Abstract

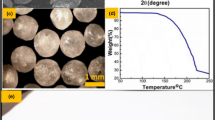

Despite the importance of porous titanium oxide (PA-TiO2) in diverse functional applications, very little information is available on the compatible mechanical properties for potential biomedical applications. In this study, PA-TiO2 foam was synthesized using space-holding powder metallurgy and sintering methods to produce interconnected opened-cell structure with surface morphology of mountain-like features associated with the extensive rift valley system. Three different types of PA-TiO2 foams with porosities of 35–52% and mean pore diameter of 190–210 μm were fabricated for evaluating the effect of porosity on mechanical properties of bulk PA-TiO2. The modulus of elasticity of PA-TiO2 foams exhibited in the range of 45–262 MPa which was within the range of modulus of elasticity of human cancellous bone. Cytotoxicity test is performed in vitro analysis to observe the effect of cell toxicity to produce osteointegration when used as implantable materials. There was no cytotoxicity effect found and remarkable cell growth was observed for human cancerous (HeLa) cell line. However, there was no cytotoxicity effect found and cell growth was not observed for Vero cell line. This study suggested that PA-TiO2 facilitates cell growth without spreading toxicity and has mechanical properties of cancellous bone. Hence, it has potential application as implant and medical devices in biomedical applications.

Similar content being viewed by others

References

Acharya S, Suwas S, Chatterjee K (2021) Review of recent developments in surface nanocrystallization of metallic biomaterials. Nanoscale 13(4):2286–2301

Albulescu R, Popa AC, Enciu AM, Albulescu L, Dudau M, Popescu ID, Mihai S, Codrici E, Pop S, Lupu AR (2019) Comprehensive in vitro testing of calcium phosphate-based bioceramics with orthopedic and dentistry applications. Materials 12(22):3704

Aleni AH, Kretzschmar N, Jansson A, Ituarte IF, St-Pierre L (2020) 3D printing of dense and porous TiO2 structures. Ceram Int 46(10):16725–16732

Allen NS, Mahdjoub N, Vishnyakov V, Kelly PJ, Kriek RJ (2018) The effect of crystalline phase (anatase, brookite and rutile) and size on the photocatalytic activity of calcined polymorphic titanium dioxide (TiO2). Polym Degrad Stab 150:31–36

An YH, Draughn RA (1999) Mechanical testing of bone and the bone-implant interface. CRC Press, USA

Ansari M (2019) Bone tissue regeneration: biology, strategies and interface studies. Prog Biomater 8(4):223–237

Ashby MF, Evans T, Fleck NA, Hutchinson J, Wadley H, Gibson L (2000) Metal foams: a design guide. Elsevier, USA

Biswal T, BadJena SK, Pradhan D (2020a) Sustainable biomaterials and their applications: a short review. Mater Today 30:274–282

Biswal T, BadJena SK, Pradhan D (2020b) Synthesis of polymer composite materials and their biomedical applications. Mater Today 30:305–315

Bobyn J, Wilson G, MacGregor D, Pilliar R, Weatherly G (1982) Effect of pore size on the peel strength of attachment of fibrous tissue to porous-surfaced implants. J Biomed Mater Res 16(5):571–584

Borghols WJ, Wagemaker M, Lafont U, Kelder EM, Mulder FM (2008) Impact of nanosizing on lithiated rutile TiO2. Chem Mater 20(9):2949–2955

Chen J, Liu G, Button T (2013) Mechanical properties of porous TiO2 ceramics fabricated by freeze casting process. Adv Appl Ceram 112(7):436–441

Chen Z, Yan X, Yin S, Liu L, Liu X, Zhao G, Ma W, Qi W, Ren Z, Liao H (2020) Influence of the pore size and porosity of selective laser melted Ti6Al4V ELI porous scaffold on cell proliferation, osteogenesis and bone ingrowth. Mater Sci Eng 106:110289

Dash S, Pradhan D (2020) Synthesis of nano soy/ZnO nanocomposite and evaluation of its properties. Mater Today 30:299–304

Davies G, Zhen S (1983) Metallic foams: their production, properties and applications. J Mater Sci 18(7):1899–1911

Gerhardt L-C, Jell G, Boccaccini A (2007) Titanium dioxide (TiO2) nanoparticles filled poly (D, L lactid acid)(PDLLA) matrix composites for bone tissue engineering. J Mater Sci 18(7):1287–1298

Gouma PI, Mills MJ (2001) Anatase-to-rutile transformation in titania powders. J Am Ceram Soc 84(3):619–622

Gupta K, Singh N, Pandey A, Shukla S, Upadayay S, Mishra V, Srivastava P, Lalla N, Mishra P (2013) Effect of anatase/rutile TiO2 phase composition on arsenic adsorption. J Dispers Sci Technol 34(8):1043–1052

Hanaor DA, Sorrell CC (2011) Review of the anatase to rutile phase transformation. J Mater Sci 46(4):855–874

Haugen H, Will J, Köhler A, Hopfner U, Aigner J, Wintermantel E (2004) Ceramic TiO2-foams: characterisation of a potential scaffold. J Eur Ceram Soc 24(4):661–668

Haugen HJ, Monjo M, Rubert M, Verket A, Lyngstadaas SP, Ellingsen JE, Rønold HJ, Wohlfahrt JC (2013) Porous ceramic titanium dioxide scaffolds promote bone formation in rabbit peri-implant cortical defect model. Acta Biomater 9(2):5390–5399

Ishaug-Riley SL, Crane-Kruger GM, Yaszemski MJ, Mikos AG (1998) Three-dimensional culture of rat calvarial osteoblasts in porous biodegradable polymers. Biomater 19(15):1405–1412

Itälä AI, Ylänen HO, Ekholm C, Karlsson KH, Aro HT (2001) Pore diameter of more than 100 μm is not requisite for bone ingrowth in rabbits. J Biomed Mater Res 58(6):679–683

Jones AC, Arns CH, Hutmacher DW, Milthorpe BK, Sheppard AP, Knackstedt MA (2009) The correlation of pore morphology, interconnectivity and physical properties of 3D ceramic scaffolds with bone ingrowth. Biomater 30(7):1440–1451

Kapat K, Srivas PK, Rameshbabu AP, Maity PP, Jana S, Dutta J, Majumdar P, Chakrabarti D, Dhara S (2017) Influence of porosity and pore-size distribution in Ti6Al4 V foam on physicomechanical properties, osteogenesis, and quantitative validation of bone ingrowth by micro-computed tomography. ACS Appl Mater Interfaces 9(45):39235–39248

Kay S, Thapa A, Haberstroh KM, Webster TJ (2002) Nanostructured polymer/nanophase ceramic composites enhance osteoblast and chondrocyte adhesion. Tissue Eng 8(5):753–761

Klug HP, Alexander LE (1974) X-ray diffraction procedures: for polycrystalline and amorphous materials. Wiley, USA

Krishna BV, Bose S, Bandyopadhyay A (2007) Low stiffness porous Ti structures for load-bearing implants. Acta Biomater 3(6):997–1006

Kulkarni M, Mazare A, Schmuki P, Iglič A (2014) Biomaterial surface modification of titanium and titanium alloys for medical applications. Nanomed 111:111

Kumar K-NP (1995) Growth of rutile crystallites during the initial stage of anatase-to-rutile transformation in pure titania and in titania-alumina nanocomposites. Scr Metall Mater 32(6):873–877

Kunzmann A, Andersson B, Thurnherr T, Krug H, Scheynius A, Fadeel B (2011) Toxicology of engineered nanomaterials: focus on biocompatibility, biodistribution and biodegradation. Biochim Biophys Acta 3:361–373

Laptev A, Vyal O, Bram M, Buchkremer H, Stöver D (2005) Green strength of powder compacts provided for production of highly porous titanium parts. Powder Metall 48(4):358–364

Lee GH (2016) Synthesis of TiO2 nanowires via thermal oxidation process in air. Mater Res Innov 20(6):421–424

Mayo M, Siegel R, Narayanasamy A, Nix W (1990) Mechanical properties of nanophase TiO2 as determined by nanoindentation. J Mater Res 5(5):1073–1082

Mydin R, Hazan R, FaridWajidi MF, Sreekantan S (2018) Titanium dioxide nanotube arrays for biomedical implant materials and nanomedicine applications. In: Yang D (ed) Titanium dioxide—material for a sustainable environment, pp 469–483

Oh HJ, Lee JH, Kim YJ, Suh SJ, Lee JH, Chi CS (2008) Surface characteristics of porous anodic TiO2 layer for biomedical applications. Mater Chem Phys 109(1):10–14

Otitoju TA, Okoye PU, Chen G, Li Y, Okoye MO, Li S (2020) Advanced ceramic components: materials, fabrication, and applications. J Ind Eng Chem 85:34–65

Petit C, Montanaro L, Palmero P (2018) Functionally graded ceramics for biomedical application: Concept, manufacturing, and properties. Int J Appl Ceram Technol 15(4):820–840

Pradhan D, Sukla LB (2017) Thin film of Yttria stabilised zirconia on NiO using vacuum cold spraying process for solid oxide fuel cell. Int J Nano Biomater 7(1):38–47

Rahman M, Hossain M, Das B (2016) Synthesis of TiO2 nanotube by electrochemical anodization of Ti foil in room temperature. Mech Eng Res J 10:90–93

Rahman MA, Wang X, Wen C (2015) Enhanced electrochemical performance of Li-ion batteries with nanoporous titania as negative electrodes. J Energy Chem 24(2):157–170

Rahman MA, Wong YC, Song G, Wen C (2018) Improvement on electrochemical performances of nanoporous titania as anode of lithium-ion batteries through annealing of pure titanium foils. J Energy Chem 27(1):250–263

Rehman F, Zhao C, Jiang H, Wang X (2016) Biomedical applications of nano-titania in theranostics and photodynamic therapy. Biomater Sci 4(1):40–54

Ryan G, Pandit A, Apatsidis DP (2006) Fabrication methods of porous metals for use in orthopaedic applications. Biomater 27(13):2651–2670

Schoenfeld C, Lautenschlager E, Meyer P (1974) Mechanical properties of human cancellous bone in the femoral head. Med Biol Eng 12(3):313–317

Seuba J, Deville S, Guizard C, Stevenson AJ (2016) Mechanical properties and failure behavior of unidirectional porous ceramics. Sci Rep 6(1):1–11

Sham EL, Aranda MA, Farfan-Torres EM, Gottifredi JC, Martınez-Lara M, Bruque S (1998) Zirconium titanate from sol–gel synthesis: thermal decomposition and quantitative phase analysis. J Solid State Chem 139(2):225–232

Singh S, Bhatnagar N (2018) A survey of fabrication and application of metallic foams (1925–2017). J Porous Mater 25(2):537–554

Sivaprakash V, Narayanan R (2021) Surface modification TiO2 nanotubes on titanium for biomedical application. Materials science forum. Trans Tech Publ, pp 157–163

Soenen SJ, Manshian B, Montenegro JM, Amin F, Meermann B, Thiron T, Cornelissen M, Vanhaecke F, Doak S, Parak WJ (2012) Cytotoxic effects of gold nanoparticles: a multiparametric study. ACS Nano 6(7):5767–5783

Srivastava V, Sahoo K (2007) Processing, stabilization and applications of metallic foams. Art of science. Mater Sci 25(3):733–753

Taniguchi N, Fujibayashi S, Takemoto M, Sasaki K, Otsuki B, Nakamura T, Matsushita T, Kokubo T, Matsuda S (2016) Effect of pore size on bone ingrowth into porous titanium implants fabricated by additive manufacturing: an in vivo experiment. Mater Sci Eng 59:690–701

Thavornyutikarn B, Chantarapanich N, Sitthiseripratip K, Thouas GA, Chen Q (2014) Bone tissue engineering scaffolding: computer-aided scaffolding techniques. Prog Biomater 3(2–4):61–102

Vejerano EP, Ma Y, Holder AL, Pruden A, Elankumaran S, Marr LC (2015) Toxicity of particulate matter from incineration of nanowaste. Environ Sci 2(2):143–154

Wang S, Liu L, Huang Z, Li Z, Liu J, Hao Y (2021) Honeycomb structure is promising for the repair of human bone defects. Mater Des 207:109832

Wang YQ, Jie T, Zhang JL, Tao W (2011) Effects of addition of NH4HCO3 on pore characteristics and compressive properties of porous Ti-10% Mg composites. Trans Nonferrous Met Soc China 21(5):1074–1079

Wang Z, Wang C, Li C, Qin Y, Zhong L, Chen B, Li Z, Liu H, Chang F, Wang J (2017) Analysis of factors influencing bone ingrowth into three-dimensional printed porous metal scaffolds: a review. J Alloys Compd 717:271–285

Wu S, Weng Z, Liu X, Yeung K, Chu PK (2014) Functionalized TiO2 based nanomaterials for biomedical applications. Adv Funct Mater 4(35):5464–5481

Zoccal JVM, Arouca FO, Gonçalves JAS (2010) Synthesis and characterization of TiO2 nanoparticles by the method Pechini. Materials science forum. Trans Tech Publ, pp 385–390

Acknowledgements

This work was supported by Chittagong University of Engineering & Technology, Chittagong-4349, Bangladesh through Research Grant CUET/REC-06-09/02/2017.

Funding

The authors declare that they have no financial disclosures.

Author information

Authors and Affiliations

Contributions

Methodology: FAK and MAR, experiment: FAK, writing: MAR, review and editing: all authors, and fund acquisition: MAR. All authors have read and agreed to the submitted version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest

Informed consent

Not applicable.

Human or animal rights

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Koly, F.A., Rahman, M.A., Islam, M.S. et al. Fabrication of porous TiO2 foams by powder metallurgy technique and study of bulk crushing strength for biomedical application. Prog Biomater 10, 299–308 (2021). https://doi.org/10.1007/s40204-021-00173-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40204-021-00173-4