Abstract

In this work, we report that hydrogen (H2) doped in n-type a-Si:H thin films strongly influences the electronic correlation in increasing the conversion output power of solar cells. Type n a-Si:H thin films were grown using PECVD on ITO substrates with various H2-doping, to obtain various thin films for solar-cell applications. N-type a-Si:H thin films were prepared, and then characterized using ellipsometric spectroscopy, atomic force microscopy, Fourier transform infrared spectroscopy, and transmission electron microscopy. The addition of doped-H2 to the thin layer shows a decrease in optical conductivity, while the energy gap in the thin layer shows a significant increase in the a-Si:H-type thin layer. Our results show that H2 doping plays a very important role in the electronic structure, which is indicated by the significant energy gap difference. On the other hand, the bond structure of each H2-doped thin film showed a change from amorphous to nanocrystalline structures which were evenly distributed in each H2-doped bonding. Overall, we believe that the addition of doped-H2 to our findings could help increase the power conversion output of the solar cell due to the modification of the electronic structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

To create high-quality thin films for large-area devices like photovoltaic (PV) cells, a popular technology called plasma-enhanced chemical vapor deposition (PECVD) has emerged [1]. The formation of an a-Si:H thin film was found to be influenced by a number of deposition factors in the PECVD process, including gas flow rate, excitation power, pressure, substrate temperature, and dilution of the source gas (silane) with another gas hydrogen [2]. The glow-discharge decomposition of mixed SiH4 + H2 gas was used to create the a-Si:H films [3], which were then examined for how hydrogen dilution affected their structural and optical characteristics [4]. For the single p-type and n-type thin layers, a dopant is used in the form of mixing diborane gas (B2H6) for the p-type layer and phosphine gas (PH3) for the n-type coating into the gas source [5]. The thin-layer growth process is carried out using silane gas (SiH4) and hydrogen (H2) as gas sources [6]. However, the high localized state density in the extrinsic layer of amorphous silicon reduces the effectiveness of the doped process. The localized state density can be reduced by adding hydrogen gas [7], or what is popularly known as the hydrogenation process [8].

Electrical conductivity, layer thickness, and band gap are the most important parameters in p–i–n solar cells, because these three parameters influence each other, so each layer will affect the p–i–n structure [9]. Therefore, the quality of each layer (p-type, i-type, and type-n) must be considered, so that the optimum conditions for each layer will be obtained and the resulting efficiency in the application of solar cells will increase [10]. Film thickness and optical energy gap can also be determined from both optical transmission spectroscopy ellipsometry [11]. Although optical transmission is the most convenient and precise approach for analyzing thin films formed on transparent substrates [12], spectroscopy ellipsometry is the most suitable and effective alternative method [13]. This is because the substrate has no effect on ellipsometry [14]. Additionally, it has been utilized to analyze the kinetics of hydrogen interaction with a-Si:H during H2 plasma treatment as well as hydrogen diffusion into the films [15]. Through the analysis of the dielectric function using suitable models like the Tauc–Lorentz (TL) [16], Cody–Lorentz [17], Forouhi–Bloomer [18], Tetrahedral [19], Harmonic oscillator [20], and Bruggman Effective Medium Approximation (BEMA) [21]. To acquire accurate and reliable results, it is crucial to select an appropriate model and verify that best fitting.

Here, we present a novel approach to generating amorphous structures of silicon from SiH4 with H2 doped by the PECVD technique and reveal the detailed evolution of the electronic structure in n-type a-Si:H and their relationship to the performance of photovoltaic devices. The impact of intermittent hydrogen plasma treatment on the microstructure and optoelectronic characteristics of a-Si:H films is the topic of the current article. To explore the microstructure of the films, ex-situ spectroscopy ellipsometry measurements were carried out. The data were then analyzed using the TL and TL + BEMA models to find the optical constants, thickness, surface roughness, and volume fractions. Optimizing the deposition parameters of the PECVD system, which includes an increase in the rate of hydrogen gas, is expected to produce a single thin layer of a-Si:H type-n with optimum quality to improve the performance of solar cells based on a-Si:H p–i–n structure.

Experiment method

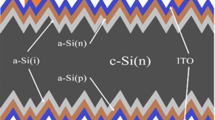

The a-Si:H thin layer is intrinsically deposited on corning 1737 glass and ITO substrates that do not use plasma waves plus chemical vapor chemical deposition (PECVD) techniques in key-based UHV space loads with a key electrode area of 19.62 cm2 and 4 cm electrode separation. The total deposition time for each film was kept constant at 30 min and 60 min. The deposition parameters for the doped of hydrogen SiH4/H2 are 0, 16, and 36, RF power 10 W, substrate temperature 270 °C, and process pressure (PP) 2000 mTorr. For N-0, no doped-H2 was carried out during precipitation, while for N-16 and N-36 hydrogen was diluted for 30 min and 60 min, as shown in Table 1. No plasma treatment is carried out on the film’s top surface. The scheme of precipitation and doped hydrogen for the sample is shown in Fig. 1.

For the characterization of hydrogenated a-Si:H, hydrogenated nanocrystalline silicon (nc-Si:H), and hydrogenated microcrystalline silicon (c-Si:H) films produced by RF-PECVD, numerous researchers have used the spectroscopy ellipsometry technique shown in Fig. 2 for the observed values of Ψ and Δ. The spectroscopy ellipsometry provides more precise structural information than Raman and can distinguish between nc/c-Si:H films and a-Si:H films [22]. With in-situ and ex-situ methods, the transition from the amorphous to the nc/c-Si:H phase can be qualitatively examined [23]. The real-time spectroscopy ellipsometry technique has provided a clear explanation for the structural phase transitions from a-Si:H to c-Si:H [24], the growth process of the films throughout various stages of film deposition [25], and the surface morphology of the films [26]. It has been effective to use spectroscopy ellipsometry during the nucleation phase of films as thin as monolayers.

The current article discusses the impact of doped H2 plasma treatment on the microstructure and optoelectronic characteristics of a-Si:H films. To study the microstructure of the films. The data were then analyzed using the TL + Gauss model and TL + BEMA models to determine the optical constants [27], thickness [28], surface roughness [29], volume fractions of the amorphous/microcrystalline phase [30], and voids in the films [31]. It was discovered that the estimated values agreed with those obtained from FTIR, transmission electron microscopy, and other methods.

Results and discussion

High-resolution TEM images on a-Si:H doped-H2 thin films are shown by electron diffraction patterns; a-Si:H doped-H2 thin film shows a dark contrast with a significant growth direction on H2-doped and a corresponding electron diffraction pattern is shown from the diffraction ring, as well as spots indicating mixed-phase amorphous and nanocrystal morphologies shown in Fig. 3. The enlarged TEM image also shows the formation of a nanocrystalline structure with the same nanocrystalline electron diffraction pattern for the a-Si:H doped-H2 thin film. Therefore, the a-Si:H doped-H2 thin film exhibits nanocrystals embedded in the amorphous thin film [32]. Here, there are morphological differences between a-Si:H thin films without H2-doped and with H2-doped a-Si:H which can cause appropriate differences in structural properties [33]. We further obtained an a-Si:H thin film without H2-doped and with H2-doped a-Si:H included in its hydrogen-related electronic structure characteristics.

Topographic measurements of a-Si:H surface thin films were carried out using the manufactured instrument by AIST-NT (Smart SPM 1000). This measurement uses tapping mode on a scan area of 1 μm by 1 μm, and the results of topographic measurements were evaluated using the Gwyddion 79 software including data leveling, and background reduction [34]. Figure 4 shows the topography and surface morphology of the sample with roughness values of 8.95, 6.20, and 3.50 nm, as shown in Table 2. The root means that the squared roughness values for the three a-Si:H thin films are around 0.1 μm. Based on these results, the surface roughness was not modeled for the ellipsometry spectroscopic evaluations as a separate layer. This observation shows an increase in structural orders with the doped-H2 [35]. It was also observed that the volume fraction of the amorphous and void phases decreased and the nanocrystalline phase increased with increasing plasma hydrogen phase.

To support the optical and electronic analysis of each sample, the surface roughness of the N-1 and N-2 samples was obtained, as shown in Fig. 4, which shows the surface morphology of N-1 and N-2 on a 2 × 2 μm2 film area. It is clear that this sample is very uniform across samples, small grain size is observed in sample N-1, and grain size increases in sample N-2. It is caused by changes in the nucleation and growth process on samples with an increase in gas-doped H2 [36]. The surface roughness value Root-Mean-Square (RMS) of the samples was obtained from AFM measurements of 5.45 and 6.12 nm according to the samples N-1 and N-2 samples. The a-Si:H n-type layer is measured at room temperature in the optical energy range of 0.6–6.6 eV. The results of the N-1 and N-2 fitting samples obtained information and parameters from the optical properties of the material, including refractive index, dielectric constant, thickness, and roughness of the n-type layer a-Si:H [37].

It has been possible to express the dielectric function of a-Si:H N-type films using a variety of models. The Tauc–Lorentz model, the Harmonic Oscillator model, the Gauss model, and a mixture of these models are the most often utilized models among these [38]. To calculate the amorphous, nanocrystalline, and void fractions in a-Si:H, the TL Model, and BEMA were also used. To fit the dielectric function of amorphous films N-type in our situation, we utilized TL and TL and Gauss model, respectively [39]. The band gap, optical constants, and thickness of these films are estimated using a two-layer system consisting of an ITO substrate, bulk layer, surface roughness layer, and air (Fig. 5a). The measured experimental ψ and Δ of photon energy and those obtained using model fitting are shown in Fig. 6a.

For films with the hallmark of nanocrystalline N-1, the Gauss model is used to fit the two band-to-band transition near 3.2 and 4.6 eV along with the TL model for fundamental transition near 3.6 eV. In contrast, for films with amorphous films N-0, the TL model alone could give a good fitting to the experimental data with a single peak in < ε2 > corresponding to a-Si:H around 1.0–4.6 eV shown in Fig. 7a. By deconvoluting the peak in the < ε2 > spectra of these samples using the peak fit algorithm of the software ORIGIN 8.5, the initial values of various peaks for the fitting were produced. Table 3 contains the values of the fitted parameters A, E0, C, and Eg. The values of the thickness and band gap were determined via UV–vis-NIR transmission.

We have also estimated the amorphous (fa), crystalline (fc), and void (fv) fractions as well as the thickness, band gap, and optical constants of the films using the TL model in conjunction with BEMA. To achieve this, we used a two-layer structure that included a corning substrate, bulk layer, surface roughness layer, and air (Fig. 5b). A blend of amorphous, crystalline, and void phases makes up both the bulk layer and the surface layer [40]. Figure 6b displays the experimentally measured and calculated photon energies as well as results from model fitting with TL + BEMA. Table 3 also includes the values of the fitted parameters A, E0, C, and Eg as determined by TL + BEMA. Along with the roughness values acquired from AFM, the computed values of the amorphous, crystalline, and void percent for both the bulk layer and rough surface layer are reported in Table 2. This observation shows an increase in structural orders with dilution of H2. It was also observed that the volume fraction of the amorphous and void phases decreased and the crystalline phase increased with increasing plasma hydrogen phase (Fig. 8). The thickness, band gap, and refractive index (at 632 nm) calculated using the two models also agreed with the values obtained from the UV–VIS transmission data. The roughness of the film from the AFM study is also very similar to the thickness of the rough surface layer (Fig. 9). The table clearly shows that the values of A, E0, C, and Eg between the two models (TL/TL + G and TL + BEMA) are in good agreement. With an increase in the number of H2 plasma doped steps, the value of the amplitude parameter (A) is found to rise, while the broadening parameter (C) is found to fall.

Our results show that with increasing hydrogen dilution not only does the total hydrogen content in the film increase, but the amount of hydrogen bound as strong Si–H also increases. Band gap increases, because the Si–H bond has a greater energy than the Si–Si bond and the valence band is lowered in the film. Figure 10 shows an increase in band gap with total hydrogen content in the film. It was observed that the band gap increased almost linearly with the total hydrogen content. The increase in hydrogen content can be understood as follows: During hydrogen plasma treatment, a small part of the amorphous phase is engraved and the nc-Si seed layer is formed [41]. This facilitates the movement of hydrogen atoms on the surface of the film and allows it to diffuse in large numbers and replace weak Si–Si bonds with strong Si–H bonds. With more plasma treatment steps, more hydrogen enters most of the film as the amorphous phase is etched and what remains is the more regular nc-Si phase [42]. This results in a change in peak position at < ε2 > toward higher energy. The peak amplitude < ε2 > was also found to increase with H2 and the widening parameter decreased (Fig. 10). The thickness of the film decreases with increasing hydrogen dilution; the growth rate is lower than the nc-Si: H. phase. Initially, when most of the amorphous phase will be scratched, its thickness decreases rapidly [43]. However, when most of the a-Si:H phase is carved with subsequent plasma treatments and the nc-Si phase remains stable, the rate of decrease in total thickness decreases.

Where there is a change in Ex-1 energy in the N-2 sample which changes the energy to a smaller one compared to the N-1 sample with a large change of 0.5 eV. Likewise, with the E x-2 value, this proves that at this energy, the N-2 sample can absorb more energy than the N-1 sample and ultimately can improve the performance of the n-type layer on a-Si:H p–i–n solar cell. It is explained that along with the addition of H2 gas to the N-1 sample in the deposition process, the Si atoms that will bind to H atoms will also increase in addition to bonding with fellow Si atoms [44]. The more Si atoms that are bonded, the less empty Si hands will be; in other words, the dangling bond which causes defects in the forbidden band gap is also reduced [45]. The reduced defects in the band gap will make it easier for the electrons in the valence band to jump or move to the conduction band, so that the electrical conductivity will increase with increasing doped of H2. Because H2 gas acts as a reduction in the defect condition in the band gap by passivating the dangling bond so as to bring an effective dopant [46]. However, the N-2 sample shows different results, where the electrical conductivity of the coating decreases. In addition to lowering disability, H2 incoming interstitials in tetrahedral bonding configuration can also make sure that the active dopant is PH3, so that H2 gas can limit the atoms that appear in the active dopant configuration (P4+) [47].

Figure 11 shows the FTIR spectra of the a-Si:H thin-film samples deposited at different film growth rates on the gas mixture of SiH4 and H2, respectively. The infrared absorption measurements of both samples showed very similar spectral results. The bonding that occurs in a-Si:H thin film shows relatively low Si–Hn-bond characteristics. The Si–H dangling bonds can be correlated to the passivation of the internal surfaces of microscale voids by trapping H2 molecules [48]. However, the relatively dense a-Si:H thin film N-0, as compared to the a-Si:H thin film N-2, showed a large intensity from the Si–H bond. This indicates that the a-Si:H thin film N-2 forms a reduced internal structure of nanoscale voids including the Si–H bonds. The structural change from microvoids to nanovoids induces an increase in the Si–H bond length, so that the band gap of the a-Si:H thin film decreased to that of the a-Si:H thin film N-2.

FTIR absorption spectra of the a-Si:H-doped H2 thin films grown by PECVD. The a-Si:H thin film shows the larger infrared light absorptions for the hydrogen-related chemical bonds of Si H at 2000 cm−1 and the a-Si:H thin film shows the chemical bonds of Si H2 at 2100 cm−1 as well as Si H at 2000 cm−1, indicating the existence of nanocrystalline grain boundaries saturated by H2 molecules

Figure 12 shows describe the model of a-Si:H type-n energy levels as a result of increased doped H2 gas, where the atomic state of H can diffuse into a new dangling bond. The dangling bond is then left behind by the H atom, which then recombines with D− to form a normal Si–Si bond [49]. The observed conductivity reduction was thought to be caused by the active dopant activation mechanism by H2, and it was found that the addition of a high doped of H2 made the doping ineffective, thereby reducing the electrical conductivity value of the a-Si:H type-n layer. Meanwhile, the increasing number of H2 atoms results in the re-formation of defects in the forbidden band gap but not as a dangling bond but in the form of another defect. This excessive number of H atoms results in the formation of a gap state in the energy band gap [50]. The existence of a gap state in the energy band gap will prevent electrons from jumping from the valence band to the conduction band. Electrons that should be able to move from the valence band must first pass through the gap state and then jump to the conduction band [51].

The effect of increasing H2 doped on the energy band gap width in the a-Si:H type-n layer, where the bandwidth of the energy band gap increases with increasing doped of H2. Increased doped of H2 plays a role in reducing the defects in the bandgap of amorphous silicon materials. The mechanism of defect reduction can occur where the atoms H will make the bonds Si empty into passive. Along with the addition of the H2 gas rate, the bonds of Si are empty and will be filled by the atoms H2, so that defects in the energy band gap will be reduced resulting in the shift of the valence band to the bottom and the valence band to the top. This will result in the widening of the energy band gap, so that the band gap will get bigger. Likewise, increasing the doped of H2 will slow down the rate of silane gas by most researchers associated with an increase in hydrogen concentration, which will reduce the thickness of the layer formed.

Conclusion

In summary, the effect of increasing H2 gas doped on the optical characteristics of the n-type layer a-Si:H deposition of the PECVD technique shows that the change in the energy gap increases along with the increase in H2 doped, but the increasing number of hydrogen atoms results in defects in the energy gap but not as a dangling bond but in the form of another defect. We observed that the microstructure factor is directly related to a void fraction in the films and to the amplitude of the imaginary part of the pseudo-dielectric function. The single TL model could not give accurate results in the case of mixed-phase films and TL + G model must be used to calculate the optical constants, thickness, and band gap of the films. Further, results obtained from the TL + G model have been compared with those obtained using TL + BEMA for the accuracy of the model. Meanwhile, the effect of increasing the H2 gas doped shows a decrease in the optical conductivity value of the a-Si:H type-n layer. On the other hand, the bond structure of each H2-doped thin film showed a change from an amorphous structure to a nanocrystal which was evenly distributed at each H2-doped binding. Overall, we believe that the addition of doped-H2 to our findings can help increase the power conversion output of solar cells due to modifications in the electronic structure.

Data Availability

The data used to support the findings of this study are included in the article.

References

Ma, D., et al.: Highly improved passivation of PECVD p-type TOPCon by suppressing plasma-oxidation ion-bombardment-induced damages. Sol. Energy 242, 1–9 (2022)

Pandey, A., Bhattacharya, S., Panigrahi, J., Mandal, S., Komarala, V.K.: Effect of gas flow rate in PECVD of amorphous silicon thin films for interface passivation of silicon heterojunction solar cells. Phys. Status Solidi A 219(16), 2200183 (2022)

Prayogi, S., Cahyono, Y., Iqballudin, I., Stchakovsky, M., Darminto, D.: The effect of adding an active layer to the structure of a-Si:H solar cells on the efficiency using RF-PECVD. J. Mater. Sci. Mater. Electron. 32(6), 7609–7618 (2021)

Khatami, Z., Bosco, G.B.F., Wojcik, J., Tessler, L.R., Mascher, P.: Influence of deposition conditions on the characteristics of luminescent silicon carbonitride thin films. ECS J. Solid State Sci. Technol. 7(2), N7 (2018)

Wang, Y., et al.: Use of phosphine as an n-type dopant source for vapor-liquid-solid growth of silicon nanowires. Nano Lett. 5(11), 2139–2143 (2005)

Dimitrakellis, P., et al.: Disilane as a growth rate catalyst of plasma deposited microcrystalline silicon thin films. AIP Adv. 6(7), 075306 (2016)

Rambhujun, N., et al.: Renewable hydrogen for the chemical industry. MRS Energy Sustain. 7(1), 33 (2020)

Navarro-Ruiz, J., Cornu, D., López, N.: Prevalence of trans-alkenes in hydrogenation processes on metal surfaces: a density functional theory study. J. Phys. Chem. C 122(44), 25339–25348 (2018)

Kherodia, A., Panchal, A.K.: Analysis of thickness-dependent optical parameters of a-Si:H/nc-Si: H multilayer thin films. Mater. Renew. Sustain. Energy 6(4), 23 (2017)

Prayogi, S., Cahyono, Y., Darminto, D.: Electronic structure analysis of a-Si:H p-i1-i2-n solar cells using ellipsometry spectroscopy. Opt. Quantum Electron. 54(11), 732 (2022)

Prayogi, S., et al.: Observation of resonant exciton and correlated plasmon yielding correlated plexciton in amorphous silicon with various hydrogen content. Sci. Rep. (2022). https://doi.org/10.1038/s41598-022-24713-5

Hillier, J.A., et al.: When ellipsometry works best: a case study with transparent conductive oxides. ACS Photonics 7(10), 2692–2702 (2020)

Joo, K.-N., Park, H.-M.: Recent progress on optical tomographic technology for measurements and inspections of film structures. Micromachines 13(7), 1074 (2022)

Kosyachenko, L.A.: Possibilities to decrease the absorber thickness reducing optical and recombination losses in CdS/CdTe solar cells. Mater. Renew. Sustain. Energy 2(3), 14 (2013)

Kanneboina, V., Agarwal, P.: Spectroscopic ellipsometry investigation to study the microstructure evolution in boron-doped amorphous silicon films as a result of hydrogen dilution. SN Appl. Sci. 3(4), 500 (2021)

Likhachev, D.V., Malkova, N., Poslavsky, L.: Modified Tauc–Lorentz dispersion model leading to a more accurate representation of absorption features below the bandgap. Thin Solid Films 589, 844–851 (2015)

Marcos, L.V.R., Larruquert, J.I.: Analytic optical-constant model derived from Tauc–Lorentz and Urbach tail. Opt. Express 24(25), 28561–28572 (2016)

Forouhi, A.R., Bloomer, I.: New dispersion equations for insulators and semiconductors valid throughout radio-waves to extreme ultraviolet spectral range. J. Phys. Commun. 3(3), 035022 (2019)

Huang, X., et al.: A density functional study of the structural, electronic, optical and lattice dynamical properties of AgGaS2. Results Phys. 35, 105309 (2022)

Moazzami Gudarzi, M., Aboutalebi, S.H.: Self-consistent dielectric functions of materials: toward accurate computation of Casimir–van der Waals forces. Sci Adv 7(22), 2272 (2021)

Liu, Y., Qiu, J., Liu, L.: Applicability of the effective medium approximation in the ellipsometry of randomly micro-rough solid surfaces. Opt. Express 26(13), 16560–16571 (2018)

Rojwal, V., Singha, M.K., Mondal, T.K., Mondal, D.: Formation of micro structured doped and undoped hydrogenated silicon thin films. Superlattices Microstruct. 124, 201–217 (2018)

Bayer, B.C., et al.: In situ observations of phase transitions in metastable nickel (carbide)/carbon nanocomposites. J. Phys. Chem. C 120(39), 22571–22584 (2016)

Mukherjee, D., Petrik, P.: Real-time ellipsometry at high and low temperatures. ACS Omega 8, 3684–3697 (2023)

Li, J., et al.: Spectroscopic ellipsometry. In: Abou-Ras, D., Kirchartz, T., Rau, U. (eds.) Advanced characterization techniques for thin film solar cells, pp. 215–256. Wiley, New York (2016)

Zollner, S., Abadizaman, F., Emminger, C., Samarasingha, N.: Spectroscopic ellipsometry from 10 to 700 K. Adv. Opt. Technol. 11(3–4), 117–135 (2022)

Yokosuk, M.O., Tiwald, T.E., Saunders, D.L., Blake, T.A., Myers, T.L.: Combining spectroscopic techniques to determine the optical constants of powdered lactose. Appl. Opt. 60(8), 2412–2421 (2021)

Richert, C., Odermatt, A., Huber, N.: Computation of thickness and mechanical properties of interconnected structures: accuracy, deviations, and approaches for correction. Front. Mater. 6, 2019 (2019)

Milenković, M., Pfeifer, N., Glira, P.: Applying terrestrial laser scanning for soil surface roughness assessment. Remote Sens. 7(2), 2007–2045 (2015)

Affonso, R.R.W., Dam, R.S.F., Salgado, W.L., da Silva, A.X., Salgado, C.M.: Flow regime and volume fraction identification using nuclear techniques, artificial neural networks and computational fluid dynamics. Appl. Radiat. Isot. 159, 109103 (2020)

Rad, S.Z.I., Peyvandi, R.G., Pour, H.G.: Evaluation of nuclear data analysis techniques for volume fraction prediction in the flow meter. Radiochim. Acta 111(1), 73–79 (2023)

Garozzo, C., et al.: Evolution of SiHx hydrides during the phase transition from amorphous to nanocrystalline silicon films. J. Appl. Phys. 111(4), 043510 (2012)

Li, Z., Li, W., Jiang, Y., Cai, H., Gong, Y., He, J.: Raman characterization of the structural evolution in amorphous and partially nanocrystalline hydrogenated silicon thin films prepared by PECVD. J. Raman Spectrosc. 42(3), 415–421 (2011)

Jiang, H., et al.: Structures and functional properties of amorphous alloys. Small Struct. 2(2), 2000057 (2021)

Pedrak, R., et al.: Micromachined atomic force microscopy sensor with integrated piezoresistive sensor and thermal bimorph actuator for high-speed tapping-mode atomic force microscopy phase-imaging in higher eigenmodes. J. Vac. Sci. Technol. B Microelectron. Nanometer. Struct. Process. Meas. Phenom. 21(6), 3102–3107 (2003)

Dzedzickis, A., et al.: Modification of the AFM sensor by a precisely regulated air stream to increase imaging speed and accuracy in the contact mode. Sensors 18(8), 2694 (2018)

Vora, A.: “Increasing solar energy conversion efficiency in thin film hydrogenated amorphous silicon solar cells with patterned plasmonic silver nano-disk array. Diss. Masters Theses Masters Rep. (2015)

Franta, D., Čermák, M., Vohánka, J., Ohlídal, I.: Dispersion models describing interband electronic transitions combining Tauc’s law and Lorentz model. Thin Solid Films 631, 12–22 (2017)

Bohórquez, C., Bakkali, H., Delgado, J.J., Blanco, E., Herrera, M., Domínguez, M.: Spectroscopic ellipsometry study on tuning the electrical and optical properties of Zr-doped ZnO thin films grown by atomic layer deposition. ACS Appl. Electron. Mater. 4(3), 925–935 (2022)

Khelil, M., Kraiem, S., Khirouni, K., Alaya, S.: Growth of crystalline silicon by a seed layer approach using plasma enhanced chemical vapor deposition. Phys. B Condens. Matter 609, 412817 (2021)

Gorodetskiy, D.V., Guselnikov, A.V., Kurenya, A.G., Smirnov, D.A., Bulusheva, L.G., Okotrub, A.V.: Hydrogen plasma treatment of aligned multi-walled carbon nanotube arrays for improvement of field emission properties. Materials 13(19), 4420 (2020)

Soman, A., Das, U.K., Hegedus, S.S.: Interface engineering by intermediate hydrogen plasma treatment using Dc-PECVD for silicon heterojunction solar cells. ACS Appl. Electron. Mater. 5, 803–811 (2023)

Beake, B.D., McMaster, S.J., Liskiewicz, T.W.: Contact size effects on the friction and wear of amorphous carbon films. Appl. Surf. Sci. Adv. 9, 100248 (2022)

Hamdani, D., Prayogi, S., Cahyono, Y., Yudoyono, G., Darminto, D.: The influences of the front work function and intrinsic bilayer (i1, i2) on p–i–n based amorphous silicon solar cell’s performances: a numerical study. Cogent Eng. 9(1), 2110726 (2022)

Choi, S., et al.: Formation and suppression of hydrogen blisters in tunnelling oxide passivating contact for crystalline silicon solar cells. Sci. Rep. 10(1), 9672 (2020)

Zhou, H.P., et al.: Hydrogen-plasma-induced rapid, low-temperature crystallization of μm-thick a-Si: H films. Sci. Rep. 6(1), 1–8 (2016)

Wang, Q., et al.: p-type c-Si/SnO2/Mg heterojunction solar cells with an induced inversion layer. Appl. Phys. Lett. 119(26), 263502 (2021)

Meng, F., et al.: Role of the buffer at the interface of intrinsic a-Si:H and p-type a-Si:H on amorphous/crystalline silicon heterojunction solar cells. Appl. Phys. Lett. 107(22), 223901 (2015)

Wang, S.-H., Chang, H.-E., Lee, C.-C., Fuh, Y.-K., Li, T.T.: Evolution of a-Si:H to nc-Si: H transition of hydrogenated silicon films deposited by trichlorosilane using principle component analysis of optical emission spectroscopy. Mater. Chem. Phys. 240, 122186 (2020)

Liu, X., Chu, P.K., Ding, C.: Formation of apatite on hydrogenated amorphous silicon (a-Si:H) film deposited by plasma-enhanced chemical vapor deposition. Mater. Chem. Phys. 101(1), 124–128 (2007)

Duan, W., Qiu, Y., Zhang, L., Yu, J., Bian, J., Liu, Z.: Influence of precursor a-Si:H dehydrogenation on the aluminum induced crystallization process. Mater. Chem. Phys. 146(1), 141–145 (2014)

Acknowledgements

The author would like to thank Pertamina University and Institut Teknologi Sepuluh Nopember for the support, and the authors would like to thank Prof. AR who has provided useful discussion for this paper. We also acknowledge the NUS Singapore Synchrotron Light Source (SSLS) SE measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Prayogi, S., Ayunis, A., Cahyono, Y. et al. N-type H2-doped amorphous silicon layer for solar-cell application. Mater Renew Sustain Energy 12, 95–104 (2023). https://doi.org/10.1007/s40243-023-00232-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40243-023-00232-9