Abstract

In the present work, 6082 Al alloy has been rolled to 40% and 70% thickness reductions at the cryogenic and room temperatures for the improvement in mechanical and fracture toughness properties. All cryorolled samples are subjected to aging at different temperatures, i.e., 140, 160, and 190 °C to improve the strength, ductility, and fracture toughness. The microstructures of the cryorolled (CR) and room temperature rolled (RTR) alloy after 40% and 70% thickness reductions are characterized by FE-SEM to reveal the modes of failure. The results show that the starting bulk Al alloy specimen is fractured in total ductile manner, consisting of well-developed dimples over the entire surface. The mechanical properties and fracture toughness of the 70% CR alloy are found better than 70% RTR alloy due to higher dislocations density and formation of sub-grain structures in the CR alloy.

Similar content being viewed by others

References

S.K. Panigrahi, R. Jayaganthan, Mater. Sci. Forum 584–586, 734 (2008)

S.K. Panigrahi, R. Jayaganthan, Mater. Sci. Eng. A 480, 299 (2008)

Z. Vaiev, Adv. Eng. Mater. 5, 296 (2003)

C.L. Terry, R.Z. Valiev, JOM 56, 64 (2004)

A. Nikolaos, S. Antonis, C. John, Mech. Mater. 58, 55 (2013)

D. Huges, N. Hansen, Acta Mater. 45, 3871 (1997)

Q. Wei, S. Cheng, K. Ramesha, E. Ma, Mater. Sci. Eng. 381, 71 (2004)

N. Rajasekaran, V. Sampath, J. Min. Mater. Charact. Eng. 10, 527 (2011)

P. Das, S. Dutta, H. Roy, R. Jayaganthan, Int. J. Technol. Eng. Syst. 2, 143 (2011)

R. Valiev, R. Islamgaliev, I. Alexandrov, Prog. Mater Sci. 45, 103 (2000)

G. Nowotnik, J. Sieniawski, A. Nowotnik, J. Achiev. Mater. Manuf. Eng. 17, 105 (2006)

E647-08, Standard Test Method for Measurement of Fatigue Crack Growth Rates, Annual Book of ASTM Standards (2008)

E1820-11, Standard Test Method for Measurement of Fracture Toughness, Annual Book of ASTM Standards (2008)

E399-08, Standard Test Method for Linear-elastic Plane-strain Fractures Toughness KIc of Metallic Materials, Annual Book of ASTM Standards (2008)

X. Gomez, L. Galdos, C. Garcia, J. Eng. Mater. Technol. 131, 501 (2009)

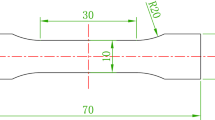

E8/E8 M-09, Standard Test Methods for Tension Testing of Metallic Materials, Annual Book of ASTM Standards (2009)

S.K. Panigrahi, R. Jayaganthan, Mater. Sci. Eng. A 528, 3147 (2011)

D. Singh, P.N. Rao, R. Jayaganthan, Mater. Des. 50, 646 (2013)

H. Somekawa, T. Mukai, Scr. Mater. 53, 1059 (2005)

S. Chang, S. Seo, S. Lee, C. Kang, S. Hong, S. Dong, Mater. Sci. Forum 449, 589 (2004)

G. Nowotnik, Archiv. Mater. Sci. Eng. 29, 93 (2008)

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Kumar, V., Singh, I.V., Mishra, B.K. et al. Improved Fracture Toughness of Cryorolled and Room Temperature Rolled 6082 Al Alloys. Acta Metall. Sin. (Engl. Lett.) 27, 359–367 (2014). https://doi.org/10.1007/s40195-014-0057-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-014-0057-z