Abstract

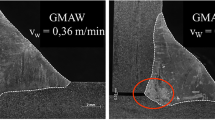

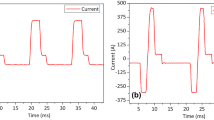

In gas metal arc welding (GMAW) the arc power, in general, increases when the wire feed speed is increased. Thus, controlling heat input into the workpiece becomes a challenge, especially when trying to increase productivity. Metal transfer modes such as pulsed and controlled short circuit have been successfully applied to allow smooth metal transfer with relatively low energy. The effect of increasing the electrified length of the electrode or decreasing wire diameter in reducing current has been known for years. However, to some extent, this effect is limited to the physical conditions when using a large distance from contact tip to workpiece. To further increase melting efficiency and reduce arc power the torch presented in this paper includes a second electric circuit into GMAW to preheat the wire by ohmic heating before it reaches the main circuit. In this context, the objective of this work was to verify the effects of active wire preheating in GMAW in lap joint case in terms of electric signal behavior, thermal behavior in the plate, and weld bead formation. By increasing the preheating current, significant reduction in arc power was achieved. This reflects on the resulting weld by avoiding molten pool sagging, reducing fused area, silicate formation, and backside oxidation. The reduction in heat input resulted finally in a smaller heat affected zone which had a finer microstructure. In conclusion, the use of active wire preheating in GMAW expands the potential for increasing productivity and controlling heat input into the workpiece.

Similar content being viewed by others

References

Palani PK, Murugan N (2006) Selection of parameters of pulsed current gas metal arc welding. J Mater Process Technol 172:1–10. https://doi.org/10.1016/j.jmatprotec.2005.07.013

e Silva RHG, dos Santos Paes LE, Barbosa RC et al (2018) Assessing the effects of solid wire electrode extension (stick out) increase in MIG/MAG welding. J Braz Soc Mech Sci Eng 40:31. https://doi.org/10.1007/s40430-017-0948-9

Henckell P, Gierth M, Ali Y et al (2020) Reduction of energy input in wire arc additive manufacturing (WAAM) with gas metal arc welding (GMAW). Materials 13:2491. https://doi.org/10.3390/ma13112491

Scotti A, Ponomarev V, Lucas W (2012) A scientific application oriented classification for metal transfer modes in GMA welding. J Mater Process Technol 212:1406–1413. https://doi.org/10.1016/j.jmatprotec.2012.01.021

Kah P, Latifi H, Suoranta R et al (2014) Usability of arc types in industrial welding. Int J Mech Mater Eng 9:15. https://doi.org/10.1186/s40712-014-0015-6

Haelsig A, Kusch M, Mayr P (2015) Calorimetric analyses of the comprehensive heat flow for gas metal arc welding. Weld World 59:191–199. https://doi.org/10.1007/s40194-014-0193-0

Egerland S, Colegrove P (2011) Using solid state calorimetry for measuring gas metal arc welding efficiency. In: Sudnik W (ed) Arc welding. InTech

Shahi AS, Pandey S (2008) Effect of auxiliary preheating of the filler wire on quality of gas metal arc stainless steel claddings. J Materi Eng Perform 17:30–36. https://doi.org/10.1007/s11665-007-9132-1

Shahi AS, Pandey S, Gill JS (2007) Effect of auxiliary preheating of filler wire on dilution in gas metal arc stainless steel surfacing using RSM. Surf Eng 23:384–390. https://doi.org/10.1179/174329407X247127

Ni J, Hongming G (2013) Effect of the wire temperature on the weld formation in GMAW. Adv Mater Res 652–654:1178*11813. https://doi.org/10.4028/www.scientific.net/AMR.652-654.2289

International Organization for Standardization. (2019). Welding and allied processes - Welding positions (ISO 6947:2019). https://www.iso.org/obp/ui/#iso:std:iso:6947:ed-4:v1:en

Jorge VL, Scotti FM, Reis RP et al (2020) The potential of wire feed pulsation to influence factors that govern weld penetration in GMA welding. Int J Adv Manuf Technol 110:2685–2701. https://doi.org/10.1007/s00170-020-06037-8

Hertel M (2014) Steigerung der Wirtschaftlichkeit der MSGSchweißprozesse durch konsequente Nutzung der Potentiale von Schutzgasen (MSG-Schutzgase). Technische Universitat Dresden, Dresden. https://tu-dresden.de/ing/maschinenwesen/if/fue/forschung/lichtbogenprozesse/projekte/AiF_17.431__Webpage_MSG_Schutzgase

Derrien R (2011) Understanding the mechanisms underlying the formation of silicate islands in gas metal arc welding. Colorado School of Mines. https://repository.mines.edu/handle/11124/170385

Kim H, Inoue J, Okada M, Nagata K (2017) Prediction of Ac3 and martensite start temperatures by a data-driven model selection approach. ISIJ Int 57:2229–2236. https://doi.org/10.2355/isijinternational.ISIJINT-2017-212

Kou S (2003) Welding metallurgy, 2nd edn. John Wiley & Sons Inc, Hoboken, New Jersey

Wang L, Wu L, He S et al (2023) Effect of heat input on microstructure and impact toughness in the simulated coarse-grained heat-affected zones of X90 pipeline steel. J of Materi Eng and Perform 32:348–365. https://doi.org/10.1007/s11665-022-07093-9

Shi M, Di M, Zhang J et al (2021) Effect of initial microstructure on the toughness of coarse-grained heat-affected zone in a microalloyed steel. Materials 14:4760. https://doi.org/10.3390/ma14164760

Acknowledgements

The authors thank Linde’s Arc Technologies working team and Linde Technology management for the direct and indirect support through the conduction of this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Scotti, F.M., Pudenz, M., Perrin, S. et al. Heat input control in horizontal lap joint welding through active wire preheating in GMAW-P. Weld World 68, 893–904 (2024). https://doi.org/10.1007/s40194-023-01654-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-023-01654-9