and discussions

The average values of the main physico-mechanical characteristics and standard deviations of the studied rocks before the salt crystallization weathering process (untreated samples) are showed in Table 3. This table indicates that the mean values of bulk densities for rock samples range between 2.53 and 2.65. In general, marble samples have a higher bulk density than that of limestone samples. Water absorption of rock samples varies between 0.14% and 0.64% in MSC and LEM, respectively. The main values of porosity range between 0.35% (MSC samples) and 1.58% (LEM samples). As observed in this table, marble rocks have a lower water absorption and porosity than that of limestone rocks. The mechanical strength tests such as abrasion loss, point load index strength, uniaxial compression strength were presented in Table 3. As this table shows, the lowest abrasion loss of 0.62 mm for MSC samples compared to the highest abrasion rate (2.41 mm) for LEM specimens. Generally, marble rocks have the highest resistance to abrasion compared to limestone rocks. This table also shows the point load strength of rock specimens varies between 5.74 MPa and 8.88 MPa. Moreover, the uniaxial compression strength of these samples ranges between 48.40 MPa and 81.22 MPa. Overall, marble samples have a higher point load index and uniaxial compressive strengths than that of limestone specimens.

(ρb) bulk density, (Wabs) water absorption, (ne) apparent porosity, (AL) abrasion loss or loss in thickness of surface layer, (Is) point load index strength and (UCS) uniaxial compressive strength. (LEM) Limestone-El-Minia, (LNS) Limestone-North Sinai, (LC) Limestone-Cairo, (MRS) Marble-Red Sea and (MSS) Marble-South Sinai.

3.1 Evaluation of the physico-mechanical properties under cyclic salt weathering

As proven by numerous studies, the rock durability is a function of their physical and mechanical properties. Therefore, evolution of these properties is critical for the assessment of stone durability. Table 4 displays the evaluation of the physico-mechanical properties prior and after the salt crystallization weathering cycles. The abrasion loss, the apparent porosity, the point load index strength and the uniaxial compressive strength are determined after the end of each five cycles up to 20 cycles. Twenty five samples for every type of rock (Five samples for each type of rock after every five cycles) and then their average values and standard deviations were showed in Table 4.

As shown in Table 4, the results indicate that the values of the abrasion and the apparent porosity increased for all studied rock samples under the salt crystallization weathering cycles, while the values of the point load and uniaxial compressive strengths reduced. Depending on the literature survey, it was revealed that the porosity and /or capacity of water absorption are the most critical parameters affecting stone behavior due to the salt weathering process and control the durability of the rock samples (Akin and Ozsan 2011). It can be concluded that rocks with increasing porosity have a higher level of degradation than rocks with lower porosity.

According to the initial porosity values of the studied rock samples, it is found that the LEM specimens exhibit the highest porosity (1.58%) while the other studied samples were less than 1% (Table 3). It is expected that rocks with a higher level of damage have the greatest decrease in strength properties and the highest increase in the abrasion loss rate.

As seen in Table 4, the LEM specimens have the highest level of deterioration under the salt weathering cycles, whilst the lowest level of deterioration was for MSS samples. The main cause for such deterioration in the physico-mechanical characteristics is the high stresses caused by the deposition of salt crystals in the pore network of samples. Therefore, new micro fissures were developed and finally the rock deteriorated. As a result, the stone resistance to crystallization of salts is a significant parameter that assesses the stone durability (La Iglesia et al. 1997). Rock specimens of LEM and LC have the greatest values of the abrasion and the porosity during the salt crystallization and also have the lowest values of the point load and the uniaxial compression strengths in comparison with the other stones (Table 4). Consequently, these stones are less resistant to the salt weathering and less durable. It was also observed that the LNS specimens are more durable during the salt crystallization aging processes due to their higher strength values as compared to LEM and LC samples. Whilst, rock samples of MRS and MSS indicated a noticeable similarity in the properties during the salt crystallization cycles due to their low values of the abrasion and the porosity and high strength values (point load and uniaxial compression) in comparison with all studied rock samples.

Overall, the results of the salt crystallization weathering showed that limestone rocks have the lowest durability compared to marble rocks. Therefore, it is concluded that limestone rocks are more sensitive to the cyclic salt crystallization weathering than marble rocks.

For assessing the degradation in the physical and mechanical properties of studied rock specimens during salt crystallization weathering cycles, the variation rate in these parameters including, the abrasion loss, the apparent porosity, the point load index strength, and the uniaxial compression strength values were obtained after every five cycles up to 20. The change rate determines the degree of stone material decay. Therefore, the variation rate in abrasion and apparent porosity values due to salt crystallization weathering cycles is given by the following expression:

Where, ∆ is the variation rate of a property (abrasion, and porosity), Pf is the final property values after the end the cyclic treatment, and Pi is the initial property values of untreated samples. The variation rate in abrasion loss and apparent porosity values against salt crystallization cycles were depicted in Figs. 4 and 5. As observed in these figures, after the end of twenty cycles of salt crystallization weathering, the variation rates of abrasion loss (∆AL) and apparent porosity (∆ne) values increased in limestone samples than marble samples.

Based on these results, it can be observed in Fig. 4, the highest percent increase in abrasion loss after the end of twenty cycles is 14.1% for LEM specimens, while the lowest percent increase was for MSS samples (6.5%). Therefore, limestone specimens were found to be more prone to abrasion compared to marble samples. Also, it is noticed that there is a slight variation in the increase rate of abrasion loss after the fifth cycle up to the tenth cycle for MSS samples. These changes in abrasion loss values for these samples during salt crystallization cycles are due to differences in rock type and pores size distribution (Eren and Bahali 2005). As can also be seen in Fig. 5, the MSS samples exhibited the smallest increase in apparent porosity (3.1%), while the greatest increase was showed by LEM samples (8.9%) after the end of 20 cycles. It is thought that the increase in apparent porosity is caused by an increase in the number of microcracks and expansion of existing fractures within the stones during salt crystallization action (Akin and Ozsan 2011).

Based on these observations, the LEM samples are the most sensitive to the salt weathering action due to having the greatest increase in porosity and abrasion, whereas the MSS samples showed the highest resistance against salt crystallization action due to having the lowest increase in the porosity and abrasion.

Repeated salt weathering process leads to the formation and/or development of new micro-fractures and thus the mechanical strength of the rocks decreases. (Celik and Sert 2020). As mentioned above, when the studied rock samples were subjected to consecutive cycles of salt weathering, their point load and uniaxial compression strength decreased. The variation rate of the point load and uniaxial compression strengths for the tested rock samples against salt weathering cycles were identified by using the following equation:

Where, ∆ is the change rate of a property (point load index strength, and uniaxial compression strength), Pf is the final property values after the end of the cyclic treatment, and Pi is the initial property values of untreated samples. Figures 6 and 7 displayed the change rate of point load (∆Is) and uniaxial compression strength (∆UCS) values caused by the salt crystallization cycles.

As seen in these figures, at the end of twenty cycles of salt weathering, there is a strong decrease in the point load index and uniaxial compression strengths for limestone samples compared to marble specimens. As illustrated in Fig. 6, the LEM specimens exhibited the highest reduction in the point load strength (38.2%) whereas the lowest reduction was for MSS samples (18.7%) after the end of twenty cycles.

As can also be observed in Fig. 7, after the end of twenty cycles, the greatest decrease in the uniaxial compression strength was for LEM samples (34.7%), while the specimens of MSS showed the smallest decrease (12.4%). These results propose that the changes against the salt weathering cycles are due to widening or expansion of pores and fractures within the rocks samples.

Overall, it is concluded that the variation limits for the tested marble specimens are low which may support the resistance of marble rocks against the action of salt crystallization cycles compared to limestone rocks.

3.2 Investigating correlations between abrasion loss and physico-mechanical degradation

The regression analysis is one of the most commonly acceptable techniques for dataset analysis which may be proper when checking the relationship between the dependent variable and any other parameters (independent variables). Therefore, this method was used to investigate the correlations between the abrasion loss (∆AL) and the physico-mechanical deterioration rates (∆ne, ∆Is & ∆UCS) of the studied rock samples against the salt weathering cycles. In this study, we aimed to find the best relationships between ∆AL and ∆ne, ∆Is & ∆UCS in order to obtain reliable empirical equations. The fit degree to a line for each regression can be examined by the coefficient of determination (R2). The best fit line, regression line associated with the data obtained here is linear trend. Figures 8, 9, 10 and 11, show the relations between ∆AL and (∆ne, ∆Is & ∆UCS) at 5, 10, 15 and 20 cycles, respectively. As illustrated in Figs. 8, 9 and 10, there are no strong relations between abrasion loss (∆AL) and apparent porosity (∆ne) at 5, 10 and 15 cycles of salt crystallization weathering. However, Fig. 11 shows a strong correlation between the abrasion loss and the apparent porosity after the end of twenty cycles (R2 = 0.9275). It is thought that the increase of the number of salt weathering cycles led to an increase in the correlation between abrasion loss and apparent porosity. Figure 8 displayed a poorer correlation between the abrasion loss and the point load strength (∆Is) after five cycles of salt crystallization with low value of R2 of 0.3791. Whilst, as shown in Fig. 11, after the end of twentieth cycle, the best correlation between the abrasion loss and the point load strength were found (R2 = 0.9923). Moreover, the strongest relationship between the abrasion and the uniaxial compression strength (∆UCS) were obtained at 20 cycles of salt crystallization (R2 = 0.9471) (Fig. 11). It is observed that the point load and the uniaxial compression strengths exhibited the best correlations with the abrasion loss against salt crystallization weathering cycles. Overall, the results show that the data points are located near to the curves and scattered regularly around it. Therefore, the correlations obtained after the end of the twentieth cycle suggest that the studied parameters of the physico-mechanical deterioration (∆ne, ∆Is & ∆UCS) related to abrasion loss rate (∆AL) may be suitable for predicting the abrasion loss of the studied rocks against salt weathering process without need to do any testing. These correlations are positive and linear (Fig. 11). It can also be stated that the uniaxial compression and the point load methods are the best properties that show the degradation of rock samples and estimate the long term durability during the salt crystallization test.

4 Conclusions

Because of the difficulties experienced in the salt weathering test such as time consuming and specimen’s preparation, the use of the parameters of the physico-mechanical degradation of rocks due to the cyclic salt weathering may be significant in practical prediction of abrasion loss and in obtaining valuable information about the rock durability under the salt crystallization process. Therefore, in this research, the relationships between the abrasion loss rate and the deterioration of the physico-mechanical parameters such as the apparent porosity, the point load index and the uniaxial compression strength of some types of carbonate rocks against the cyclic salt crystallization weathering were investigated. The change in the physico-mechanical properties was determined after every five cycles of the salt crystallization process up to 20 cycles.

The major findings in our study include the following:

-

1.

The tested limestones are more sensitive to salt crystallization action than marbles. The tested limestone samples exhibited the greatest abrasion and porosity and the smallest strength values after the cyclic salt weathering compared to marble samples. Also, a slightly disintegration at the edges and corners of the samples after the end of the cyclic salt crystallization were seen in LEM specimens. Therefore, the studied rocks can be used as building and ornamental stones in salty environment conditions and in applications subject to abrasion. Nevertheless, more attention should be paid to limestone rock namely LEM because of their relatively high porosity and abrasion as well as low strength characteristics.

-

2.

The uniaxial compression and the point load methods are the best properties that show the deterioration of rocks during the salt weathering process and estimate the long term durability.

-

3.

The abrasion loss rate (∆AL) are in high correlations with the variation rates of the point load strength (∆Is), uniaxial compression strength (∆UCS) and the apparent porosity (∆ne) of the studied rock samples after the end of 20 cycles of salt weathering but the relationship between ∆AL and (∆Is & ∆UCS) are higher than that relationship between ∆AL and ∆ne. This is meant that these results support the superiority of the point load and uniaxial compression methods in showing the weathering of rocks against the cyclic salt crystallization. Therefore, these correlations may be useful in pre determining the abrasion loss rate of rocks under the cyclic salt weathering conditions at the preliminary stage of design but should be applied with the studied types.

The obtained results can also be used as a fundamental data for new rock engineering applications, replacement works as well as resource development in marine environmental conditions. However, the following studies should conduct investigations on several types of stones and use more advanced statistical methods with different tests to obtain a perfect evaluation of the relationships between the stone characteristics.

Data availability

The data used to support the findings of this study are included within the article in the section of results.

References

Abdelhamid MMA, Mousa BG, Waqas H, Elkotb MA, Eldin SM, Munir I, Ali R, Galal AM (2022) Artificial Thermal quenching and salt crystallization weathering processes for the Assessment of Long-Term degradation characteristics of some Sedimentary Rocks, Egypt. Minerals 12(11):1393. https://doi.org/10.3390/min12111393

Akin A, Ozsan A (2011) Evaluation of the long-term durability of yellow travertine using accelerated weathering tests. Bull Eng Geol Environ 70:101–114

ASTM (2001) Standard test method for density, relative density (specific gravity), and absorption of Coarse Aggregate. Annual Book of ASTM Standards, West Conshohocken, PA, USA

ASTM (2008) Standard test method for determination of the Point load Strength Index of Rock and Application to rock strength classifications. ASTM Publication, West Conshohocken, PA, USA

ASTM D 5731 (2005) Standard test method for the determination of the point load strength index of rock. American Society for Testing and Materials, Pennsylvania

Barone G, Mazzoleni P, Pappalardo G, Raneri S (2015) Microtextural and microstructural influence on the changes of physical and mechanical proprieties related to salts crystallization weathering in natural building stones. The example of Sabucina stone (Sicily). Constr Build Mater 95:355–365

Bayram F (2012) Predicting mechanical strength loss of natural stones after freeze–thaw in cold regions. Cold Reg Sci Technol 83–84:98–102

Bell FG (1993) Durability of carbonate rock as building stone with comments on its preservation. Environ Geol 21:187–200

Benavente D, Garcia del Cura MA, Fort R, Ordonez S (1999) Thermodynamic modeling of changes induced by salt pressure crystallization in porous media of stone. J Cryst Growth 204:168–178

Benavente D, Martinez–Martinez J, Cueto N, Ordoñez S, Garcia–del–Cura MA (2018) Impact of salt and frost weathering on the physical and durability properties of travertines and carbonate tufas used as building material. Environ Earth Sci 77:147

Bozdağ A, Bayram AF, İnce İ, Asan K (2016) The relationship between weathering and welding degree of pyroclastic rocks in the Kilistra ancient city, Konya (Central Anatolia, Turkey). J Afr Earth Sci 123:1–9

Çelik MY, Ibrahimoglu A (2021) Characterization of travertine stones from Turkey and assessment of their durability to salt crystallization. J Build Eng 43:102592

Çelik MY, Sert M (2020) Accelerated aging laboratory tests for the evaluation of the durability of hydrophobic treated and untreated andesite with respect to salt crystallization, freezing–thawing, and thermal shock. Bull Eng Geol Environ 79:3751–3770

Çelik MY, Tığlı R (2018) The investigation of the water repellent chemical influence on salt crystallization in high porous building stones. Gazi Univ J Eng Arc 34(1):535–552

Coussy O (2006) Deformation and stress from in-pore drying-induced crystallization of salt. J Mech Phys Solids 54:1517–1547

Cultrone G, Luque A, Sebastián E (2012) Petrophysical and durability tests on sedimentary stones to evaluate their quality as building materials. Q J Eng Geol Hydro 45:415–422

De Kock T, Turmel A, Fronteau G, Cnudde V (2017) Rock fabric heterogeneity and its influence on the petrophysical properties of a building limestone: Lede stone (Belgium) as an example. Eng Geol 216:31–41

Diamantis K, Gartzos E, Migiros G (2009) Study on uniaxial compressive strength, point load strength index, dynamic and physical properties of serpentinites from Central Greece: test results and empirical relations. Eng Geol 108:199–207

Doehne E, Price CA (2010) Stone conservation: an overview of current research. The Getty Conservation Institute: second edition. J Paul Getty Museum Publications, Los Ángeles, p 158

Egyptian code. http://www.eos.org.eg/public/en-us/

EN14157 (2004) Natural stone—determination of the abrasion resistance

Eren O, Bahali M (2005) Some engineering properties of natural building cut stones of Cyprus. Constr Build Mater 19:213–222

Franklin JA (1985) Suggested method for determining point load strength. Inter J Rock Mech Min Sci 22(2):53–60

Garcia-del-Cura MA, Benavente D, Martinez-Martinez J, Cueto N (2012) Sedimentary structures and physical properties of travertine and carbonate tufa building stone. Constr Build Mater 28:456–467

Ghobadi MH, Babazadeh R, Khodabakhsh S (2014) Petrophysical and durability tests on sandstones for the evaluation of their quality as building stones using Analytical Hierarchy process (AHP). Geopersia 4(1):25–43

Iphar M, Goktan RM (2006) Mermerlerde surtunme ile asınma kaybının uyarlan-abilir sinirsel-bulanık ag etkilesim sistemi yardımıyla kestirilmesi. Proceedings of MERSEM’2006, Turkey Marble and Stone Symposium, Afyon, 2–3:171–182

ISRM (1981) Rock characterization, testing, and monitoring. ISRM Suggested Methods, Pergamon Press, Oxford, UK

ISRM (1985) Suggested method for determining point load strength. Inter J Rock Mech Min Sci Geomech Abstr 22(2):53–60

Jamshidi A, Nikudel MR, Khamehchiyan M (2013) Predicting the long-term durability of building stones against freeze–thaw using a decay function model. Cold Reg Sci Technol 92:29–36

Jamshidi A, Nikudel MR, Khamehchiyan M (2016) Evaluation of the durability of Gerdoee travertine after freeze-thaw cycles in fresh water and sodium sulfate solution. Eng Geol 202:36–43

Khodabandeh MA, Rozgonyi-Boissinot N (2022) The Effect of Salt Weathering and Water absorption on the Ultrasonic pulse velocities of highly porous limestone. Period Polytech Civ Eng 66:627–639

La Iglesia A, Gonzalez V, Lopez-Acevedo V, Viedma C (1997) Salt crystallization in porous construction materials. I. Estimation of crystallization pressure. J Cryst Growth 177:111–118

Lezzerini M, Tomei A, Gallello G, Aquino A, Pagnotta S (2022) The crystallization effect of Sodium Sulfate on some italian marbles, Calcarenites and Sandstones. Heritage 5:1449–1461

Ludovico-Marques M, Chastre C (2012) Effect of salt crystallization ageing on the compressive behavior of sandstone blocks in historical buildings. Eng Fail Anal 26:247–257

MacGregor ID, Chiu KY (2000) Porosity and wear resistance in stone flooring tiles. J Test Eval 28:149–154

Menendez B, Petranova V (2016) Effect of mixed vs single brine composition on salt weathering in porous carbonate building stones for different environmental conditions. Eng Geol 210:124–139

Rothert E, Eggers T, Cassar J, Ruedrich J, Fitzner B, Siegesmund S (2007) Stone properties and weathering induced by salt crystallization of maltese Globigerina Limestone. Geol Soc Lond Spec Publ 271:189

Ruffolo SA, La Russa MF, Ricca M, Belfiore CM, Macchia A, Comite V, Pezzino A, Crisci GM (2017) New insights on the consolidation of salt weathered limestone: the case study of Modica stone. Bull Eng Geol Environ 76(1):11–20

Selim RMA (2016) Exploitation Management of Ornamental stone (Firan Solaf rejoin, South Sinai), Egypt. M.Sc. thesis, pp. 62

Shakoor A, Bonelli RE (1991) Relationship between petrophysical characteristics, engineering index properties and mechanical properties of selected sandstones.Environ Eng Geosci xxviii(1):55–71

Stück H, Plagge R, Siegesmund S (2013) Numerical modeling of moisture transport in sandstone: the influence of pore space, fabric and clay content. Environ Earth Sci 69(4):1161–1187

Temraz MG, Khallaf MK (2016) Weathering behavior investigations and treatment of Kom Ombo temple sandstone, Egypt—based on their sedimentological and petrogaphical information. J Afr Earth Sci 113:194–204

Ulusay R, Hudson JA (eds) (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring. Kozan of set, Ankara, pp 1974–2006

UNE-EN 1926 Natural Stone Tests Methods (2007) Determination of Uniaxial Compressive Strength. European Committee for Standardization. Bruxelles, Belgium

Vazquez P, Alonso FJ, Carrizo L, Molina E, Cultrone G, Blanco M, Zamora I (2013) Evaluation of the petrophysical properties of sedimentary building stones in order to establish quality criteria. Constr Build Mater 41:868–878

Yavuz AB (2006) Deterioration of the volcanic kerb and pavement stones in a humid environment in the city centre of Izmir. Turk Environ Geol 51:211–227

Yavuz AB, Turk N, Koca MY (2005) Material properties of the Menderes massif marbles from SW Turkey. Eng Geol 82:91–106

Yavuz H, Ugur I, Demirdag S (2008) Abrasion resistance of carbonate rocks used in dimension stone industry and correlations between abrasion and rock properties. Int J Rock Mech Min Sci 45:260–267

Acknowledgements

The authors thank Al-Azhar university, The Science, Technology & Innovation Funding Authority (STDF), and The Egyptian Knowledge Bank (EKB) for providing fund for this research. Thanks also for editor and the reviewers.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

Methodology: MMAA and BGM; Formal analysis: MMAA and BGM; Writing—original draft preparation: BGMand MMAA; Writing—review and editing: MMAA and BGM.

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work.

Ethical approval

All the guidelines of the Committee on Publication Ethics (COPE) have been followed during the preparation of the manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdelhamid, M.M.A., Mousa, B.G. A prediction method for abrasion loss rate of some Egyptian carbonate rocks due to cyclic salt crystallization weathering using physico-mechanical deterioration: insights from laboratory investigations. Acta Geod Geophys 58, 53–70 (2023). https://doi.org/10.1007/s40328-023-00401-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40328-023-00401-2