Abstract

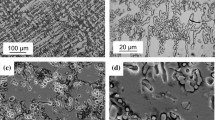

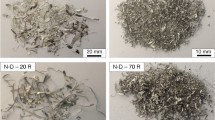

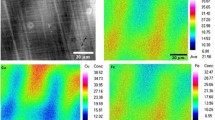

A CoCrFeMnNi high-entropy alloy with a high content of carbon was synthesized, and its hot deformation behavior was studied at the temperatures 800–1000 °C at the strain rates ranging from 0.001 to 0.1 s−1. As-prepared alloy is a face-centered cubic-structured solid solution, with a large amount of carbides residing at grain boundaries. True stress–strain curves were employed to develop the constitutive equation of apparent activation energy. The apparent activation energy (Q) was found to be 423 kJ mol−1, indicating a dynamic flow softening behavior. The size of dynamic recrystallized (DRXed) grains increases with increasing the temperature or decreasing the strain rate. A processing map was sketched on the basis of the flow stress. The temperature range of 900–1000 °C and 10−3–10−2.6 s−1 strain rate were found to be the optimum hot-forging parameter. With increasing temperature or decreasing strain rate, the volume fraction of fine carbides (≤ 1 μm) increases. A lot of coarse carbides can be found in the matrix after deformation at 800 °C, which leads to a high hardness value of 345 HV. The carbides after deformation at 1000 °C are mainly nano-sized M7C3 and M23C6, which can promote the nucleation of DRX.

Similar content being viewed by others

References

K. Fukaura, Y. Yokoyama, D. Yokoi, N. Tsujii, K. Ono, Metall. Mater. Trans. A 35, 1289 (2004)

I. Picas, N. Cuadrado, D. Casellas, A. Goez, L. Llanes, in Fatigue 2010, ed. by P. Lukas (Elsevier Science Bv, Amsterdam, 2010), p. 1777

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004)

C.J. Tong, Y.L. Chen, J.W. Yeh, S.J. Lin, S.K. Chen, T.T. Shun, C.H. Tsau, S.Y. Chang, Metall. Mater. Trans. A 36, 881 (2005)

J.W. Yeh, S.Y. Chang, Y.D. Hong, S.K. Chen, S.J. Lin, Mater. Chem. Phys. 103, 41 (2007)

A. Li, X. Zhang, Acta Metall. Sin. (Engl. Lett.) 22, 219 (2009)

X. Yang, X. Wang, X. Ling, D. Wang, Results Phys. 7, 1412 (2017)

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, R.O. Ritchie, Science 345, 1153 (2014)

H. Shahmir, T. Mousavi, J. He, Z. Lu, M. Kawasaki, T.G. Langdon, Mater. Sci. Eng. A 705, 411 (2017)

X.L. Shang, Z.J. Wang, Q.F. Wu, J.C. Wang, J.J. Li, J.K. Yu, Acta Metall. Sin. (Engl. Lett.) 32, 41 (2019)

Y. Lu, H. Huang, X. Gao, C. Ren, J. Gao, H. Zhang, S. Zheng, Q. Jin, Y. Zhao, C. Lu, T. Wang, T. Li, J. Mater. Sci. Technol. 35, 369 (2019)

B. Zhang, Y. Zhang, S. Guo, J. Mater. Sci. 53, 14729 (2018)

W. Li, P.K. Liaw, Y. Gao, Intermetallics 99, 69 (2018)

Y.Z. Tian, S.J. Sun, H.R. Lin, Z.F. Zhang, J. Mater. Sci. Technol. 35, 334 (2019)

S.G. Ma, Y. Zhang, Mater. Sci. Eng. A 532, 480 (2012)

C.Y. Hsu, J.W. Yeh, S.K. Chen, T.T. Shun, Metall. Mater. Trans. A 35, 1465 (2004)

A. Zaddach, R. Scattergood, C. Koch, Mater. Sci. Eng. A 636, 373 (2015)

H. Zuhailawati, T.C. Geok, P. Basu, Mater. Des. 31, 2211 (2010)

S. Kang, Y.S. Jung, J.H. Jun, Y.K. Lee, Mater. Sci. Eng. A 527, 745 (2010)

S. Fang, W. Chen, Z. Fu, Mater. Des. 54, 973 (2014)

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, Z.Q. Hu, J. Alloys Compd. 509, 3476 (2011)

T.D. Huang, L. Jiang, C.L. Zhang, H. Jiang, Y.P. Lu, T.J. Li, Sci. China Technol. Sci. 61, 117 (2018)

Z. Wu, C.M. Parish, H. Bei, J. Alloys Compd. 647, 815 (2015)

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, Z.P. Lu, Acta Mater. 102, 187 (2016)

L.B. Chen, R. Wei, K. Tang, J. Zhang, F. Jiang, L. He, J. Sun, Mater. Sci. Eng. A 716, 150 (2018)

S. Orhan, A.O. Er, N. Camuşcu, E. Aslan, NDT E Int. 40, 121 (2007)

N. Camuşcu, E. Aslan, J. Mater. Process. Technol. 170, 121 (2005)

E.O. Ezugwu, Z.M. Wang, A.R. Machado, J. Mater. Process. Technol. 86, 1 (1999)

X. Qin, D. Huang, X. Yan, X. Zhang, M. Qi, S. Yue, J. Alloys Compd. 770, 507 (2019)

M. Saadati, R.A. Khosroshahi, G. Ebrahimi, M. Jahazi, Mater. Charact. 131, 234 (2017)

J. Li, B. Gao, S. Tang, B. Liu, Y. Liu, Y. Wang, J. Wang, J. Alloys Compd. 747, 571 (2018)

C. Zener, J.H. Hollomon, J. Appl. Phys. 15, 22 (1944)

N.R. Jaladurgam, A.K. Kanjarla, Mater. Sci. Eng. A 712, 240 (2018)

F. Kong, Y. Chen, D. Zhang, S. Zhang, Mater. Sci. Eng. A 539, 107 (2012)

N.D. Stepanov, N.Y. Yurchenko, M.A. Tikhonovsky, G.A. Salishchev, J. Alloys Compd. 687, 59 (2016)

C.C. Tung, J.W. Yeh, T.T. Shun, S.K. Chen, Y.S. Huang, H.C. Chen, Mater. Lett. 61, 1 (2007)

W. Ji, Z. Fu, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, J. Alloys Compd. 589, 61 (2014)

W. Ji, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, Z. Fu, Intermetallics 56, 24 (2015)

S. Liu, Q. Pan, H. Li, Z. Huang, K. Li, X. He, X. Li, J. Mater. Sci. 54, 1 (2019)

N. Stepanov, M. Tikhonovsky, N. Yurchenko, D. Zyabkin, M. Klimova, S. Zherebtsov, A. Efimov, G. Salishchev, Intermetallics 59, 8 (2015)

G. Qin, R. Chen, H. Zheng, H. Fang, L. Wang, Y. Su, J. Guo, H. Fu, J. Mater. Sci. Technol. 35, 578 (2019)

Z. Wang, Q. Fang, J. Li, B. Liu, Y. Liu, J. Mater. Sci. Technol. 34, 349 (2018)

K. Evans, Treatise on Materials Science & Technology (Elsevier, Amsterdam, 1974), p. 113

B. Liu, J. Wang, Y. Liu, Q. Fang, Y. Wu, S. Chen, C.T. Liu, Intermetallics 75, 25 (2016)

S. Chen, D. Fu, H. Luo, Y. Wang, J. Teng, H. Zhang, Vacuum 149, 297 (2018)

R.R. Eleti, T. Bhattacharjee, L. Zhao, P.P. Bhattacharjee, N. Tsuji, Mater. Chem. Phys. 210, 176 (2018)

K.Y. Tsai, M.H. Tsai, J.W. Yeh, Acta Mater. 61, 4887 (2013)

S. Jiang, Y. Zhang, S. Wang, C. Zhao, J. Mater. Sci. 52, 3199 (2017)

T.Y. Kwak, W.J. Kim, J. Mater. Sci. Technol. 35, 181 (2019)

G. Laplanche, P. Gadaud, O. Horst, F. Otto, G. Eggeler, E. George, J. Alloys Compd. 623, 348 (2015)

Z. Wang, I. Baker, W. Guo, J.D. Poplawsky, Acta Mater. 126, 346 (2017)

S. Zhang, W. Zeng, X. Gao, D. Zhou, Y. Lai, J. Alloys Compd. 684, 201 (2016)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51601022), the National Key Research and Development plan of China (No. 2016YFB0700302) and the Science and Technology Planning Project of Hunan Province of China (No. 2015SK1002-1).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Wang, YT., Li, JB., Xin, YC. et al. Hot Deformation Behavior and Hardness of a CoCrFeMnNi High-Entropy Alloy with High Content of Carbon. Acta Metall. Sin. (Engl. Lett.) 32, 932–943 (2019). https://doi.org/10.1007/s40195-019-00916-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-019-00916-0