Abstract

The laser-material interaction Katrin Wudy for laser-material processes, such as laser welding, where several phase changes occur, still needs to be fully understood. The high energy input in the material in a short time and small space renders the laser-material interaction a complex and highly dynamic mechanism. This interaction and the resulting radiation absorption govern the process behavior during manufacturing and, in turn, the quality of parts. In situ monitoring of the laser radiation absorption can be facilitated to evaluate the process. The absorption can be determined using an integrating sphere. To employ such a measuring system reliably without intense calibration effort for high throughput experiments, the robustness of the measuring signal toward changes to the system is crucial. This work evaluates said robustness by a series of experiments for which the signal of the integrating sphere diode and the back-reflection sensor of the laser are considered. The measuring system was altered by varying the electronic gain and the distance between the sphere and the specimen. Multiple experiments with varying laser powers were conducted for every configuration of the measuring system. Additionally, the stability of the reflective properties of the coated inner sphere was evaluated by analyzing the change in the measurements over time. The experimental results show the robustness of the integrating sphere signal trend toward the changes in the measurement parameters and degradation of the inner sphere coating. These are properties of a robust measuring system, which has excellent use in high throughput experiments for fundamental research in laser-material interaction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Laser processing is no exception to the rule of an everlasting strive to push technologies to their limits and continuously improve upon the state of the art to complete ever more complex tasks faster at a higher quality and reproducibility level. To this end, the available process parameters, such as laser power and scan speed, for processes like laser beam welding or laser-based powder bed fusion of metals (PBF-LB/M) are varied to optimize the process to the specific requirements. This optimization process is commonly executed analogously to the process development with the following approach: Experiments mimicking the targeted process conditions are conducted for which process parameters are used based on literature and the expertise of experienced personnel. The results of those experiments are analyzed by ex-situ specimen testing, such as micrographically imagery and mechanical testing. Based on the test results, the process parameters are adjusted for the following experiments to improve the result and meet the targeted requirements. This procedure is iteratively repeated until all aspired properties are achieved. This approach can be very time-consuming and resource-intensive because the required number of iterations is related to the investigated parameter space. With ongoing research, innovative technologies and strategies continuously expand the available parameter envelope. For example, variable intensity distributions within the laser spot, known for process optimization, are added to the parameter space [1]. This further increases the effort of process development. To keep up with these advancements, the process development approach has to evolve to reduce the time per iteration and their number.

One possibility, which promises great potential in accelerating the process development, is automatically collecting all necessary information for parameter improvement between two iterations from in situ data instead of manually collecting it from ex-situ gathered data. This is why many technologies for in situ process monitoring are investigated and are at varying technology readiness levels; this is true for laser welding [2] and PBF-LB/M [3]. Various defects and process features can be detected depending on the measuring method.

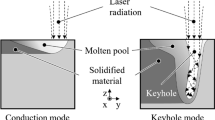

Laser processing is conducted in two specific process regimes, the “conduction mode” and the “keyhole mode” [4, 5]. The laser power is absorbed at the surface and conducted in the material during the former. During the latter, the laser intensity is high enough to partially vaporize the material to form a keyhole, allowing a deeper laser penetration in the material. Within this keyhole, the radiation is reflected from wall to wall, resulting in multiple absorptions. This results in a significantly higher degree of absorption [6]. Different heat transport mechanisms, such as the Marangoni effect, take over. The relation between radiation intensity, the prevailing process regime, and the resulting degree of absorption is visualized in Fig. 1, with schematic depictions of a cross-section of the process zone for both process regimes.

The different process regimes result in significantly different welds. For example, welding in the keyhole mode is associated with deeper penetrating welds with a higher aspect ratio of weld width and depth than conduction welding. This makes it the preferred process regime for applications concerning thick plate joints, as in the maritime industry. However, PBF-LB/M processes in the keyhole mode have been associated with porous results [7]. In turn, the conduction mode is the preferred process regime. The region between the conduction and keyhole regimes is referred to as the transition mode and exhibits an unstable process dynamic in laser welding [8] and PBF-LB/M [9]. Therefore, application-specific parameter sets must be identified to ensure a process is conducted in a process regime that delivers the desired outcome. Determining the prevailing process regime is based on evaluating the resulting melt track via metallographic cross-sections. Decisive, in this case, is the aspect ratio between the width and depth of the melt track, calculated by dividing the depth by the width. The aspect ratio threshold between conduction and keyhole mode is a variable defined in the literature. Fabbro et al. set it at 1 [10], Tenbrock et al. at 0.8 [11], and Helm et al. at 0.5 [12]. In contrast to the prefund impact of different process regimes on the process result, this loose definition would make an in situ and sensor-based identification of the prevailing process regime highly beneficial. To this end, various in situ monitoring approaches were applied in research to identify the prevailing process regime.

For instance, Drissi-Daoudi et al. [13] utilized acoustic emission monitoring to detect deviations from the conduction mode in PBF-LB/M, while Shevchik et al. [14] used them to identify the process regime during laser welding of titanium, and Luo et al. [15] offers a classification for penetration through acoustic monitoring. Nevertheless, the substantial additional noise introduced during acoustic measurement, originating from sources like shielding gas flow, necessitates thorough data preparation. Additionally, due to the indirect connection of acoustic emission to the welding process, complex data processing is essential for process characterization. On the other hand, the temperature in the process zone is closely linked to the welding process and can be monitored in various ways. For example, Vallabh et al. [16] predicted melt pool depth in PBF-LB/M using two-wavelength pyrometry, and Xiao et al. [17] identified the prevailing process regime during laser welding with a coaxial pyrometer. However, a drawback of point pyrometry is its need for spatial resolution and the high calibration effort to deduce reliable temperature values. Infrared imaging can combine high spatial resolution with temperature information. Infrared imaging has been successfully employed in laser welding [18] and PBF-LB/M [19] to detect keyhole formation. Nonetheless, the image-based approach generates substantial raw data, posing reliable and timely processing challenges.

Another technique focuses on monitoring the absorption of laser radiation, which governs how much energy is introduced to the system. This key property can indicate the change in the prevailing process regime via the characteristic difference in the degree of absorption. The absorption can be monitored time-resolved, for example, using an integrating sphere. An integrating sphere is established in photometry and radiometry as a precise tool to measure material properties, such as the absorption coefficient of materials under idealized conditions. For the in situ measurement, this tool was adapted to be applied in conditions mimicking realistic production conditions. Still, the basic measurement concept remains the same: The laser radiation, which is reflected and not absorbed by the material, is captured by the integrating sphere. Within the sphere, the radiation is reflected multiple times between its boundaries. Because of the diffuse reflective property of the inner sphere, the radiation is distributed homogeneously in the sphere. This allows the location-independent measurement of the radiation intensity by a photodetector. Thus, the reflected radiation in the process zone can be quantified. Based on the reflection, the absorption can be deduced because no radiation is transmitted when metal is used as the target material.

As the following examples show, this technique has been employed to gather process regime-specific absorption data to identify and characterize the process regimes.

Norris and Robino [20] introduced 2008 a methodology with two integrating spheres to explore the specific energy absorption during laser beam spot welds. The diffuse reflected radiation was measured with the second sphere, and the secondary sphere measured the direct reflected radiation. The key findings were the relation between the absorption behavior and the prevailing process regime.

Simonds et al. [21] developed a test setup using an integrating sphere to analyze the absorption change during a 10 ms laser spot weld in 316L stainless steel. Based on micrographs, they prove that the coupling efficiency increases when changing the process regime. Allen et al. [22] complemented the integrating sphere setup by equipping it with a real-time melt depth measurement to confirm and explore the correlation between the highly dynamic vapor depression geometry during the keyhole regime and the laser power absorption.

The significantly different surface texture of powder material compared to substrate plates can lead to a considerably different absorption behavior. The higher absorption of rougher surfaces, such as powder material, is based on multiple reflections between the troughs and peaks of the surface topology [23]. Due to the multiple reflections between individual powder particles, the packing density strongly influences the absorptivity in powder [23]. Nevertheless, Trapp et al. [24] showed that forming a keyhole in powder materials increases absorption.

Simonds et al. [25] investigated the periodic nature of absorption in laser welds of Ti6Al4V through simultaneous measurements of laser power absorption and high-speed x-ray imaging. They linked it to distinct changes in the keyhole geometry. These investigations were enlarged to absorption measurements in the powder bed and simultaneous high-speed synchrotron imaging [26]. They concluded that there is a direct relation between the stability of the vapor depression and the absorption.

While these investigations yielded valuable insights into the mechanisms of the laser-material interaction, the system's calibration requires considerable effort. This makes conducting many experiments in close succession unfeasible because the system has to be recalibrated after every experiment. But to accelerate the process development via the in situ integrating sphere measurement, it is necessary to conduct many experiments quickly. Such high throughput experiments require, on the one hand, a robust measuring system, which can be used for back-to-back experiments without the need for intermediate calibration, and on the other hand, an automated data analysis pipeline. Furthermore, the calibration requirements render an absorption measurement in the current state unfeasible for industrial in situ monitoring. Therefore, the article investigates the feasibility of a robust and calibration-less absorption measurement system based on an integrating sphere to enable high throughput and industrial in situ absorption measurement. For this, the isolated influences of system parameters on the measurement are analyzed by varying the individual parameters and evaluating the change. A reference technique is also developed, which utilizes a sensor fusion approach to reference the absorption signal to the input laser power, avoiding the need for absolute absorption values, which require system calibration.

2 Materials and methods

2.1 Experimental set-up

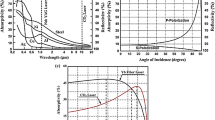

The experimental investigations were conducted on an in-house developed test rig. An IR laser (wavelength 1070 nm) of the type nLIGHT AFX-1000 was used for experiments. This laser can provide a series of different beam shapes ranging from a Gaussian to different ring-shaped intensity profiles. For this investigation, the Gaussian profile was selected. The laser is guided by a Raylase AM-Module, a 3-axis scanner with an additional z-axis to change the spot diameter in the focus plane. A caustic measurement, conducted according to DIN EN ISO 11146, yielded for the described setup and applied settings a spot size of 93 µm. The normalized measured intensity distribution is shown in Fig. 2.

A cross jet, which provides a strong airflow between the test specimen and the sphere, was mounted to the system. The vector of the air current is perpendicular to the scan speed vector. This cross jet is necessary because previous experiments showed substantial contamination of the inner sphere surfaces by oxides, which entered the sphere carried by the weld plume.

2.2 Measurement system

The measurement system used for the investigation is based on an integrating sphere. During the process, the incident laser radiation is partially reflected and absorbed by the target. The reflection consists of direct, spread, and diffuse reflection [27]. The integrating sphere captures a portion of the scattered and diffuse reflected radiation.

The sphere is depicted in Fig. 3. It has an inner diameter of 120 mm and was assembled from two half spheres made from PA12 utilizing laser-based powder bed fusion with plastics. The sphere incorporates two opposite apertures, normal to the target. The aperture on the target size has a diameter of \({d}_{IS,1}=15 {\text{mm}}\). The aperture on the scanner optic side has a wider diameter of \({d}_{IS,2}=30 mm\) to ensure a clipping free passage of the processing beam. Multiple layers of a barium sulfate (BaSO4) coating on the inner sphere surface create a near Lambertian Surface. Therefore, multiple reflections within the sphere distribute the captured radiation evenly to an average intensity. As seen in Fig. 4, the magnitude of the captured radiation is measured by a switchable-gain photodetector (Thorlabs PDA100A2), which is fiber coupled to a third aperture of the integrating sphere. Upstream to the photodetector, a 1070 nm-bandpass filter isolates the former laser radiation, which is focused on the detector by a lens. A baffle within the sphere blocks the direct line of sight between the fiber inlet and the process zone to avoid the measurement of the direct reflection before the internal reflections within the sphere. The signal of the photodetector will be referred to as the integrating sphere signal. Additionally, the back-reflection is monitored by default within the laser to facilitate an emergency shutdown in case of excessive back-reflection. This back-reflection signal was also taken into consideration during the data analysis. A principal illustration of the system is shown in Fig. 4.

2.3 Job design and process parameter

Every experimental point consists of 49 parallel melt tracks, produced in direct succession, with a length of 10 mm and a distance of 200 µm. The scan speed for all experimental points was set to 500 mm/s. The melt tracks were produced on 5 mm thick AISI 316L test specimens, which were sandblasted to create a reproducible dull surface finish. This process design is summarized in Fig. 5.

Only the investigated parameter and the laser power varied during the investigation, while the other parameters stayed constant in a test series. With this approach, the isolated influence of individual measuring parameters on the signal development of the measurement over an increase in laser power can be evaluated. With the first test series, the effect of the gain setting of the photodiode on the signal trend was investigated, and with the second test series, the influence of the sphere-specimen distance \({d}_{ss}\). For this the gain setting was varied from 10 to 50 dB in 10 dB steps and \({d}_{ss}\) was set to 5, 11, 20 mm. With the third test series, the impact of the integrating sphere in the laser path between the scanning optic and the test specimen on the back-reflection signal was evaluated by measuring the back reflection with and without the sphere. The experimental points of the lines with a grey background were also facilitated to evaluate the effectiveness of the cross jet in preventing the contamination of the sphere by the weld plume. Table 1 lists the process parameter sets for every test series.

2.4 Data logging

The analog signal from the integrating sphere photodetector and the back-reflection sensor of the laser were sampled at a frequency of 20 kHz. The constant scan speed, sampling rate, melt track length, and number lead to 400 measuring points per track. Of every melt track, the first and last 5% of the integrating sphere´s and back-reflection´s measuring points were discarded because the signals shown in the beginning and at the end of every melt track process related irregularities, which are not representative of the quasi-static conditions in the middle of the track. This results in a two-layered matrix \({\text{M}}_{{\text{E}}{\text{P}}_{\text{x}}}\). The first layer of the matrix contains the trimmed integrating sphere values, and the second the trimmed back-reflection values for those measuring points, the median and the standard deviation are calculated for every experimental point.

2.5 Laser power measurement

As part of the system characterization, power measurements of the system were conducted to investigate the discrepancy between the ser laser power and the output laser power in the system. A Primes CPM F-10 was used to measure the output power at a set laser power of 100, 200, 300, 500, and 600 W.

3 Results and discussion

3.1 Influence of the gain setting for different laser powers

The first test series was analyzed to evaluate the influence of the photodiode´s gain setting on the measuring signal. The purpose of the gain setting is the electronic amplification of the diode signal. The drawback of the amplification is a decrease in the bandwidth. The electronic amplification of the signal could mitigate the challenge of analyzing the signal if process conditions, such as low laser power or high absorption, led to a weak signal in relation to the measuring noise. To use electronic amplification for a qualitative signal evaluation, it must be ensured that the signal trend is not affected by the gain setting through a signal intensity-dependent component. Figure 6(a) shows the median and standard deviation of the integrating sphere signal from 100 to 600 W for different gain settings. Because of the signal amplification, a significantly different value domain at different gain settings is expected. Thus, the potential influence of the gain setting can only made apparent by comparing the individual trends of the signal´s median in the same value domain. For this, a z-score standardization is carried out on the median trend of every gain setting.

As depicted in Fig. 6(b), the median and the standard deviation exhibit the same trend independent of the gain setting, comprised of an initial drop of the reflection from 100 to 200 W followed by a plateau-type section to 400 W and a rise in reflection to 600 W. The initial drop in the first section seems to coincide with a change in the process regime [28]. This matter is discussed and validated in a future publication. The standard deviation for 500 W and 600 W is significantly higher than for lower laser powers. The described median trend results from the twofold influence of the laser power on the diode signal. On the one hand, the laser power can change the process dynamic as any other process parameter and, in turn, alter the laser reflection and the resulting measuring signal during the process. On the other hand, even with a constant rate of absorption during the process, the rise in laser power still leads to an increase in absolute reflection. This is further discussed in Sect. 3.5.

The independence of the standardized trend from the gain setting proves an isolated influence of the gain setting on the value domain without significantly affecting the relative signal trend by a signal intensity-dependent component. This allows a tailored choice of gain setting for different experiments without affecting the comparability of the standardized data in terms of trends and characteristics. The following described experiments were conducted with a fixed gain setting of 40 dB.

3.2 Influence of the sphere-specimen distance for different laser powers

The sphere-specimen distance \({d}_{SS}\) describes the distance between the interaction zone and the bottom aperture of the sphere, as seen in Fig. 7. This distance inevitably affects the signal, because it influences the amount of light captured by the sphere. The variation of the sphere-specimen distance for measuring purposes is only possible when the distance change does not affect the relative signal trend. To evaluate the influence of \({d}_{SS}\) on the signal, the second test series was considered, and their medians are visualized together with the standard deviation in Fig. 3 (a). In this figure, an increasing intensity level of the diode signal with decreasing \({d}_{SS}\) is recognizable. This is a result of different amounts of captured reflected radiation. The signal intensity depends on the sphere-specimen distance because this distance controls the angle of the light cone, which enters the sphere after the reflection.

As seen in Fig. 7, the higher \({d}_{ss}\) is, the smaller the angle of a radial section of the spherical diffuse reflection, which is captured by the sphere. This results in more radiation escaping to the sides of the sphere. This means the smaller the distance, the higher the captured cone angle. This coincides with the increased signal intensity at small \({d}_{SS}\) seen in Fig. 8(a). As a result, the median trends at different \({d}_{SS}\) are situated in different value domains, distorting the signal trend’s comparison. Thus, a z-score standardization is conducted, analog to the evaluation of the gain setting, to compare the median trends for different \({d}_{{\text{ss}}}\). The standardized trends, shown in Fig. 8(b), exhibit a similar median tendency, which resembles the trend in Fig. 6(b) except for the missing experimental point at 100 W. This concordance is expected because the same process parameters are used. The similarity of the trends at different sphere specimen distances is less pronounced than for different gain settings. This is because the gain setting merely changes the internal processing of the otherwise unchanged measurement, and \({d}_{{\text{ss}}}\) changes the measured intensity. The intensity distribution in the reflection propagation is not uniform in space or time because of the mixture of spread, diffuse, and direct reflection [29], which can change depending on the process dynamic. Thus, the change of \({d}_{{\text{ss}}}\) does not influence the signal equally at different process conditions because the ratio between different reflection types depends on multiple factors, including surface texture and angle of incidence, which are subject to constant change for laser-material interaction due to the highly dynamic process zone.

This means the portion of captured radiation is not necessarily representative of the overall reflection. Ideally, the captured portion is maximized by minimizing \({\text{d}}_{\text{ss}}\) within the capabilities of the manufacturing system. For example, most processes require air or shielding gas flow above the process zone to avoid effects like oxidation or spatter deposition on the workpiece, which negatively influence the process result, or to mitigate damage and contamination of the optics. A minimum distance of the sphere to the process zone might be required to facilitate the described gas flow. This gas flow has also proven to be of utmost importance for a consistent absorption measurement, as described in 3.3. Other experiments were conducted at a fixed distance of 20 mm to ensure the best comparability of the experiments.

3.3 Influence of the inner sphere coating quality on the integrating sphere signal

Preliminary experiments were conducted without a cross jet, which allowed oxides formed in the process to enter the sphere carried by the weld plume and line the inner sphere. The orange lining of the inner sphere by the oxides can be seen in Fig. 9, which shows the comparison of a freshly barium sulfate-coated sphere on the left and an oxide-contaminated sphere on the right.

The oxides’ changed surface properties of the inner sphere resulted in altered reflection characteristics, which in turn affected the measurement and the comparability of the experiments significantly. A cross-jet was deployed to mitigate the contamination of the inner sphere. To verify the effectiveness of the cross jet in preventing contamination, the integrating sphere signal of the experimental points from 100 to 600 W at a gain setting of 40 dB from the first test series was compared to the experimental point from 100 to 600 W at 40 dB from the third test series. Both data sets were created using the same process and measurement parameter, but they were created 23 days and 60 experiments apart. In between the experiments, the sphere was left in the test rig without covers on the apertures. The early data set is referred to as a coating reference, and the later data set as coating reference + 60 exp. The comparison of both median trends is shown in Fig. 10.

Both median trends in Fig. 10 exhibit a similar trend of the median with a slight deviation for higher laser powers. This deviation slightly increases from 400 to 600 W. The deviation is insignificant compared to the standard deviation at those laser power levels. The standard deviation progresses similarly for both data sets, with a small standard deviation from 100 to 300 W and a substantial increase from 400 to 600 W. This similarity shows two aspects. Firstly, the coating properties and their influence on the measurement do not significantly change over this period. Neither by degradation nor contamination by airborne particles. Secondly, the cross jet successfully prevented the contamination of the inner sphere by the weld plume over multiple experiments.

3.4 Influence of the integrating sphere on the back-reflection signal

The third test series was conducted to investigate the influence of the integrating sphere in the laser path between the specimen and the optic. The medians and standard deviations of this test series are plotted in Fig. 11. The signals with and without the integrating sphere exhibit a highly similar linear trend over the linearly rising laser power with only a small deviation, which increases with the laser power. All experiments show a small standard deviation.

When comparing the integrating sphere, as seen, for example in Fig. 6(b) and the back-reflection signal, the following stand out: The standard deviations at different laser powers are significantly different, which is especially pronounced at high laser powers and the linear median trend of the back-reflection shares no visible similarity with the median trend of the integrating sphere signal. Together with the low impact of the sphere in the laser path on the back-reflection signal, these observations demonstrate no connection between the back-reflection signal and the process. Instead, the back-reflection signal is primarily a result of small internal reflections of the laser radiation at optical components within the optic, resulting in a strong connection between the change in laser power and the change of the back-reflection signal. This is further supported by measurements of the back-reflection during the power measurements from 2.5. The signal during the power measurements remained unchained in comparison to the measurements during the bead-on-plate welds. This means the back-reflection signal must solely depend on internal reflections because the power measurement device functioned as a beam dump, eliminating all reflections of the laser radiation.

To explore the connection between the back-reflection signal and the laser power, the median trend of the back-reflection was compared to the actual change in power over a stepwise increase of the set laser power. To find an analytical connection between the output power and the back-reflection signal, a linear function was fitted to both the median trend of the back-reflection over the laser power and the measured output power over the laser power. The linear fit resulted in the following two functions:

Figure 12 shows the measured back-reflection signal and the measured output power of the laser together with each of their linear fitted curves as a function of the set laser power.

The discrepancy between the set power and the actual output power was between 3 and 5%, comparable to commercial systems [30]. This insignificant discrepancy is hardly visible in Fig. 12. Both fits are of high quality because of the strongly pronounced linear characteristic of the measured data. The addition of 292 in the fit of the back-reflection signal corresponds to the baseline of the measurement noise because, the value corresponds to the signal when no laser radiation is emitted.

From the fitted functions a translation function can be derived, which provides the output laser power based on the back-reflection signal. For this \({f}_{{\text{Back}}-{\text{reflection}}}(x)\) is inversed and set as the input for \({g}_{{\text{Output}} {\text{power}}}(x)\), as seen in the following calculation:

This result is specific to the setup used in terms of the back-reflection signal and the discrepancy between the set laser power and the actual output. Because of the insignificant difference between set and output laser power, the output power can generally be closely approximated by the inversed linear fit of the back-reflection signal over a linear increase of the laser power.

Utilizing the back-reflection signal for data referencing any uncertainties of mislabeling the experimental data can be avoided because the required referencing information is contained in the corresponding integrating sphere data. Furthermore, the back-reflection signal allows experiments with a more complex laser power profile, such as changes within one measurement or changes at higher frequencies, because the power is indirectly synchronously logged via the back-reflection. For such experiments, assigning the laser power to the integrating sphere data after the fact for referencing purposes would be very difficult or impossible.

3.5 Absolute and referenced diode signal

Up to this point, the integrating sphere and the back-reflection signal were considered independently and have one significant difference: The integrating sphere signal is influenced by the laser power in two ways, as explained in 3.1, but the back-reflection is proportional to the laser power. Because of the twofold influence of the laser power on the integrating sphere signal, the influence of the increasing laser power on the measurement must be eliminated to isolate the influence of the process dynamic. Therefore, the diode signal must be referenced to the input laser power. This can be achieved in various ways: For example, for an experimental point at 400 W, the power input is twice as high as for 200 W, so the signal values at 400 W are divided by two. This approach requires knowledge of the input laser power and, thus, data labeling, which is time-consuming and error-prone.

Alternately, the stable back-reflection, proportional to the input laser power, can be facilitated as a power indicator. For this, one arbitrary experimental point is set as a baseline, which allows the signal trend to be kept in the original value domain because the value changes of the referencing procedure are conducted relative to the baseline. By calculating the quotient of the back-reflection´s medians of the to-be-referenced experimental point and the baseline, the relative change of the back-reflection is determined.

As seen in 3.4, there is a difference in the trend of the back-reflection signal and the output power over an increased set laser power. However, the referencing utilizes the relative change of the back-reflection signal. This relative change of a linear function always corresponds directly to the shift in the functions input when the function correlates with the following basic structure:

\({f}_{{\text{Back}}-{\text{reflection}}}\left(x\right)\) conforms to this structure apart from the addition of 292, which was identified as the measurement base noise. The value of the noise can be deduced from the first back-reflection measuring point of every melt track, which is not considered in the median calculation, as described in 2.4. With the deduced noise value, the back-reflection signal can automatically be corrected for the measurement noise to

\({f}_{{\text{Noise}}-{\text{free}}}\left(x\right)\) correspond now with the structure of \({f}_{{\text{basic}}}\left(x\right).\)

Therefore, the relative change of the back reflection signal directly corresponds to the change in the set laser power when corrected for the measurement base noise.

Thus, dividing the integrating sphere signal by the relative change of the corrected back reflection signal references the integrating sphere signal to the laser power in relation to the baseline.

The following calculation shows the referencing procedure with a baseline \({\text{M}}_{\text{Base}}\) and a to-be-referenced experimental point \({\text{M}}_{\text{Ref}}\):

This procedure was conducted for all experimental points with the experimental point at 100 W functioning as the baseline. The result of the referencing procedure on the median trend is shown in Fig. 13.

The referenced data show two distinct sections: A steep decline from 100 to 200 W and a steady, shallow decline from 200 to 600 W. The change of the median trend by the referencing results from the isolation of the influence of the change in process dynamic on the absorption from the influence of the increase in laser power. The referencing highlights the steep decline, between the first two experimental points. While the referencing changes the values of the standard deviations, the trend over the increase in laser power remains the same. The standard deviations show relatively low values from 200 to 400 W and significantly higher values for 500 W and 600 W. The referenced integrating sphere signal forms the foundation of future investigations on the influence of individual process parameters on the absorption behavior during the process by evaluating their isolated influence on the referenced median trend over rising laser power levels.

4 Conclusions

Process development and optimization for laser material processes, such as laser beam welding and PBF-LB/M, are currently time-consuming and labor-intensive procedures. An in situ absorption measurement with an integrating sphere promises the possibility of eliminating the ex-situ specimen testing in the future. However, the measurement procedure must be accelerated to use absorption measurement effectively for process development or in an industrial context. For this, the intermediate calibration between individual experiments, which is necessary in the state of the art, must be eliminated. Therefore, the feasibility of a robust and calibration-less system was investigated by evaluating the influences of system parameters on the absorption signal to reduce the calibration effort of an integrating-sphere-based absorption measurement. For this, isolated measuring parameters were varied over stepwise, increasing laser power in each test series. The median diode signals were analyzed in relation to the laser power for each parameter setting. The conclusions of this investigation are summarized as follows:

-

The gain-setting of the photodiode was proven to have no significant effect on the signal´s median trend over increased laser power except for the value domain. This means the amplification has no signal intensity-dependent component and can be altered to suit the application-specific requirements.

-

The results show a rising value domain with a decreasing distance between the lower aperture of the sphere and the test specimen´s surface. This effect was tied to the decreasing cone angle of the capture laser radiation with increasing distance. Nevertheless, the relative median trend remains unchanged at various sphere-specimen distances. This allows an application-specific choice of sphere distance. For example, the distance can be large enough to accommodate the airflow of a cross jet.

-

A contamination of the inner sphere alters the signal properties significantly and must be avoided. The airflow of a cross jet between the target and the sphere proved to be effective. Therefore, the deployment of the cross jet facilitated the acceleration of the experiments by eliminating the need for recoating or cleaning the sphere as well as recalibration of the system due to changed reflective parameters.

-

A synchronized logging of the laser power can be facilitated to reference the diode signal of different laser powers to a baseline. This mitigates the influence of a rising power level on the integrating sphere signal when it is not related to changes in the process dynamic and eliminates the need for absolute absorption values to evaluate the signal.

The demonstrated robustness of the investigated measurement system toward changes in measuring parameters and the possibility of a calibration-less deployment under nearly real process conditions facilitates its application for high throughput experiments. Such a system has great potential for high throughput experiments to accelerate the process development procedure and for industrial application.

Data availability

The data presented in this study are available on request from the corresponding author. The data are not publicly available as a result of ongoing research in this field.

Code availability

The code used for data analysis is available on request from the corresponding author. The code is not publicly available due to ongoing research in this field.

References

Grünewald J, Gehringer F, Schmöller M et al (2021) Influence of ring-shaped beam profiles on process stability and productivity in laser-based powder bed fusion of AISI 316L. Metals 11:1989. https://doi.org/10.3390/met11121989

You DY, Gao XD, Katayama S (2014) Review of laser welding monitoring. Sci Technol Weld Join 19:181–201. https://doi.org/10.1179/1362171813Y.0000000180

McCann R, Obeidi MA, Hughes C et al (2021) In-situ sensing, process monitoring and machine control in Laser Powder Bed Fusion: a review. Addit Manuf 45:102058. https://doi.org/10.1016/J.ADDMA.2021.102058

Hügel H, Graf T (2009) Laser in der Fertigung. Vieweg+Teubner, Wiesbaden

Poprawe R (2005) Lasertechnik für die Fertigung: Grundlagen, Perspektiven und Beispiele für den innovativen Ingenieur; mit 26 Tabellen. VDI-Buch, Springer, Berlin, Heidelberg

Khairallah SA, Sun T, Simonds BJ (2021) Onset of periodic oscillations as a precursor of a transition to pore-generating turbulence in laser melting. Addit Manuf Lett 1:100002. https://doi.org/10.1016/j.addlet.2021.100002

Wang L, Zhang Y, Chia HY et al (2022) Mechanism of keyhole pore formation in metal additive manufacturing. npj Comput Mater 8. https://doi.org/10.1038/S41524-022-00699-6

Zhang X, et al (1996) Effects of processing parameters on mode and stability of laser welding. SPIE Proceedings 343. https://doi.org/10.1117/12.237746

Bayat M, Thanki A, Mohanty S et al (2019) Keyhole-induced porosities in Laser-based Powder Bed Fusion (L-PBF) of Ti6Al4V: high-fidelity modelling and experimental validation. Addit Manuf 30:100835. https://doi.org/10.1016/j.addma.2019.100835

Fabbro R (2020) Depth dependence and keyhole stability at threshold, for different laser welding regimes. Appl Sci 10:1487. https://doi.org/10.3390/app10041487

Tenbrock C, Fischer FG, Wissenbach K et al (2020) Influence of keyhole and conduction mode melting for top-hat shaped beam profiles in laser powder bed fusion. J Mater Process Technol 278:116514. https://doi.org/10.1016/j.jmatprotec.2019.116514

Helm J, Schulz A, Olowinsky A et al (2020) Laser welding of laser-structured copper connectors for battery applications and power electronics. Weld World 64:611–622. https://doi.org/10.1007/s40194-020-00849-8

Drissi-Daoudi R, Masinelli G, de Formanoir C et al (2023) Acoustic emission for the prediction of processing regimes in Laser Powder Bed Fusion, and the generation of processing maps. Addit Manuf 67:103484. https://doi.org/10.1016/j.addma.2023.103484

Shevchik SA, Le-Quang T, Farahani FV et al (2019) Laser welding quality monitoring via graph support vector machine with data adaptive kernel. IEEE Access 7:93108–93122. https://doi.org/10.1109/ACCESS.2019.2927661

Luo Z, Di Wu, Zhang P et al (2023) Laser welding penetration monitoring based on time-frequency characterization of acoustic emission and CNN-LSTM hybrid network. Materials (Basel) 16. https://doi.org/10.3390/ma16041614

Vallabh CKP, Sridar S, Xiong W et al (2022) Predicting melt pool depth and grain length using multiple signatures from in-situ single camera two-wavelength imaging pyrometry for laser powder bed fusion. J Mater Process Technol 308:117724. https://doi.org/10.1016/j.jmatprotec.2022.117724

Xiao X, Liu X, Cheng M et al (2020) Towards monitoring laser welding process via a coaxial pyrometer. J Mater Process Technol 277:116409. https://doi.org/10.1016/j.jmatprotec.2019.116409

Chen Z, Gao X (2014) Detection of weld pool width using infrared imaging during high-power fiber laser welding of type 304 austenitic stainless steel. Int J Adv Manuf Technol 74:1247–1254. https://doi.org/10.1007/s00170-014-6081-3

Wang R, Garcia D, Kamath RR et al (2022) In situ melt pool measurements for laser powder bed fusion using multi sensing and correlation analysis. Sci Rep 12:13716. https://doi.org/10.1038/s41598-022-18096-w

Norris JT, Robino CV (2008) Development of a time resolved energy absorption measurement technique for laser beam spot welds. Int Congr Appl Lasers Electro-Opt 2008:P149. https://doi.org/10.2351/1.5061443

Simonds BJ, Sowards JW, Hadler J et al (2018) Dynamic and absolute measurements of laser coupling efficiency during laser spot welds. Procedia CIRP 74:632–635. https://doi.org/10.1016/j.procir.2018.08.065

Allen TR, Huang W, Tanner JR et al (2020) Energy-coupling mechanisms revealed through simultaneous keyhole depth and absorptance measurements during laser-metal processing. Phys Rev Appl 13:64070. https://doi.org/10.1103/PhysRevApplied.13.064070

Brandau B, Da Silva A, Wilsnack C et al (2022) Absorbance study of powder conditions for laser additive manufacturing. Mater Des 216:110591. https://doi.org/10.1016/j.matdes.2022.110591

Trapp J, Rubenchik AM, Guss G et al (2017) In situ absorptivity measurements of metallic powders during laser powder-bed fusion additive manufacturing. Appl Mater Today 9:341–349

Simonds BJ, Tanner J, Artusio-Glimpse A et al (2020) Simultaneous high-speed x-ray transmission imaging and absolute dynamic absorptance measurements during high-power laser-metal processing. Procedia CIRP 94:775–779. https://doi.org/10.1016/j.procir.2020.09.135

Simonds BJ, Tanner J, Artusio-Glimpse A et al (2021) The causal relationship between melt pool geometry and energy absorption measured in real time during laser-based manufacturing. Appl Mater Today 23:101049. https://doi.org/10.1016/j.apmt.2021.101049

Nayar SK, Ikeuchi K, Kanade T (1991) Surface reflection: physical and geometrical perspectives. IEEE Trans Pattern Anal Mach Intell 13:611–634. https://doi.org/10.1109/34.85654

Simonds BJ, Sowards J, Hadler J et al (2018) Time-Resolved Absorptance and Melt Pool Dynamics during Intense Laser Irradiation of a Metal. Phys Rev Applied 10:44061. https://doi.org/10.1103/PhysRevApplied.10.044061

Laughton MA (2003) Electrical Engineer’s Reference Book, 16th edn. Electrical Engineer’s Reference Book. Elsevier Science & Technology, Kidlington

Simondsa BJ, Rogers K, Williams PA (2022) Are additive manufacturing systems accurately delivering laser power? 12th CIRP Conference on Photonic Technologies [LANE 2022]

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

Conceptualization: M.W. and K.W.; experimental set-up: M.W.; data curation: M.W.; formal analysis: M.W.; investigation: M.W.; methodology: M.W. and K.W.; project administration: M.W. and K.W.; funding: No additional/external funding was received for conducting this study; resources: K.W.; software: M.W.; supervision: M.W. and K.W.; validation: M.W.; visualization: M.W.; writing—original draft: M.W.; writing—review and editing: M.W. and K.W.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All authors have read and agreed to the published version of the manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission IV-Power Beam Processes

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wittemer, M., Wudy, K. Robustness investigation of an in-situ absorption measurement system for laser processing. Weld World 68, 1461–1472 (2024). https://doi.org/10.1007/s40194-024-01689-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-024-01689-6