Abstract

The complex chemical hydride, ammonia borane (NH3BH3, AB) is a hydrogen rich compound. It is a promising hydrogen source for applications using proton exchange membrane fuel cells (PEMFCs) due to hydrogen content. It has reasonably lower operating temperatures compared with other solid-state hydriding materials. At present, AB is an expensive disposable source which in its pure form releases 1 mol of hydrogen at around 110 °C. This temperature is much higher than the operating temperature of PEMFC (~80 °C). At the operating temperatures of the fuel cell, the slow kinetics of pure AB is a deterrent which provides enough scope for experimentation. The paper is the result of experimental thermolysis effort by using nano-nickel as a catalyst with pure AB. The neat and catalyzed AB isothermal decomposition and kinetic behavior are illustrated through the experimental results obtained under various conditions. The focus of experimentation is to increase the rate and extent of release of hydrogen at lower temperatures. The experimental results indicated that the use of nickel as catalyst reduced the induction period with significant improvement in hydrogen release compared with neat AB.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ammonia borane (NH3BH3, AB) is a promising hydrogen source material due to its high hydrogen content (19.6 wt%). It is a white crystalline solid compound which was first synthesized and characterized by Shore and Parry [1] in the year 1955. The primary elements that make ammonia borane are nitrogen, hydrogen and boron. The elements nitrogen and hydrogen exist widely in the nature, e.g., in air and water [2]. Ammonia borane is a non-volatile material with appreciable degree of stability in air and water under ambient conditions. It can prove out to be an energy carrier for low power applications using proton exchange membrane fuel cell (PEMFC) at lower temperatures. Release of H2 from amino boranes is a difficult and complex process. Efforts are made to study the phenomenon in the experimentation. The molecular description of NH3BH3 indicates that it is a donor–acceptor adduct formed as a result of the dative bond between a Lewis acid (BH3) and a Lewis base (NH3) [3]. The compound is a solid at room temperature primarily due to di-hydrogen bonding and dipole–dipole interactions. Ammonia borane and diammoniate of diborane (DADB) are chemically similar with varying stability characteristics. It may be inferred that AB is more readily applicable than DADB to hydrogen storage for automotive use [4].

Hydrogen release studies

Ammonia borane can release more than 2 mol of H2 with heating to modest temperatures. The reactions of hydrogen evolution are summarized in Table 1.

The optimum thermal decomposition reaction of ammonium borohydride, NH4BH4 → BN + 4H2 occurs by a four-step process with H2 yields of 24 wt%. This far exceeds the US DOE set ambitious and stiff target which is 9 wt% for the year 2015. However, this will not make it an immediate option as many issues about its practical usage are yet to be addressed. The strict hydrogen purity requirements for fuel cell applications demand minimization of side reactions [6]. The possibility of toxic gaseous boranes in the evolved H2 is likely to affect the fuel cell performance. Above 500 °C, AB can be completely decomposed to form boron nitride (BN). The residue BN is not preferred for regeneration due to high chemical and thermal stability and hence ammonia borane is treated as a disposable source [7]. The main hurdle in hydrogen release is the slow kinetics at lower temperatures leading to long induction period [8, 9]. Neat AB thermally decomposes initially at 70 °C and reaches a maximum at 112 °C with the observed melting of AB to yield 1 mol of H2 and the by-product is polyaminoborane (NH2BH2)n. [2, 10, 11].

Use of catalyst is one of the methods explored by many researchers in the past to improve kinetics as well as hydrogen release at lower temperatures. Yao et al. [12] used lithium (Li) catalysis and mesoporous carbon (CMK-3) for thermal decomposition which released over 7 wt% hydrogen at 60 °C. Chen et al. [13] used Co- and Ni-based catalysts and observed a release of 1 mol of hydrogen at 59 °C. Burrell et al. [14] used Pt-catalyzed hydrogen release from AB with 4 wt% at 70 °C. Kalidindi et al. [15] used Cu and Ni nanoparticles and observed higher kinetics and hydrogen release. Sun et al. [16] performed monodisperse nickel particles catalysis in hydrolytic dehydrogenation of AB with the goal of preparation of non-noble metal catalyst. Gangal et al. [8] used silicon nanoparticles as catalyst and noted substantial reduction in activation energy and absence of induction period. Manners et al. [17] reported metals catalysis using Rh, Pd, Ru that could dehydrogenate ammonia borane at lower temperatures. Baker et al. [18] used Ni to develop unprecedented ability of hydrogen release from ammonia borane. Most of the above works included the use of organic or inorganic solvents and hydrolysis method to obtain improvements in the performance. After reviewing the performance and experimental processes adopted by earlier works, we decided to use nickel in its nano form as catalyst which holds enough promise to improve the dehydrogenation process. The goal of our work is to use the low cost and abundantly available nickel, a non-noble metal catalyst to optimize the hydrogen release from ammonia borane.

Experimental

Ammonia borane complex (97 % pure) purchased from Aldrich was used as received. Nano-nickel purchased from Laboratory Chemical Co. was used in the required quantity for mechanical mixing. Neat AB sample fourier transform infra-red (FTIR) analysis was done before dehydrogenation using Bruker Germany model 3000 Hyperion Microscope with Vertex 80 FTIR imaging system at the Sophisticated Analytical Instrumentation Facility (SAIF) in IIT Bombay.

The neat AB sample and catalyst Ni sample are characterized for XRD spectrum using XPERT-PRO diffractometer system with Cu anode and Kα having wave length of 1.554060°A, in the 2Ө range of 5.0214°–99.9834°. The TEM imaging of the both the samples was done using Philips TEM model CM200.

The experiments of isothermal decomposition were conducted in an indigenously developed Sievert’s type apparatus at 80, 100, 120, 140 and 160 °C, with different samples of AB and ABNi. The catalyzed sample was prepared by mechanical milling technique using nano-nickel in 10 % quantity i.e., 2 mg of Ni for 20 mg of AB before each experiment. The volume of the evolved gas with respect to time and pressure is recorded. The fine mix turned into gray colour and is used to perform isothermal decomposition test at five different temperatures starting from 80 °C. Each sample was loaded in a crucible of cylindrical shape within the reactor. By using different valves, sample holder is connected at separate instants to vacuum pump, hydrogen gas cylinder, and the apparatus. In each set of experiment and monitoring, the sample holder was evacuated and filled with hydrogen gas before finally connecting to the measuring setup of apparatus. A thermocouple is placed very close to the sample holder to measure the accurate temperature to which the sample is subjected. The temperature and pressure are recorded digitally at intervals of 1 min using a data logger. The change in pressure of the apparatus was used to calculate the amount of hydrogen released in wt%. The FTIR analysis was performed before and after dehydrogenation for each of the catalyzed sample to study the bond structures of reaction products.

Results and discussion

XRD and TEM of Ni samples

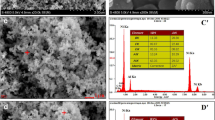

The XRD pattern of the Ni sample shown in Fig. 1 matches with the ICSD 64989, JCPDS reference code:00-004-0850. The presence of sharp peaks in the spectrum indicates the crystalline nature of the sample. The average crystal size calculated for the dominant peak (111) using Scherrer’s is found to be 55 nm. Hence, it can be confirmed that the Ni is nano-sized and the catalyst being used is nano-nickel.

The TEM images of Ni shown in Fig. 2 indicate nano particles of average size 40–65 nm. The diffraction rings indicate the crystalline nature of the material matching with the XRD pattern.

The crystallite size found using the Scherrer’s formula is estimated to be 46 nm and the dominant peak (110) appearing at the 2Ө value of 24.1831°.

The XRD pattern of the AB sample shown in Fig. 3 matches well with JCPDS reference no: 01-074-0894. In AB, the presence of sharp peaks indicates crystalline nature of the sample. This is in well accordance with the details reported in literature where it is mentioned that AB shows orthorhombic structure at lower temperatures. At higher than ambient temperatures, AB shows tetragonal structure [19].

The TEM image of the considered AB sample in Fig. 4 confirms the crystalline structure in the range 34–70 nm.

Hence, it is found through XRD characterization and TEM imaging that both ammonia borane and nickel used are nano-sized crystalline structure materials.

Isothermal decomposition

Thermolysis is a method which requires heating with temperature control. The Sievert’s type apparatus is a setup which permits this type of test on small quantities of material. Apparatus is designed to deal with challenges associated with solid-state reactions at elevated temperatures for the dehydrogenation in various stages from the material.

The isothermal decomposition of neat AB at lower temperatures is an extremely slow process with very long induction period. Strong chemical bond structure of neat AB is responsible for prolonged induction period and less hydrogen release at this temperature. The max release was achieved beyond 250 min which remained steady thereafter. Considerable reduction in the induction period is observed when isothermal decomposition was performed at 100 and 120 °C. Beyond induction period, 6–7 wt% gas is released. The literature provides the details of melting point of AB as 112–114 °C and at this temperature 1 mol equivalent of gas is liberated [20].

During 120 °C isothermal cycle, the hydrogen released is over 9 wt% which remains steady after 100 min with nominal induction period. The observations indicate that the increase in temperature decreases the induction period as well as expedites dehydrogenation process. The isothermal volumetric hydrogen release measurements presented the features that the neat AB sample released first mole of hydrogen at 110 °C and the second mole at 160 °C, respectively, in agreement with past results, respectively [19].

Catalytic dehydrogenation

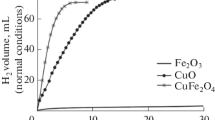

The dehydrogenation results of AB and ABNi and subsequent characterization are indicated graphically in Fig. 5, 6, 7, 8, 9. This helps to compare the pristine AB and catalyzed AB thermolysis performances at each stage of experiment. The amount of catalyst used is around 10 % of the mass of neat AB. Mechanical mixing ensures proper dispersion of the catalyst with the base material to increase material surface area. It can be observed from Fig. 5 that the ABNi dehydrogenation started with reduced induction period of 8 min compared to over 125 min for neat AB at 80 °C. The reduction in induction period may be due to nickel particles assisting in breaking of di-hydrogen bonds. The ABNi maximum hydrogen release is 4.5 wt% which is much higher compared to 3 wt% of neat AB at this temperature. It was also noted that the catalyzed samples did not foam during dehydrogenation.

The induction period and hydrogen release wt% values for various temperatures are summarized in Table 2.

It could be noted from Fig. 6 that the first mole of hydrogen is released at around 100 °C. Figure 7 indicates that the second mole at 120 °C in ABNi samples with very negligible induction period. Figures 8 and 9 show that the ABNi decomposition at 140 and 160 °C also have negligible induction period with substantial increase in the hydrogen gas release. The neat AB hydrogen release at these temperatures was in the range of 12 wt%, whereas catalyzed decomposition resulted in release of 13.5 wt%.

Transmittance spectrum of neat AB and Ni catalyzed AB

FTIR transmittance spectrum provides information about the chemical bonds in the sample under study [8]. The FTIR analysis of neat AB and Ni catalyzed AB was conducted before and after decomposition.

The FTIR of neat AB before and after decomposition is shown in Fig. 10. The FTIR of ABNi before and after decomposition is shown in Fig. 11. It is observed that various bonds are resembling in both the samples indicating the B–N bend at 700 cm−1, B–H2 torsion at 1,500 cm−1, B–H2 bend at 1,300 cm−1, B–H, B–H2 stretch at 2,300 cm−1 and N–H,N–H2, N–H3 stretch above 3,000 cm−1. This justifies the use of catalyst in the catalyzed sample is just facilitating the dehydrogenation process.

Transmittance spectrum of dehydrogenated catalyzed ABNi

The FTIR analysis of catalyzed dehydrogenated sample solid residue after each experiment with 80, 100, 120, 140 and 160 °C was performed to understand the effect of catalyst on chemical bond structures. The transmittance spectrum in each case is indicated in Fig. 12. The spectrum in (a)–(e) is almost identical with the broadening of peaks in the N–H stretch or B–H stretch which indicates the material decomposition and hydrogen release. The release of hydrogen in terms of wt% has showed improvement in comparison with neat AB with considerable reduction in the induction period. The second mole release in the experiment at 160 °C is visible in the transmittance curve with the broadening of N–H and B–H stretch.

The characteristic frequencies corresponding to N–H, N–H2 and N–H3 near 3,200 cm−1 go on broadening as the decomposition temperature increases and finally they almost disappear. The same phenomenon is observed for the frequency bands corresponding to B–H–B–H2 stretch observed near 2,200 cm−1. Shifting and broadening of the peaks corresponding to B–H2 torsion and bend in the range 1,000–1,500 cm−1 are also seen clearly in the Fig. 12.

The peak near 700 cm−1 corresponding B–N also appears to be slightly affected. It can be inferred that the hydrogen attached to borane and nitrogen is getting dissociated and the borane–nitrogen bond in its place, ruling out the possibility of formation of ammonia.

Broadening of peaks indicates the disruption of bonds resulting in the release of hydrogen. It is seen that the B–N bend is intact and has not got affected either due to catalysis or due to elevated temperatures. The non-formation of borazine is an indication that there are no unwanted reactions and by-products.

The FTIR study has indicated that there is gradual release of the hydrogen gas as the bonds are getting affected and the reactions are taking place at lower temperatures. With the rise in temperature, significant improvement in hydrogen release is observed at every stage with fast reaction kinetics and faster release of hydrogen.

Conclusion

XRD and TEM of Ni and AB confirmed the nano-sized crystalline structure of samples used.

Isothermal decomposition of ABNi clearly indicated significant improvement in hydrogen release with reduced induction period compared to AB.

The FTIR of neat and catalyzed AB is indicating no much difference in the transmittance characteristics. This helps in concluding that the presence of nickel as a catalyst is just facilitating the dehydrogenation process.

The FTIR of dehydrogenated sample indicates the release of hydrogen from various B–H and N–H bonds. The mechanical mixing of Ni with neat AB has resulted in considerable reduction in the induction time and improvement in hydrogen release rate.

The presence of BN bands in the FTIR of dehydrogenated ABNi sample near 700 cm−1 suggests that this band is not ruptured and the possibility of ammonia formation can be ruled out.

References

Shore, S.G., Parry, R.W.: The crystalline compound ammonia borane. J. Am. Chem. Soc. 77, 6084 (1955)

Peng, B., Chen, J.: Ammonia borane as an efficient and lightweight hydrogen storage medium. Energy Environ. Sci. 1, 479–483 (2008)

Weaver, J.R., Shore, S.G., Parry, R.W.: The dipole moment of ammonia–borane. J. Chem. Phys. 29, 1 (1958)

Karkamkar, A., Aardahl, C., Autrey, T.: Recent developments on hydrogen release from ammonia borane. Mater. Matters 2, 6–9 (2007)

Riis, T., Sandrock, G.: Hydrogen storage—gaps and priorities. HIA HCG Storage paper, 11 (2005)

Autrey, T., Gutowska, A., Li, L., Linehan, J., Gutowski, M.: Chemical hydrogen storage in nano-structured materials, control of hydrogen release and reactivity from ammonia borane complexes. J. Am. Chem. Soc. Div. Fuel Chem. 49(1), 150 (2004)

Diwan, M., Hwang, H.T., Al-Kukhun, A., Varma, A.: Hydrogen generation from noncatalytic hydrothermolysis of ammonia borane for vehicle applications. AIChE J. 57, 259–264 (2011)

Gangal, A.C., Kale, P., Edla, R., Manna, J., Sharma, P.: Study of kinetics and thermal decomposition of ammonia borane in presence of silicon nanoparticles. Int. J. Hydrog. Energy (2012). doi:10.1016/j.ijhydene.2012.01.017

Dileep, K., Mahajan, S.K., Mangalvedekar, H.A.: Hydrogen storage in amine borane complexes, pp. 1–5. ICFCHT, Kuala Lumpur (2011)

Stowe, A.C., Shaw, W.J., Linehan, J.C., Schmid, B., Autrey, T.: In situ solid state 11B MAS-NMR studies of the thermal decomposition of ammonia borane: mechanistic studies of the hydrogen release pathways from a solid state hydrogen storage material. Phys. Chem. Chem. Phys. 9, 1831 (2007)

Sit, V., Geanangel, R.A., Wendlandt, W.W.: The thermal dissociation of NH3BH3. Thermochim. Acta 113, 379 (1987)

Yao, X., Li, L., Sun, C., Du, A., Cheng, L., Zhu, Z., Yu, C., Zou, J., Smith, S.C., Wang, P., Cheng, H., Frost, R.L., Lu, G.Q.: Lithium-catalyzed dehydrogenation of ammonia borane within mesoporous carbon framework for chemical hydrogen storage. Adv. Funct. Mater. 19, 265–271 (2009)

Chen, P., He, T., Xiong, Z., Wu, G., Chu, H., Wu, C., Zhang, T.: Nanosized Co- and Ni-catalyzed ammonia borane for hydrogen storage. Chem. Mater. 21, 2315–2318 (2009)

Burrell, A.K., Shrestha, R.P., Diyabalanage, H.V.K., Semelsberger, T.A., Ott, K.C.: Catalytic dehydrogenation of ammonia borane in non-aqueous medium. Int. J. Hydrog. Energy 34, 2616–2621 (2009)

Kalidindi, S.B., Jagirdar, B.R.: Hydrogen generation from ammonia borane using nanocatalysts. J Indian Inst. Sci. 90, 181–187 (2010)

Sun, S., Metin, O., Mazumder, V., Ozkar, S.: Monodisperse nickel nanoparticles and their catalysis in hydrolytic dehydrogenation of ammonia borane. J. Am. Chem. Soc. 132, 1468–1469 (2010)

Manners, I., Jaska, C.A., Temple, K., Lough, A.J.: Transition metal-catalyzed formation of boron–nitrogen bonds: catalytic dehydrocoupling of amine–borane adducts to form aminoboranes and borazines. J. Am. Chem. Soc. 125, 9424 (2003)

Baker, R.T., Keaton, R.J., Blacquiere, J.M.: Base metal catalyzed dehydrogenation of ammonia–borane for chemical hydrogen storage. J. Am. Chem. Soc. 129, 1844 (2007)

Paolone, A., Palumbo, O., Rispoli, P., Cantelli, R., Autrey, T.: Hydrogen dynamics and characterization of the tetragonal-to-orthorhombic phase transformation in ammonia borane. J. Phy. Chem. C 113, 5872–5878 (2009)

Hu, M.G., Geanangel, R.A., Wendlandt, W.: The thermal decomposition of ammonia borane. Thermochim. Acta 23(2), 249–255 (1978)

Acknowledgments

The authors acknowledge the assistance of COE in CNDS Lab, VJTI Mumbai, SAIF Lab, IIT Bombay and Advanced Materials Lab at V.P.M.’s Polytechnic, Thane for the facilities offered for the experimental investigation work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under license to BioMed Central Ltd. Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Kumar, D., Mangalvedekar, H.A. & Mahajan, S.K. Nano-nickel catalytic dehydrogenation of ammonia borane. Mater Renew Sustain Energy 3, 23 (2014). https://doi.org/10.1007/s40243-014-0023-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-014-0023-8