Abstract

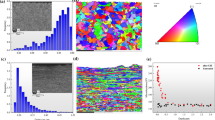

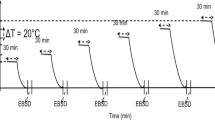

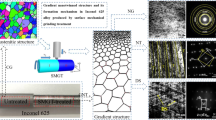

The microstructural evolution of pure nickel treated by deep rolling (DR) technique with different indent depths was investigated by means of optical microscopy and transmission electron microscopy. The surface roughness, hardness and residual stress distribution along the depth from surface were measured. Moreover, the DR-treated sample was annealed at temperatures from 300 to 700 °C for 2 h. The results reveal that dislocation movements are the fundamental mechanisms of gradient grain refinement during the DR process. With increasing indent depth of the DR, the gradient microhardness on the cross section of sample significantly increases, the maximum compressive residual stress decreases, and the affecting region of residual stress increases. The results of thermal stability depict that the microstructure can be stable as temperature up to 300 °C, and the abnormal grain growth and annealing twins are observed at 600 °C.

Similar content being viewed by others

References

M. Dadashpour, R. Yeşildal, A. Mostafapour, V. Rezazade, J. Mech. Sci. Technol. 30, 667 (2016)

H. Hamadache, Z. Zemouri, L. Laouar, S. Dominiak, J. Mech. Sci. Technol. 28, 1491 (2014)

B.N. Mordyuk, O.P. Karasevskaya, G.I. Prokopenko, N.I. Khripta, Surf. Coat. Technol. 210, 54 (2012)

J. Walker, D.J. Thomas, Y. Gao, J. Manuf. Process. 26, 419 (2017)

S. Bagherifard, R. Ghelichi, M. Guagliano, Appl. Surf. Sci. 258, 6831 (2012)

J. Muñoz-Cubillos, J.J. Coronado, S.A. Rodríguez, Int. J. Fatigue 95, 120 (2017)

I. Altenberger, in 9th International Conference on Shot Peening, Paris (2005), p. 144

A. Pimpin, I. Charoenbunyarit, W. Srituravanich, Sens. Actuators A Phys. 253, 49 (2017)

X.Y. Zhong, X.Q. Wu, E.H. Han, X.B. Song, Eng. Fail. Anal. 17, 1404 (2010)

C. Harris, M. Despa, K. Kelly, J. Microelectromech. Syst. 9, 502 (2000)

G. Palumbo, F. Gonzalez, A.M. Brennenstuhl, U. Erb, W. Shmayda, P.C. Lichtenberger, Nanostruct. Mater. 9, 737 (1997)

Z.P. Luo, H.W. Zhang, N. Hansen, K. Lu, Acta Mater. 60, 1322 (2012)

A. Zhilyaev, S. Lee, G.V. Nurislamova, R. Valiev, T.G. Langdon, Scr. Mater. 44, 2753 (2001)

A.P. Zhilyaev, B.K. Kim, G.V. Nurislamova, M.D. Baró, J.A. Szpunar, T.G. Langdon, Scr. Mater. 46, 575 (2002)

X.C. Liu, H.W. Zhang, K. Lu, Science 342, 337 (2013)

K.S. Fong, A. Danno, M.J. Tan, B.W. Chua, J. Mater. Process. Technol. 246, 235 (2017)

N. Tsuji, Y. Ito, Y. Saito, Y. Minamino, Scr. Mater. 47, 893 (2002)

R.Z. Valiev, Mater. Sci. Eng. A 234–236, 59 (1997)

X.C. Liu, H.W. Zhang, K. Lu, Scr. Mater. 95, 54 (2015)

V.V. Popov, E.N. Popova, A.V. Stolbovskiy, V.P. Pilyugin, Mater. Sci. Eng. A 528, 1491 (2011)

V. Yamakov, D. Wolf, S.R. Phillpot, A.K. Mukherjee, H. Gleiter, Nat. Mater. 1, 45 (2002)

N.R. Tao, Z.B. Wang, W.P. Tong, M.L. Sui, J. Lu, K. Lu, Acta Mater. 50, 4603 (2002)

M. Wen, G. Liu, J.F. Gu, W.M. Guan, J. Lu, Appl. Surf. Sci. 255, 6097 (2009)

B. Bay, N. Hansen, D.A. Hughes, D. Kuhlmann-Wilsdorf, Acta Metall. 40, 205 (1992)

N.P. Gurao, R. Kapoor, S. Suwas, Metall. Mater. Trans. A 41, 2794 (2010)

W. Ting, W. Dongpo, L. Gang, G. Baoming, S. Ningxia, Appl. Surf. Sci. 255, 1824 (2008)

V. Schulze, Modern Mechanical Surface Treatment: States, Stability, Effects (Wiley, Hoboken, 2003)

L. Tan, D. Zhang, C. Yao, D. Wu, J. Zhang, J. Manuf. Process. 26, 155 (2017)

L. Lu, N.R. Tao, L.B. Wang, B.Z. Ding, K. Lu, J. Appl. Phys. 89, 6408 (2001)

H. Chang, I. Baker, Mater. Sci. Eng. A 476, 46 (2008)

P. Zháňal, K. Václavová, B. Hadzima, Mater. Sci. Eng. A 651, 886 (2016)

E. Schafler, R. Pippan, Mater. Sci. Eng. A 387–389, 799 (2004)

J. Victoria-Hernández, J. Suh, S. Yi, J. Bohlen, W. Volk, D. Letzig, Mater. Charact. 113, 98 (2016)

X.P. Chen, L.F. Li, H.F. Sun, L.X. Wang, Q. Liu, Mater. Sci. Eng. A 622, 108 (2015)

P.P. Bhattacharjee, R.K. Ray, N. Tsuji, Acta Mater. 57, 2166 (2009)

S. Zaefferer, T. Baudin, R. Penelle, Acta Mater. 49, 1105 (2001)

Y. Jin, B. Lin, M. Bernacki, G.S. Rohrer, A.D. Rollett, N. Bozzolo, Mater. Sci. Eng. A 597, 295 (2014)

V.V. Popov, E.N. Popova, D.D. Kuznetsov, Mater. Sci. Eng. A 585, 281 (2013)

K. Sitarama Raju, M. Ghanashyam Krishna, K.A. Padmanabhan, V. Subramanya Sarma, N.P. Gurao, G. Wilde, J. Mater. Sci. 46, 2662 (2011)

Acknowledgements

The authors would like to acknowledge gratefully for the financial support through the National Natural Science Foundation of China (Nos. 51725503, 51605164 and 51575183) and 111 Project. X.C. Zhang is also grateful for the support by Shanghai Technology Innovation Program of SHEITC (CXY-2015-001), Fok Ying Tung Education Foundation and Young Program of Yangtze River Scholars. Y.F. Jia is also grateful for the support by Shanghai Sailing Program (16YF1402300) and Shanghai Chenguang Program (16CG34).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Li, X., Guan, B., Jia, YF. et al. Microstructural Evolution, Mechanical Properties and Thermal Stability of Gradient Structured Pure Nickel. Acta Metall. Sin. (Engl. Lett.) 32, 951–960 (2019). https://doi.org/10.1007/s40195-018-00870-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-00870-3