Abstract

Mg2Ni-based compounds were prepared using a high-energy milling technique, with a planetary ball mill, and subsequent annealing at 350 °C. X-ray diffraction analyses revealed that Mg2Ni phase was obtained after 10 milling hours, in addition to Ni phase. Increasing the ball-milling duration from 10 to 17 h causes a decrease in the crystal size of particles from 93 to 76 nm. However, the subsequent annealing of all Mg2Ni-based materials highly increases their crystallite sizes with calculated values in the range of 261–235 nm. In the same way, X-ray diffraction patterns of annealed compounds show the presence of highly crystallized Mg2Ni phases. The particle size of Mg2Ni/Ni particles is estimated at 25 µm after 10 milling hours and drops to 5 µm at longer times. The scanning electron microscopy images of Mg2Ni/Ni particles demonstrated a drastic increase of their sizes up to 100 µm upon annealing. The hydrogenation reactivity and kinetic of Mg2Ni/Ni were both characterized by solid–gas reactions. The hydrogen absorption capacity value was about 3.5 H/f.u for milled and annealed Mg2Ni/Ni compound. The highest hydrogen absorption kinetic was obtained during the first 5 h of absorption time, where 95 % of the maximum absorption capacity was reached.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ni-metal hydrides (Ni-MH) are extensively studied as secondary batteries. Their applications include portable equipments and hydrogen fuel cell transportations. Among the materials investigated as possible Ni-MH negative electrode, Mg-based alloys exhibit promising performances [1–4]. Furthermore, the intermetallic Mg2Ni compound received a great attention for the reversible hydrogen storage [5]. Mg2Ni combines with hydrogen to form Mg2NiH4 hydride and highly improves the hydrogenation kinetic of magnesium [6]. Concerning synthesis processes of materials, melting is the conventional technique to prepare Mg2Ni [7]. However, the large difference in melting points and vapor pressures between Mg and Ni make difficult the formation of high quality Mg2Ni [7]. These drawbacks could be avoided by using the mechanical alloying (MA) process since the reaction between Mg and Ni occurs easily and reliably in the solid state [8–10]. Moreover, the MA process leads to the formation of surface defects and favors the formation of nanocrystalline materials. Commonly, amorphous phases are obtained from the MA of Mg and Ni, and may act as precursors for the formation of the crystalline Mg2Ni phase. Such properties are required for the improvement of the hydrogenation kinetic and the absorption capacity [11]. Combining ball-milling with a heat-treatment step generally increases the yield of the synthesis reaction [12–14]. Spassov et al. [15, 16] showed that Mg2Ni-based alloys subjected to an annealing step after the ball-milling procedure consist in homogenously nanocrystalline particles. On the other hand, Rojas et al. [17] succeeded in reducing the long milling time (14 h), needed for the transformation of Ni and Mg into Mg2Ni, to a shorter time (5 h) by a subsequent annealing at 673 K for 1 h. We have previously reported that the heat-treatment of ball-milled Mg2Ni materials leads to a high absorption capacity of 3.5 wt% [8].

In this work, Mg2Ni-based powders were prepared by mechanical alloying and subsequent annealing at 350 °C for 24 h. This temperature induces relevant microstructural modifications in the milled phase and enhances the hydrogen absorption/desorption properties. The control of the synthesis parameters plays an important role in increasing the equilibrium pressure and reducing the activation time of the hydrogen absorption reaction. The present paper presents an investigation of the hydrogenation kinetics of numerous Mg2Ni-based powders obtained by varying the cumulated energy of milling. Series of Mg2Ni phases were prepared and characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM) and thermogravimetric analyses before being tested for the hydrogen storage.

Experimental section

A mixture of elemental Mg (VWR, 99.8 %) and Ni (VWR, 99.9 %), with an atomic ratio of 2:1, was sealed into a stainless steel vial (50 cm3 in volume) with 5 stainless steel balls (15 mm in diameter and 13.6 g in mass) in a glove box filled with purified argon gas. The ball-to-powder weight ratio was equal to 68:1. The MA experiments were performed at room temperature using a Retsh PM400 planetary ball miller. The disc rotation speed and the vial rotation speed were equal to 250 and 500 rpm, respectively. These milling conditions correspond to kinetic shock energy of 0.63 J/hit, shock frequency of 45.6 Hz, and injected shock power of 5.75 W/g.

The crystallographic characterization of synthesized powders was carried out by XRD using a (θ–2θ) Panalytical XPERT PRO MPD diffractometer operating with Cu Kα radiation (λ = 0.15406 nm). The powder morphology of the samples was characterized with a FEI Quanta 200 environmental scanning electron microscope. Thermogravimetric measurements were based on the differential scanning calorimetry (DSC) technique using a Setaram 131 instrument. The analyses were realized at a heating rate of 20 °C/min, under nitrogen gas atmosphere. Prior to the hydrogen absorption measurements, the sample was pulverized mechanically, by a metallographic hammer and an agate mortar, into a powder of 63 µm in size. Hydrogenations of synthesized compounds were performed using solid–gas reactions. The hydrogen absorption capacity was measured with a home-made Sievert’s apparatus at a pressure of 11 bars and a temperature of 280 °C.

Results and discussion

Structural characterization

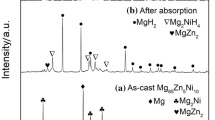

XRD patterns of mechanically alloyed powders are shown as a function of the alloying time in Fig. 1. After 10 h of milling, diffraction peaks relative to Mg2Ni phase (JCPDS 01-75-1249) are observed at 2θ (hkl) = 20° (003), 23° (102), 37° (112), 40° (200), 45° (203), 72° (220) and 86° (226). At this stage of milling, the pattern indicates the coexistence of elemental Ni and Mg2Ni phases. The presence of Ni is evidenced by diffraction peaks located at 2θ (hkl) = 44° (111), 52° (200) and 78° (220). Surprisingly, peaks relative to elemental Mg are not observed in any pattern. The absence of Mg peaks contrasts with previous studies, where elemental Mg and Ni still present in composites milled during 10 h [18–20], this behavior could be explained by the distinct shock powers injected during the mechanical alloying. In fact, in the same kinetic conditions (Ωdisc is the disc rotation speed, ωvial is the vial rotation speed, Rdisc is the disc radii, rvial is the vial radii and rball is the ball radii), the injected shock power increases by increasing the ball number and weight, or by reducing the material weight. For these reasons, the injected shock power increases by increasing the ball-to-powder weight ratio (BPR). The injected shock power in this study corresponds to a BPR of 68:1. Such a value is more important than the ones considered elsewhere by Gennari et al. [18] (BPR = 42:1) and Ebrahimi-Purkani et al. [19] (BPR = 20:1). In our previous works [21, 22], we reported that the structure of the stationary state was only a function of the injected shock power. Nevertheless, we reported that the amount of intermediary phases depends on the cumulated energy of milling (Ecum), defined by the following equation [5, 6]:

where Ecum is expressed in [Wh/g], Pinj is the injected shock power expressed in [W/g] and Δt is the alloying duration expressed in [h]. Consequently, the increase of the injected shock power allows the formation of the same intermediary states at lesser alloying durations.

In the present work, the absence of Mg diffraction peaks and the presence of remaining Ni suggest that amorphous Mg is confined in the Mg2Ni/Ni composite [18]. From 10 to 15 h of milling, i.e. cumulated energy from 57 to 86 Wh/g, the increase in the peak intensity of Mg2Ni (203) simultaneously occur with a decrease in the peak intensity of Ni (111) (Fig. 1b). After 17 h of milling, the cumulated energy is about 98 Wh/g. At this stage, the diffraction line of Ni (200) disappears, while the intensity ratio of Ni (111)/Mg2Ni (203) diminishes. These observations suggest a progressive formation of Mg2Ni phase accompanied by a loss of residual Ni in the composite. On the other hand, the increase of milling time results in broadening of peaks. Two factors may explain such a behavior: (i) the decrease of the crystallite size and, in a lesser extent, (ii) the increase of the lattice strains [23]. The average crystallite size of Mg2Ni powders were calculated from the corresponding (003) peak [8], using the following Debye-Sherrer equation [24]. The corresponding values are presented in Table 1 as a function of the milling time:

where D003 is the crystallite size of Mg2Ni, λ is the wavelength of the X-radiation, β is the full-width at half maximum (FWHM) of the peak and θ is the diffraction angle corresponding to (003) peak. Instrumental broadening and lattice distortion contributions were subtracted to values of peak broadening. Table 1 shows a continuous decrease of the crystallite size from 93 to 76 nm when the milling time varies from 10 to 17 h. The crystallite sizes estimated for as-prepared powder are higher than values reported in the literature [15, 18, 19, 25].

The heat-treatment of Mg2Ni powders was carried out at 350 °C for 24 h under vacuum. The resulting powders were characterized by XRD as shown in Fig. 1c. Independently on the milling duration, annealed powders show similar patterns reflecting a similar structural rearrangement upon annealing. The heat-treatment leads to sharper peaks, the disappearance of Ni diffraction peaks and a pure and highly crystalline Mg2Ni phase. The evaluation of the crystallite size for annealed powders indicates a steep increase of all D003 values upon annealing (Table 1) and demonstrates that heat-treating particles enhance their agglomeration.

SEM characterization

SEM micrographs of Mg2Ni powders mechanically alloyed during 10 and 12 h are shown in Fig. 2. The powder obtained after 10 h of MA shows an irregular shape of porous particles with an average size of 25 µm (Fig. 2a). As milling progresses, powder particles are fractured and their size becomes 5–6 µm, as displayed in Fig. 2b and Table 1. During the mechanical alloying, the elemental powder is blended, cold worked, welded and fragmented repeatedly. After a long period of milling, fracturing becomes the predominant event because of the brittle nature of Mg2Ni materials [19]. Further mechanical alloying from 12 to 17 h slightly affects the powder morphology (Table 1). On the other hand, Fig. 2a′ shows that subsequent annealing of Mg2Ni-based powders leads to a substantial increase of their particle size up to 100 µm. The same value was obtained for the whole series of milled and annealed Mg2Ni powders (Table 1). These observations are in a good agreement with the XRD results. The heat-treatment promotes the diffusion and the coalescence of Mg2Ni particles during the temperature increase. Thermodynamically, the particle size extends and converges to a value corresponding to the lowest free energy of Mg2Ni composite. During the growth of particles, the volume energy decreases, while the surface energy increases [26].

Thermogravimetric investigation

Figure 3 shows the DSC curves of mechanically alloyed and annealed products. During the temperature increase, the composite formed upon 10 h of milling time exhibits two exothermic peaks located at 132 and 220 °C (Fig. 3a). Both peaks were assigned elsewhere to the crystallization of amorphous Mg2Ni [17, 20]. In the present case, the first peak is assigned to the conversion of amorphous Mg2Ni to crystalline Mg2Ni, while the second one is attributed to the formation of highly crystallized Mg2Ni from residual Ni and amorphous Mg [17, 20]. The same phenomena are considered for the composite milled during 12 h since two thermal events are observed at 132 and 200 °C (Fig. 3b). It should be noticed that the second peak shifts to lower temperatures. When the milling time is increased up to 13 h (Fig. 3d), the DSC curve shows the presence of three exothermic peaks. Thermal events located at 132 and 200 °C are similar to those observed for compounds milled during 10 and 12 h and, therefore, correspond to the same reactions. However, the new peak appearing at 280 °C is associated to a further formation of Mg2Ni compound [27, 28]. This is thermodynamically favorable when the overall energy is increased by either increasing the milling time or through a thermal activation. For milling durations of 15 and 17 h, the peak located at 200 °C diminishes and only peaks located at 132 and 280 °C still present (Fig. 3f, g). XRD data demonstrated that increasing the milling time leads to Mg2Ni-rich phase (Fig. 1). The fraction of residual Ni that is transformed during the DSC scan becomes lower since it was already been transformed into Mg2Ni during the milling process. For this reason, the absence of the second exothermic peak is associated with residual precursors being mechanically transformed into Mg2Ni.

DSC curves of powders milled during 13 and 15 h and heat-treated at 350 °C for 24 h are shown in Fig. 3c, e. They are characterized by the absence of any thermal events. Curves of all annealed powders present a similar shape (data not shown). This is due to the formation of a highly crystalline Mg2Ni phase following the heat-treatment (Fig. 1c) and elucidates the role of the amorphous precursors in the Mg–Ni system.

Hydrogen storage properties

Figure 4 shows the evolution of the capacity during the hydrogen absorption for different ball-milled and annealed Mg2Ni-based materials. Independently on the milling duration, the absorption capacity of Mg2Ni expands significantly after 25 h of absorption time. For a longer time, the capacity value fairly increases and reaches a plateau. Nearly 90 % of the maximum capacity is reached after an absorption time of 25 h for all Mg2Ni powders. This behavior reflects a fast kinetic of the hydrogen absorption reaction in the beginning of the absorption process. The maximum capacity values obtained with heat-treated and unheated Mg2Ni-based powders are presented in Table 2. For all samples, experimental capacities are lower than the theoretical value expected for crystalline Mg2Ni, i.e. 4 H/f.u. This is mainly due to the heterogeneous chemical composition of prepared composites including crystallized and amorphous Mg2Ni, together with elemental Ni (Fig. 1). It was already demonstrated that amorphous Mg2Ni exhibits lower hydrogen absorption capacity than crystallized Mg2Ni [18]. Moreover, hydrogen atoms are poorly absorbed by the Ni phase in the present conditions. For these reasons, the hydrogen absorption capacity displayed by as-prepared powders is mainly related to Mg2Ni crystalline phase. Table 2 indicates that the absorption capacity increases by increasing the milling time for unheated compounds. This is explained by the decrease in the amount of residual Ni and the simultaneous formation of Mg2Ni phase during the mechanical alloying (Fig. 1b).

Evolution of the hydrogen absorption capacity during time for ball-milled Mg2Ni powders before (full lozenges) and after (open squares) annealing at 350 °C for 24 h. Milling durations are 10 h (a), 12 h (b), 13 h (c), 15 h (d) and 17 h (e). The hydrogen absorption was performed at a pressure of 11 bars H2 and a temperature of 280 °C

On the other hand, annealing Mg2Ni-based compounds enhances the capacity values for all prepared powders (Fig. 4). The absorption capacities of annealed samples vary with time following the same shape than unheated compounds. Again, the capacity value rises during the first 25 h and then stabilizes. The influence of the heat-treatment on the capacity values is indicated in Table 2. Annealed powders exhibit nearly the same absorption capacity with an average value of 3.47 ± 0.01 H/f.u. This similarity derives from the formation of comparable Mg2Ni microstructures (Fig. 1c) and morphologies upon heat-treating powders. The increase in the capacity value observed upon annealing powders is caused by the transformation of the amorphous Mg2Ni phase into a highly crystallized one, as evidenced by XRD characterizations (Fig. 1). In the same way, the annealing step promotes further conversion of residual Ni and amorphous Mg into Mg2Ni. The latter phase is characterized by an absorption capacity higher than the ones of Ni and Mg. However, experimental capacities of annealed products are still lower than theoretical values (Table 2). Westlake et al. [29] reported that the radius of octahedral sites must be larger than 0.4 Å in order to accommodate hydrogen atoms. In the same way, Switendick et al. [30] demonstrated that tetrahedral sites separated by a distance lower than 2.1 Å are unable to absorb hydrogen. Thus, the catalytic activity of as-prepared Mg2Ni samples may be limited by the narrow size of some unoccupied tetrahedral and octahedral sites.

Figure 5 focuses on the evolution of the hydrogen absorption capacity during the first 20 h of absorption time. This experiment is designated as the first absorption cycle and was consecutively repeated two times, without any hydrogen desorption step. Curves are presented for Mg2Ni-based powders milled during 10 h before and after their heat-treatment. During the first cycle, Mg2Ni-based composites quickly absorbs 3.05 H/f.u at 5.5 h, which constitutes 96 % of the maximum capacity obtained at the end of this cycle, i.e. 3.17 H/f.u (Fig. 5a). After 5.5 h, the amount of absorbed hydrogen increases weakly, reflecting a slower kinetic of the absorption mechanism. For the second and third cycles, the absorption kinetic is significantly slow as the amount of absorbed hydrogen is too small: 0.070 and 0.067 H/f.u in the second and third cycle, respectively (Fig. 5a). During the first cycle, unoccupied sites of Mg2Ni microstructure are able to accommodate and absorb hydrogen atoms easily. For further cycles, the hydrogen absorption only occurs inside highly energetic sites and only a small amount of hydrogen may be absorbed. In the case of annealed Mg2Ni powders (Fig. 5b), most hydrogen is also absorbed during the first cycle. Figure 5b shows that 3.22 H/f.u is absorbed after 5.5 h, which constitutes 85 % of the maximum capacity (3.5 H/f.u). The amounts of absorbed hydrogen in heat-treated powders are 0.29 H/f.u (second cycle) and 0.043 H/f.u (third cycle) and constitute 7.4 and 1.1 % of the maximum absorption capacity, respectively.

Evolution of the hydrogen absorption capacity with time for the first, second and third cycles of Mg2Ni powder ball-milled during 10 h before (a) and after subsequent annealing at 350 °C for 24 h (b). The hydrogen absorption was performed at a pressure of 11 bars H2 and a temperature of 280 °C. The absorption cycles were performed successively without any desorption step

Conclusions

Mechanical Alloying of Mg2Ni-based alloys were performed using a high injected shock power mill. The formation of Mg2Ni/Ni compound was obtained after only 10 h milling, which corresponds to a cumulated energy of 57 Wh/g. The as-prepared composite also contains Mg–Ni amorphous phase and residual Ni. When the cumulated energy increases from 57 to 98 Wh/g, less residual Ni and higher Mg2Ni contents are obtained. Consequently, an enhancement of the hydrogen absorption capacity was observed from 3.02 to 3.28 H/f.u upon the increase in the cumulated energy of milling. The combination of mechanical alloying and subsequent annealing at 350 °C for 24 h was able to improve the hydrogen absorption capacity and the hydrogenation kinetics. Independently on the preparation conditions of Mg2Ni/Ni powders, nearly 95 % of the hydrogen absorption capacity was reached after 5 h of absorption time. For longer absorption durations, the hydrogenation kinetics becomes very slow due to a drastic decrease of unoccupied sites, available to absorb hydrogen atoms, inside Mg2Ni lattice.

References

Abe, T., Tachikawa, T., Hatano, Y., Watanabe, K.: Electrochemical behavior of amorphous MgNi as negative electrodes in rechargeable Ni–MH batteries. J. Alloys Compds. 332, 792–795 (2002)

Abdellaoui, M., Mokbli, S., Cuevas, F., Latroche, M., Percheronguegan, A., Zarrouk, H.: Structural, solid–gas and electrochemical characterization of Mg2NiMg2Ni-rich and MgxNi100-xMgxNi100-x amorphous-rich nanomaterials obtained by mechanical alloying. Int. J. Hydrog. Energy 31, 247–250 (2006)

Nohara, S., Hamasaki, K., Zhang, S.G., Inoue, H., Iwakura, C.: Electrochemical characteristics of an amorphous Mg0.9V0.1Ni alloy prepared by mechanical alloying. J. Alloys Compds. 280, 104–106 (1998)

Lenain, C., Aymard, L., Dupont, L.: A new Mg0.9Y0.1Ni hydride forming composition obtained by mechanical grinding. J. Alloys Compds. 292, 84–89 (1999)

Dehouche, Z., Djaozandry, R., Goyette, J., Bose, T.K.: Evaluation techniques of cycling effect on thermodynamic and crystal structure properties of Mg2Ni alloy. J. Alloys Compds. 288, 269–276 (1999)

Nohara, S., Inoue, H., Fukumoto, Y.: Compositional and structural characteristics of MgNi alloy prepared by mechanical alloying for use as negative electrodes in nickel-metal hydride batteries. J. Alloys Compds. 259, 183–185 (1997)

Kim, J.-H., Kim, J.-H., Hwang, K.-T., Kang, Y.-M.: Hydrogen storage in magnesium based-composite hydride through hydriding combustion synthesis. Int. J. Hydrog. Energy 35, 9641–9645 (2010)

Abdellaoui, M., Cracco, D., Percheron-Guegan, A.: Structural characterization and reversible hydrogen absorption properties of Mg2Ni rich nanocomposite materials synthesized by mechanical alloying. J. Alloys Compds. 268, 233–240 (1998)

Abdellaoui, M., Cracco, D.: Structural investigation and solid-H2 reaction of Mg2Ni rich nanocomposite materials elaborated by mechanical alloying. J. Alloys Compds. 295, 501–507 (1999)

Tojo, T., Yamamoto, I., Zhang, Q., Saito, F.: Discharge properties of Mg2Ni–Ni alloy synthesized by mechanical alloying. Adv. Powder Technol. 16, 649–658 (2005)

Zaluski, L., Zaluska, A., Ström-Olsen, J.O.: Hydrogen absorption in nanocrystalline Mg2Ni formed by mechanical alloying. J. Alloys Compds. 217, 245–249 (1995)

Wang, S., Li, C., Yong, W., Hou, X., Geng, H., Xu, F.: Formation of La-modified L12-Al3Ti by mechanical alloying and annealing. Mater. Charact. 59, 440–446 (2008)

Mohammadnezhad, M., Shamanian, M, Enayati, M.H., Salehi, M.: Influence of annealing temperature on the structure and properties of the nanograined NiAl intermetallic coatings produced by using mechanical alloying. Surf Coat Technol. doi:10.1016/j.surfcoat.2012.11.073

Obregón, S.A., Andrade-Gamboa, J.J., Esquivel, M.R.: Synthesis of Al-containing MmNi5 by mechanical alloying: milling stages, structure parameters and thermal annealing. Int. J. Hydrog Energy 37, 14972–14977 (2012)

Spassov, T., Solsona, P., Suriñach, S., Baró, M.D.: Optimisation of the ball-milling and heat treatment parameters for synthesis of amorphous and nanocrystalline Mg2Ni-based alloys. J. Alloys Compds. 349, 242–254 (2003)

Spassov, T., Solsona, P., Bliznakov, S., Suriñach, S., Baró, M.D.: Synthesis and hydrogen sorption properties of nanocrystalline Mg1.9M0.1Ni (M = Ti, Zr, V) obtained by mechanical alloying. J. Alloys Compds. 356–357, 639–643 (2003)

Rojas, P., Ordoñez, S., Serafini, D., Zúñiga, A., Lavernia, E.: Microstructural evolution during mechanical alloying of Mg and Ni. J. Alloys Compds. 391, 267–276 (2005)

Gennari, F.C., Esquivel, M.R.: Structural characterization and hydrogen sorption properties of nanocrystalline Mg2Ni. J. Alloys Compds. 459, 425–432 (2008)

Ebrahimi-Purkani, A., Kashani-Bozorg, S.F.: Nanocrystalline Mg2Ni-based powders produced by high-energy ball milling and subsequent annealing. J. Alloys Compds. 456, 211–215 (2008)

Ordoñez, S., Rojas, P., Bustos, O., MartÍnez, V., Serafini, D., San MartÍn, Y.A.: Crystalline Mg2Ni obtained from Mg–Ni amorphous precursor produced by mechanical alloying. J. Mater. Sci. Lett. 22, 717–720 (2003)

Abdellaoui, M., Gaffet, E.: A mathematical and experimental dynamical phase diagram for ball-milled Nil0Zr7. J. Alloys Compds. 209, 351–361 (1994)

Abdellaoui, M., Gaffet, E.: The physics of mechanical alloying in a planetary ball mill: mathematical treatment. Acta Metal. Mater. 43, 1087–1098 (1995)

Krill III, C.E., Haberkorn, R., Birringer, R.: Fabrication and spectroscopic characterization of organic nanocrystals. In: Nalwa, H.S. (ed.) Handbook of Nanostructured Materials and Nanotechnology, chap. 8. Academic Press, San Diego (2000)

Modak, S., Karan, S., Roy, S.K., Mukherjee, S., Das, D., Chakrabarti, P.K.: Preparation and characterizations of SiO2-coated nanoparticles of Mn0.4Zn0.6Fe2O4. J. Magn. Magn. Mater. 321, 169–174 (2009)

Niu, H., Northwood, D.O.: Enhanced electrochemical properties of ball-milled Mg2Ni electrodes. Int. J. Hydrog. Energy 27, 69–77 (2002)

Poter, D.A., Easterling, K.E.: Phase Transformations in Metals and Alloys. Chapman and Hall, London (1992)

Ruggeri, S., Lenain, C., Roué, L., Liang, G., Huot, J., Schulz, R.: Mechanically driven crystallization of amorphous MgNi alloy during prolonged milling: applications in NiMH batteries. J. Alloys Compd. 339, 195–201 (2002)

Yamamoto, K., Orimo, S., Fujii, H., Kitano, Y.: Hydriding properties of the heat-treated MgNi alloys with nanostructural designed multiphase. J. Alloys Compd. 293–295, 546–551 (1999)

Westlake, D.G.: Site occupancies and stoichiometries in hydrides of intermetallic compounds: geometric considerations. J. Less Common Met. 90, 251–273 (1983)

Switendick, A.C.: Band structure calculations for metal hydrogen systems. Z. Phys. Chem. Neue Folge 117, 89–112 (1979)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under license to BioMed Central Ltd. Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Marzouki, M., Ghodbane, O. & Abdellaoui, M. Study of hydrogen absorption kinetics of Mg2Ni-based powders produced by high-injected shock power mechanical alloying and subsequent annealing. Mater Renew Sustain Energy 2, 9 (2013). https://doi.org/10.1007/s40243-013-0009-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-013-0009-y