Abstract

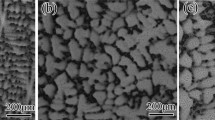

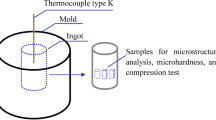

The transformation mechanism of (γ + γ′) was studied by analyzing the microstructure and elemental distribution of the U720Li samples heated at 1250 °C and cooled at the rates in the range of 1–100 °C/s. Although the (γ + γ′) is deemed to be formed by a eutectic reaction and has been called eutectic (γ + γ′), it was found in the present study that the (γ + γ′) precipitation begins with a peritectic reaction of (L + γ) → γ′, and develops by the eutectic reaction of L → (γ + γ′). The energy for the γ′ nucleation is low because the interfacial energy for the γ/γ′ interface is about one-tenth of the solid/liquid interface, and hence, the nucleation rate is high and the fine structure of (γ + γ′) is formed at the initial precipitation stage. The γ and γ′ in (γ + γ′) tend to grow into a lamellar structure because it is difficult for them to nucleate directly from the residual liquids, and hence, the γ′ precipitates naturally tend to grow divergently direction of the regions rich in Al and Ti, forming a fan-like structure of the (γ + γ′). As a result, the γ′ precipitates will coarsen finally because the space between them is enlarged. The solidification of the final residual liquids is a diffusion dependent process. When cooled at a higher rate, a higher degree of super cooling is reached and finally the solidification is finished by the pseudo-eutectic reaction of L → (γ + boride) and L → (γ + η), which can absorb Zr and B. When cooled at a rate low enough, most of the residual liquids are consumed by the (γ + γ′) growth due to the sufficient diffusion, and the boride and Zr-bearing phase are precipitated at a quasi-equilibrium state. Under this condition, Ti is depleted at the (γ + γ′) growth front. However, the η-Ni3Ti phase is formed there occasionally due to the boride precipitation, because the compositions of the two phases are complementary.

Similar content being viewed by others

References

S.M. Seo, J.H. Lee, Y.S. Yoo, C.Y. Jo, H. Miyahara, K. Ogi, Metall. Mater. Trans. A 42, 3150 (2011)

H. Monajati, A.K. Taheri, M. Jahazi, S. Yue, Metall. Mater. Trans. A 36, 895 (2005)

J. Mao, K.M. Chang, W. Yang, K. Ray, S.P. Vaze, D.U. Ferrer, Metall. Mater. Trans. A 32, 2441 (2001)

G.D. Zhao, L.X. Yu, F. Qi, F. Liu, W.R. Sun, Z.Q. Hu, Acta Metall. Sin. (Engl. Lett.) 29, 518 (2016)

L. Chang, H. Jin, W. Sun, J. Alloys Compd. 653, 266 (2015)

J. Zhang, R.F. Singer, Metall. Mater. Trans. A 35, 1337 (2004)

K. Hilpert, D. Kobertz, V. Venugopal, M. Miller, H. Cerads, F.J. Bremer, H. Nickel, Z. Naturforsch. A 42, 1327 (1987)

N. D’Souza, H.B. Dong, Scr. Mater. 56, 41 (2007)

X.Y. Zhang, L. Liu, T.W. Huang, J. Zhang, H.Z. Fu, Rare Metal Mater. Eng. 42, 2547 (2013)

L. Liu, T.W. Huang, J. Zhang, H.Z. Fu, Mater. Lett. 61, 227 (2007)

B.C. Wilson, J.A. Hickman, G.E. Fuchs, JOM 55, 35 (2003)

T.J. Garosshen, T.D. Tillman, G.P. McCarthy, Metall. Trans. A 18, 69 (1987)

B.C. Yan, J. Zhang, L.H. Lou, Mater. Sci. Eng., A 474, 39 (2008)

A.V. Shulga, J. Alloys Compd. 436, 155 (2007)

G. Zhao, L. Yu, G. Yang, W. Zhang, W. Sun, J. Alloys Compd. 686, 194 (2016)

S.M. Seo, I.S. Kim, J.H. Lee, C.Y. Jo, H. Miyahara, K. Ogi, Metall. Mater. Trans. A 38, 883 (2007)

N. Warnken, D. Ma, M. Mathes, I. Steinbach, Mater. Sci. Eng., A 413, 267 (2005)

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Zhao, GD., Yang, GL., Liu, F. et al. Transformation Mechanism of (γ + γ′) and the Effect of Cooling Rate on the Final Solidification of U720Li Alloy. Acta Metall. Sin. (Engl. Lett.) 30, 887–894 (2017). https://doi.org/10.1007/s40195-017-0566-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0566-7