Abstract

In this study, new polypyrrole films (ppy) were synthesized using a physical plasma deposition (PAPVD) system; where the equipment design and methodology for plasma-assisted pyrrole polymerization were improvement. The morphology, functional groups, and thermal stability of the polymer network films were characterized by X-ray photoelectron spectroscopy (XPS), thermogravimetric analysis (TGA), and differential scanning calorimetry (DSC) techniques, respectively. The electrochemical properties of the films as capacitor were evaluated by cyclic voltammetry and electrochemical impedance spectroscopy. The results observed by SEM showed that the ppy 100W-1 and ppy 100W-2 films present uniformity in their structure. The analyses of TGA and DSC confirmed the improvement in stability; meanwhile for 100W-1 film, the presence of ppy bonds was corroborated by XPS. Plasma-activated ppy 100W-1 film exhibited higher capacitance and minor Rct resistance than that obtained for ppy 100W-2 film. The specific capacitances values of ppy 100W-1 and ppy 100w-2 films are 196 and 150 F/g in 1 M KCl. After charging and discharging tests of 1000 cycles at 5 mA cm−2 current density of ppy 100W-1 film retains 89% of its initial capacitance. Therefore, ppy 100W-1 film showed to be a promising material for use as an electrochemical capacitor.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The deposition by plasma technique on substrates has been of interest to the scientific and industrial community for the processes of polymerization of thin layers. In addition to the problems that arise such as: long deposition times, generation of tributaries, uniformity, adhesion, useful lifetime, reproducibility, the production of toxic waste where those can affect the operator and the control of the thickness specified by the geometry of the part (slits and curvatures) are difficult to take over [1]. In this context, novel studies have been developed to replace the conventional ones, considering the offering for materials with the same electrical characteristics or improvement that become competitive [2].

Therefore, the analysis of the films deposited on substrates is important, due to several parameters influence the growth mechanism of the deposits, type of geometries and morphological characteristics [3, 4].

In recent years, vapor phase deposition processes have been important with respect to wet methods, this due to the above problems. Particularly, plasma-assisted deposition techniques, such as PAPVD (plasma physical deposition) is adequate to obtain thin films with a wide range of technological applications, for example the creation of integrated circuits [5], thermal coatings [6], biomedical sensors, tribological applications [1], etc.

For the development of this work, the technique PAPVD will be addressed for the deposition of polypyrrole. This polymer was studied with the objective to improve its electrical and physicochemical properties compared to chemical or electrochemical oxidation techniques in liquid phase, that result, in a solid phase difficult to process and convert into film [7, 8]. Thus, a polymerization study and mechanism by plasma deposition was carried out using different methodologies, to compare structure, electrical properties according to initial conditions such as humidity, pressure and temperature. Subsequently, Fourier transform infrared spectrometry (FTIR), photoelectronic x-ray spectroscopy (XPS) and electrochemical techniques were used to characterize the films. The main objective of this work was to evaluate the properties as capacitor of coatings based-on the conductive polymer ppy on the aluminum plates, improving the charge dispersion without sacrifice the inherent properties of the metal, to be applied in the industrial field [9, 10].

Experimental methodology

Metallographic preparation of the aluminum substrate

The substrate used consisted in samples of 15 × 3 cm 2024 aluminum plates, which were pretreated by applying 10 W of power with plasma during 10 min to generate a porous surface.

Polypyrrole polymerization on aluminum plates

Stainless steel discharge equipment with a dimension of 50 cm in diameter and 30 cm wide was used for plasma polymerization coupling with an internal electrode at 30 MHz power supply, where the evaporation of the monomer (ppy) was carried out. The process was performed as follows: the substrate was attached to the chamber where the deposition will be accomplished by means of a pressure valve and a needle where the monomer is transported. Previously the chamber was subjected at 0.18 mbar of pressure and then filled with the monomer steam (ppy), where the desired pressure was reached [11]. When the pressure was stable, the system's energy source was turned on to inject the monomer through the needle valve, where the flow of the monomer in vapor phase was regulated. The monomer begins to fragment due to the Ar plasma between the electrodes in the system. The vacuum was maintained between 3 × 10–1 and 9 × 10–2 Torr [12, 13].

Physicochemical characterization

X-Ray diffraction (XRD) was measured using the Bruker X-ray diffractometer (model PW3710). The thermal properties of pyrrole plasma polymerization films were investigated with a thermogravimetric analyzer 2950 TGA HR V5.5 TA, following the variation in a temperature range between 25 °C and 800 °C at 5 °C. C min−1 of heating rate with the incorporation of differential scanning calorimetry technique DSC. The composites were characterized using Fourier transform infrared spectrometry (FTIR) in a Shimadzu FTIR 8400, Japan. The morphology of films was tested using scanning electron microscopy (SEM), JEOL JSM6010plus. The analysis of X-ray photoelectron spectroscopy (XPS) was conducted to know the characteristic bonds of pyrrole and the cross-linking effect by the plasma polymerization process using a Monochromatic Magics Thermo Scientifics instrument, model K-Alpha + under conditions of v = 1 min−1 scan at t = 20.5 s and CAE = 20.

Electrochemical characterization

The electrochemical measurements were performed on a Biologic brand potentiostat/galvanostat at 25 °C using a three-electrode system in 1 M KCl as electrolyte. An standard calomel electrode (SCE), and a platinum mesh were used as reference and counter electrode, respectively; meanwhile the working electrode consisted in the generated ppy films by plasma on the aluminum substrate, having an active mass of 1.95 mg. Electrochemical impedance spectroscopy EIS experiment was accomplished at an open circuit potential in a frequency range of 10–100 kHz with 5 mV of amplitude [14]. Charge and discharge tests were performed from − 0.5 to 0.1 V under 5 mA cm−2 of current density [15].

Results and discussion

Films were obtained by polymerization via plasma (ppy 100W-1 and ppy 100W-2) under different conditions as working powers, deposit time and variation of the methodologies, resulting in important electrical and physicochemical differences. The expectation of this work is to deposit ppy films via plasma with fewer defects compared to those already reported and obtained by other techniques and methods [16,17,18,19,20].

Structural analysis of ppy 100W-1 and ppy 100W-2 films by XRD

The crystallographic structure of the films was studied by XRD, as is shown in Fig. 1. As pattern, a ppy target was used, which could be associate with a broad characteristic peak located at 2θ = 25°, confirming the amorphous nature of ppy. Subsequently the analysis was carried out for samples obtained by different working powers of the plasma deposition process named as 100W-1 and 100W-2. The characteristic peak of the amorphous ppy exhibits an increase in crystallinity as the working power and deposition time increase [21,22,23]. Thus, the intensity 2θ = 25° showed a broad halo that denoted the amorphous nature of these polymers, his can be attributed to the presence of pyrrole rings in the main polymer chain, which restricted the free rotation of the chains and hindered the dense packing [21].

FT-IR spectra of ppy 100W-1 and ppy 100W-2

The FT-IR spectrum of ppy was recorded between 1200 and 2000 cm−1, as is shown in Fig. 2. Compared to previous reports, the broad absorption peak located at 1300–1350 cm−1 belongs to the vN–H and the vC–H stretch vibration. In addition, the 1078 and 1385 cm−1 bands are connected to C–H strain vibrations and vC–N stretching vibrations, respectively. The peaks situated at 1360–1450 cm−1 correspond to the vibration of movement vN–H and the symmetrical stretch C–vN–C [13]. The peak present at 1588 cm−1 is attributed to the vC=C stretch vibration of the ppy chains. Therefore, samples of ppy 100W-1 and ppy 100W-2 show typical ppy peaks. In addition, the sample has broad peaks. It means that branching and cross-linking process occur in pyrrole rings [9].

SEM images of ppy 100W-1 and ppy 100W-2

The morphology of the aluminum surface 2024 without treatment, plasma treatment on aluminum 2024 treated by plasma, ppy 100W-2 and ppy 100W-1 was examined by SEM and the results are presented in Fig. 3a–d, respectively. Figure 3a shows a typical morphology of the untreated aluminum surface. Figure 3b presents the morphology of plasma treatment with the formation of pores on the surface of aluminum 2024. The coating of ppy100W-2 on 2024 aluminum treated by plasma can be seen in Fig. 3c, where there is a distributed surface of polymerized pyrrole resulting from the interaction of the ppy bond and aluminum 2024 in the polymerization process [1, 13]. Figure 3d shows the coating of ppy100W-1 on aluminum 2024 treated by plasma. This film presents a solid cross-linking reaction by the conditions of plasma polymerization in the purchase of Fig. 3c to reach a new state of equilibrium through the creation of containing oxygen and pyrrolic nitrogen groups that provide more active nucleation sites that could facilitate the binding between ppy monomers [24] giving polymerization. This result was confirmed by XPS, IR, and XRD analyses.

XPS spectra of ppy 100W-1 and ppy 100W-2

Using X-ray photoelectronic spectroscopy (XPS) technique, the analysis of ppy 100W-1 and ppy 100W-2 films was carried out, as is shown in Fig. 4. The broad spectrum of the samples, made for two study materials using ppy pattern (Fig. 4a), indicates the presence of C, O, and N, which are typical of the monomer structure from pyrrole and a difference can be observed in the signals of the peaks corresponding ot O 1 s and N 1 s for the samples of ppy 100W-1 and ppy 100W-2. This result is attributed to the plasma polymerization process. The spectra of C 1 s can be observed in Fig. 4b, where a comparison in the composition between each plasma polymerization in ppy 100W-1 and ppy 100W-2 was done. For the ppy 100W-1 sample, there are deconvolution orbitals in C 1 s with peaks of 283.74 eV corresponding to C sp2 of hybridization, 284.5 eV to C with sp3 hybridization, 285.25 eV to C–O, C–N, 286.03 eV to C–O–C bonds, 287 eV to C=O, C=N and 288.62 eV to C–CH2–O bonds. This is attributed to the cross-linking structure corresponding to the pyrrole polymerization [19, 25]. For the ppy 100W-2 sample, the signals are 283.22 eV for the C–O bond, 283.9 eV for the C–O hybridization in sp2, 285.44 eV for the C sp3 hybridization, and 287.54 eV in the C=O, C=N bonds. A higher concentration of sp2 and sp3 is observed for the sample of ppy 100W-2; meanwhile for ppy 100W-1, there is a distribution of the cross-linking bonds, which are confirmed by the electrochemical analysis, where a greater capacitance is observed [13].

a High-resolution XPS general spectra of ppy blank, ppy 100W-1 and ppy 100W-2. b High-resolution spectrum in the C 1 s region for ppy 100W-1 and ppy 100W-2. c High-resolution spectrum in the N 1 s region for ppy 100W-1 and ppy 100W-2 and d high-resolution spectrum in the O 1 s region in ppy 100W-1 and ppy 100W-2

The high-resolution scan of N 1 s is presented in Fig. 4c. For the ppy 100W-2 sample, the peaks are observed at 399.7 eV for = N–, –NH– and 401.8 eV for C–NH–O. Also a higher concentration is observed for the peak located at 399.7 eV. For the ppy 100W-1 sample, peaks were found at 398.08 eV, 399.5 eV, 400.1 eV, 401 eV corresponding to N=O, =N–, –NH–, pyrrole N and C–NH–O, respectively [26, 27]. These signals are present due to the decrease in the N signal in the samples. This result is consistent with the electrochemical studies where a decrease of the capacitance on the ppy 100W-2 sample is observed. The high-resolution scan of O 1 s is presented in Fig. 4d, where the deconvoluted spectra for the sample of ppy 100W in 531.7 eV for C=O, C=N and 532.9 eV for the O–C, N–O, O–H bonds is presented. Further a higher concentration for the peak 531.7 eV is observed. While for the ppy 100W-2, sample get the peaks at 529.18 eV for the Ox-M signals, which can be attributed to the substrate-coating of the ppy film by plasma, 530.54 eV for C=O, C=N and 532.3 eV for the O–C, N–O, O–H bonds [26], so this shows that the ppy 100W-2 film does not have a homogeneity of the active sites. This behavior is consistent with the electrochemical tests and exhibit that the plasma polymerization process can confer differences in the cross-linking by varying operating parameters of methodology proposed in this work. Through the XPS analysis, it can be inflicted that the elemental composition and the relationship of concentrations, which refers to physicochemical techniques in this work, is conclusive.

Thermal stability of the ppy 100W-1 and ppy 100W-2 films

Thermogravimetric analysis was used to evaluate the thermal stability of the polymer on the aluminum surface. Mass loss results with respect to temperature was obtained using a ramp of 10 °C/min between 15 and 800 °C of temperature range under nitrogen atmosphere [24]. The comparison with the pattern of ppy by plasma was made with the samples of ppy 100W-1 and ppy 100W-2, as is shown in Fig. 5, where can be seen four degradation zones; the first in the range of 85–200 °C a loss of 10% of weight for the sample of ppy pattern. However, for the sample of ppy 100W-1 there is a loss of 8% and for the sample of ppy 100W-2 6%. The second important change is presented in the range of 200–300 °C, losing 42%. Meanwhile for the ppy by plasma and the other samples, there is a loss of 2–4% less than the initial pattern of the ppy target. The third zone of 350 °C at 500 °C, exhibited a loss of 12% of weight; meanwhile for the samples of ppy 100W-1 the loss is 4% less and for ppy 100W-2 less than 2%. Finally a degradation zone that oscillates between 500 °C and 650 °C with 35% due to weight loss for the ppy target is observed. ppy 100W-1 and ppy 100W-2 suffered a loss of less than 2% compared to ppy blank. Finally, the 97% of ppy blank was decomposed in a temperature at 650 ºC. At the same temperature, the degradation for ppy 100W-2 and ppy 100W-1 was 94% and 86% respectively. This results indicate that by plasma polymerization of polypyrrole improves the thermal stability of the films for carrying out the cross-linking of the characteristic bonds of pyrrole by propagating the bonds of the oxygen, nitrogen, and carbon groups [24]. Pyrrolic nitrogen can bind polypyrrole through a conjugate structure, resulting in excellent thermal stability, as observing in the ppy 100W-1 film.

Electrochemical behavior of the deposited films

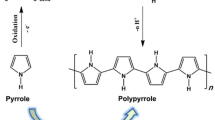

Figure 6a illustrates the cyclic voltamperometry (CV) behavior of ppy, ppy 100W-1 and ppy 100W-2 (with different deposition times respectively) in 1 M KCl aqueous solution at 5 mV s−1 scan rate. I vs E curves for ppy 100W-1 exhibited a quasi rectangular shape in the given potential range that show a characteristic capacitive behavior compared to that obtained with the ppy 100W-2 sample. These results indicate that electrodes coated by physical plasma deposition show and ideal capacitive behavior for capacitor applications. However, the ppy blank curve is not completely rectangular, indicating an electrochemical behavior similar to that of a resistance [28].

The specific capacitance is often calculated from a CV curve using Eq. [24].

where i is the sweep current, E1 and E2 are the low limit potential and the upper limit potential (V), ν is the scan rate (V/s) and m is the active material mass (g). The specific capacitances calculate for the ppy 100W-1 and ppy 100W-2 electrodes were 190 F/g, and 150 F/g, in different electrolytic media, respectively, as is shown in Fig. 6c.

However, the approach presented, to improve the interaction between substrate and ppy polymerized by physical deposition by plasma could be applied to other systems that have been published by other authors, such as carbon-polymer graphene, carbon–polymer–polymer and carbon–polymer–metallic oxides [15, 29,30,31], to say the few.

To characterize the ppy 100W-1 and ppy 100W-2 electrodes, several experiments were performed with electrochemical techniques in 1 M KCl aqueous solution. EIS for the samples of ppy blank, ppy 100W-1, and ppy 100W-2 are shown in Fig. 6b. Two patterns are observed: the depressed arc in the high-frequency region, which is related to interfacial processes, and the inclined line in the low-frequency region, that indicates capacitive behavior. Adjusted data based on the equivalent circuit are shown in Fig. 6d. The equivalent circuit includes: the resistance of the solution (Rs) which is observed at the high-frequency intersection of the natural arc, consisting of the ionic resistance of the electrolyte. Also the resistance of the substrate, and the contact resistance at the current/coating interface, and the charge transfer resistance (Rct), which is attributed to the diameter of the arc by Faradaic reactions and double layer capacitance (Cd) at the interfaces of the electrode and electrolyte solution. The surface of the working electrode is related to the dependence of the diffusion/ion transport frequency, which is known as Warburg impedance (Z) and the pseudocapacitive element CF of the redox process involving the conductive polymer (ppy) [21, 32]. The circuit model parameters for the ppy blank, ppy 100W-1, and ppy 100W-2 electrodes are shown in Table 1. The solution resistance (Rs) and the load transfer resistance (Rct) can be obtained from Nyquist graphs, where the high-frequency semicircle intersects the real axis at Rs and Rs + Rct, respectively (Fig. 6b and Table 1). An insignificant difference is exhibited in the Rs values for the ppy 100W-1 and ppy 100W-2 working electrodes with respect to ppy blank, where Rs is higher. The Warburg impedance (Z) for ppy 100W-1 and ppy 100W-2 is higher than that obtained for the ppy blank sample. This result means that the samples coatings have the lowest Warburg diffusion resistors. A poor adjustment is observed in the low-frequency range for ppy 100W-1, which suggests that there is no distribution of the homogeneities existing in the electrode–electrolyte interface and the porosity of the working electrode of ppy 100W-1, as can be seen in the SEM analyses. The results of the further experiments demonstrate that ppy 100W-1 has the ability for faster electron transport and charge transfer at the electrode/solution than the ppy 100W-2 sample. According to the results obtained from the capacitance, as is shown in Fig. 6c for the films generated in this work, a comparison with respect to the literature is presented in Table 2. Here can be verified that the pyrrole polymerization method by plasma showed an improvement in capacitance behavior, without the need of the use of dopants or new compounds to the polymerization process; also a better efficiency was reached, compared to some results already reported.

Conclusions

Pyrrole polymerization was carried out by the PAPVD technique. The methodology for the generation of ppy 100W-1 and ppy 100W-2 films was improved by the plasma-activated oxygen, nitrogen, and carbon groups and the cross-linking process of the pyrrolic rings, characteristic of pyrrole and pyrrolic N groups that provide active sites to form a conjugated structure. The ppy 100W-1 and ppy 100W-2 films were characterized by XPS technique and the morphology by SEM, where a polymer matrix is verified for both samples. Further, thermal stability properties and conductivity were confirmed by TGA and EIS analyses, respectively. Due to the pyrrolic groups generated by plasma activation, the ppy 100W-1 film shows a larger specific capacitance and a minor Rct resistance than that obtained with the ppy 100W-2 and pure ppy samples. Finally, the 89% of the specific capacitance value (196 F/g) at 5 mA cm−2 of current density for ppy 100W-1 film is retained. These result mean that the ppy 100W-1 film could be a promising material for electrochemical supercapacitors and related applications in the sector.

References

Azam, M.U., Samad, M.A.: A novel organoclay reinforced UHMWPE nanocomposite coating for tribological applications. Prog. Org. Coatings. 118, 97–107 (2018). https://doi.org/10.1016/J.PORGCOAT.2018.01.028

Han, Y., Dai, L.: Conducting polymers for flexible supercapacitors. Macromol. Chem. Phys. 220, 1800355 (2019). https://doi.org/10.1002/MACP.201800355

Lovascio, S.: Cold plasma deposition of organisilicon films with diferent monomers in a dielectric-barrier discharge Ph. D. Thesis. 133, 34–44 (2010)

Yagüe, J.L., Agulló, N., Borrós, S.: Plasma polymerization of polypyrrole-like films on nanostructured surfaces. Plasma Process. Polym. 5, 433–443 (2008). https://doi.org/10.1002/ppap.200700139

Joglekar, Y.N., Wolf, S.J.: The elusive memristor: properties of basic electrical circuits. Eur. J. Phys. 30, 661–675 (2009). https://doi.org/10.1088/0143-0807/30/4/001

Hassanzadeh-Aghdam, M.K., Mahmoodi, M.J., Jamali, J.: Effect of CNT coating on the overall thermal conductivity of unidirectional polymer hybrid nanocomposites. Int. J. Heat Mass Transf. 124, 190–200 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2018.03.065

Regula, C., Ihde, J., Lommatzsch, U., Wilken, R.: Corrosion protection of copper surfaces by an atmospheric pressure plasma jet treatment. Surf. Coat. Technol. 205, S355–S358 (2011). https://doi.org/10.1016/j.surfcoat.2011.03.126

Dieckhoff, S., Standfuß, J., Pap, J.S., Klotzbach, A., Zimmermann, F., Burchardt, M., Regula, C., Wilken, R., Apmann, H., Fortkamp, K., Hackius, J.: New concepts for cutting, surface treatment and forming of aluminium sheets used for fibre-metal laminate manufacturing. CEAS Aeronaut. J. 10, 419–429 (2019). https://doi.org/10.1007/s13272-018-0324-1

Dhillon, A., Kaur, A., Srivastava, A.K., Avasthi, D.K.: Experimental investigations of semi-crystalline plasma polymerized polypyrrole for surface coating. Prog. Org. Coat. 69, 396–401 (2010). https://doi.org/10.1016/j.porgcoat.2010.08.002

Biederman, H., Slavínská, D.: Plasma polymer films and their future prospects. Surf. Coat. Technol. 125, 371–376 (2000). https://doi.org/10.1016/S0257-8972(99)00578-2

Sakthi Kumar, D., Yoshida, Y.: Dielectric properties of plasma polymerized pyrrole thin film capacitors. Surf. Coat. Technol. 169–170, 600–603 (2003). https://doi.org/10.1016/S0257-8972(03)00118-X

Kylián, O., Shelemin, A., Solař, P., Pleskunov, P., Nikitin, D., Kuzminova, A., Štefaníková, R., Kúš, P., Cieslar, M., Hanuš, J., Choukourov, A., Biederman, H.: Magnetron sputtering of polymeric targets: from thin films to heterogeneous metal/plasma polymer nanoparticles. Materials (Basel) 12, 2366 (2019). https://doi.org/10.3390/ma12152366

Lommatzsch, U., Ihde, J.: Plasma polymerization of HMDSO with an atmospheric pressure plasma jet for corrosion protection of aluminum and low-adhesion surfaces. Plasma Process. Polym. 6, 642–648 (2009). https://doi.org/10.1002/ppap.200900032

Wilson, J., Radhakrishnan, S., Sumathi, C., Dharuman, V.: Polypyrrole-polyaniline-Au (PPy-PANi-Au) nano composite films for label-free electrochemical DNA sensing. Sens. Actuators B Chem. 171–172, 216–222 (2012). https://doi.org/10.1016/j.snb.2012.03.019

Dhibar, S., Bhattacharya, P., Hatui, G., Das, C.K.: Transition metal doped poly(aniline-co-pyrrole)/multi-walled carbon nanotubes nanocomposite for high performance supercapacitor electrode materials. J. Alloys Compd. 625, 64–75 (2015). https://doi.org/10.1016/j.jallcom.2014.11.108

Yagüe, J.L., Agulló, N., Borrós, S.: Growth of polypyrrole-like films on self-assembly nanostructured silicon surfaces by PECVD. Chem. Vap. Depos. 15, 128–132 (2009). https://doi.org/10.1002/cvde.200806746

Boscher, N.D., Choquet, P., Duday, D., Verdier, S.: Chemical compositions of organosilicon thin films deposited on aluminium foil by atmospheric pressure dielectric barrier discharge and their electrochemical behaviour. Surf. Coat. Technol. 205, 2438–2448 (2010). https://doi.org/10.1016/j.surfcoat.2010.09.037

Zhang, J.W., Zhang, B., Zhang, X.: Enhanced catalytic activity of ternary NiCoPd nanocatalyst dispersed on carbon nanotubes toward methanol oxidation reaction in alkaline media. J. Solid State Electrochem. 21, 447–453 (2017). https://doi.org/10.1007/s10008-016-3331-3

Wang, M., Wang, X., Moni, P., Liu, A., Han Kim, D., Jun Jo, W., Sojoudi, H., Gleason, K.K., Wang, M., Wang, X., Moni, P., Liu, A., Kim, D.H., Jo, W.J., Sojoudi, H., Gleason, K.K.: CVD polymers for devices and device fabrication. Adv. Mater. (2016). https://doi.org/10.1002/adma.201604606

McKenzie, D.R., McFall, W.D., Sainty, W.G., Yin, Y., Durandet, A., Boswell, R.W.: New technology for PACVD. Surf. Coat. Technol. 82, 326–333 (1996). https://doi.org/10.1016/0257-8972(95)02776-9

Mi, H., Zhang, X., Ye, X., Yang, S.: Preparation and enhanced capacitance of core-shell polypyrrole/polyaniline composite electrode for supercapacitors. J. Power Sources. 176, 403–409 (2008). https://doi.org/10.1016/j.jpowsour.2007.10.070

Koduru, H.K., Marino, L., Vallivedu, J., Choi, C.J., Scaramuzza, N.: Microstructural, wetting, and dielectric properties of plasma polymerized polypyrrole thin films. J. Appl. Polym. Sci. 133, 1–10 (2016). https://doi.org/10.1002/app.43982

Joulazadeh, M., Navarchian, A.H.: Ammonia detection of one-dimensional nano-structured polypyrrole/metal oxide nanocomposites sensors. Synth. Met. 210, 404–411 (2015). https://doi.org/10.1016/j.synthmet.2015.10.026

Yang, L., Shi, Z., Yang, W.: Polypyrrole directly bonded to air-plasma activated carbon nanotube as electrode materials for high-performance supercapacitor. Electrochim. Acta. 153, 76–82 (2015). https://doi.org/10.1016/j.electacta.2014.11.146

Nitschke, M.: Plasma modification of polymer surfaces and plasma polymerization. In: Polymer surfaces and interfaces characterization modification and applications, pp. 203–214. Springer (2008)

Zhou, J., Fisher, E.R.: Synthesis and properties of plasma-polymerized polypyrrole/Au composite nanofibers. J. Nanosci. Nanotechnol. 4, 539–547 (2004). https://doi.org/10.1166/jnn.2004.083

Yang, P., Zhang, J., Guo, Y.: Synthesis of intrinsic fluorescent polypyrrole nanoparticles by atmospheric pressure plasma polymerization. Appl. Surf. Sci. 255, 6924–6929 (2009). https://doi.org/10.1016/j.apsusc.2009.03.016

Liang, B., Qin, Z., Li, T., Dou, Z., Zeng, F., Cai, Y., Zhu, M., Zhou, Z.: Poly(aniline-co-pyrrole) on the surface of reduced graphene oxide as high-performance electrode materials for supercapacitors. Electrochim. Acta. 177, 335–342 (2015). https://doi.org/10.1016/j.electacta.2015.01.135

Wang, Z., Chen, J., Sun, S., Huang, Z., Zhang, X., Li, X., Dong, H.: Plasma-enabled synthesis and modification of advanced materials for electrochemical energy storage. Energy Storage Mater. 50, 161–185 (2022). https://doi.org/10.1016/J.ENSM.2022.05.018

Dou, S., Tao, L., Wang, R., El Hankari, S., Chen, R., Wang, S.: Plasma-assisted synthesis and surface modification of electrode materials for renewable energy. Adv. Mater. 30, 1705850 (2018). https://doi.org/10.1002/ADMA.201705850

Wang, W., Zhu, F., Dai, Y., Zhang, H., Lei, J.: Short communication: Electrosynthesis and performance of poly(aniline/pyrrole) copolymer. Int. J. Electrochem. Sci. 11, 4000–4006 (2016). https://doi.org/10.20964/110458

Yang, H., Xu, J., Zhai, L., Liu, X., Deng, B., Xu, W.: Polypyrrole/organic sulfonic acid coated activated carbon fiber felt as flexible supercapacitor with high-performance. Fibers Polym. 22, 2119–2126 (2021). https://doi.org/10.1007/s12221-021-0920-2

Yuan, W., Han, G., Xiao, Y., Chang, Y., Liu, C., Li, M., Li, Y., Zhang, Y.: Flexible electrochemical capacitors based on polypyrrole/carbon fibers via chemical polymerization of pyrrole vapor. Appl. Surf. Sci. 377, 274–282 (2016). https://doi.org/10.1016/j.apsusc.2016.03.114

Pothukuchi, S., Li, Y., Wong, C.P.: Development of a novel polymer-metal nanocomposite obtained through the route of in situ reduction for integral capacitor application. J. Appl. Polym. Sci. 93, 1531–1538 (2004). https://doi.org/10.1002/app.20626

Iurchenkova, A.A., Kallio, T., Fedorovskaya, E.O.: Relationships between polypyrrole synthesis conditions, its morphology and electronic structure with supercapacitor properties measured in electrolytes with different ions and pH values. Electrochim. Acta. 391, 138892 (2021). https://doi.org/10.1016/j.electacta.2021.138892

Acknowledgements

The authors acknowledge to the Mexican Council for Science and Technology (CONACYT) for the financial support through the project XXX.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Espinosa-Lagunes, F.I., Torres-González, J. Development of thin film coatings with polypyrrole (ppy) by physical plasma deposition technique (PAPVD) for electrochemical capacitor. Mater Renew Sustain Energy 12, 63–71 (2023). https://doi.org/10.1007/s40243-023-00230-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40243-023-00230-x