Abstract

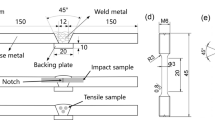

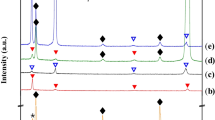

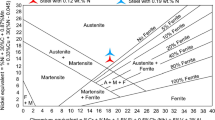

A 16Cr-25Ni superaustenitic stainless steel weld metal for austenitic stainless steel/ferrite heat-resistance steel dissimilar metal weld was designed and prepared through tungsten inert-gas welding. The precipitate evolution and its correlation with mechanical properties were investigated during post-weld heat treatment (PWHT) at 690 °C for up to 12 h. The primary precipitates in the as-welded weld metal were identified as Mo-rich M6C carbides in the interdendritic region and semicontinuous fine-sized M23C6 carbides along grain boundary. After PWHT, three types of precipitates coexisted in the interdendritic region: primary M6C carbides, newly precipitated Mo-rich M2X carbonitrides and some of the secondary M23C6 carbides. Additionally, mass secondary M23C6 carbides formed and coarsened along grain boundary. No undesirable intermetallic phases formed during the whole period. The M2X and interdendritic M23C6 improved the strength of the weld metal after PWHT, but the elongation and impact toughness degraded, which were mainly owing to the intergranular M23C6 carbides that changed the fracture mode from ductile transgranular mode to mixed mode of transgranular and intergranular fracture. Meanwhile, the coarsening of M2X carbonitrides may lead to the elongation loss during 8 h to 12 h. Evolution of impact toughness was also related to the M2X carbonitrides, which made the crack easier to propagate compared with austenitic matrix and contributed to the decline of impact toughness. However, due to the sluggish precipitation of M2X carbonitrides with longer holding time, the decreasing trend became slow from 4 to 12 h. The results showed that PWHT should be controlled within 8 h to obtain better combination of strength and ductility.

Similar content being viewed by others

References

K. Aoto, P. Dufour, Y. Hongyi, J.P. Glatz, Y.I. Kim, Y. Ashurko, R. Hill, N. Uto, Prog. Nucl. Energy. 77, 247 (2014)

G.L. Fiorini, A. Vasile, Nucl. Eng. Des. 241, 3461 (2011)

D. Hahn, Y.I. Kim, C.B. Lee, S.O. Kim, J.H. Lee, Y.B. Lee, B.H. Kim, H.Y. Jeong, Nucl. Eng. Technol. 39, 193 (2007)

H.Y. Lee, S.H. Lee, J.B. Kim, J.H. Lee, Int. J. Fatigue. 29, 1868 (2007)

T. Jayakumar, M.D. Mathew, K. Laha, R. Sandhya, Nucl. Eng. Des. 265, 1175 (2013)

C.E. Sessions, S.D. Reynolds, M.A. Hebbar, J.F. Lewis, J.H. Kiefer, Nucl. Technol. 55, 270 (1981)

M. Konomura, M. Ichimiya, J. Nucl. Mater. 371, 250 (2007)

A.K. Bhaduri, S. Venkadesan, P. Rodriguez, P.G. Mukunda, Int. J. Press. Vessels Pip. 58, 251 (1994)

A. Kulkarni, D.K. Dwivedi, M. Vasudevan, J. Mater. Process. Technol. 274, 116280 (2019)

H. Ming, J. Wang, E.H. Han, Mater. Charact. 139, 186 (2018)

D.W. Rathod, R.K.R. Singh, S. Pandey, S. Aravindan, P.K. Singh, Mater. Sci. Eng. A 702, 289 (2017)

T. Suzuki, I. Mutoh, T. Yagi, Y. Ikenaga, J. Nucl. Mater. 139, 97 (1986)

T. Furukawa, S. Kato, E. Yoshida, J. Nucl. Mater. 392, 249 (2009)

A.K. Bhaduri, I. Gowrisankar, V. Seetharaman, S. Venkadesan, P. Rodriguez, Mater. Sci. Technol. 4, 1020 (1988)

M. Sireesha, V. Shankar, S.K. Albert, S. Sundaresan, Mater. Sci. Eng. A 292, 74 (2000)

K.D. Ramkumar, J.L.N. Varma, G. Chaitanya, A. Choudhary, N. Arivazhagan, S. Narayanan, Mater. Sci. Eng. A 636, 1 (2015)

M. Qian, J.N. DuPont, Corros. Sci. 52, 3548 (2010)

L. Brissonneau, J. Nucl. Mater. 423, 67 (2012)

Z. Fei, Z. Pan, D. Cuiuri, H. Li, W. Huang, Z. Peng, Int. J. Adv. Manuf. Technol. 108, 3207 (2020)

T. Koutsoukis, A. Redjaïmia, G. Fourlaris, Mater. Sci. Eng. A 561, 477 (2013)

K.D. Adams, J.N. DuPont, A.R. Marder, J. Mater. Eng. Perform. 16, 123 (2007)

J. Anburaj, S.S.M. Nazirudeen, R. Narayanan, B. Anandavel, A. Chandrasekar, Mater. Sci. Eng. A 535, 99 (2012)

J.S. Ogborn, D.L. Olson, M.J. Cieslak, Mater. Sci. Eng. A 203, 134 (1995)

A.K. Bhaduri, S.K. Ray, P. Rodriguez, Mater. Sci. Technol. 13, 356 (1997)

J. Moon, J.J. Lee, C.H. Lee, J. Nucl. Mater. 542, 152499 (2020)

J.M. Bai, Y. Yuan, P. Zhang, J.B. Yan, Mater. Sci. Eng. A 784, 138943 (2020)

S. Heino, B. Karlsson, Acta Mater. 49, 339 (2001)

E. Keehan, L. Karlsson, H.O. Andrén, H.K.D.H. Bhadeshia, Sci. Technol. Weld. Join. 11, 19 (2006)

A. Kulkarni, D.K. Dwivedi, M. Vasudevan, Mater. Sci. Eng. A 790, 139685 (2020)

G. Dak, C. Pandey, J. Manuf. Process. 58, 377 (2020)

Y. Li, X. Fan, H. Cui, F. Lu, X. Tang, Sci. Technol. Weld. Join. 26, 37 (2021)

J.K. Kim, H.J. Park, D.N. Shim, Acta Metall. Sin.-Engl. Lett. 29, 1107 (2016)

C. Lee, S. Roh, C. Lee, S. Hong, Mater. Chem. Phys. 207, 91 (2018)

M.K. Chen, J. Xie, D.L. Shu, G.C. Hou, S.L. Xun, J.J. Yu, L.R. Liu, X.F. Sun, Y.Z. Zhou, Acta Metall. Sin.-Engl. Lett. 33, 1699 (2020)

Z. Qiu, B. Wu, H. Zhu, Z. Wang, A. Hellier, Y. Ma, H. Li, O. Muransky, D. Wexler, Mater. Des. 195, 109007 (2020)

J. Zhang, L. Yu, Z. Ma, Y. Liu, C. Liu, H. Li, H. Wang, Metall. Mater. Trans. A 51, 4549 (2020)

A. Zieliński, G. Golański, M. Sroka, Mater. Sci. Eng. A 796, 139944 (2020)

T.H. Lee, H.Y. Suh, S.K. Han, J.S. Noh, J.H. Lee, J. Nucl. Mater. 479, 85 (2016)

M.S.A. Rahman, N.A.A. Raheem, M.R. El Koussy, Acta Metall. Sin.-Engl. Lett. 27, 259 (2014)

M. Manikandan, N. Arivazhagan, M.N. Rao, G.M. Reddy, Acta Metall. Sin.-Engl. Lett. 28, 208 (2015)

Y.L. Ji, W. Zhang, X.Y. Chen, J.G. Li, Acta Metall. Sin.-Engl. Lett. 29, 382 (2016)

E.S. Lee, W.J. Park, J.Y. Jung, S. Ahn, Metall. Mater. Trans. A 29, 1395 (1998)

Z.F. Xu, J.S. Dong, L. Jiang, Z.J. Li, X.T. Zhou, Acta Metall. Sin.-Engl. Lett. 28, 951 (2015)

D. Tytko, P.P. Choi, J. Klöwer, A. Kostka, G. Inden, D. Raabe, Acta Mater. 60, 1731 (2012)

C.Z. Zhu, Y. Yuan, J.M. Bai, P. Zhang, J.B. Yan, C.Y. You, Y.F. Gu, Mater. Sci. Eng. A 740–741, 71 (2019)

K. Karthick, S. Malarvizhi, V. Balasubramanian, S.A. Krishnan, G. Sasikala, S.K. Albert, Nucl. Eng. Technol. 50, 116 (2018)

A. Kulkarni, D.K. Dwivedi, M. Vasudevan, Mater. Sci. Eng. A 731, 309 (2018)

V.D. Vijayanand, M. Vasudevan, V. Ganesan, P. Parameswaran, K. Laha, A.K. Bhaduri, Metall. Mater. Trans. A 47, 2804 (2016)

T. Liu, J.S. Dong, L. Wang, Z.J. Li, X.T. Zhou, L.H. Lou, J. Zhang, J. Mater. Sci. Technol. 31, 269 (2015)

R. Sridhar, K. Devendranath Ramkumar, N. Arivazhagan, Acta Metall. Sin.-Engl. Lett. 27, 1018 (2014)

Acknowledgements

This work was financially supported by the innovation project of Shenyang National Laboratory for Materials Science (No. SYNL-2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Tian, W., Wu, D., Li, Y. et al. Precipitation Behavior and Mechanical Properties of a 16Cr-25Ni Superaustenitic Stainless Steel Weld Metal During Post-weld Heat Treatment. Acta Metall. Sin. (Engl. Lett.) 35, 577–590 (2022). https://doi.org/10.1007/s40195-021-01274-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01274-6