Abstract

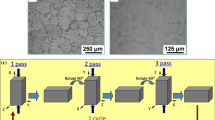

Mg-Zn-Zr wrought alloys have been widely developed for lightweight applications. Zr microalloying contributes to remarkable grain refinement during solidification and bimodal microstructure via forging. To obtain an optimum Zr content for a balance between cost and mechanical property, it is necessary to understand the influence of varied Zr addition levels on the microstructure and mechanical property of the final forged product. In the present study, two levels of Zr addition (nominally 0.40 wt.% and 0.60 wt.%) were added to a Mg-3 wt.% Zn alloy to investigate the effect of varied Zr contents on the microstructures under as-cast, as-forged and tensile-strained conditions, as well as the uniaxial tensile properties of the as-forged alloy. The as-forged microstructures comprise fine dynamic recrystallized (DRXed) grains and coarse deformed (unDRXed) domains, which become more refined with the Zr content increasing from ~ 0.43 wt.% to ~ 0.67 wt.%. The microstructural change caused by the increased Zr addition has minor impact on 0.2% proof stress but remarkably improves both uniform and post-uniform elongations, for which the underlying mechanisms have been discussed.

Similar content being viewed by others

Data Availability

The raw/processed data required to obtain these results can be shared upon reasonable request to the corresponding author.

References

E.F. Emley, Principles of Magnesium Technology (Pergamon Press, Oxford, 1966).

Y. Lee, A. Dahle, and D. StJohn, Metall. Mater. Trans. A 31, 2895 (2000).

Y. Tamura, N. Kono, T. Motegi, and E. Sato, Keikinzoku 47, 679 (1997).

M. Sun, M.A. Easton, D.H. StJohn, G. Wu, T.B. Abbott, and W. Ding, Adv. Eng. Mater. 15, 373 (2013).

H.E. Friedrich, and B.L. Mordike, Magnesium technology (Springer, 2006).

A.I.H. Committee, ASM Int. 2, 1143 (1992).

X. Lin, L. Tan, Q. Zhang, K. Yang, Z. Hu, J. Qiu, and Y. Cai, Acta Biomater. 9, 8631 (2013).

S. Karparvarfard, S.K. Shaha, S.B. Behravesh, H. Jahed, and B.W. Williams, J. Mater. Sci. Technol. 33, 907 (2017).

M. Alvarez-Leal, A. Orozco-Caballero, F. Carreño, and O.A. Ruano, Mater. Sci. Eng. A 710, 240 (2018).

G. Govind, K. Nair, M. Mittal, R. Sikand, and A. Gupta, Mater. Sci. Technol. 24, 399 (2008).

M. Carsí, F. Carreño, and O.A. Ruano, Materials science forum (Trans Tech Publication, 2018), pp2325–2330.

A. Malik, Y. Wang, F. Nazeer, M.A. Khan, M. Sajid, S. Jamal, and W. Mingjun, J. Alloy. Compd. 858, 157740 (2021).

S. Karparvarfard, S. Shaha, S. Behravesh, H. Jahed, and B. Williams, MATEC web of conferences (EDP Sciences, 2018), p06009.

G. Popescu, P. Moldovan, D. Bojin, and W.H. Sillekens, Univ. Politeh. Buchar. Sci. Bull. Ser. B Chem. Mater. Sci. 71, 85 (2009).

A. Dziubińska, A. Gontarz, M. Dziubiński, and M. Barszcz, Adv. Sci. Technol. Res. J. 10, 31 (2016).

B. Nagasivamuni, G. Wang, D.H. StJohn, and M.S. Dargusch, J. Cryst. Growth 512, 20 (2019).

X. Tong, G. Wu, M.A. Easton, M. Sun, D.H. StJohn, R. Jiang, and F. Qi, Scr. Mater. 215, 114700 (2022).

M. Qian, L. Zheng, D. Graham, M. Frost, and D. StJohn, J. Light Met. 1, 157–165 (2001).

P. Sasha, and S. Viswanathan, Trans. Am. Found. Soc. 119, 469 (2011).

M. Qian, Z. Hildebrand, and D. StJohn, Metall. Mater. Trans. A 40, 2470 (2009).

M. Qian, D.H. StJohn, and M.T. Frost, Materials science forum (Trans Tech Publication, Zurich-Uetikon, 2003), pp593–598.

B. Mordike, Mater. Sci. Eng. A 324, 103 (2002).

M. Qian, D. StJohn, and M. Frost, Scr. Mater. 46, 649 (2002).

M. Qian, and D.H. StJohn, Int. J. Cast Met. Res. 22, 256 (2009).

J. Robson, and C. Paa-Rai, Acta Mater. 95, 10 (2015).

J. You, Y. Huang, C. Liu, H. Zhan, L. Huang, and G. Zeng, Materials 13, 2348 (2020).

A. Hadadzadeh, F. Mokdad, B.S. Amirkhiz, M. Wells, B.W. Williams, and D.L. Chen, Mater. Sci. Eng. A 724, 421 (2018).

K. Huang, and R.E. Logé, Mater. Des. 111, 548 (2016).

T. Bhattacharjee, T. Sasaki, B. Suh, T. Nakata, S. Kamado, N. Kim, and K. Hono, Magnesium technology 2015 (Springer, 2015), pp209–213.

A. Hadadzadeh, F. Mokdad, M. Wells, and D. Chen, Mater. Sci. Eng. A 709, 285 (2018).

K. Oh-Ishi, C. Mendis, T. Homma, S. Kamado, T. Ohkubo, and K. Hono, Acta Mater. 57, 5593 (2009).

T. Bhattacharjee, T. Nakata, T. Sasaki, S. Kamado, and K. Hono, Scr. Mater. 90, 37 (2014).

J. Da Silva Rodrigues, L.M. Antonini, A.A. Da Cunha Bastos, J. Zhou, and C. De Fraga Malfatti, Surf. Coat. Technol. 410, 126983 (2021).

J.F. Chinella, CCDC army research laboratory Aberdeen proving ground United States (2020)

F. Bachmann, R. Hielscher, and H. Schaeben, Solid state phenomena (Trans Tech Publication, 2010), pp63–68.

J. Li, J. Barrirero, G. Sha, H. Aboulfadl, F. Mücklich, and P. Schumacher, Acta Mater. 108, 207 (2016).

W. Wang, D. Wu, R. Chen, Y. Qi, H. Ye, and Z. Yang, J. Alloy. Compd. 832, 155016 (2020).

K. Guan, B. Li, Q. Yang, D. Zhang, X. Zhang, J. Zhang, L. Zhao, X. Liu, and J. Meng, Mater. Charact. 145, 329–336 (2018).

X.-L. Nan, H.-Y. Wang, L. Zhang, J.-B. Li, and Q.-C. Jiang, Scr. Mater. 67, 443 (2012).

D. Sun, and C. Chang, Mater. Sci. Eng. A 603, 30 (2014).

H. Kim, J.-H. Lee, C. Lee, W. Bang, S. Ahn, and Y. Chang, Mater. Sci. Eng. A 558, 431 (2012).

M. Vaughan, W. Nasim, E. Dogan, J. Herrington, G. Proust, A. Benzerga, and I. Karaman, Acta Mater. 168, 448 (2019).

J. Koike, Y. Sato, D. Ando, Materials transactions, 0811070603–0811070603 (2008)

D. Ando, J. Koike, and Y. Sutou, Mater. Sci. Eng. A 600, 145 (2014).

M. Barnett, Mater. Sci. Eng. A 464, 8 (2007).

J. Koike, Metall. Mater. Trans. A. 36, 1689 (2005).

A. Jain, O. Duygulu, D. Brown, C. Tomé, and S. Agnew, Mater. Sci. Eng. A 486, 545 (2008).

P. Cizek, and M. Barnett, Scr. Mater. 59, 959 (2008).

M. Hämäläinen, and K. Zeng, Calphad 22, 375 (1998).

M.A. Kumar, and I.J. Beyerlein, Mater. Sci. Eng. A 771, 138644 (2020).

M. Tsai, and C. Chang, Mater. Sci. Technol. 29, 759 (2013).

B. Li, S.P. Joshi, O. Almagri, Q. Ma, K. Ramesh, and T. Mukai, Acta Mater. 60, 1818 (2012).

H. Asgari, A. Odeshi, J. Szpunar, L. Zeng, and E. Olsson, Mater. Charact. 106, 359 (2015).

T. Homma, C. Mendis, K. Hono, and S. Kamado, Mater. Sci. Eng., A 527, 2356 (2010).

A. Chapuis, and J.H. Driver, Acta Mater. 59, 1986 (2011).

B. Wang, D. Xu, L. Sheng, E. Han, and J. Sun, J. Mater. Sci. Technol. 35, 2423 (2019).

C. Xu, G. Fan, T. Nakata, X. Liang, Y. Chi, X. Qiao, G. Cao, T. Zhang, M. Huang, and K. Miao, Metall. Mater. Trans. A. 49, 1931 (2018).

X. Huang, K. Suzuki, A. Watazu, I. Shigematsu, and N. Saito, Mater. Sci. Eng. A 488, 214 (2008).

P. Dobroň, F. Chmelík, S. Yi, K. Parfenenko, D. Letzig, and J. Bohlen, Scr. Mater. 65, 424 (2011).

H. Fan, S. Aubry, A. Arsenlis, and J.A. El-Awady, Scr. Mater. 112, 50 (2016).

M. Jiang, C. Xu, T. Nakata, H. Yan, R. Chen, and S. Kamado, Mater. Sci. Eng. A 678, 329 (2016).

H. Watanabe, J. Mater. Eng. Perform. 22, 3450 (2013).

B. Shi, R. Chen, W. Ke, and J. Magnes, Alloys 1, 210 (2013).

Q. Yang, and A. Ghosh, Acta Mater. 54, 5159 (2006).

Acknowledgements

The authors acknowledge the experimental assistance from Mr. Jinlong Zhu from GM China Science Lab. G.Z. acknowledges the funding from National Natural Science Foundation of China (51904352), and Scientific Research Foundation of Hunan Provincial Education Department, China (22A0004). W. Sun is grateful for the Fundamental Research Funds for the Central Universities of Central South University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could influence this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zeng, G., Yao, H., Sun, W. et al. Microstructure Evolution and Tensile Properties of Forged Mg-Zn-Zr Alloys: Effects of Zr Microalloying. JOM 75, 3041–3054 (2023). https://doi.org/10.1007/s11837-023-05902-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05902-7