Abstract

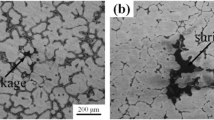

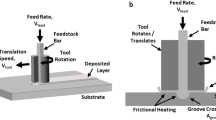

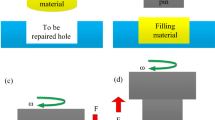

Volumetric defects in high-strength aluminum alloy components were repaired via friction stir remanufacturing (FSR). Various consumable pins made of AA7075-T6 were designed. Top diameters of the consumable pins affected material flow, which ensured that the materials at the repairing interface were forged to metallurgical bonding. Conical angles determined load transfer besides material flow, which affected the fracture of the pins before the dwelling stage. Sound repaired components were achieved when the conical angle of the consumable pin was 1° larger than that of the volumetric defect. The ultimate tensile strength and elongation of the repaired components reached 445.9 MPa and 9.6%, respectively. The design criteria of the consumable pin in the FSR was established, which provided valuable references to repair volumetric defects in high-strength aluminum components.

Similar content being viewed by others

References

X. Meng, Y. Huang, J. Cao, J. Shen, F. Jorge, Prog. Mater. Sci. 115(706), 100706 (2021)

W. Wang, P. Han, P. Peng, T. Zhang, Q. Liu, S.N. Yuan, L.Y. Huang, H.L. Yu, K. Qiao, K.S. Wang, Acta Metall. Sin. -Engl. Lett. 33, 43 (2020)

P. Gong, Y.Y. Zuo, S.D. Ji, D.J. Yan, D.C. Li, Z. Shang, Acta Metall. Sin. -Engl. Lett. 35, 763 (2022)

H.J. Liu, H.J. Zhang, Sci. Technol. Weld. Join. 17, 169 (2012)

S. Ji, X. Meng, L. Ma, H. Lu, S. Gao, Mater. Des. 68, 72 (2015)

M. Reimann, J. Goebel, T.M. Gartner, J.F. dos Santos, J. Mater. Process. Technol. 245, 157 (2017)

B. Du, Z.P. Sun, X.Q. Yang, L. Cui, J.L. Song, Z.P. Zhang, Mater. Sci. Eng. A 654, 21 (2016)

L. Cui, P. Lu, W. Li, H. Wang, D. Wang, Z. Zhang, J. Song, Sci. Technol. Weld. Join. 24, 27 (2019)

D.F. Metz, E.R. Weishaupt, M.E. Barkey, B.S. Fairbee, J. Eng. Mater. Technol. 134, 021005 (2012)

Y. Huang, X. Meng, Y. Xie, L. Wan, Z. Lv, J. Cao, J. Feng, Compos. Part A Appl. Sci. Manuf. 105, 235 (2018)

X. Liu, Z. Sun, Int. J. Heat Mass Transf. 185, 122418 (2022)

X. Liu, Y. Zhen, Z. Shen, H. Chen, W. Li, W. Guo, Z. Yue, Chin. J. Mech. Eng. 33, 90 (2020)

L. Cui, X. Yang, D. Wang, J. Cao, W. Xu, Mater. Des. 62, 271 (2014)

Y.S. Sato, F. Yamashita, Y. Sugiura, S.H.C. Park, H. Kokawa, Scr. Mater. 50, 365 (2004)

H. Liu, K. Ushioda, H. Fujii, Acta Mater. 166, 324 (2019)

S. Chen, Y. Han, X. Jiang, X. Li, T. Yuan, W. Jiang, X. Wang, J. Mater. Process. Technol. 297, 117205 (2021)

W. Tang, X. Yang, S. Li, H. Li, Mater. Lett. 288, 129361 (2021)

Y. Xie, X. Meng, F. Wang, Y. Jiang, X. Ma, L. Wan, Y. Huang, Corros. Sci. 192, 109800 (2021)

S. Sree Sabari, S. Malarvizhi, V. Balasubramanian, J. Manuf. Process. 22, 278 (2016)

S.D. Ji, X.C. Meng, Z.W. Li, L. Ma, S.S. Gao, Int. J. Adv. Manuf. Technol. 84, 2391 (2016)

B. Das, S. Pal, S. Bag, J. Manuf. Process. 27, 8 (2017)

R. Beygi, M.Z. Mehrizi, D. Verdera, A. Loureiro, J. Mater. Process. Technol. 255, 739 (2018)

U. Acharya, B.S. Roy, S.C. Saha, J. Manuf. Process. 38, 113 (2019)

Acknowledgements

This work was financially supported by the China Postdoctoral Science Foundation (Nos. 2021T140151, 2021M690820), the National Natural Science Foundation of China (No. 52001099) and the Shanghai Aerospace Science and Technology Innovation Fund, China (No. SAST2020-108).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Meng, X., Xie, Y., Ma, X. et al. Towards Friction Stir Remanufacturing of High-Strength Aluminum Components. Acta Metall. Sin. (Engl. Lett.) 36, 91–102 (2023). https://doi.org/10.1007/s40195-022-01444-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-022-01444-0