Abstract

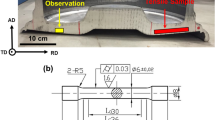

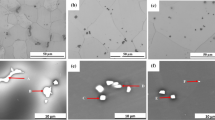

In this work, the microstructure and mechanical properties of large cross-sectioned Mg–9Gd–3Y–1.2Zn–0.5Zr (VWZ931) samples produced by the small extrusion ratio has been investigated. The as-extruded VWZ931 sample with diameter of ~ 30 mm can exhibit the high yield strength (YS) of 339 MPa, ultimate tensile strength (UTS) of 387 MPa and elongation of 8.2%, respectively. After peak-aged, the YS and UTS of the Mg samples were significantly increased to 435 MPa and 467 MPa. The small extrusion ratio leads to the low fraction of dynamic recrystallized (DRX) grains in VWZ931 sample, and the texture hardening effect can be fully utilized to achieve high strength. The combined effect of precipitation strengthening due to the long-period stacking ordered phases and the \(\beta\)′ phase, grain boundary strengthening due to the fine DRX grains, heterogeneous deformation-induced strengthening caused by bimodal microstructure, can together contribute to the high strength of present Mg alloy. The findings can shed light on designing other large-sized Mg wrought alloys with high mechanical performance.

Similar content being viewed by others

References

S.S.A. Shah, D. Wu, R.S. Chen, G.S. Song, Acta Metall. Sin. -Engl. Lett. 33, 243 (2020)

W.J. Yin, F. Briffod, T. Shiraiwa, M. Enoki, J. Magnes. Alloy. 10, 2158 (2022)

W. Rong, Y. Zhang, Y. Wu, M. Sun, J. Chen, Y. Wang, J. Han, L. Peng, H. Ding, J. Alloys Compd. 692, 805 (2017)

T. Homma, N. Kunito, S. Kamado, Scr. Mater. 61, 644 (2009)

C. Xu, M. Zheng, S. Xu, K. Wu, E. Wang, G. Fan, S. Kamado, Mater. Sci. Eng. A 643, 137 (2015)

M.Y. Fan, Y. Cui, Y. Zhang, X.H. Wei, X. Cao, P.K. Liaw, Y.S. Yang, Z.W. Zhang, J. Magnes. Alloy. 11, 1321 (2023)

Z.J. Xu, Z. Li, L.D. Tan, X.S. Xu, R.C. Luo, B. Chen, Mater. Charact. 117, 76 (2016)

W. Rong, Y. Wu, Y. Zhang, M. Sun, J. Chen, L. Peng, W. Ding, Mater. Charact. 126, 1 (2017)

R. Guo, X. Zhao, B.W. Hu, X.D. Tian, Q. Wang, Z.M. Zhang, Acta Metall. Sin. -Engl. Lett. 36, 1680 (2023)

W. Rong, Y. Zhang, Y. Wu, Y. Chen, M. Sun, J. Chen, L. Peng, Mater. Sci. Eng. A 740–741, 262 (2019)

C. Xu, T. Nakata, X.G. Qiao, M.Y. Zheng, K. Wu, S. Kamado, Sci. Rep. 7, 43391 (2017)

X.B. Liu, R.S. Chen, E.H. Han, J. Alloys Compd. 465, 232 (2008)

Y.Q. Chi, M.Y. Zheng, C. Xu, Y.Z. Du, X.G. Qiao, K. Wu, X.D. Liu, G.J. Wang, X.Y. Lv, Mater. Sci. Eng. A 565, 112 (2013)

L. Zheng, C. Liu, Y. Wan, P. Yang, X. Shu, J. Alloys Compd. 509, 8832 (2011)

Z. Yu, Y. Huang, X. Qiu, G. Wang, F. Meng, N. Hort, J. Meng, Mater. Sci. Eng. A 622, 121 (2015)

B. Li, B. Teng, G. Chen, Mater. Sci. Eng. A 744, 396 (2019)

M. Zemkova, P. Minarik, J. Dittrich, J. Bohlen, R. Kral, J. Magnes. Alloy. 11, 509 (2023)

W.T. Sun, X.G. Qiao, M.Y. Zheng, C. Xu, S. Kamado, X.J. Zhao, H.W. Chen, N. Gao, M.J. Starink, Acta Mater. 151, 260 (2018)

J. Wang, L. Xu, R. Wu, J. Feng, J. Zhang, L. Hou, M. Zhang, Acta Metall. Sin. -Engl. Lett. 33, 490 (2020)

L.B. Tong, J.H. Chu, W.T. Sun, C. Xu, D.N. Zou, K.S. Wang, S. Kamado, M.Y. Zheng, Mater. Charact. 171, 110804 (2021)

M.R. Zhou, Z.R. Zeng, C. Cheng, Y. Morisada, Q.Y. Shi, J.Y. Wang, H. Fujii, J. Magnes. Alloy. 10, 3064 (2022)

R.G. Li, H.R. Li, H.C. Pan, D.S. Xie, J.H. Zhang, D.Q. Fang, Y.Q. Dai, D.Y. Zhao, H. Zhang, Scr. Mater. 193, 142 (2021)

M. Yamasaki, M. Sasaki, M. Nishijima, K. Hiraga, Y. Kawamura, Acta Mater. 55, 6798 (2007)

X. Yang, X. Zhou, S. Yu, J. Zhang, X. Lu, X. Chen, L. Lu, W. Huang, Y. Liu, Mater. Sci. Eng. A 851, 143634 (2022)

E. Abe, Y. Kawamura, K. Hayashi, A. Inoue, Acta Mater. 50, 3845 (2002)

A. Umantsev, M. Ode, Comput. Mater. Sci. 124, 173 (2016)

C. Li, J. Jin, H. Yan, Z. Shan, Y. Mao, R. Chen, J. Alloys Compd. 953, 170112 (2023)

T. Honma, T. Ohkubo, S. Kamado, K. Hono, Acta Mater. 55, 4137 (2007)

C. Xu, J.P. Pan, T. Nakata, X.G. Qiao, Y.Q. Chi, M.Y. Zheng, S. Kamado, Mater. Charact. 124, 40 (2017)

X.H. Shao, Z.Q. Yang, X.L. Ma, Acta Mater. 58, 4760 (2010)

K. Liu, J.X. Liu, S.B. Li, Z.H. Wang, W.B. Du, Q.F. Wang, Trans. Nonferrous Met. Soc. China 28, 890 (2018)

Y. Wang, F. Zhang, Y. Wang, Y. Duan, K. Wang, W. Zhang, J. Hu, Mater. Sci. Eng. A 745, 149 (2019)

D. Wang, W. Zhang, X. Zong, K. Nie, C. Xu, J. Zhang, Mater. Sci. Eng. A 618, 355 (2014)

X.H. Shao, Z.Z. Peng, Q.Q. Jin, X.L. Ma, Acta Mater. 118, 177 (2016)

M. Matsuda, S. Ii, Y. Kawamura, Y. Ikuhara, M. Nishida, Mater. Sci. Eng. A 386, 447 (2004)

X. Zheng, W. Du, Z. Wang, S. Li, K. Liu, X. Du, Mater. Lett. 212, 155 (2018)

C. Xu, T. Nakata, X. Qiao, M. Zheng, K. Wu, S. Kamado, Sci. Rep. 7, 40846 (2017)

J.F. Nie, Metall. Mater. Trans. A 43, 3891 (2012)

X. Wei, L. Jin, S. Dong, F. Wang, J. Dong, Mater. Charact. 169, 110670 (2020)

Y.F. Wang, C.X. Huang, X.T. Fang, H.W. Höppel, M. Göken, Y.T. Zhu, Scr. Mater. 174, 19 (2020)

Acknowledgements

The work is supported by the National Key Research and Development Program of China (No. 2021YFB3701000), the National Natural Science Foundation of China (Nos. U2167213, 51971053). H.C. Pan acknowledges the financial assistance from the Young Elite Scientists Sponsorship Program by China Association for Science and Technology (2019-2021QNRC001-003) and the fund from the Fundamental Research Funds for the Central Universities (N2202020).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, S., Pan, H., Jiang, C. et al. Microstructure and Mechanical Property of the Large Cross-Sectioned Mg–Gd–Y–Zn–Zr Alloy Produced by Small Extrusion Ratio. Acta Metall. Sin. (Engl. Lett.) (2024). https://doi.org/10.1007/s40195-024-01682-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40195-024-01682-4