Abstract

Multilayer thin films with alternate hydrogenated amorphous (a-Si:H) and nanocrystalline silicon (nc-Si:H) layers are deposited in hot wire chemical vapor deposition (HWCVD) chamber using hydrogen (H2) dilution of silane (SiH4). Two sets (two samples for each set) have different nc-Si:H layer thickness with the same a-Si:H thickness. The transmittance spectra, refractive index and absorption coefficient are obtained using UV–Vis spectroscopy. An analysis of Tauc plot suggests thickness-dependent optical band gap shift. The films with thick nc-Si:H layers show a decrease in band gap from 1.78 to 1.68 eV, whereas the films with lower nc-Si:H layer thickness have an increased band gap from 1.64 to 1.72 eV. Further, the slope of the Tauc plot (B) and disorder indicator (Urbach energy, E u) show that the films with thick nc-Si:H layers are poorly ordered as hydrogen dilution increases. These results illustrate that band gap shift can be attributed to the crystal size effect and film disorder. This shifting of optical band gap with the nc-Si:H layer thickness is useful in tuning of the absorber layer band gap which finds an application in photovoltaics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the first generation of solar photovoltaics technologies, the crystalline silicon (c-Si) is the leading material for solar cell fabrication. c-Si offers the highest efficiency and long-term stability [1]. As of today, almost 89% of the PV market is captured by the c-Si wafer-based technology. However, the high cost of obtaining ultrapure silicon material has forced scientists to search for cost-effective alternate materials. As an alternative material, amorphous silicon (a-Si:H) film can be fabricated at very low temperature. The films have higher light absorption than c-Si and hence need very small film thickness for solar cell fabrication in comparison with the c-Si wafer. On the contrary, the light-induced instability in the a-Si:H films (Staebler-Wronski effect) causes long-term degradation in efficiency [2]. To get rid of this problem in the a-Si:H films, the films are prepared with higher hydrogen dilution. Thus, films with higher hydrogen contents are known as hydrogenated nanocrystalline silicon (nc-Si:H) films. nc-Si:H is a material in which silicon nanocrystals are embedded in the amorphous matrix. The films have excellent structural and electronic properties than the a-Si:H films. The nc-Si:H films provide better carrier transport and have a broader absorption range in the visible solar spectrum, tunable band gap, almost complete absence of light-induced degradation [3], higher electrical conductivity and greater doping efficiency [4]. An a-Si:H p-i-n solar cell has an efficiency of ~ 6%, whereas an nc-Si:H p-i-n cell offers slightly higher efficiency. To take advantage of both the materials, the properties of nc-Si:H together with good absorption characteristics of a-Si:H are utilized in multijunction structures. A tandem cell (a-Si:H/µc-Si:H) and triple junction silicon cell (a-Si:H/µc-Si:H/µc-Si:H) have been fabricated with efficiencies ~ 13% [5, 6]. Another option by which to combine the properties of both the materials is to incorporate the silicon multilayer structure. The multilayer structure seems a potential candidate as an absorber layer in p-i-n or n-i-p solar cells, through which the efficiency of the solar cell can be tailored by adjusting the optical, structural and electronic properties of nanocrystalline silicon layers. Solar cells with silicon multilayer as an absorber have been constructed. The multilayer contains a silicon layer sandwiched between dielectric layers of SiO2, Si3N4 and SiC [7, 8]. The quality of the sandwiched silicon layer is improved by post-deposition annealing at very high temperatures. However, the use of low-cost substrates is not possible with the high temperature annealing step. In addition, the dielectric layers hinder the charge carrier transport and deteriorate the performance of the solar cell. To avoid the disadvantage of the dielectric layers, it can be replaced by the silicon layer, which definitely helps in improving the electrical properties of the device. Therefore, a mixed phase of silicon in the form of an a-Si:H/nc-Si:H multilayer is found to be a suitable absorber layer in solar cells. This structure provides tuning of the optical band gap and crystalline volume fraction [1, 9]. Improved quantum efficiency is observed in a solar cell with the sandwiched nc-Si:H layers with variable thickness of the a-Si:H layers [10]. The a-Si:H/nc-Si:H superlattice with reduction in the thickness of nc-Si:H layer shows an increased absorption near the ultraviolet region, together with the band gap widening as a result of the quantum confinement effect [11]. A stable photoluminescence and an enhanced vertical photosensitivity [12, 13] are observed in a-Si:H/nc-Si:H superlattice-based solar cells [14].

The size-dependent characterization of the materials has fostered the band gap tuning of semiconductor materials. The tailoring in band gap can be done by changing the process parameters such as pressure, temperature, process gas dilution, deposition time (thickness) or power. The hot wire chemical vapor deposition (HWCVD) technique is used in this experiment for deposition of the multilayer structure, as it provides better gas utilization, defect-free deposition from ion bombardment and moderate deposition rate in comparison with the plasma-enhanced CVD technique. The objective of this paper is to discuss the effect of nanocrystalline layer thickness on the optical properties of a 50-layer stack of alternate a-Si:H/nc-Si:H silicon multilayers deposited on a quartz substrate.

Experimental

Two sets of a-Si:H/nc-Si:H stacks are prepared by HWCVD on an RCA-cleaned quartz substrate. The films are prepared by hydrogen (H2) dilution of silane (SiH4). The hydrogen dilution ratio is defined as the ratio of [H2/SiH4] gas flow rate. The distance between the substrate and filament is adjusted to 5 cm. The base pressure of a load lock chamber is observed to be ~ 10−6 mbar and the gas pressure is ~ 10−4 mbar. The substrate temperature of 250 °C and filament temperature of 2000 °C are kept constant. An a-Si:H layer is formed by pure SiH4 and the nc-Si:H layer is deposited by a mixture of H2 and SiH4 gas inside the chamber. Twenty-five cycles of this bilayer (i.e., 50 layers) structure is deposited, with the a-Si:H layer being first on the quartz substrate as shown in Fig. 1. As reported in [15], the improper thickness of a-Si:H and nc-Si:H layers may cause problems in charge collection; hence, films with varied deposition time for nc-Si:H layers and constant deposition time for a-Si:H layer have been developed in the present work. The a-Si:H layer deposition time is kept for 1 min in both sets, and the nc-Si:H layer deposition time is 3 min for set 1 and 1 min for set 2. The total deposition time is 100 min for set 1 and 50 min for set 2.

The optical behavior is characterized by a self-assembled UV–visible spectroscopy measurement setup. The setup mainly includes broadband tungsten–halogen lamp as the light source (Ocean Optics), a monochromator (Oriel cornerstone), an optical chopper (Stanford Research), a lock-in amplifier (Stanford Research) and a silicon photo detector (Edmond Optics). The wavelength range of 500–1100 nm with step size of 5 nm is used at room temperature to get the transmission spectra of the deposited films. The normalized transmission spectrum interference fringes are used to determine the film thickness. The absorption coefficient (α) of the films is calculated by the PARAV software [16], which applies the envelope method to generate the maxima and minima points on the envelope. The refractive index of the quartz substrate is taken as 1.5 [16]. The optical band gap is estimated by linear extrapolation of the Tauc plot [17].

Results and discussion

The transmittance spectra for the deposited multilayer films are shown in Fig. 2 with different nc-Si:H layer deposition times. Increased transmittance with reduction in photon energy is observed for both sets of films. The pattern shows interference fringes, and the number of fringes observed clearly gives films with different thicknesses. The transmission spectrum shows lower transmission probability for multilayer films set 1 compared to multilayer set 2, indicating the thickness-dependent transmittance. The absorption edges at zero transmittance, in case of set 1 films, nearly overlap, and in set 2 the absorption edges are different.

The refractive index is an important optical parameter which gives information about the film structure and porosity of the deposited films. The plot in Fig. 3 shows that the films exhibit almost constant refractive index in the range of 3.1–3.3 for the lower photon energy. With increased photon energy, the films of set 1 indicate slow increment in the refractive index, whereas this change is rapid for the films of set 2. This indicates that the film composition and volume fractions change with the film thickness and the dilution ratio. In both sets, the film with lower hydrogen dilution shows higher refractive index than higher dilution ratio, indicating densely packed films. As hydrogen dilution increases, the film crystallization may increase with the enhancement of void fraction, making the material porous and resulting in lowering the refractive index. The films with higher nc-Si:H layer thickness (set 1) have lower refractive index compared to films with lesser nc-Si:H layer thickness (set 2).

The presence of mixed silicon phases can have a profound effect on the absorption characteristics of the films (Fig. 4). A decreased absorption with an increase in hydrogen dilution is observed in the visible spectrum, indicating that films are becoming more crystalline. The films with lower hydrogen dilution have higher absorption compared to higher diluted films. This indicates that the films with lower hydrogen dilution may consist of smaller nanocrystals embedded in the amorphous matrix and grain boundaries.

In these films, the light scattering and residual amorphous fraction may contribute to enhanced light absorption. The film thickness also shows a significant effect on the absorption characteristics. The thicker films have comparatively low absorption in the visible region as α is inversely proportional to the film thickness, though it is significant, indicating its porous nature as shown by lower refractive index. The film behavior changes and a wavy pattern is seen below 1.8 eV, which can be due to the light scattering and multiple reflections at the interfaces of the film structure [18].

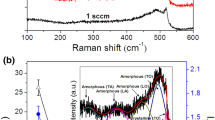

The hydrogen dilution, film thickness, structural defects and disorder of the films typically affect the optical properties of a multilayer film. To estimate the effect on optical band gap (E gopt) of the deposited a-Si:H/nc-Si:H multilayer films, the Tauc plot, (α*E)0.5 = B*(E–E gopt) is illustrated in Fig. 5. Here, α is the absorption coefficient (cm−1), E the photon energy (eV) and B the constant known as the edge width parameter, which indicates the sharpness of the band edge. The band gap of the multilayer films in the present study varies with the film thickness and hydrogen dilution. As seen in Fig. 5, the films with greater nc-Si:H thickness show a decrease in band gap from 1.78 to 1.68 eV as the hydrogen dilution ratio (R) is varied from 2 to 4. The reduction in the band gap is supported by the XRD measurements as shown in Fig. 6. The < 220 > is the dominating phase at 47.6° with a small hump of < 111 > at the 28.5° phase and their intensity increases with increase in hydrogen dilution. This result clearly indicates that the film with higher dilution contains more nc-Si:H. The grain size calculated using D’bye Scherer formula lies in the range ~ 23 nm for R = 2, and ~ 30 nm for R = 4. With an increase in the hydrogen dilution, the grain size increases and the band gap reduces. Similar results have been reported by researchers. [11, 19,20,21].

The band gap estimation has shown reverse trend in the films of set 2 with lower nc-Si:H layer thickness. The band gap increases from 1.64 to 1.72 eV when R increases from 2 to 4. This result is in agreement with the results in literature [11, 22]. Thus, we see that films with greater nc-Si:H layer thickness have reduced band gap with increase in hydrogen dilution. This can possibly happen as the nanocrystals are embedded in amorphous silicon matrix. The increase in hydrogen dilution can cause greater crystallization and coalescence of small crystals into large nanocrystals due to greater deposition time of the nanocrystalline layers. This can cause a decrease in the amorphous content (or increased crystalline fraction), and hence a decrease in E gopt (1.78–1.68 eV) with increased hydrogen dilution is observed (Table 1). This indicates that the multilayer band gap shifts toward bulk silicon value. In case of multilayer with lower thickness nanocrystalline layers, the band gap shifts toward higher values (1.64 eV to 1.72 eV) on increasing hydrogen dilution from 2 to 4. This can be justified on the basis that intermediate nanocrystalline layer deposition time is only 1 min (Table 1). The results reported for thin Ge films [23] show strong dependence of band gap on the film thickness.

The Tauc slope B indicates the sharpness of the band edges and is related to the width of the band tails. This denotes the film disorder in terms of bond angle and bond length distribution [24, 25]. Usually, B is inversely proportional to the width of the tail states, which widen with an increase in disorder indicated by the Urbach energy (E u). The typical value of B is close to 700 (cm*eV)−0.5 for pure a-Si:H [18]. The higher the B factor, the higher is the structural order of the film [25]. According to the relation between electronic density and the B factor, one can estimate the crystalline fraction from the observed value of the Tauc slope (B). As seen in Table 1, the slope (B) of the Tauc plot decreases with increase in hydrogen dilution for the films with thick nanocrystalline silicon layers. This indicates that with larger thickness and increased hydrogen dilution, the crystalline volume fraction increases. The films with lower nc-Si:H silicon layer thickness show increase in value of Tauc slope B with increased hydrogen dilution and hence reduction in crystalline volume fraction can be predicted.

To further evaluate the quality of the films in terms of disorder, the Urbach energy (E u) is calculated [26]. The E u defines the width of the exponential band tails of density of states (DOS) which extends into the band gap. These exponential band tails of DOS refer to the localized states, which are responsible for structural disorder where high value of E u indicates higher disorder:

Here, α 0 is a constant. With reference to Eq. 1, a plot of ln(α) versus energy and a straight line mathematical fit to linear regions suggest the increased value of the Urbach tail width from 40 to 75 meV for set 1 as hydrogen dilution increases from 2 to 4. This gives an indication that with increased nanocrystalline layer thickness, the disorder (defects and grain boundaries) is increased as this result is well supported by a decreased value of the Tauc slope factor B. The set 2 films show a decrease in value of E u from 74 meV to 56 meV as hydrogen dilution increases from 2 to 4 (Table 1). Thus, a decrease in E u and an increase in the Tauc slope factor B guarantee films with better structural order. The typical value of device quality amorphous silicon film is < 50 meV [27].

The reduction in band gap of the films can also be related to the Urbach tail width [28]. The Urbach tail width increases in set 1 film with increase in hydrogen dilution, whereas the band gap shows decreasing trend while reverse is observed for set 2 films with lower thickness nc-Si:H films. Thus, by proper choice of nanocrystalline silicon layer thickness and hydrogen dilution, we can tune the band gap and structural order of multilayer films. The higher value Tauc slope factor (B) and lower Urbach tail width make the film structurally ordered with less defects. We conclude that the a-Si:H/nc-Si:H multilayers deposited at high hydrogen dilution of silane and lower nanocrystalline silicon thickness are compact with less band tails characterizing good-quality materials.

Conclusion

The experiment deals with the effect of nanocrystalline silicon layer thickness on the optical properties of a multilayer stack of a-Si:H/nc-Si:H. The band gap of the multilayer films varies with the film thickness and the hydrogen dilution. The multilayer film with greater nc-Si:H thickness shows decrease in the band gap, and multilayers with lower nc-Si:H film thickness show increase in band gap as hydrogen dilution increases. This change in band gap can be attributed to change in the value of the Urbach tail width. A higher value of Tauc slope B and a lower value of the Urbach energy E u for multilayer film with thin nanocrystalline silicon layers imply the growth of lower grain boundary defects and disorder. The lowering of the defects in multilayer film with thin nc-Si:H layer provides it the potential to be used as an absorber layer in the multijunction solar cells. Thus, by optimizing the nanocrystalline silicon layer thickness and the hydrogen dilution, one can tune the band gap and structural order of multilayer films. Therefore, the a-Si:H/nc-Si:H multilayer film with high hydrogen dilution and lower nc-Si:H layer thickness can be used for good-quality thin film silicon solar cells.

References

Gajovic, A., Gracin, D., Krunoslav, J.S., Ceh Parramon, M.: Correlating Raman spectroscopy and high resolution transmission electron microscopy studies of amorphous/nanocrystalline silicon thin films. Thin Solid Films 517, 5453–5458 (2009)

Staebler, D.L., Wronski, C.R.: Reversible conductivity changes in discharge-produced amorphous Si. Appl. Phys. Lett. 31, 292 (1977)

i-Cabarrocas, P.R.: Plasma enhanced chemical vapor deposition of amorphous, polymorphous and microcrystalline silicon films”. J. Non-Cryst. Solids 266–269, 31–37 (2000)

Saleh, R., Nickel, N.H.: Raman spectroscopy of B-doped microcrystalline silicon films. Thin Solid Films 427, 266 (2003)

Sai, H., Matsui, T., Koida, T., Matsubara, K., Kondo, M., Sugiyama, S., Katayama, H., Takeuchi, Y., Yoshida, I.: Triple-junction thin-film silicon solar cell fabricated on periodically textured substrate with a stabilized efficiency of 13.6%. Appl. Phys. Lett. 106, 213902 (2015)

Cashmore, J.S., Apolloni, M., Braga, A., Caglar, O., Cervetto, V., Fenner, Y., Aschemann, S.G., Goury, C., Hotzel, J.E., Iwahashi, T., Kalas, J., Kitamura, M., Klindworth, M., Kupich, M., Leu, G.F., Lin, J., Lindic, M.H., Losio, P.A., Mates, T., Matsunaga, D., Mereu, B., Nguyen, X.V., Psimoulis, I., Ristau, S., Roschek, T., Salabas, A., Salabas, E.L., Sinicco, I.: Record 12.34% stabilized conversion efficiency in a large area thin film silicon tandem (MICROMORPH™) module. Prog. Photovolta. Res. Appl. 23(11), 1441–1447 (2015)

Mavilla, N.R., Solanki, C.S., Vasi, J.: Raman spectroscopy of silicon-nanocrystals fabricated by inductively coupled plasma chemical vapor deposition. Phys. E 52, 59–64 (2013)

Panchal, A.K., Solanki, C.S.: Fabrication of silicon quantum dots in SiNx multilayer using hot-wire CVD. J. Cryst. Growth 311, 2659–2663 (2009)

Goh, B.T., Wah, C.K., Aspanut, Z., Rahman, S.A.: Structural and optical properties of nc-Si: H thin films deposited by layer by layer technique. Journal of Material Science: Mater Electron 25, 286–296 (2014)

Dalal, V.L., Madhavan, A.: Alternative designs for nanocrystalline silicon solar cells. J. Non-Cryst. Solids 354, 2403–2406 (2008)

Kar, D., Das, D.: Superior optical response of size-controlled silicon nano-crystals in a-Si:H/nc-Si: H superlattice films for multijunction solar cells. RSC Adv. 5, 61118–61126 (2015)

Tong, S., Liu, X., Bao, X.: Study of photoluminescence in nanocrystalline silicon/amorphous silicon multilayers. Appl. Phys. Lett. 66, 469–471 (1995)

Jun, K.H., Lim, K.S.: Enhanced vertical photo-sensitivity in & #x03BC;c-Si:H/a-Si: H superlattices. J. Non-Cryst. Solids 261, 268–272 (2000)

Pattnaik, S., Chakravarty, N., Biswas, R., Dalal, V., Slafer, D.: Nano-photonic and nano-plasmonic enhancements in thin film silicon solar cells. Sol. Energy Mater. Sol. Cells 129, 115–123 (2014)

Madhvan A., Dalal,, V.L., Noack M.A.: Superlattice structures for nanocrystalline silicon solar cell. In: IEEE International conference on Electro/Information Technology (EIT 2008) (2008), pp 383–388

Ganjoo, A., Golovchak, R.: Computer program PARAV for calculating optical constants of thin films and bulk materials: Case study of amorphous semiconductors. J. Optoelectron. Adv. Mater. 6, 1328–1332 (2008)

Tauc, J. (ed.): Amorphous and liquid semiconductor. Plenum Press, New York (1974)

Gracin, D., Aramon, J.S., Juraic, K., Gajovic, A., Ceh, M.: Analysis of amorphous nano crystalline multilayer structure by optical photo-deflection and photo-current spectroscopy. Micron 40, 56–60 (2009)

Rotaru, C., Nastase, S., Tomozeiu, N.: Amorphous phase influence on the optical bandgap of polysilicon. Phys. Status Solidi (A) 171, 365–370 (1999)

Hwang, H.S., Park, M.G., Ruh, H., Yu, H.: Investigations on microcrystalline silicon films for solar cell application. Bull. of Korean Chem. Soc. 31(10), 2909–2912 (2010)

Bakr, N.A., Mubarak, T.H., Habubi, N.F.: Impact of dilution gases on structure, properties and growth of hydrogenated nanocrystalline silicon (nc-Si:H) prepared by HW-CVD method. Int. J. Thin Film Sci. Technol. 2(2), 113–126 (2013)

Funde, A.M., Bakr, N.A., Kamble, D.K., Hawaldar, R.R., Amalnerkar, D.P., Jadkar, S.R.: Influence of hydrogen dilution on structural, electrical and optical properties of hydrogenated nanocrystalline silicon (nc-Si:H) thin films prepared by plasma enhanced chemical vapour deposition(PE-CVD). Solar Energy Material and Solar Cells 92, 1217–1223 (2008)

Goh, E.S.M., Chen, T.P., Sun, C.Q., Liu, Y.C.: Thickness effect on the band gap and optical properties of germanium thin films. J. Appl. Phys. 107, 024305 (2010)

Bhattacharya, K., Das, D.: Effect of deposition temperature on the growth of nanocrystalline silicon network from helium diluted silane plasma. J. Phys. D Appl. Phys. 41, 155420 (2008)

Tong, G.B., Aspanut, Z., Muhamad, M.R., Rahman, S.A.: Optical properties and crystallinity of hydrogenated nanocrystalline silicon (nc-Si:H) thin films deposited by rf-PECVD. Vacuum 86(8), 1195–1202 (2012)

Cody, G.D., Tiedje, T., Abeles, B., Brooks, B., Goldstein, Y.: Disorder and optical absorption edge of the hydrogenated amorphous silicon. Phys. Rev. Lett. 47(20), 1480–1483 (1981)

Street, R.A.: Hydrogenated amorphous silicon. Cambridge University Press, New York (1991). (ISBN: 0521371562)

Acknowledgements

The authors would like to thank Indian Nano-electronics Users Program (INUP) at IIT Bombay for project number M0085 and Sophisticated Analytical Instruments Facility (SAIF) at IIT Bombay for film deposition and characterization facilities. The authors also thank Dr. Vipul Kheraj, Assistant Professor and Mr. Sanjay Patel, Applied Physics Department, SVNIT, Surat for technical help.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kherodia, A., Panchal, A.K. Analysis of thickness-dependent optical parameters of a-Si:H/nc-Si:H multilayer thin films. Mater Renew Sustain Energy 6, 23 (2017). https://doi.org/10.1007/s40243-017-0107-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-017-0107-3