Abstract

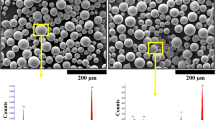

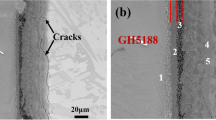

Vacuum brazing of NbSS/Nb5Si3 composite was performed with BNi2 and BNi5 filler alloys at 1293-1423 K for 1800 seconds. The joint microstructures were examined by a scanning electron microstructure (SEM) equipped with an X-ray energy-dispersive spectrometer (XEDS), and shear test for the brazed joints was conducted at room temperature. The NbSS/Nb5Si3 joint brazed with BNi2 filler alloy at 1293 K mainly consisted of Ni3Si + Nb3Si, NiSS and borides. As the brazing temperature increased to 1423 K, Cr2Nb and NbNi phases were formed and the shear strength of the joints was increased from 180 to 253 MPa. Concerning the joints brazed with BNi5 filler at 1423 K, they exhibited an average strength of 274 MPa, and the joint micro-hardness was lower than BNi2 filler. The BNi5 filler alloy not only raised the shear strength but also decreased the joint brittleness to some extent. As a new finding in this study, 4-5 at. pct Ni had been dissolved into (Nb,Ti)SS in the NbSS/Nb5Si3 composite, providing a new insight into the design of novel specific filler material for NbSS/Nb5Si3 joining.

Similar content being viewed by others

References

[1] B.P. Bewlay, J.J. Lewandowksi, and M.R. Jackson: JOM, 1997, vol. 49, pp. 44-45.

[2] B.P. Bewlay, M.R. Jackson, J.C. Zhao, P.R. Subramanian, M.G. Mendiratta, and J.J. Lewandowski: MRS Bull., 2003, vol. 28, pp. 646-653.

[3] J.H. Kim, T. Tabaru, M. Sakamoto, and S. Hanada: Mater. Sci. Eng. A, 2004, vol. 372, pp. 137-144.

[4] Gang F, Kauffmann A, and Heilmaier M: Metall. Mater. Trans. A, 2018, vol. 49, pp. 763-771.

W. Liu, H. P. Xiong, N. Li, S.Q. Guo, and R. Y. Qin: Acta Metall. Sin. Engl. Lett., 2018, vol. 31, pp. 362-370.

[6] Y.W. Kang, Y.C. Yan, J.X. Song, and H.S. Ding: Mater. Sci. Eng. A, 2014, vol. 599, pp. 87-91.

[7] Y. Tang, and X. Guo: Metall. Mater. Trans. A, 2018, vol. 49, pp. 4884-4894.

[8] C.L. Yeh, and W.H. Chen: J. Alloys Compd., 2005, vol. 402, pp. 118-123.

[9] J.L. Yu, K.F. Zhang, Z.K. Li, X. Zheng, G.F. Wang, and R. Bai: Scr. Mater., 2009, vol. 61, pp. 620-623.

[10] Y.W. Kang, S.Y. Qu, J.X. Song, Q. Huang, and Y.F. Han: Mater. Sci. Eng. A, 2012, vol. 534, pp. 323-328.

[11] G.M. Cheng, Y.X. Tian, L.L. He, and J.T. Guo: Philos. Mag., 2009, vol. 89, pp. 2801-2812.

[12] J.L. Yu, and K.F. Zhang: Scr. Mater., 2008, vol. 59, pp. 714-717.

[13] L. N. Jia, and H. Zhang: Metall. Mater. Trans. A, 2018, vol. 49, pp. 1295-1303.

[14] D. Liu, Y.Y. Song, B. Shi, Q. Zhang, X.G. Song, H.W. Niu, and J.C. Feng: J. Mater. Sci. Technol., 2018, vol. 34, pp. 1843-1850.

[15] W.W. Li, B. Chen, Y. Xiong, H.P. Xiong, Y.Y. Cheng, and W.J. Zou: J. Mater. Sci. Technol., 2017, vol. 5, pp. 487-491.

[16] R.F. Li, Z.S. Yu, and K. Qi: Adv. Mater. Res., 2013, vol. 602, pp. 2087-2091.

[17] A.R. Miedema, F.R. De Boer, and R. Boom: Calphad, 1977, vol. 1, pp. 341-359.

[18] J.S.C. Jang, and H.P. Shih: J. Mater. Sci. Lett., 2003, vol. 22, pp. 79-82.

[19] J. Ruiz-Vargas, N. Siredey-Schwaller, N. Gey, P. Bocher, and A. Hazotte: J. Mater. Process. Technol., 2013, vol. 213, pp. 20-29.

[20] J. Geng, P. Tsakiropoulos, and G.S. Shao: Intermetallics, 2007, vol. 15, pp. 69-76.

[21] X.J. Yuan, C.Y. Kang, and M.B. Kim: Mater. Charact., 2009, vol. 60, pp. 923-931.

[22] M.A. Arafin, M. Medraj, D.P. Turner, and P. Bocher: Mater. Chem. Phys., 2017, vol. 106, pp. 109-119.

[23] M.A. Arafin, M. Medraj, D.P. Turner, and P. Bocher: Mater. Sci. Eng. A, 2007, vol. 447, pp. 125-133.

[24] Z. Chen, and Y.W. Yan: J. Alloys Compd., 2006, vol. 413, pp. 73-76.

[25] Y. Luo, W.C. Jiang, Y.C. Zhang, M.M. Hao, and S.T. Tu: Mater. Sci. Eng. A, 2018, vol. 711, pp. 223-232.

[26] Deardorff, D. K., Siemens, R. E., Romans, P. A., and McCune, R. A: J. Less-Common Met., 1969, vol. 18, pp. 11-26.

[27] Y.X. Tian, J.T. Guo, L.Y. Sheng, G.M. Cheng, L.Z. Zhou, L.L. He, and H.Q. Ye: Intermetallics, 2008, vol. 16, pp. 807-812.

[28] M.M. Verdian, K. Raeissi, and M. Salehi: Appl. Surf. Sci., 2012, vol. 261, pp. 493-498.

[29] S. Milenkovic, and R. Caram: J. Cryst. Growth, 2002, vol. 237, pp. 95-100.

[30] V. Jalilvand, H. Omidvar, H.R. Shakeri, and M.R. Rahimipour: Mater. Charact., 2013, vol. 75, pp. 20-28.

[31] Vignoul G. E., Tien J. K., and Sanchez J. M: Mater. Sci. Eng. A, 1993, vol. 170, pp. 177-183.

[32] J Chen, V Demers, D.P. Turner, and P Bocher: Metall. Mater. Trans. A, 2018, vol. 49, pp. 1244-1253.

[33] Furuya, H.S., Sato, Y.S., Kokawa, H., Huang, T., and Xiao, R. S: Metall. Mater. Trans. A, 2018, vol. 49, pp. 6215-6223.

[34] H.S. Ren, H.P. Xiong, B. Chen, S.J. Pang, B.Q. Chen, and L. Ye: J. Mater. Sci. Technol., 2016, vol. 32, pp. 372-380.

N. Li, S. Huang, G.D. Zhang, R.Y. Qin, W. Liu, H.P. Xiong, G.Q. Shi, and J. Blackburn: J. Mater. Sci. Technol., 2019, vol. 35, pp. 242–69.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 3, 2019.

Rights and permissions

About this article

Cite this article

Ren, X.Y., Xiong, H.P., Kang, Y.W. et al. Microstructure and Mechanical Properties of Vacuum Brazed NbSS/Nb5Si3 Composite Joints Using Ni-Based Filler Alloys. Metall Mater Trans A 50, 5181–5190 (2019). https://doi.org/10.1007/s11661-019-05435-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05435-2