Abstract

Zinc oxide is one of the most researched semiconductors owing to the outstanding properties that make it useful in various industrial applications, such as solar cells and other optoelectronics. In this work, ZnO thin films were prepared in five different concentrations and doped with four nitrogen atoms from triethylene tetramine (TETA) to fabricate a ZnO for optoelectronic applications using an electrodeposition technique. The doped ZnO thin films were synthesized and deposited on ITO glass substrates. The deposited thin films were annealed at 400°Cfor 60min in a furnace under the same conditions. The thin films' optical, electrical, and surface morphological properties were characterized using UV–Vis Spectrophotometer, Four Point Probe (FPP), and Scanning Electron Microscope (SEM), respectively. The optical properties confirmed the film's suitability for various transparent device applications with a high optical transmittance of about 90% at the wavelength between 250 and 950 nm. The optical band gaps of 3.25 eV to 3.50 eV were obtained at ZnO concentrations from 0.2 M to 1.0 M. The SEM images depicted a polycrystalline nature of the films with irregular nanoparticle shapes across the substrates. Electrical results established the high conductivity of nitrogen-doped ZnO thin films, thereby making the thin films suitable as transparent conducting oxides for devices such as solar cells and optoelectronics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Semiconductor devices are the consequent of the advancement in thin film technology. The thin film technology is the deposition of molecules on a 2D-material deposited by either molecule-by-molecule or atom-by-atom condensation method [1]. Transparent conducting oxides (TCOs) have drawn much attention because of their wide range of potential device applications, from transistors to optical detection and emission [2]. Electrochemical deposition of thin film materials is a simple process of deposition for many chalcogenide elements like zinc, gallium, cadmium, indium, tin, lead, sulfides, and selenide [3,4,5]. Zinc oxide is a promising semiconductor material with wide band gap (~ 3.5 eV) and large exciton binding energy (60 meV). Its optical properties make it useful in several applications such as a reflector [6], filter [7] and planar wave guide [8]. Moreover, it has an enormous potential for use in optoelectronics and electroluminescent devices [9]. The advancement in p-type transparent semiconductor oxides with good performance is a manifestation for diverse applications where transparency, power efficiency, and greater circuit complexity are required [10]. These applications include transparent electronics [11], sensors [12], displays [13], photovoltaics [14], electrochromics, [15] and memristors [16]. Several deposition techniques have been applied to synthesize ZnO thin films by different researchers to modify and improve its properties by both physical and chemical processes, the methods include; pulse laser deposition (PLD) [17], radio frequency (RF) sputtering [18, 19], molecular beam epitaxy (MBE) [20, 21], thermal evaporation [22, 23], sol–gel [24, 25], chemical vapor deposition (CVD) [26], chemical bath deposition (CBD) [27], chemical spray pyrolysis (CSP) [28, 29], and electrochemical deposition [30, 31]. Among these techniques, electrodeposition exhibits more advantages, such as its simplicity, equipment cost effectiveness, good thickness uniformity and control, etc.

In this study, the effect of concentration was reported. We prepared ZnO thin films at different concentrations, doped with four nitrogen atoms and deposited on ITO glass using a locally made electrochemical deposition chamber. The deposited samples were characterized to study the effects of concentration and nitrogen-doped on optical, electrical and surface morphological properties of the films. The properties were investigated using UV–visible spectrophotometer, scanning electron microscopy (SEM) and four-point probe (TPP).

Experimental procedure

Preparation of zinc oxide thin films

All chemicals were of analytical grade of 99.8% purity and used as received. The ZnO was prepared from the reaction of zinc acetate dehydrate ((CH3COO)2 Zn.2H2O) and triethylene tetramine TETA (NH2 CH2CH2NHCH2). The distilled water was obtained from Automatic Water Distiller Model No. SZ-1. Indium Tin Oxide (ITO) coated glass was used as the substrate for thin film deposition. Prior to film deposition, the substrates and glassware were properly cleaned with distilled water, ethanol, acetone and then oven dried at 60 °C for 1 h. ZnO thin film was prepared at five different concentrations of 0.2, 0.4, 0.6, 0.8, and 1.0 M by dissolving 4.39, 8.78, 13.17, 17.56 and 21.95 g of zinc acetate salts respectively into 100 ml of distilled water using Eq. 1. The zinc acetate solution was carefully placed in a covered glass beaker to prevent contamination and stirred gently with magnetic bar on thermostatic magnetic stirrer for 30 min at 40 °C to ensure total dissolution. The doping agents were also prepared at 0.5 M ratio with distilled water.

The ZnO thin film of 100 ml was measured in five different beakers of 250 ml containing each concentration. Each 100 ml ZnO precursor in a beaker was doped with triethylene tetramine, and stirred.

Properties of the substrate glass

Indium tin oxide (ITO) is a transparent conducting oxide (TCO) substrate with a sheet resistance of 10Ω/sq and a thickness of 1.1 mm. The substrate properties allowed us to study the influence of the substrate surface on the structure and morphology of the samples. ITO was used to obtain the samples via electrochemical cell arrangement.

Deposition of zinc oxide thin films

A conventional two-electrode electrochemical cell in Fig. 1b was used to carry out the experiments at room temperature. In the configuration as shown in Fig. 1a, ITO glass substrate is the working electrode while the counter electrode is graphite (carbon plate). Electrolytes were the thin film precursor solutions prepared at different concentrations for electrodeposition. Coating of the substrate started immediately the power supply connected to the electrodeposition system is powered on. The substrates were directly mounted through a long conducting crocodile clip in the electrochemical cell. The coating surface of the working electrode was vertically placed at 40 mm directly facing the counter electrode. The deposition chamber was continuously stirred with a magnetic stirrer throughout the deposition period. A constant voltage of 6.0 V was applied to the system for 7 min deposition time [3]. The progress of deposition was monitored with multimeter, the value of electric current (I) continue to decrease until it become zero, which indicates the completion of deposition process. This principle was reported by Faraday’s first law of electrolysis [32]. After the deposition, the thin film samples were placed in the crucible and annealed in the muffle furnace at 400 °C for 60 min.

Results and discussions

Optical properties of the films

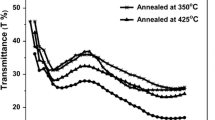

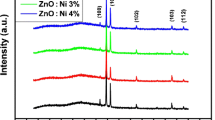

The plots of transmittance against wavelength for ZnO thin films prepared at different concentrations are shown in Fig. 2. It was observed that more than 80% transmittance was recorded within the ultraviolet–visible region. The smoothness of the curve and absence of interference pattern is an indication of homogeneity and low surface roughness of the films. The spikes in the UV–visible absorption edge from blue shift to red shift can be observed between 350 and 650 nm. This observation is consistent with previous reports on the optical properties of ZnO [33,34,35]. The optical band gap of ZnO thin film was calculated from the Tauc’s expression in Eq. (2) and the plot is shown in Fig. 3.

Optical band gap of ZnO thin films

Energy band gap is often important in developing the electronic band structure of a thin film material. Absorption coefficient (α) is related to the incident photons energy (\(hv)\) by a conventional Tauc’s relation (Ding et al. 2010):

where A is an optical absorption constant while n is an index which characterizes the optical absorption process and theoretically equal to ½, 2, 3/2, or 3 for direct allowed, indirect allowed, direct forbidden and indirect forbidden transitions, respectively. The t is the film thickness and T is the transmittance. The data from wavelength λ, transmittance, absorbance and thickness of the deposited films were computed to obtain (αhv)n. In a direct semiconductor material, energy band gaps are estimated by extrapolating the linear fit of (αhʋ)2 curve to the zero-crossing value of the x-axis as shown Fig. 3. In this study, the value of n in Eq. (2) is ½, indicating that the thin film is a direct band gap semiconductor. The absorption coefficient α was mainly affected by two factors which are scattering losses and fundamental absorption. At the shorter wavelengths closed to the band gap, the influence of fundamental absorption on α was more prominent than to scattering losses and α might be obtained by (Kumar et al. 2011) [36] in Eq. (3). The band gap variation of ZnO with concentrations is shown in Fig. 3. The optical band gap (Eg) was obtained by extrapolating the linear part of the Tauc’s plot to intercept the energy axis at (αhv)2 = 0. The energy band gap of the films gave the values between the range 3.30 eV and 3.50 eV, respectively. It was clearly shown that the band gaps decreased with the increase in concentration (Table 1, Fig. 4).

Surface morphology of ZnO thin films

Figure 5i–v is the SEM image that gives the microscopic information about the surface structural morphology and roughness of the films. In this work, the scanning electron microscopic technique appeared to be useful in specifying the growth mode through the study of surface roughness and to determine the effect of concentration on the film morphology. Figure 5 shows the surface topography of ZnO thin film at different concentration and doped with 4-nitrogen atoms. The grain size increased as the concentration changed from 0.2 to 1.0 M as shown in Fig. 5i–v. This could be referenced to earlier reports [37]. As the concentration increases, the amount of zinc acetate (solute) also increases, therefore the electrostatic interaction of the solute particles becomes wider, thereby increasing the possibility of more solutes to be connected to form more grains. Consequently, as the concentration increases, the grain size also increases. The polycrystalline formation of the films with grain boundary micropores is quite evident from the micrographs. The results were consistent with previous results [38, 39].

Electrical properties of the films

Apart from the optical and morphological properties of the materials, the electrical property is also an important parameter to obtain the performance of ZnO thin films. Electrical properties of the samples were studied using a four-point probe (FPP) to achieve a high degree of accuracy measurements involving low resistivity. The generated current–voltage (I–V) data from FPP was used to calculate sheet resistance (Rs), sheet resistivity (ρs) and sheet conductivity (σs) from Eqs. (4, 5, and 6), respectively. In FPP, the current (I) was injected through two outer probes 1 and 4, while the corresponding voltage drop (V) was measured by two other inner probes 2 and 3 [40].

where t is the thickness of the film. The response of film concentration on the electrical resistivity was presented in Table 2. Figure 5 shows the trends of the electrical resistivity of ZnO films depending on the concentration. It was observed that the resistivity of the films decreased with increasing concentration.

Conclusions

We successfully deposited transparent nitrogen-doped ZnO thin films on ITO glass substrates using electrodeposition technique at room temperature and thereafter annealed at 400 °C in a closed vacuum furnace. The optical, surface morphology and electrical properties of the films were studied. The films revealed high optical transmittance of about 90% in the wavelength between 350 and 850 nm of the electromagnetic spectrum. The energy band gaps evaluated are in the range of 3.50 eV and 3.25 eV, the result shows that there is decrease with respect to the increase in the precursor concentration. The SEM images analyzed show smooth homogeneous grains at lower concentration, while rough nonhomogeneous grain surfaces at higher concentrations. Electrical measurements established low resistivity with the high conductivity of nitrogen-doped ZnO thin films. These results had fulfilled the requirements for practical applications as transparent interconnection layers in thin film photovoltaic cells and other optoelectronics.

Data availability

The SEM images confirmed that grain size became denser from smooth homogeneous to inhomogeneous as the concentration increased from 0.2 M to 1.0 M.

References

Deependra, M.D., Agni, D., Buddha, R.S.: effect of annealing on optical properties of ZnO thin films prepared by homemade spin coater. Nepal J. Sci Technol. 15(2), 111–116 (2014)

Hoel, C.A., Mason, T.O., Gaillard, J.F., Poeppelmeier, K.R.: Transparent conducting oxides in the ZnO-In2O3-SnO2 system. Chem. Mater. 22(12), 3569–3579 (2010)

Musiliyu, K.A., Alao, O.A., Olaniran, S.A., Akin-Ojo, O.: Design and development of an electrodeposition system and application to a thin film semiconductor material (CdZnSeS) for solar cell application. Abuad J. Eng. Res. Dev. 3(1), 114–122 (2019)

Manivannan, R., ViDeependra, M.D., Agni, D., Buddha, R.S.: Preparation of chalcogenide thin films using electrodeposition method for solar cell applications–a review. Sol. Energy 173, 1144–1157 (2014). (Effect of annealing on optical properties of ZnO thctoria, S. N. (2018))

Iffelsberger, C., Ng, S., Pumera, M.: Catalyst coating of 3D printed structures via electrochemical deposition: case of the transition metal chalcogenide MoSx for hydrogen evolution reaction. Appl. Mater. Today 20, 100654 (2020)

Wang, Y.P., Lu, J.G., Bie, X., Ye, Z.Z., Li, X., Song, D., Ye, W.Y.: Transparent conductive and near-infrared reflective Cu-based Al-doped ZnO multilayer films grown by magnetron sputtering at room temperature. Appl. Surf. Sci. 257(14), 5966–5971 (2011)

Schneider, S.L., Lim, H.W.: A review of inorganic UV filters zinc oxide and titanium dioxide. Photodermatol. Photoimmunol. Photomed. 35(6), 442–446 (2019)

Ajayi, A.A., Alabi, A.B., Abodunrin, A.W., Musiliyu, K.A.: Structural and optical characterization of chemically synthesize nanaostructured ZnO thin film. Abuad Int J. Nat. Appl. Sci. 1(1), 18–23 (2021)

Mursal, I., Bukhari, Z.J.: Structural and optical properties of ZnO based thin films deposited by Sol-Gel coating method. J. Phys Conf. Ser. 1116, 1–7 (2018)

Wang, Z., Nayak, P.K., Caraveo-Frescas, J.A., Alshareef, H.N.: Recent developments in p-Type oxide semiconductor materials and devices. Adv. Mater. 28(20), 3831–3892 (2016)

Gieraltowska, S., Wachnicki, L., Witkowski, B.S., Godlewski, M., Guziewicz, E.: Atomic layer deposition grown composite dielectric oxides and ZnO for transparent electronic applications. Thin Solid Films 520(14), 4694–4697 (2012)

Fang, X., Bando, Y., Gautam, U.K., Zhai, T., Zeng, H., Xu, X., Golberg, D.: ZnO and ZnS nanostructures: ultraviolet-light emitters, lasers, and sensors. Crit. Rev. Solid State Mater. Sci. 34(3–4), 190–223 (2009)

Dimitrov, D., Tsai, C.L., Petrov, S., Marinova, V., Petrova, D., Napoleonov, B., Lin, S.H.: Atomic layer-deposited Al-doped ZnO thin films for display applications. Coatings 10(6), 539 (2020)

Wang, Y., Zhou, C., Elquist, A.M., Ghods, A., Saravade, V.G., Lu, N., Ferguson, I.: A review of earth abundant ZnO-based materials for thermoelectric and photovoltaic applications. Oxide-Based Mater. Dev. IX 10533, 163–179 (2018)

Wang, J., Sun, X.W., Jiao, Z.: Application of nanostructures in electrochromic materials and devices: recent progress. Materials 3(12), 5029–5053 (2010)

Santos, Y.P., Valença, E., Machado, R., Macêdo, M.A.: A novel structure ZnO-Fe-ZnO thin film memristor. Mater. Sci. Semicond. Process. 86, 43–48 (2018)

Masood, K.B., Kumar, P., Malik, M.A., Singh, J.: A comprehensive tutorial on the pulsed laser deposition technique and developments in the fabrication of low dimensional systems and nanostructures. Springer Emerg. Mat. 4, 737–754 (2021)

Vyas, S., Gir, P., Singh, S., Chakrabarti, P.: Comparative study of As-deposited ZnO thin films thermal evaporation, pulse laser deposition and RF sputtering methods for electronic and optoelectronic applications. J. Electr. Mat. 44, 3401–3407 (2015)

Stamate, E.: Spatially resolved optoelectronic properties of Al-doped ZnO thin films deposited by RF magnetron plasma sputtering without substrate heating. J. Nanomater. 10(4), 1–11 (2019)

Shuang-peng, W., Chong-Xin, S., et al.: Electrical and optical properties of ZnO thin films grown by molecular beam epitaxy. Appl. Surf. Sci. 255(9), 4913–4915 (2009)

Wang, J., Hao, J., Zhang, Y., Wei, H., Mu, J.: Molecular beam epitaxy of Gd2O3 thin films on SrTiO3 (100) substrate. Phys E. Low-Dimens. Syst. Nanostruct. 80, 185–190 (2016)

Faraj, M.G., Ibrahim, K.: (2011); Optical and structural properties of thermally evaporated zinc oxide thin films on polyethylene terephthalate substrates. Int. J. Polym. Sci. 4, 1–4 (2011)

Paul, P., Faruk Hossain, Md., Sifatul, M. Md.: Fabrication of a cost effective thermal evaporation system for thin film deposition. In: 4th International Conference on IEEE (2018)

Konan, F.K., Hartiti, B., Nkuissi, H.J.: Optical structural characterization of i-ZnO thin films deposited by chemical route. J. Mat. Environ. Sci. 10(10), 1003–1010 (2019)

Daniya, M., Konstantin, M., Nikolay, C., Nurlan, T.: Fabrication and study of sol-gel ZnO films for use in Si-based heterojunction photovoltaic devices. J. Mod. Electr. Mater. 3(4), 158–161 (2017)

Afishah, A., Kouta, H., Nobuaki, K., Hisashi, F., Katsuhiro, U.: Fabrication of ZnO thin-film transistors by chemical vapor deposition method using zinc acetate solution. Jpn. J. Appl. Phys. 50(152), 215–223 (2011)

Ashok, A., Regmi, G., Romero-Nunez, A., Solis-Lopez, M., Velumani, S., Casteaneda, H.: Comparative studies of CDS thin films by chemical bath deposition techniques as a buffer layer for solar cell applications. J. Mater. Sci. 31, 7499–7518 (2020)

Murugesan, R., Sivakumar, S., Karthik, K., Amandan, P., Haris, M.: Effect of Mg/Co on the properties of CDS thin films deposited by spray pyrolysis technique. Curr. Appl. Phys. 19(10), 1136–1145 (2019)

Ramadhani, M.F., Pasaribu, M.A.H., Prian, Y.N.: Fabrication of ZnO nanorod using spray pyrolysis and chemical bath deposition methods. AIP Conf. Proc. 1586, 74–77 (2014)

Abhijit, R.: Electrodeposition of thin films for low-cost solar cells, Electroplating of nanostructures. Web of Science, pp. 1–30 (2015)

Taliatu, B.A., Fasasi, A.Y., Di Santo, G., et al.: Electro-chemical deposition of Zinc-oxide nanostructures by using two electrodes. AIP Adv. 1(032147), 1–10 (2011)

Jensen, W.B.: Faraday’s laws or Faraday’s law? J. Chem. Educ. 89(9), 1208–1209 (2012)

Foo, K.L., Kashif, M., Hashim, U., Wei-Wen, L.: Effect of different solvents on the structural and optical properties of zinc oxide thin film for optoelectronic applications. Ceram. Int. 40, 753–761 (2014)

Marouf, S., Beniache, A., Guessasa, H., Azizi, A.: Morphological, structural and optical properties of ZnO thin films deposited by dip coating method. Mater. Res. 20(1), 88–95 (2017)

Tang, G., Lin, H., Zhang, W.: The variation of optical bandgap for ZnO in films prepared by sol-gel technique. Adv. Mater. Sci. Eng. 348601, 1–4 (2013)

Kumar, A., Kumar, R., Verma, N., Anupama, A.V., Choudhary, H.K., Philip, R., Sahoo, B.: Effect of the band gap and the defect states present within band gap on the non-linear optical absorption behaviour of yttrium aluminium iron garnets. Opt. Mater. 108, 110163 (2020)

Hossain, M.P., Zhang, Z.H., Takahashin, T.: Novel micro-ring structured ZnO photoelectrode for dye-sensitized solar cell. Nano-Micro Lett. 2, 53–555 (2010)

Qiu, J., Weng, B., Zhao, L., Chang, C., Shi, Z., Li, X., Kim, H., Hwang, Y.: Synthesis and characterization of flower-like bundles of ZnO nanosheets by surfactant-free hydrothermal process. J. Nanomater. 5, 5 (2014). https://doi.org/10.1155/2014/281461

Stamate, E.: Spatially resolved opto-electronic properties of Al-doped zinc oxide thin films deposited by radio frequency magnetron plasma sputtering without substrate heating. Nanomaterials 10(14), 1–11 (2019)

Muchuweni, E., Sathiaraj, T.S., Nyakotyo, H.: Synthesis and characterization of Zinc oxide thin films for optoelectronic applications. Heliyon 3, 1–19 (2017)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Musiliyu, K.A., Ogunmola, E.D., Ajayi, A.A. et al. Effect of concentration on the properties of nitrogen-doped zinc oxide thin films grown by electrodeposition. Mater Renew Sustain Energy 12, 23–29 (2023). https://doi.org/10.1007/s40243-022-00225-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40243-022-00225-0