Abstract

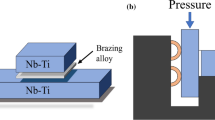

A five-element medium-entropy filler alloy with composition of Ti-(18 ~ 24)Mn-(12 ~ 18)Fe-(3 ~ 8)Ni-(3 ~ 8)Zr (wt.%) was proposed for vacuum brazing of TiAl-based alloy. The filler alloy was mainly composed of Ti-based solid solution and Ti-(Fe, Mn) compound dissolved with elements of Ni and Zr. The filler alloy ingot was ground into powder and then the filler powder was preset into the V-shaped groove butt joint with a gap of 50 μm. The Ti-Mn-Fe-Ni-Zr brazing alloy showed the liquidus temperature of 1060.1 °C, and also presented excellent wettability on TiAl substrate at 1110 °C for 10 min. The brazed joint mainly consisted of γ-TiAl, α2-Ti3Al, and residual brazing filler reaction phase. The brazing condition of 1210 °C/45 min exhibited the maximum joint thickness of 308 μm and the maximum area percentage of γ-TiAl phase of 33.77%, with almost elimination of residual brazing filler reaction phase within the joint, and meanwhile offered the maximum room-temperature tensile strength of 418 MPa, 70.85% of the base alloy. The joint fracture showed a mixed mode of intergranular and transgranular fracture.

Similar content being viewed by others

Data availability

No data was used for the research described in the article.

References

Perrut M, Caron P, Thomas M, Couret A (2018) High temperature materials for aerospace applications: Ni-based superalloys and γ-TiAl alloys. C R Phys 19:657–671. https://doi.org/10.1080/09603409.2016.1206294

Wu XH (2006) Review of alloy and process development of TiAl alloys. Intermetallics 14:1114–1122. https://doi.org/10.1016/j.intermet.2005.10.019

Bewlay BP, Nag S, Suzuki A, Weimer MJ (2016) TiAl alloys in commercial aircraft engines. Mater High Temp 33(4–5):549–559. https://doi.org/10.1080/09603409.2016.1183068

Clemens H, Mayer S (2013) Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv Eng Mater 15(4):191–215. https://doi.org/10.1002/adem.201200231

Rastkar AR, Sohi MH (2020) Phase identification and fracture strength of plasma brazed joints of Ti-45Al-2Nb-2Mn-1B with Ti-Ni-Cu filler metals. Mater Lett 286:129249. https://doi.org/10.1016/j.matlet.2020.129249

Mishra S, Sharma A, Jung DH, Jung JP (2020) Recent advances in active metal brazing of ceramics and process. Met Mater Int 26:1087–1098. https://doi.org/10.1007/s12540-019-00536-4

Abbasi M, Bagheri B, Sharifi F, Abdollahzadeh A (2021) Friction stir vibration brazing (FSVB): an improved version of friction stir brazing. Weld World 65:2207–2220. https://doi.org/10.1007/s40194-021-01173-5

Tillmann W, Ulitzka T, Wojarski L, Manka M, Ulitzka H, Wagstyl D (2020) Development of high entropy alloys for brazing applications. Weld World 64:201–208. https://doi.org/10.1007/s40194-019-00824-y3

Kokabi D, Kaflou A (2021) TiAl/IN718 dissimilar brazing with TiZrNiCuCo high-entropy filler metal: phase characterization and fractography. Weld World 65:1189–1198. https://doi.org/10.1007/s40194-021-01075-6

Jöckel A, Baumgartner J, Tillmann W, Bültena J, Bobzin K, Heinemann H, Hebing J, Erck M (2022) Influence of brazing process and gap size on the fatigue strength of shear and peel specimen. Weld World 66:1941–1955. https://doi.org/10.1007/s40194-022-01304-6

Shiue RK, Wu SK, Chen SY (2003) Infrared brazing of TiAl intermetallic using BAg-8 braze alloy. Acta Mater 51(7):1991–2004. https://doi.org/10.1016/S1359-6454(02)00606-7

Li XQ, Li L, Hu K, Qu SG (2015) Vacuum brazing of TiAl-based intermetallics with Ti-Zr-Cu-Ni-Co amorphous alloy as filler metal. Intermetallics 57:7–16. https://doi.org/10.1016/j.intermet.2014.09.01

Ren XY, Ren HS, Kang YW, Xiong HP, Pei C, Chen B, Cheng YY, Ustinov AI (2019) Solid-state diffusion bonding of NbSS/Nb5Si3 composite using Ni/Al and Ti/Al nanolayers. Acta Metall Sin-Engl 32:1142–1150. https://doi.org/10.1007/s40195-019-00906-2

Ren HS, Xiong HP, Chen B, Pang SJ (2015) Vacuum brazing TiAl to Ti3Al using two Ti-based filler metals. Weld World 59(5):639–646. https://doi.org/10.1007/s40194-015-0239-y

Shang YL, Ren HS, Jing YJ, Xiong HP, Chen B (2019) Vacuum brazing of TiAl-based alloy using Ti-Zr-Fe filler metal. Weld World 63(5):1461–1467. https://doi.org/10.1007/s40194-019-00759-4

Ren HS, Shang YL, Ren XY, Jing YJ, Xiong HP, Cheng YY (2022) Microstructure and mechanical properties of TiAl/TiAl joints brazed with a newly developed Ti-Ni-Nb-Zr quaternary filler alloy. Prog Nat Sci-Mater 32(6):758–768. https://doi.org/10.1016/j.pnsc.2022.07.006

Ren XY, Ren HS, Shang YL, Xiong HP, Zhang K, Zheng JH, Liu D, Lin JG, Jiang J (2020) Microstructure evolution and mechanical properties of Ti2AlNb/TiAl brazed joint using newly-developed Ti-Ni-Nb-Zr filler alloy. Prog Nat Sci-Mater 30(3):410–416. https://doi.org/10.1016/j.vacuum.2023.112365

Jing YJ, Xiong HP, Shang YL, Ren XY (2021) Interfacial microstructure and tensile strength of TiAl joint brazed with an improved Ti-Zr-Cu-Ni filler. Weld World 65(7):1–8. https://doi.org/10.1007/s40194-020-01015-w

Shang YL, Ren XY, Ren HS, Pang SJ, Jing YJ, Cheng YY, Xiong HP (2022) Effect of element Zr in Ti-Zr-Ni-Nb system brazing filler alloys on the microstructure and strength of TiAl/TiAl joints. Weld World 66(7):1437–1446. https://doi.org/10.1007/s40194-022-01274-9

Herziga C, Przeorskia T, Frieselb M, Hiskera F, Divinski S (2001) Tracer solute diffusion of Nb, Zr, Cr, Fe, and Ni in γ-TiAl: effect of preferential site occupation. Intermetallics 9(6):461–472. https://doi.org/10.1016/S0966-9795(01)00025-5

Liu B, Liu Y, Qiu CZ, Zhou CX, Li JB, Li HZ, He YH (2015) Design of low-cost titanium aluminide intermetallics. J Alloy Compd 640:298–304. https://doi.org/10.1016/j.jallcom.2015.03.239

Motha S, Maledi N, Tlotleng M (2022) Characterization of Mn micro alloyed TiAl fabricated using laser engineered net shaping (LENS). Mater Today: Proc 640:298–304. https://doi.org/10.1016/j.matpr.2022.04.817

Villars P, Prince A, Okamoto H (1995) Handbook of ternary alloy phase diagrams. ASM International, New York

Massalski TB (1992) Alloy phase diagrams binary alloy phase diagrams. ASM International, New York

Ren HS, Feng HL, Ren XY, Pang SJ, Cheng YY, Xiong HP (2022) Joining of TiAl-based alloy and a Ni-based superalloy with a NiCoFeCuSiB high entropy filler metal. Weld World 66:557–565. https://doi.org/10.1007/s40194-021-01245-6

Hardwick L, Rodgers P, Pickering E, Goodall R (2021) Development of a novel Ni-based multi-principal element alloy filler metal, using an alternative melting point depressant. Metall Mater Trans A 52(6):2534–2548. https://doi.org/10.1007/s11661-021-06246-0

Cai YS, Liu RC, Ji HB, Cui YY, Yang R (2021) Vacuum brazing TiAl-based intermetallics using novel Ti-Fe-Mn eutectic brazing alloy. Intermetallics 136:107274. https://doi.org/10.1016/j.intermet.2021.107274

Song XG, Cao J, Liu YZ, Feng JC (2012) Brazing high Nb containing TiAl alloy using TiNi-Nb eutectic braze alloy. Intermetallics 22:136–141. https://doi.org/10.1016/j.intermet.2011.10.020

Ren XY, Liu W, Ren HS, Jing YJ, Mao W, Xiong HP (2020) Microstructures and joining characteristics of NbSS/Nb5Si3 composite joints by newly-developed Ti66-Ni22-Nb12 filler alloy. J Mater Sci Technol 58:95–99. https://doi.org/10.1016/j.jmst.2020.03.047

Ren XY, Xiong HP, Kang YW, Pei C, Chen B, Cheng YY (2019) Microstructure and mechanical properties of vacuum brazed NbSS/Nb5Si3 composite joints using Ni-based filler alloys. Metall Mater Trans A 50:5181–5190. https://doi.org/10.1007/s11661-019-05435-2

Ren HS, Xiong HP, Ye L, Ren XY, Li WW, Qin RY (2021) Microstructures and mechanical properties of TiAl/Ni-based superalloy joints brazed with Fe-based filler metal. Weld World 65:79–85. https://doi.org/10.1007/s40194-020-00998-w

Srivatsan TS, Gupta M (2020) High entropy alloys: innovations, advances, and applications, 1st edn. CRC Press, Florida

Yang W, Pang SJ, Wang G, Liu Y, Liaw PK, Zhang T (2022) Ti-Zr-Hf-Nb-Ta-Sn high-entropy alloys with good properties as potential biomaterials. Rare Met 41:2305–2315. https://doi.org/10.1007/s12598-021-01938-3

Takeuchi A, Inoue A (2005) Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans 46(12):2817–2829. https://doi.org/10.2320/matertrans.46.2817

Biswas K, Gurao NP, Maiti T, Mishra RS (2022) High entropy materials processing, properties, and applications. Springer Nature Singapore Pte Ltd., Singapore

Ohnuma I, Fujita Y, Mitsui H, Ishikawa K, Kainuma R, Ishida K (2000) Phase equilibria in the Ti-Al binary system. Acta Mater 48(12):3113–3123. https://doi.org/10.1016/S1359-6454(00)00118-X

Schuster JC, Palm M (2006) Reassessment of the binary aluminum-titanium phase diagram. J Phase Equilib Diff 27(3):255–277. https://doi.org/10.1361/154770306X109809

Witusiewicz VT, Bondar AA, Hecht U, Rex S, Velikanova TY (2008) The Al-B-Nb-Ti system III. thermodynamic re-evaluation of the constituent binary system Al-Ti. J Alloy Compd 465(12):64–77. https://doi.org/10.1016/j.jallcom.2007.10.061

Lee SJ, Wu SK, Lin RY (1999) Infrared joining of TiAl intermetallics using Ti-15Cu-l5Ni foil-I. the microstructure morphologies of joint interfaces. Acta Mater 46(4):1283–1295. https://doi.org/10.1016/S1359-6454(97)00298-X

Si XQ, Zhao HY, Cao J, Song XG, Tang DY, Feng JC (2015) Brazing high Nb containing TiAl alloy using Ti-28Ni eutectic brazing alloy: interfacial microstructure and joining properties. Mater Sci Eng A 636:522–528. https://doi.org/10.1016/j.msea.2015.03.108

Lütjering G, Williams JC (2003) Titanium. Springer Berlin, Heidelberg. https://doi.org/10.1007/978-3-540-71398-2

Liu W, Huang S, Ye CT, Jia L, Kang YW, Sha JB, Chen BQ, Wu Y, Xiong HP (2023) Progress in Nb-Si ultra-high temperature structural materials: a review. J Mater Sci Technol 149:127–153. https://doi.org/10.1016/j.jmst.2022.11.022

Funding

This research was supported by the National Natural Science Foundation of China under Grant Nos. 51804286, 51705489, and 52201050.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• A 5-element medium-entropy brazing filler alloy with Ti-Mn-Fe-Ni-Zr composition system was proposed for joining TiAl-based alloy and microstructures and mechanical properties of the TiAl brazed joint were studied.

• The brazing parameters had an evident effect on the joint thickness, the area percentage of γ-TiAl phase within the joint and the thickness of residual brazing filler reaction phase, as well as the fracture location.

• Under the brazing condition of 1210 °C/45 min, the brazed joint exhibited the maximum tensile strength of 418 MPa at room temperature, corresponding to the highest joint strength coefficient of 70.85%.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhai, Z., Ren, X., Shang, Y. et al. Microstructures and mechanical properties of TiAl joint brazed with Ti-Mn-Fe-Ni-Zr system medium-entropy filler alloy. Weld World (2024). https://doi.org/10.1007/s40194-024-01785-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40194-024-01785-7