Abstract

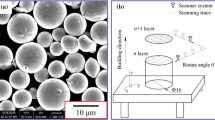

The influence of selective laser melting (SLM) process parameters on the microstructure and mechanical properties of a typical Ni-based superalloy was researched. The optimum parameters of P = 170 W, V = 0.8 m/s were determined, under which the SLMed samples exhibited both the largest relative density of 99.57% and the best mechanical properties, including the microhardness (329.3 ± 3.8 HV), yield strength (726 ± 8.1 MPa), ultimate tensile strength (900 ± 5.9 MPa) and elongation ((31.9 ± 0.24)%). The average grain size ranges of SLMed samples are from 15.2 to 17.4 μm, with a typical mixed grain structure. Owing to the high cooling rate and remelting during SLM process, a large number of low-angle grain boundaries (LAGBs), dislocations and sub-grains were formed, and the fraction of LAGBs reached above 65%. At the same time, the content of low-Σ coincidence site lattice (CSL) boundaries was mostly less than 1%, while there was almost no γ′ phase precipitated in the matrix. The texture of SLMed samples was weak, and there was no obvious preferred growth direction. Combining with the microstructure characterization, both grain refinement strengthening and dislocation strengthening were considered as the main strengthening mechanisms. Moreover, the fracture mechanism of the optimum sample belonged to ductile fracture.

Similar content being viewed by others

References

A. Deshpande, S.D. Nath, S. Atre, K. Hsu, Metals 10, 629 (2020)

S. Ma, X. Lv, J. Zhang, Y. Zhang, P. Li, H. Jin, W. Zhang, X. Li, S. Mao, J. Alloys Compd. 743, 372 (2018)

I. Galilea, B. Ruttert, J. He, T. Hammerschmidt, R. Drautz, B. Gault, W. Theisen, Addit. Manuf. 30, 100874 (2019)

Y.L. Kuo, T. Nagahari, K. Kakehi, Materials 11, 996 (2018)

W. Wei, J. Xiao, C. Wang, Q. Cheng, F. Guo, Q. He, M. Wang, S. Jiang, C. Huang, Mater. Sci. Eng. A 831, 142276 (2022)

O. Sanchez-Mata, X. Wang, J.A. Muiz-Lerma, S.E. Atabay, M. Brochu, J. Alloys. Compd. 865, 158868 (2021)

D. Alexey, P. Anna, M. Igor, B. Philippe, P. Nathalie, D. Benjamin, S. Sebastien, D. Christophe, Addit. Manuf. 15, 66 (2017)

K. Osakada, M. Shiomi, Int. J. Mach. Tool Manuf. 46, 1178 (2006)

Y. Guo, Z. Gong, C. Li, B. Gao, P. Li, X. Wang, B. Zhang, X. Li, Chem. Eng. J. 392, 123682 (2020)

H. Attar, M. Calin, L.C. Zhang, S. Scudino, J. Eckert, Mater. Sci. Eng. A 593, 170 (2014)

S. Sun, Q. Teng, Y. Xie, T. Liu, R. Ma, J. Bai, C. Chao, Q. Wei, Addit. Manuf. 46, 102168 (2021)

V.S. Sufiiarov, E.V. Borisov, I.A. Polozov, Appl. Mech. Mater. 698, 333 (2015)

M. Benoit, M. Mazur, M. Easton, M. Brandh, Int. J. Adv. Manuf. Technol. 114, 915 (2021)

X. Huang, H. Chen, B. Liu, R. Mohammadzadeh, J. Li, Q. Fang, Optik 243, 167456 (2021)

Y. Zhao, Z. Ma, L. Yu, J. Dong, Y. Liu, J. Mater. Sci. Technol. 68, 184 (2021)

C. Zhen, S. Chen, Z. Wei, L. Zhang, B. Lu, S. Zhang, Y. Xiang, Prog. Nat. Sci. 28, 496 (2018)

B. Cheng, J. Gu, M. Song, Mater. Sci. Eng. A 790, 139704 (2020)

H. Zhang, K. Zhang, Z. Lu, C. Zhao, X. Yang, Mater. Sci. Eng. A 604, 1 (2014)

H. Li, H. Wei, H. Peng, T. Lin, J. Feng, Y. Huang, Intermetallics 34, 69 (2013)

Y. Hu, X. Lin, Y. Li, J. Wang, W. Huang, J. Alloys Compd. 800, 163 (2019)

Y. Bai, Y. Yang, D. Wang, M. Zhang, Mater. Sci. Eng. A 703, 116 (2017)

Z. Chen, Z. Wei, P. Wei, S. Chen, B. Lu, J. Du, J. Li, S. Zhang, J. Mater. Eng. Perform. 26, 5897 (2017)

X. Zhao, Q.S. Wei, N. Gao, E.L. Zheng, Y.S. Shi, S.F. Yang, J. Mater. Process. Technol. 270, 8 (2019)

A. Luca, C. Kenel, S. Griffiths, S. Joglekar, D. Dunand, Mater. Des. 201, 109531 (2021)

J. Han, J. Yang, H. Yu, J. Yin, M. Gao, Z. Wang, X. Zeng, Rapid Prototyp. J. 23, 217 (2017)

Y. Bai, Z. Shi, J. Yan, H. Wang, J. Mater. Process. Technol. 280, 116597 (2020)

T. Voisin, J. Forien, A. Perron, S. Aubry, N. Bertin, A. Samanta, A. Baker, Y. Wang, Acta Mater. 203, 116476 (2021)

Y. Zhao, Q. Guo, Z. Du, S. Chen, J. Tan, Z. Yang, Z. Ma, Mater. Sci. Eng. A 832, 142505 (2022)

K. Small, Z. Clayburn, R. DeMott, S. Primig, D. Fullwood, M. Taheri, Mater. Sci. Eng. A 785, 139380 (2022)

D. Ahmadkhaniha, H. Mller, C. Zanella, J. Mater. Eng. Perform. 30, 6588 (2021)

G. Casalino, S. Campanelli, N. Contuzzi, A. Ludovico, Opt. Laser Technol. 65, 151 (2015)

S. Li, Q. Wei, Y. Shi, Z. Zhu, D. Zhang, J. Mater. Sci. Technol. 31, 946 (2015)

S. Qin, H. Zhang, J. Liu, W. Zheng, J. Mater. Res. 31, 1348 (2016)

O. Gokcekaya, N. Hayashi, T. Ishimoto, K. Ueda, T. Narushima, T. Nakano, Addit. Manuf. 36, 101624 (2020)

H. Zhang, S. Qin, H. Li, J. Liu, Y. Lv, Y. Wang, P. Zhang, H. Zhou, T. Wu, J. Mater. Res. 34, 321 (2018)

S. Shakerin, A. Hadadzadeh, B. Amirkhiz, S. Shamsdini, M. Mohammadi, Addit. Manuf. 29, 100797 (2019)

K. Han, S. Qin, H. Li, J. Liu, H. Zhou, Mater. Charact. 158, 109936 (2019)

B. Almangour, J. Yang, Mater. Des. 110, 914 (2016)

C. Kmbab, B. Gmdba, B. Bka, B. Djta, Acta Mater. 199, 19 (2020)

D. Tomus, Y. Tian, P. Rometsch, M. Heilmaier, X. Wu, Mater. Sci. Eng. A 667, 42 (2016)

T. Vilaro, C. Colin, J. Bartout, L. Naze, M. Sennour, Mater. Sci. Eng. A 534, 446 (2012)

K. Kunze, T. Etter, J. Grsslin, V. Shklover, Mater. Sci. Eng. A 620, 213 (2014)

C. Man, C. Dong, T. Liu, D. Kong, D. Wang, X. Li, Appl. Surf. Sci. 467–468, 193 (2019)

N. Hansen, Scr. Mater. 51, 801 (2004)

F. Greulich, L. Murr, Mater. Sci. Eng. 39, 81 (1979)

Acknowledgements

This work was financially supported by the National Nature Science Foundation of China (No. 52175297) and the Project of Shandong Province Higher Educational Young Innovative Talent Introduction and Cultivation Team (Performance Enhancement of Deep Coal Mining Equipment).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interests, and we do not have any possible conflicts of interest.

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Lu, Z., Zhang, C., Deng, N. et al. Influence of Selective Laser Melting Process Parameters on Microstructure and Properties of a Typical Ni-Based Superalloy. Acta Metall. Sin. (Engl. Lett.) 35, 1673–1687 (2022). https://doi.org/10.1007/s40195-022-01401-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-022-01401-x