Abstract

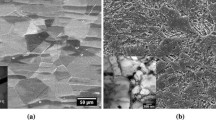

Two 15Cr–9Ni–Nb austenitic stainless steel weld metals with 2.5% Si and 3.5% Si (namely 2.5Si and 3.5Si samples, respectively) were designed and prepared through tungsten inert gas (TIG) welding and then hold at 800 °C or 900 °C for 3 h for stabilization. The microstructure and mechanical properties were investigated both for the as-welded and after-stabilization heat treatment (SHT) weld metals. There are 3.0–4.0% martensite and 2.5–3.5% δ ferrite in the 2.5Si as-welded weld metal and 6.0–7.0% δ ferrite in the 3.5Si as-welded weld metal. After SHT, a large amount of martensite formed in the 2.5Si weld metal, and δ → γ transition occurred during the SHT process both for the 2.5Si and 3.5Si weld metals. There were a large amount of coarse NbC and few nanoscale NbC in the as-welded weld metal. During the SHT, a large amount of nanoscale NbC formed in the matrix, while a large number of G phases formed at the austenite grain boundaries and the δ/γ interfaces. The decrease in solid solution C and δ ferrite content led to the decline of the yield strength of the weld metal after SHT. The martensite formed in 2.5Si weld metal after SHT had less effect on strength because of its low carbon content. The G phases formed during the SHT reduced the impact energy of the weld metal because it promoted the intergranular fracture, while the δ → γ transition reduced the amount of the δ/γ interfaces and avoided the intergranular fracture, which was beneficial for the impact toughness of the weld metals.

Similar content being viewed by others

References

J.L. Séran, M.L. Flem, Structural Materials for Generation IV Nuclear Reactors (Woodhead Publishing, England, 2017), pp.285–328

A.L. Johnson, D. Parsons, J. Manzerova, D.L. Perry, K. Dan, B. Hosterman, J.W. Farley, J. Nucl. Mater. 328, 88 (2004)

C. Schroer, O. Wedemeyer, J. Novotny, A. Skrypnik, J. Konys, Corros. Sci. 84, 113 (2014)

Y. Kurata, H. Yokota, T. Suzuki, J. Nucl. Mater. 424, 237 (2012)

V. Tsisar, C. Schroer, O. Wedemeyer, A. Skrypnik, J. Konys, J. Nucl. Mater. (2014).

Y. Kurata, S. Saito, Mater. Trans. 50, 2410 (2009)

I.G. Vladimir, I.S. Viktor, I.O. Mihail, S.C. Tatyana, Mater. Sci Power Eng. 91, 130 (2015)

J.C. Lippold, D.J. Kotecki, Welding Metallurgy and Weldability of Stainless Steels (Wiley, New Jersey, 2005), pp.140–160

R.A. Farrar, R.G. Thomas, J. Mater. Sci. 18, 3461 (1983)

R.A. Farrar, J. Mater. Sci. 22, 363 (1987)

R.A. Farrar, J. Mater. Sci. 20, 4215 (1985)

J.J. Smith, R.A. Farrar, J. Mater. Sci. 26, 5025 (1991)

L. Zhao, S. Wei, D. Gao, S. Lu, Acta Metall. Sin.-Engl. Lett. 34, 11 (2021)

A.B. Korostelev, S.V. Evropin, A.G. Derzhavin, I.V. Vershinin, A.N. Romanov, At. Energy 129, 1 (2021)

L. Cinotti, C.F. Smith, H. Sekimoto, L. Mansani, M. Reale, J.J. Sienicki, J. Nucl. Mater. 415, 245 (2011)

A. Nassour, W.W. Bose, D. Spinelli, J. Mater. Eng. Perform. 10, 693 (2001)

K. Guan, X. Xu, X. Hong, Z. Wang, Nucl. Eng. Des. 235, 2485 (2005)

G. Eichelman, F.C. Hull, Trans. Am. Soc. Met. 45, 77 (1953)

B. Arh, F. Tehovnik, F. Vode, Metals 11, 935 (2021)

B. Leone, H.W. Kerr, Weld. J. 61, 1 (1982)

A.F. Padilha, G. Schanz, K. Anderko, J. Nucl. Mater. 105, 77 (1982)

A.S. Grot, J.E. Spruiell, Metall. Trans. A 6, 2023 (1975)

J.M. Leitnaker, J. Bentley, Metall. Trans. A 8, 1605 (1977)

A.R. Jones, P.R. Howell, B. Ralph, J. Mater. Sci. 11, 1600 (1976)

H. Uno, A. Kimura, T. Misawa, Sumitomo Search (Japan) 54, 48 (1993)

H.W. Cao, X.H. Luo, G.F. Zhan, S. Liu, Acta Metall. Sin.-Engl. Lett. 31, 81 (2018)

R.A.P. Ibaez, G. Soares, L. Almeida, I.L. May, Mater. Charact. 30, 243 (1993)

N. Vaché, P. Steyer, C. Duret-Thual, M. Perez, Materialia 9, 100593 (2020)

D.J. Powell, R. Pilkington, D.A. Miller, Acta Metall. 36, 713 (1988)

X.F. Guo, Y.Y. Ni, J.M. Gong, L.Y. Geng, J.Q. Tang, Y. Jiang, X.K. Jia, X.Y. Yang, Acta Metall. Sin.-Engl. Lett. 30, 11 (2017)

D.M. Knowles, C.W. Thomas, D.J. Keen, Q.Z. Chen, Int. J. Press. Vessel. Pip. 81, 499 (2004)

D. Hauser, J.E. Vanecho, Weld J. 50, 61 (1982)

J. Vojvodic-Tuma, B. Sustarsic, F. Vodopivec, Nucl. Eng. Des. 238, 1511 (2008)

Acknowledgements

This work was financially supported by the China Institute of Atomic Energy (E141L803J1) and the innovation project of Shenyang National Laboratory for Materials Science (SYNL-2022).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors state that there are no conflict of interest to disclose.

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Y., Wu, D., Li, D. et al. Effects of Stabilization Heat Treatment on Microstructure and Mechanical Properties of Si-Bearing 15Cr–9Ni–Nb Austenitic Stainless Steel Weld Metal. Acta Metall. Sin. (Engl. Lett.) 36, 637–649 (2023). https://doi.org/10.1007/s40195-022-01497-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-022-01497-1