Abstract

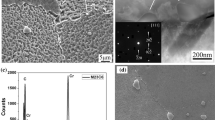

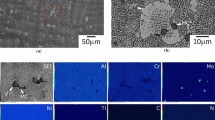

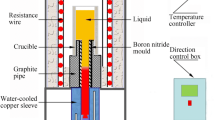

The tensile properties and deformation behavior of several cast Ni-based superalloys, respectively, in the equiaxed, columnar-crystal and single-crystal styles are comparatively studied. The effects of solidification way, heat treatment and strain rate on the tensile properties are discussed in detail. It is found that the reduction of grain boundaries by the feasible solidification ways offers cast Ni-based superalloys the potential capability of improving the mechanical properties, the ultimate achievement of which is also confirmed to lie on the appropriate modifications of chemical composition and heat treatment. The prolongation of solid solution facilitates the precipitation of fine secondary γ′ phase, whereas the extension of high-temperature aging leads to the coarsening of secondary γ′ phase. The combination of these two aspects has a crucial influence on the tensile properties. Under tensile applied stress, the surface grains of DZ-A alloy deform slightly, while the inner grains deform heavily. This deformation inhomogeneity is ascribed to the occurrence of cracks or oblique grains near the surface of specimens and the sliding or decohesion of grain boundaries between the surface and inner grains. Regardless of strain rate, the ILTDM (intermediate-low-temperature ductility minimum) phenomenon always happens in the temperature range from 400 to 600 °C in all the investigated alloys, the occurrence of which is closely related to the strong strain-hardening behavior in the deformation process. Finally, the interaction of slip bands which are the main deformation mode below 600 °C is established to be the essential reason for the strain hardening.

Similar content being viewed by others

References

D.X. Wen, Y. Lin, H.B. Li, X.M. Chen, J. Deng, L.T. Li, Mater. Sci. Eng. A 591, 183 (2014)

J.M. Zhang, Z.Y. Gao, J.Y. Zhuang, Z.Y. Zhong, P. Janschek, J. Mater. Process. Technol. 70, 252 (1997)

B. Du, J. Yang, C. Cui, X. Sun, Mater. Des. 65, 57 (2015)

R.C. Reed, The Superalloys Fundamentals and Applications (Cambridge University Press, New York, 2006), pp. 1–32

Q.Y. Huang, H.K. Li, Superalloys (Metallurgical Industry Press, Beijing, 2000), pp. 9–66 (in Chinese)

J.T. Guo, Materials Science and Engineering for Superalloys (Superalloy Materials and Their Engineering Applications) (Science Press, Beijing, 2010), pp. 543–566 (in Chinese)

R.F. Zhou, Y.F. Han, S.S. Li, High Temperature Structure Materials (National Defence Industry Press, Beijing, 2006), pp. 75–85 (in Chinese)

M.C. Thomas, R.C. Helmink, D.J. Frasier, K. Harris, G.L. Erickson, S.L. Sikkenga, J.M. Eridon, in Proceeding of the 5th Liège Conference, Materials for Advanced Power Engineering 1994, Liège, Belgium, 1994, pp. 1075–1098

K. Hrutkay, D. Kaoumi, Mater. Sci. Eng. A 599, 196 (2014)

L.X. Tian, C.L. Ma, Mater. Sci. Eng. A 620, 198 (2015)

W.W. Milligan, S.D. Antolovich, Metall. Trans. A 18, 85 (1987)

Y.C. Lin, J. Deng, Y.Q. Jiang, D.X. Wen, G. Liu, Mater. Des. 55, 949 (2014)

R.R. Jensen, J.K. Tien, Metall. Trans. A 16, 1049 (1985)

K. Gopinath, A.K. Gogia, S.V. Kamat, R. Balamuralikrishnan, U. Ramamurty, Metall. Trans. A 39, 2340 (2008)

X. Zhang, T. Jin, N.R. Zhao, Z.H. Wang, X.F. Sun, H.R. Guan, Z.Q. Hu, Mater. Sci. Eng. A 492, 364 (2008)

X.Z. Qin, J.T. Guo, C. Yuan, C.L. Chen, H.Q. Ye, Mater. Trans. A 38, 3014 (2007)

A.K. Koul, R. Castillo, Metall. Trans. A 19, 2049 (1988)

E.W. Ross, C.T. Sims, in Superalloys II, ed. by C.T. Sims, N.S. Stoloff, W.C. Hagel (Wiley, New York, 1987), pp. 97–133

X.F. Sun, T. Jin, Y.Z. Zhou, Z.Q. Hu, Mater. China 31, 1 (2012)

Q.Y. Huang, H.K. Li, Superalloys (Metallurgical Industry Press, Beijing, 2000), pp. 140–146. (in Chinese)

Z.K. Chu, J.J. Yu, X.F. Sun, H.R. Guan, Z.Q. Hu, Mater. Sci. Eng. A 527, 3010 (2010)

R.H. Bricknell, D.A. Woodford, Metall. Trans. A 12, 425 (1981)

C.T. Liu, V.K. Sikka, J. Met. 38, 19 (1986)

E.P. George, C.T. Liu, H. Lin, D.P. Hope, Mater. Sci. Eng. A 192/193, 277 (1995)

D.A. Woodford, Metall. Trans. A 12, 299 (1981)

J.L. Liu, Stress Rupture Properties and Microstructural Evolution of a Ni-Base Superalloy. Ph.D. Thesis, Institute of Metal Research, CAS, Shenyang, 2002 (in Chinese)

X. Zhang, Heat Treatment and Tensile, Fatigue Properties of a Ni-Based Single Crystal Superalloy. Ph.D. Thesis, Institute of Metal Research, CAS, Shenyang, 2006 (in Chinese)

Z.K. Chu, Investigation of Mechanical Property and Deformation Mechanism of DZ951 Alloy. Ph.D. Thesis, Institute of Metal Research, CAS, 2008 (in Chinese)

Y.H. Liu, Y.Q. Ning, Z.K. Yao, Y.Z. Li, J.L. Zhang, M.W. Fu, J. Mater. Res. 31, 2164 (2016)

K.V.U. Praveen, G.V.S. Sastry, V. Singh, Metall. Mater. Trans. A 39, 65 (2008)

F. Ebrahimi, J. Yanevich, D.P. Deluca, Acta Mater. 48, 469 (2000)

Z.W. Lian, J.J. Yu, X.F. Sun, H.R. Guan, Z.Q. Hu, Mater. Sci. Eng. A 489, 227 (2008)

I.S. Kim, B.G. Choi, S.M. Seo, D.H. Kim, C.Y. Jo, Mater. Lett. 62, 1110 (2008)

W.S. Walston, I.M. Bernstein, A.W. Thompson, Metall. Trans. A 22, 1443 (1991)

T.M. Pollock, A.S. Argon, Acta Mater. 42, 1859 (1994)

F.R.N. Nabarro, Metall. Trans. A 27, 513 (1996)

O. Paris, M. Fährmann, E. Fährmann, T.M. Pollock, P. Fratzl, Acta Mater. 45, 1085 (1997)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51001101) and the National Energy Administration Program of China (No. NY20150102).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Li, HT., Liang, YC., Zhong, WL. et al. Tensile Properties and Deformation Behavior of Several Cast Ni-Based Superalloys Fabricated by Different Solidification Ways. Acta Metall. Sin. (Engl. Lett.) 30, 280–288 (2017). https://doi.org/10.1007/s40195-016-0499-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-016-0499-6