Abstract

In this study, we synthesized neat and loaded lead phosphate glass (PbO–P2O5) with the inclusion of Cr, Co, Ni, and Zn using an inexpensive sol–gel technique. These composites were then deposited on silica glass substrates. Our objective was to investigate the influence of these fillers on the properties of the glass. The concentrations of the fillers were varied from 0 to 16 wt%, and the resulting thin films were characterized by measuring the absorption coefficient and estimating the optical band gap at room temperature. Additionally, we measured the electrical resistivity of the semiconducting thin films as a function of filler concentrations and temperature. To assess the overall performance of the films, we calculated the figure of merit using the Iles and Soclof approach, considering the DC resistance versus free carrier concentration and absorption coefficient. Interestingly, our results revealed a significant improvement in the figure of merit at specific filler concentrations. The obtained results are comprehensive and provide detailed insights. They indicate that the thin films produced in this study have the potential to be useful in energy devices, particularly in applications involving P–N junctions and similar structures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Amorphous semiconductors of this work are metal-particle-containing lead phosphate glasses. These latters have garnered a lot of interest in both the solar and electronics fields. The investigated composites are comparable to the conventional semiconductors known as chalcogenide glasses, and they can be used in optical, electrical, and opto-electrical devices such image sensors, electrical switches, non-volatile memory, and optical data storage, among others [1,2,3]. As a result, research on optical and electrical properties has been ongoing for the past 20 years [2, 3]. It is well known that the loading of fillers affects the electrical and optical characteristics of amorphous semiconductors [4]. As a result, cost-effective sol gel preparation methods have been used to create amorphous thin films based on lead phosphate glass. This paper researched and analyzed various optical, electrical, and thermo-electrical properties, including optical constants, optical gap energy, Urbach energy, and electrical conductivity at ambient temperature and as a function of temperature.

Materials and methods

A method of nondestructive optical characterization is UV–Visible Spectrophotometry. Working with minuscule quantities of chemicals is possible. It offers details about the sample's optical characteristics, including light transmission and absorption, optical gap, and estimated layer thickness. Transmission measurements have been used to calculate the optical energy gap (Eg) and the absorption coefficient (α). Using a Shimadzu double beam spectrophotometer of model UV310PC, transmittance spectra of based phosphate glass thin films were measured in the spectral wavelength range 300–800 nm. Optical properties are the most important aspect of thin films. Therefore, we used a dual-beam UV–Vis spectrometer. One for the reference (glass substrate) and the other for the examined sample (thin film + glass substrate). The spectra obtained show a change in transmittance T (%) as a function of wavelength (nm) for different samples.

Results

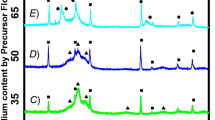

In Fig. 1, we have shown the transmission spectra in the range from 300 to 800 nm. Note that the produced films are loaded with different concentrations of metal particle precursors (Cr, Co, Ni, and Zn).

Figure 1 shows that the shapes of the spectra are almost identical and essentially consist of two regions: a region of strong absorption, which corresponds to the basic absorption (< 380 nm). This absorption results from electronic band–band transitions. The variation in transmission in this area is used to determine the optical gap.

-

A region of strong absorption which corresponds to fundamental absorption (λ < 380 nm). This absorption is resulting from band–band electronic transitions. The variation of transmission in this region is exploited for the determination of optical gap.

-

A region of high transparency located between 380 and 800 nm.

From the above depicted transmittance data, it can be seen that glass based thin films are almost transparent in the visible range. However, there is a decrease in the transmittance of lead phosphate glass thin films with the rise of metal particles concentration. This is more likely due to the increase of absorption phenomenon induced by increasing charge carriers concentration.

By exploiting these curves. It is possible to calculate optical characteristics (thickness and refractive index), optical absorption threshold (gap energy), absorption coefficient and the width of the band tails (Urbach parameter).

In the spectral range where the light is absorbed, and knowing the thickness of the thin film, we can determine the absorption coefficient [4]:

where d is film thickness and T denotes the measured transmittance. Note that this calculation implies that (1 − T) is the absorption of the layer. Whereas, in fact, a part of the incident light is neither absorbed, nor transmitted but is reflected, that is to say: A + T + R = 1. This approximation is less valid as the thickness of the layer is relatively low [5, 6].

Loading effect on optical transmission

Figure 1 shows transmittance spectra of loaded glass thin films ranging from 0 to 15 wt%. The spectra display the same shape for all the films. Moreover, it is observed for the whole studied films, that fillers loading increase leads to transmittance decrease. However, we notice that transmittance ascribed to nickel (at 10 wt%) and Zn (10 and 12 wt%) decreases more remarkably. This behavior seems to be related to the number of charge carriers increase with higher fillers loading. The system gradually tends toward a semiconducting behavior. Hence, more states are present for the photon energy to be absorbed thereby increasing the absorption [7, 8].

Optical gap and Urbach energy

The absorption coefficient is related to the photon energy and the gap Eg which is determined in the case of a semiconductor by Tauc’s relationship [9]

This relation can be also rewritten in logarithmic scale as:

where h is Planck’s constant, α is the absorption coefficient, ν is the frequency of absorption, B is a constant and sometimes called the band tailing parameter, and Eg is the optical energy gap, which is situated between the localized states near the mobility edges according to the density of states model proposed by Mott and Davis [10].The exponent n is a constant, which takes values for direct allowed or indirect allowed transitions as 1/2 and 2, respectively. Note that, the energy gap or the electron transition is tightly dependent upon the composition itself, its constituents and its electronic band structure as revealed by khashan et al. [11].

The obtained experimental curves (αhν) versus photon energy hν (Figs. 2, 3, 4, 5, and 6) were fitted with Eq. (2) in the almost end straight region using the mean square method, with n, B, and Eg as adjustable parameters [8] to ascertain whether the electronic transition that occurred in the studied samples is direct or indirect. Good correlation factors were used to get the results. Insets of Figs. 2, 3, 4, 5, and 6 depict them as solid lines, and Table 1 lists the extracted parameters (n, B, and Eg). Moreover, the obtained parameters were added to Eq. (3) in order to verify the accuracy of the method used.

a Determination of type of optical transition by plotting (αhν) versus photon energy (hν) using mean square fit of Eq. (2). b Representation of ln(αhν) against ln(hν − Eg) for PbP film

a Determination of type of optical transition by plotting (αhν) versus photon energy (hν) using mean square fit of Eq. (2). b Representation of ln(αhν) against ln(hν − Eg) for different PbP/Cr composite films

Determination of type of optical transition by plotting (αhν) versus photon energy (hν) using mean square fit of Eq. (2). b Representation of ln(αhν) against ln(hν − Eg) for different PbP/Co composite films

Determination of type of optical transition by plotting (αhν) versus photon energy (hν) using mean square fit of Eq. (2). b Representation of ln(αhν) against ln(hν − Eg) for different PbP/Ni composite films

Determination of type of optical transition by plotting (αhν) versus photon energy (hν) using mean square fit of Eq. (2). b Representation of ln(αhν) against ln(hν − Eg) for different PbP/Zn composite films

As can be seen the correlation between experiment and theory is good. This treatment may show that, the kind of the optical transition of the elaborated unloaded and loaded thin films is indirect with n + 2. The plot (αhν)1/2 versus hν, using the power factor n obtained by aforementioned fit, gives good agreement of band gaps and Tauc’s slopes (Table 1).

Figures 7, 8, 9, 10 and 11 exhibit the evolution of optical band gap with the variation of loading concentration corresponding to every metal particles (Cr, Co, Ni and Zn). The whole curves reveal that the obtained plots give a straight line in a certain region. In order to obtain the value of the indirect allowed optical energy gap (Eg) of thin films, we can extend this straight line to intercept with x-axis. The intersection of the tangent with the x-axis represents the gap Eg.

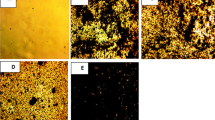

It is worthy to mention that in my earlier paper [12]. I outlined in detail how the resulting thin films are nanocomposites. I examined the elaborate thin films' structural characteristics and tracked how they changed with temperature and filler concentration. Additionally, the crystallite size D was determined using Scherrer's formula, and it was discovered that the cluster size for the four series of thin films is less than 16 nm.

The optical energy gap was estimated from the absorption coefficient values using Tauc’s procedure. It was found that the obtained optical gap is high for neat phosphate glass thin film, it exhibits a band gap value of 3.73 eV (Table 1). It is optically transparent and this means that no absorption of charge carriers was done, because they cannot be excited across such wide band gap. However, the bad gap Eg shifts toward lower values with the rise of metal concentrations, attaining a minimal value of 2.13 eV for the glass thin film loaded with 15 wt% Ni. These obtained results of indirect optical energy gap (Eg) are consistent with those found in some literature works [13, 14]. Also, the optical band gap values are close to the band gap obtained with spin coated on chalcogenide glass, as reported in previous studies [15], which evidenced that the investigated chalcogenide glasses can be regarded as amorphous semiconductors since their band gap can range between 1 and 3 eV. Thus, in our case, this shift is an expected behavior [16]. The obtained results are in good agreement with other previous works [17, 18].

The Tauc’s slope B of energy band gap decreases steadily from 48.87 × 109 (eV cm−1)1/2 for pure lead phosphate glass matrix to much more lower values for the four sets of composites (Table 1). This trend appears to be connected to the fact that as metallic concentration rises, so do the numbers of free carriers. In fact, the presence of metallic nanoparticles causes crystalline clusters to develop inside the amorphous matrix. The thin layers of the composite appear to be significantly affected in terms of electronic conduction by this. It appears that even at room temperature, the effect of developing crystal structure by adding metallic filler increases lattice quantized vibrations, increasing the longevity and density of the phonons. No matter how dense a material is, depending on its lattice-quantized vibrations, phonons are always present. Diffusion eliminates the phonon's influence in amorphous solids. However, when metal particles have a long-range periodic structure, as in the current instance, their energy is no longer negligible and they can be absorbed to aid in the transition. Thus, their interaction with electrons becomes important, enabling indirect interband transitions. Moreover, the electrons must share their energy with other particles for this action to occur. This seems to have prominent effect on electronic conduction of the composite’s thin films. It appears that even at room temperature, the effect of developing crystal structure by adding metallic filler increases lattice quantized vibrations, increasing the longevity and density of the phonons. No matter how dense a material is, depending on its lattice-quantized vibrations, phonons are always present. Diffusion eliminates the phonon's influence in amorphous solids. However, when metal particles have a long-range periodic structure, as in the current instance, their energy is no longer negligible and they can be absorbed to aid in the transition. Thus, their interaction with electrons becomes important, enabling indirect interband transitions. Additionally, for such activity to occur, the electrons need to interchange their momentum with phonons and their momentum with photons [8]. It has also been demonstrated that, unlike in a direct gap, where the conservation of momentum serves as the selection criterion, electronic transitions in an indirect gap do not have such a rule. Since the latter need a three-particle process involving an electron, photon, and phonon for the conservation of lattice momentum, the direct transitions would, therefore, predominate the absorption when the photon's energy approaches the energy of the direct gap rather than the indirect transitions. As a result, the process of indirect transitions can occur in two steps: first, energy is absorbed by the absorption of a photon, then momentum is conserved by emission or the absorption of a phonon [8]. In light of the preferred indirect transition of the investigated nanocomposites thin films, it appears that the contribution of phonon is significant in lead phosphate glass/fillers nanocomposites. Similar actions have been seen elsewhere [19].

Determination of Urbach energy

An important parameter, which characterizes the disorder in the material, is called the Urbach energy. It characterizes the disorder or defects in poor crystalline or predominantly amorphous solid. It is measured as width of exponential band tail energy of localized states, near band edges [23].

These exponential tails are mainly formed by structural disorder or defects, which produce localized states extended in the band gap. It is possible to deduce Urbach energy from the variation of the absorption coefficients.

In fact, the absorption coefficient is linked to the disorder by the law [24]:

where αo is a constant, h is the Planck’s constant, ν is the frequency of absorption and EU denotes the width of band tail or Urbach energy, which is weakly dependent upon temperature and is often interpreted as the width of the band tail due to localized states. This is associated with disordered or low crystalline materials.

Taking the logarithm of the two sides of the last equation, one can get a straight-line equation. It is given as follows:

Therefore, the band tail energy or Urbach energy (EU) can be obtained from the slope of the straight line of ln(α) against the incident photon energy (hν) (Fig. 12).

One can note that, the value of absorption coefficient depends on the filler fraction. This behavior is attributed to the absorbing nature of metallic particles. Thus, Urbach energy is tightly related on the absorption coefficient (Eq. (4)).

The value of Urbach energy varies in the range (0.065–0.51 eV). The obtained values in our study are comparable to those found by Fayek et al. [25]. They have interpreted Urbach energy as being the width of the bands of located states inside the width of the forbidden band.

The Urbach energy EU manifests increase, while Eg decreases from 3.68 (almost without tailing) to 1.32 eV when the conducting particles amount rises (see Table 1). The observed variation in EU indicates that the addition of metallic fillers creates some local structural order inside the phosphate glass matrix. This finding is presumably in good agreement with X-ray analysis, showing some crystallizations. Indeed, the PbP/metal nanocomposites consist of a heterogeneous binary system formed of an amorphous lead phosphate glass and a crystallized phase. The disorder is characterized by the tail width of valence or conduction band, the optical gap is the energy gap between the tails of bands. Thus, an increase in disorder with the rise in weight fraction of metal, is accompanied by a decrease in the optical gap. The increase of Urbach energy comes opposite to the narrowing of the optical band gaps with the rise in weight fraction of metal particles as shown in Figs. 13a, 14a, 15a, 16a and 17a. It is clear that the Urbach energy is coherent with the determined values of band gap energy (Figs. 13b, 14b, 15b, 16b). Such behavior was firstly observed by our equip on epoxy/Ag nanocomposites [8].

Thickness determination from optical transmittance

Thickness of the obtained films has been measured by optical interference methods, these later were used elsewhere [26, 27]:

In fact, in the case of a relatively thick and smooth layer, multiple reflections of the light take place between the lower surface in contact with the substrate and the free surface of the layer. This leads to the transmission spectrum containing interference fringes with minima and maxima as a function of the wavelength. Let us consider wavelengths (λ1 and λ2) related to two consecutive transmission maxima (TM1 and TM2) and Tm the transmission of the minima between the two maxima (see Fig. 18). The thickness of the obtained layers is determined from the following relation [28]:

n1 and n2 are the refractive index of the layer for the wavelengths λ1 and λ2, respectively. The index n1 and n2 are derived from the relationship [29]:

where S is the refractive index of the glass substrate and N1,2 can be calculated using the relation:

The obtained results are given in Table 1. As can be seen that the fillers loading might be influencing the growth rates of thin films. Also, this may result in a slight increase in film thickness as the metallic fillers content increased.

Refractive index

It is crucial to recall that in the given relation 7, the real component index n is defined as the ratio of the velocity c of light in a free medium to the velocity v. This index serves as a measure of the speed at which light propagates through a medium. Dispersion phenomena have a wavelength dependence that is typically described by Cauchy’s law. The extinction coefficient, an imaginary component, defines the absorption. It is significant to highlight that this work does not take the impacts of anisotropy into account. Therefore, we made use of the mean values.

The optical constants can be determined from the UV–visible transmittance spectra, using the approximate method (n >> κ) of Manifacier and Swanepoel [26, 27]. Thus, the refractive index n of the film is determined by Eq. (7). The refractive index values are compiled in Table 2, it is slightly increasing with increasing fillers content. Indeed, it was shown in that the density of the composite increases linearly with filler enhancement. This densification slows down the propagation of light by lowering its speed and, therefore, increases the refractive index.

However, refractive index remains relatively low, ranging from 2.17 to 2.43.

Elsewhere, the porosity of thin films is estimated from the following equation [30]:

where nD is the refractive index of pore-free lead phosphate glass and n is the refractive index of the porous thin films.

From this equation, we can assume the relationship between the refractive index and the porosity. Mathematically, low porosity led to the increase of n. Thus, in order to have remarkably higher refractive indexes, our films must be highly densified.

Note that the high absorption coefficient and the relatively low refractive index are two main criteria that make these materials good candidates for the realization of solar cells [30].

Electrical properties of loaded phosphate glass thin films

In aforementioned figures (from Figs. 17, 19, 20 and 21), the whole curves exhibit a prominent change in the slope at a specific threshold related to glass/metal composite film for both Urbach energy and optical band gap. The decrease of Eg and increase of EU becomes faster above this threshold. It seems that this behavior is related to the percolation transition. In order to assess this behavior, it will be more convenient to measure the DC conductivity at ambient temperature versus fillers loading variation.

DC conductivity measurements at ambient temperature

The DC conductivity is based on resistivity measurements. Studies of the electrical resistivity measurement by two-point probe method [31] were carried out within room temperature. Note that the resistivity represents its ability to oppose the flow of electric current. It is expressed in (Ω cm). The electrical Resistivity measurements at ambient temperature are performed through plotting current–voltage characteristics (I = f (V)), as showed in Fig. 22:

Current–voltage characteristics curves are exploited to extract the resistance from the slope of the linear curve. Note that the two-point measurement method was used to measure the electrical conductivity, as well as the variation of the electrical conductivity and the activation energy as a function of the annealing temperature (see next section).

The loading process of thin films may play a role in decreasing the electrical resistivity values; thus, it was suitable to measure the sheet resistance. Firstly, we have measured the electrical resistance of the deposited material. Then, knowing its dimensions, the calculation of sheet resistance can be easily performed using the following formula [32]

where ρ resistivity (Ω cm), Rs = ρ/d: electrical sheet resistance (Ω cm), w: width (cm), d: thickness (cm) which can be determined with optical measurements, L: length (cm).

And the conductivity is given by σ = 1/ρ (Ω cm)−1.

The curves of DC conductivity behavior versus metallic fillers concentrations are represented in Fig. 23.

According to Fig. 23, it is worthy to note that electrical conductivity of unloaded thin film is of the order of 10–7 (Ω cm)−1. It is nonlinearly enhanced when the concentration of metal transition particles is elevated. Typical curve shapes are obtained for thin films loaded with chromium, cobalt, nickel and Zinc particles. The studied thin films exhibit a sharp electrical conductivity transition at critical concentration (around 6 wt%). Thus, the conductivity is found to be expressing percolating behavior; this is quite similar to the previously examined conductivity behavior of bulk composites.

Like in the case of bulk composites, this behavior is more likely attributed to percolative phenomenon. Indeed, above the percolation threshold, the composites become semiconductor and their number of carriers increases significantly. Therefore, the gap must drop significantly, in good agreement with Burstein–Moss theory [33, 34].

Correlation of electrical findings with optical, structural and morphological properties

Optical transmission spectra of thin films were plotted in the spectral range of 300–800 nm. It was found that the determined optical gap decreases with increasing fillers concentration.

The minimal band gap value is achieved at the highest loading level for all the elaborated thin films. However, even at elevated fillers concentrations, the films are still retaining relatively transparent quality (T% ≈ 40%).

These results are in good agreement with the electrical conductivity curves, which are increasing progressively as a function of the fillers concentration, they express sharp and sudden increase of 7 orders of magnitudes at critical fillers concentrations. The enhanced electrical conductivity is probably due to the increase in free carriers within the insulator glass films. In this case, the free charge carriers contribute to the increase of the mobility and thus give arise to electrical conductivity of nanocomposite thin films. After examining the structural, morphological, optical and electrical properties of the elaborated nanocomposites thin films, it should be concluded that all the findings are perfectly corroborating.

Evaluation of thin films performance through the calculation of figure of merit

The optical and electrical properties of thin films are very important features for all known transparent conducting oxides (TCO) applications. Ideally, a good TCO is recognized by optical transmission factors as well as high electrical conductivity. This later is directly related to one of the most characteristic of transparent conductor thin films, which is the charge carrier mobility. Thus, the material is considered as performant when both, the optical transmission and electrical conductivity are important. These two parameters are inversely dependent and linked by a single factor called figure of merit (FOM). Figure of merit allows reasonable comparison of thin films properties and permits to estimate their opto-electrical performance [35].

Researchers have developed several methods for determining the figures of merit of the elaborated thin films. Fraser and Cook have set earliest equations [36]. In order to measure the thin films performance, the following equation is expressed:

where T is the transmission and Rs is the sheet resistance of the thin film.

Haacke has developed another equation defining strategy of the figure of merit calculation. It is noted FH [37]. It is also linked to the above-mentioned relation. However, FH puts more emphasis on the optical transparency because FFC was too much in favor of sheet resistance, resulting in a maximum figure of merit at relatively large film thicknesses. The figure of merit was redefined as:

where x > 1, Haacke’s definition is also thickness dependent.

Iles and Soclof established the third definition for figure of merit. It is independent of film thickness and is given by [38]

The inverse of the sheet resistance and the visible absorption coefficient allow the identification of the figure of merit.

By this definition, a low value of figure of merit indicates films of better quality.

The studied thin films represent a compromise between electrical conductivity and optical transmission. Reduction of resistivity involves either increase in the carrier concentration or in their mobility. Increasing the number of carriers leads to an increase in the absorption, while increasing the mobility has no negative effects on the figure of merit.

Unlike transparent conducting oxides (TCO) materials, amorphous thin films are usually electrically insulating. Therefore, they are not useful as a transparent conducting material despite their high optical transparency. To ensure that the material meets required criteria for transparent conducting applications, the charge carrier’s incorporation have been the popular approaches to be adopted so far. In fact, the performed heterogeneous mixture or composites lead to new physical properties such as high optical transparency and good electrical conductivity [37, 38]. One key criterion of their possible industrial applications is their electrical figure of merit. Such efficiency is determined as a ratio of the electrical conductivity to absorption coefficient. The figure of merit of amorphous thin film is given by [37]:

where σ [Ω−1]: electric conductivity, α [cm−1]: absorption coefficient, RSh [Ω] = \(\frac{\rho }{d}\): sheet resistance, T [%]: total transmission, R [%]: total reflection.

This is typically used to describe the material’s performance. Therefore, any choice of transparent and conducting material, for industrial application, should take into account the figure of merit quantity. Hence, a good material should have high electrical conductivity combined with low absorption coefficients. We show in Table 3 several figures of Merit for some commonly known transparent conducting oxides (TCO) as reported in the literature [37, 38]:

The above relationship expressing the figure of merit is practically the inverse of relation (13) and both are approximate because they assume very low absorption and high conductivity. That spurred us to find a compromise. It has been shown that, useful thin films must have FOM greater than or equal to 7 [20].

Thus, taking into account relationship (14), the variation of determined FOM values of the studied thin films as a function of fillers concentration is plotted in the inset of Fig. 24. We noted an enhancement of figure of merit values by increasing loading concentration.

Electrical conductivity presents a particular interest of semiconductor materials. Measuring the electrical conductivity of semiconducting thin films is a rather difficult problem, since it depends upon a series of factors whose actions cannot be separated, especially the temperature.

Temperature-dependent conductivity of glass composites thin films

The goal of this section is to present some experimental results related to the electrical conductivity dependence of loaded phosphate glass in thin film shape versus temperature.

The characterizations of the studied thin films were performed by determining temperature dependent dc conductivities through measuring electrical resistance of thin films with fixed concentration (we have chosen 6 wt%)versus varying temperatures from 300 to 500 K. Note that the current–voltage (I–V) measurements were performed on samples placed in the dark.

Schematically, the plots of Lnσ as a function of reciprocal absolute temperature (1000/T) take linear behaviors with slope changes at specific point as shown in Fig. 25.

The variation of Lnσ with reciprocal temperature exhibits two main linear parts. It is noteworthy that the slop changes did not occur at the same temperature for all samples. Thus, the slope change cannot be assigned to any change of structure, in a good consistence with the early XRD patterns [12], it is rather due to two different mechanisms of conduction.

The mechanism of amorphous semiconductor films is complex and depends on several parameters; such as the contribution of localized states in tail of bands or near the Fermi-level [39, 40] and the glass composition [41, 42].

Thus, at high temperature, the conduction is thermally stimulated following Arrhenius behavior and at lower temperature, it seems that, the process of this conduction is ensured by hopping of charge carriers in localized states near the Fermi level EF and in the tails of conduction and valence bands, this is corresponding to a transport type of variable range hopping (VRH) mechanism [20, 39]. This process is usually predominant at low temperatures [37]. Elsewhere, activation energy values in the same orders were obtained in similar phosphate materials [41,42,43,44]. It should be mentioned that, DC conductivity behavior versus temperature of the studied thin films is similar to bulk phosphate Pb/metals composites.

Generally, such variation in electrical conductivity as a function of temperature obeys to Arrhenius law which unquestionably characterizes a semiconductor. The conductivity of a semiconductor increases with temperature increasing. It was shown that increase in conductivity is also explained by the increase of the clusters size with the temperature of the substrate. Indeed, we have highlighted the variation in cluster’s size as a function of temperature of the substrate.

From these findings, it is possible to express the conductivity of nanocomposites thin films using the following expression:

\({\sigma }_{0}\) the pre exponential factor, \(\sigma \) is the DC conductivity, \(\Delta {\varvec{E}}\) is activation energy which is expressed as follows:

where EC defines the mobility edge in the conduction band of the films and EF is the energy of the Fermi level.

The modeling of DC conductivity versus the reciprocal of temperature is performed by introducing the logarithm in Eq. (15) as follows:

We can see that the activation energy is deduced from the slope of ln σ variation versus the inverse of the measurement temperature.

According to Fig. 25, electrical conductivity increases with increasing temperature, this behavior indicates that the conductivity is thermally activated. The variation of the activation energy of the electrical conductivity is reported in Table 4.

According to Table 4, it is noteworthy that the activation energy provides information on the position of the Fermi level, which is relative to the bottom of the conduction band. The nature of the states involved in transport essentially depends on the position of the Fermi level, which is typically halfway located between the last occupied state and the first empty level as reported by Adler and Yoffa [45]. We have clearly stated that band structure of amorphous or polycrystalline semiconductors and band structure of crystalline semiconductors are similar. It was noted that, the existing short range in amorphous semiconductors give rise to band-like structure of electron energy states similar to that of crystalline semiconductors.

The maximum value of the activation energies of PP/Cr and PbP/Co samples took values which are less than the half of the optical gap [46,47,48,49]. This is indicating that films are of n-type. Whereas the activation energies related to PbP/Ni and PbP/Zn express values greater than the half of the mobility gap assigned to each sample, respectively [49]. Consequently, they can be useful as p-type thin films [50]. Therefore, these sets of nanostructured thin films are potentially useful in industrial devices, as P–N junctions, etc. Thus, their practical application in materials development for energy sector needs to be carefully considered.

Conclusion

Thin films of lead phosphate glass-based nanocomposites were studied from an optical and electrical standpoint. High transmission properties (up to 70%) were demonstrated by thin films in the visible wavelength band. Higher filler loading was observed to be narrowing the optical band gap. Lead phosphate glass film loaded with metallic fillers at a rate of roughly 10 wt% produces the best estimated optical and electrical characterizations. A good figure of merit (FOM) is provided by the films at this loading rate (10 wt%). Thermally activated behavior at high temperatures and variable range hoping (VRH) at low temperatures were two conduction mechanisms that showed semiconducting nature in the measurement results of electrical conductivity thin films as a function of temperature. The examined thin films have the best chances to meet the rising needs for materials that may be used in optoelectronics, thermoelectricity and solar cells due to their optical transparency, electrical, and thermo-electrical conductivities, among other fascinating properties.

Data availability

The data that support the findings of this study are available from the corresponding author, Maryama Hammi, upon reasonable request.

References

Roumaih, K., Kaiser, M., Elbatal, F.H., Ali, I.S.: Transport properties of lead phosphate glass doped by cobalt, vanadium and chromium oxides. Philos. Mag. 91, 3830–3843 (2011)

Peng, M., Wondraczek, L.: Bismuth-doped oxide glasses as potential solar spectral converters and concentrators. J. Mater. Chem. 19, 627–630 (2009)

Shubha, G.N., Tejaswini, M.L., Lakshmi, K.P.: Advanced material for newer applications. Mater Today Proc 5, 2541–2546 (2018)

Aly, S.A.: Influence of film thickness on optical absorption and energy gap of thermally evaporated CdS0.1Se0.9 thin films. Chalcogenide Lett. 12, 489–496 (2015)

Owe, A.E.: Electronic and optical properties of amorphous semiconductors: their principles and applications. Doctoral thesis, University of Edinburgh, UK (1994)

Fridman: Optical properties and electronic structure of amorphous germanium. Phys. Status Solidi 15, 627–637 (1966)

Ganaie, M., Ahmad, S., Zulfequar, M.: Electrical transport mechanism in Cd5Se95−xZnx chalcogenide thin films. J. Mater. Sci. Mater. Electron. 27(1), 77–81 (2016)

Ashraf, S., Alam, A., Ashraf, S.S., Zulfequar, M.: Optical and electrical properties of chalcogenide glass thin film subjectivity in data mining: new interestingness measures of rules mining view project stock market prediction by using machine learning and deep learning approaches view project optical and electrical properties of chalcogenide glass thin film. (n.d.). https://www.researchgate.net/publication/328858868

Tauc, J., Menth, A.: States in the gap. J. Non Cryst. Solids 10, 569–585 (1972)

Davis, E.A., Mott, N.F.: Conduction in non-crystalline systems. V. Conductivity, optical absorption and photoconductivity in amorphous semiconductors. Philos. Mag. 22(179), 903–922 (1970)

Khashan, K.S., Saimon, J.A., Hassan, A.I.: Optical properties of CUO thin films with different concentration by spray pyrolysis method. Eng. Technol. J. 32, 86–93 (2014)

Hammi, M., El Haimeur, A.: Structural and morphological characterizations of glass based composites in thin films form. Heliyon 9(4), e14967 (2023)

Abdul-Ameer, N.M., Abdulrida, M.C.: Direct optical energy gap in amorphous silicon quantum dots. J. Mod. Phys. 2, 1530–1537 (2011)

Choi, J.Y., et al.: Engineering of band gap states of amorphous SiZnSnO semiconductor as a function of Si doping concentration. Sci. Rep. 6, 36504 (2016)

Thobega, M., Sathiaraj, S.T., Maabong, K., Muiva, C.M.: Topology of chemical ordering and influence on optical band gap in ternary Se–In–Bi chalcogenide glasses. (n.d.). www.pelagiaresearchlibrary.com

Singh, K., Saxena, N.S., Srivastava, O.N., Patidar, D., Sharma, T.P.: Energy band gap of Se100−x Inx chalcogenide glasses. Chalcogenide Lett. 3(3), 363–369 (2006)

Amany Abou Elseoud Elshazly, B., Zekry, A., Elarabi, M.S., Hatem Hassan Amer, P.: Amorphous semiconductors characteristics and their modern application supervised by Cairo 2013 acknowledgment (2002)

Belahcene, A., Kharroubi, M., Bourezg, Y.I., Harfouche, M., Gacem, L.: Experimental investigation on electric and dielectric properties of thallium ions doped sodium zinc phosphate glass. Phys. Status Solidi B. (2023). https://doi.org/10.1002/pssb.202300162. (accepted author manuscript)

Fritzsche, H.: Optical and electrical energy gaps in amorphous semiconductors. J. Non Cryst. Solids 6, 49–71 (1971)

Mott, N.F., Davis, E.A.: Electronic Processes in Noncrystalline Materials, 2nd edn. Clarendon, Oxford (1979)

Le Comber, P.G., Spear, W.E., Müller, G., Kalbitzer, S.: Electrical and photoconductive properties of ion implanted amorphous silicon. J. Non Cryst. Solids 356, 327–332 (1980)

Paquette, M.M., Nordell, B.J., Caruso, A.N., Sato, M., Fujiwara, H., King, S.W.: Optimization of amorphous semiconductors and low-/high-k dielectrics through percolation and topological constraint theory. MRS Bull. 42, 39–44 (2017)

Studenyak, P., Kurik, M.V., Kranjc, M.: On the Urbach rule in non-crystalline solids. J. Non Cryst. Solids 355, 54–57 (2009)

Urbach, F.: The long-wavelength edge of photographic sensitivity and of the electronic absorption of solids. Phys. Rev. 92, 1324–1324 (1953)

Fayek, S.A., Maged, A.F.: Optical absorption of glasses in the system (As2Se3)1−xTix. Mater. Sci. Eng. B 32, 47–49 (1995)

Manifacier, C., Murcia, D.M., Fillard, J.P., Vicario, E.: Optical and electrical properties of SnO2 thin films in relation to their stoichiometric deviation and their crystalline structure. Thin Solid Films 41, 127–135 (1977)

Swanepoel, R.: Determination of the thickness and optical constants of amorphous silicon. J. Phys. E Sci. Instrum. 16, 1214–1222 (1983)

Nenkov, M.R., Pencheva, T.G.: Determination of thin film refractive index and thickness by means of film phase thickness. Cent. Eur. J. Phys. 6, 332–343 (2008)

Nikam, P.S., Borse, R.Y., Pawar, R.R.: Composition dependence of electrical properties of Al-Sb thin films. Bull. Mater. Sci. 20, 1015–1021 (1997)

Kim, D.J., et al.: Influence of calcination temperature on structural and optical properties of TiO2 thin films prepared by sol–gel dip coating. Mat. Lett. 57, 355–360 (2002)

Singh, Y.: Electrical resistivity measurements: a review. Int. J. Mod. Phys. Conf. Ser. 22, 745–756 (2013)

Domaradzki, J., Kaczmarek, D., Drabczyk, K., Panek, P.: Investigations of electrical and optical properties of functional TCO thin films. Mater. Sci. Pol. 33, 363–368 (2015)

Burstein, E.: Anomalous optical absorption limit in InSb. Lett. Editor 93, 632–633 (1953)

Moss, S.: The interpretation of the properties of indium antimonide. Proc. Phys. Soc. 76, 755–782 (1954)

Sylvie, F.A.Ÿ. : L'oxyde de zinc par dépôt chimique en phase vapeur comme contact électrique transparent et diffuseur de lumière pour les cellules solaires. Ecole polytechnique Fédérale de Lausanne (EPFL), Thèse no 2899 (2003)

Fraser, D.B., Cook, H.D.: Highly conductive, transparent films of sputtered In2−xSnxO3−y. J. Electrochem. Soc. 119, 1368–1374 (1972)

Gordon, R.G.: Criteria for choosing transparent conductors. MRS Bull. 25, 52–57 (2000)

Maruyama, T., Kitamura, R.: Transformations of the wavelength of the lightincident upon CdS/CdTe solar cells. Sol. Energy Mater. Sol. Cells 69, 61–68 (2001)

Misrar, A., Saiter, J.-M., Vautier, C.: Dark conductivity or amorphous Ge0.08Te0.92 thin films. J. Non-Cryst. Solids 97, 671–674 (1987)

Nagels, P.: In: Brodsky, M.H. (ed.) Amorphous Semiconductors. Springer, Berlin (1986)

Šantić, B., Moguš-Milanković, A., Day, D.E.: The DC electrical conductivity of iron phosphate glasses. J. Non Cryst. Solids 296, 65–73 (2001)

Tawati, D.M., Jamel BashaAdlan, M., Johar Abdullah, M.: DC electrical conductivity of semiconducting cobalt-phosphate glasses. J. Non Cryst. Solids 357, 2152–2155 (2011)

Maaroufi, Oabi, O., Lucas, B., El Amrani, A., Degot, S.: New composites of ZnO–P2O5/Ni having PTC transition and high Seebeck coefficient. J. Non Cryst. Solids 358, 3312–3317 (2012)

Oabi, O., Maaroufi, A., Lucas, B., Degot, S., El Amrani, A.: Positive temperature coefficient and high Seebeck coefficient in ZnO-P2O5/Co composites. J. Non Cryst. Solids 385, 89–94 (2014)

Adler, D., Yoffa, E.: Electronic structure of amorphous semiconductors. J. Phys. Rev. Lett. 36, 1197–1200 (1976)

Optical and electrical properties of the Ge10InxSe(90−x) amorphous thin film. Egypt. J. Phys. 45, 39–47 (2017)

Pandey, V., Tripathi, S.K., Kumar, A.: Effect of In incorporation on optical properties of amorphous Se–Ge thin films. Phys. B Condens. Matter 388, 200–205 (2007)

Sharma, A., Barman, P.B.: Transport properties of amorphous Ge20Te80–xBix glassy alloys. Phys. Procedia 32, 144–151 (2012)

Wu, D., Zhou, H., Li, L., Chen, Y.: Gd/Mn Co-doped CaBi4Ti4O15 aurivillius-phase ceramics: structures, electrical conduction and dielectric relaxation behaviors. Materials 15(17), 5810 (2022). https://doi.org/10.3390/ma15175810

Ütten, M., Kaes, M., Albert, A., et al.: Relation between bandgap and resistance drift in amorphous phase change materials. Sci. Rep. 5, 173 (2015)

Acknowledgements

The article itself has never been published anywhere else, although parts of the present work's data have been partially given within the 12th International Conference on Chemistry Meeting October 20–21, 2022 | Webinar

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

The author confirms sole responsibility for the following: study conception and design, data collection, analysis and interpretation of results, and manuscript preparation.

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hammi, M. Exploratory study of potential usefulness of cost-effective composites thin films for energy device. Mater Renew Sustain Energy 12, 171–186 (2023). https://doi.org/10.1007/s40243-023-00238-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40243-023-00238-3