Abstract

In this study, the microstructure evolution and mechanical properties of the explosive welded (EXWed) steel–bronze bilayer composite sheets before and after rolling are presented. Dissimilar welding was performed at two stand-off distances with various charge thicknesses. The welded bilayer sheets were rolled at ambient and 300 °C with a 33.3% thickness reduction. A feasibility welding window based on the process parameters was developed, and the samples were fabricated accordingly. Steel–bronze interfaces were divided into four distinct categories based on changes in microstructure and elemental distribution. After rolling, the initially formed wavy interface was stretched and flattened, and the vortex zones were compressed and, in some cases, submerged inside the steel part. Despite the proper connection in most parts of the interface, some parts suffered from local discontinuities. By implementing rolling, depending on the force and the rolling temperature, the diffusion barriers were partially removed, separate boundaries were brought closer, and a metallic bond was established at the bronze/steel interface. In addition, shrinkage cavities and pores were compressed and compacted. EXW and subsequent cold rolling increased the hardness since hot rolling diminished the interface hardness.

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings are available from the corresponding authors upon reasonable request.

References

Zhang H, Jiao KX, Zhang JL, Liu J (2019) Comparisons of the microstructures and micro-mechanical properties of copper/steel explosive-bonded wave interfaces. Mater Sci Eng, A 756:430–441

Zhang H, Jiao KX, Zhang JL, Liu J (2018) Microstructure and mechanical properties investigations of copper-steel composite fabricated by explosive welding. Mater Sci Eng A 731:278–287

Zhang H, Jiao KX, Zhang JL, Liu J (2018) Experimental and numerical investigations of interface characteristics of copper/steel composite prepared by explosive welding. Mater Des 154:140–152

Mousavi SA, Sartangi PF (2009) Experimental investigation of explosive welding of cp-titanium/AISI 304 stainless steel. Mater Des 30(3):459–468

Ben-Artzy A, Stern A, Frage N, Shribman V, Sadot O (2010) Wave formation mechanism in magnetic pulse welding. Int J Impact Eng 37(4):397–404

Wang H, Wang Y (2019) High-velocity impact welding process: a review. Metals 9(2):144

Liu BX, Huang LJ, Geng L, Wang B, Liu C, Zhang WC (2014) Fabrication and superior ductility of laminated Ti–TiBw/Ti composites by diffusion welding. J Alloy Compd 602:187–192

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R Rep 50(1–2):1–78

Kraetzsch M, Standfuss J, Klotzbach A, Kaspar J, Brenner B, Beyer E (2011) Laser beam welding with high-frequency beam oscillation: welding of dissimilar materials with brilliant fiber lasers. In International Congress on Applications of Lasers & Electro-Optics (Vol. 2011, No. 1, pp. 169–178). Laser Institute of America

Mokhtarishirazabad M, Simpson C, Horne G, Kabra S, Truman C, Moffat A, Mostafavi M (2019) Study of the fracture toughness in electron beam welds. In Pressure Vessels and Piping Conference (Vol. 58974, p. V06AT06A053). American Society of Mechanical Engineers

Chen Z, Wang D, Cao X, Yang W, Wang W (2018) Influence of multi-pass rolling and subsequent annealing on the interface microstructure and mechanical properties of the explosive welding Mg/Al composite plates. Mater Sci Eng A 723:97–108

Zhang T, Wang W, Zhang W, Wei Y, Cao X, Yan Z, Zhou J (2018) Microstructure evolution and mechanical properties of an AA6061/AZ31B alloy plate fabricated by explosive welding. J Alloy Compd 735:1759–1768

Wu Y, Lu J, Tan S, Jiang F, Sun J (2018) Modified implementation strategy in explosive welding for joining between precipitate-hardened alloys. J Manuf Process 36:417–425

Hokamoto K, Fujita M, Shimokawa H, Okugawa H (1999) A new method for explosive welding of Al/ZrO2 joint using regulated underwater shock wave. J Mater Process Technol 85(1–3):175–179

Mousavi AA, Al-Hassani STS (2005) Numerical and experimental studies of the mechanism of the wavy interface formations in explosive/impact welding. J Mech Phys Solids 53(11):2501–2528

Athar MH, Tolaminejad B (2015) Weldability window and the effect of interface morphology on the properties of Al/Cu/Al laminated composites fabricated by explosive welding. Mater Des 86:516–525

Hokamoto K, Nakata K, Mori A, Tsuda S, Tsumura T, Inoue A (2009) Dissimilar material welding of rapidly solidified foil and stainless steel plate using underwater explosive welding technique. J Alloy Compd 472(1–2):507–511

Wang Y, Beom HG, Sun M, Lin S (2011) Numerical simulation of explosive welding using the material point method. Int J Impact Eng 38(1):51–60

Acarer M, Gülenç B, Findik F (2003) Investigation of explosive welding parameters and their effects on microhardness and shear strength. Mater Des 24(8):659–664

Jaramillo D, Szecket A, Inal OT (1987) On the transition from a waveless to a wavy interface in explosive welding. Mater Sci Eng 91:217–222

Wronka B (2010) Testing of explosive welding and welded joints: joint mechanism and properties of explosive welded joints. J Mater Sci 45(15):4078–4083

Bataev IA, Bataev A, Mali VI, Esikov MA, Bataev VA (2011) Peculiarities of weld seams and adjacent zones structures formed in process of explosive welding of sheet steel plates. In Materials Science Forum (Vol. 673, pp. 95–100). Trans Tech Publications Ltd

Xie MX, Zhang LJ, Zhang GF, Zhang JX, Bi ZY, Li PC (2015) Microstructure and mechanical properties of CP-Ti/X65 bimetallic sheets fabricated by explosive welding and hot rolling. Mater Des 87:181–197

Shi CG, Yu WANG, Zhao LS, Hou HB, Ge YH (2015) Detonation mechanism in double vertical explosive welding of stainless steel/steel. J Iron Steel Res Int 22(10):949–953

Yan YB, Zhang ZW, Shen W, Wang JH, Zhang LK, Chin BA (2010) Microstructure and properties of magnesium AZ31B–aluminum 7075 explosively welded composite plate. Mater Sci Eng A 527(9):2241–2245

Asemabadi M, Sedighi M, Honarpisheh M (2012) Investigation of cold rolling influence on the mechanical properties of explosive-welded Al/Cu bimetal. Mater Sci Eng A 558:144–149

Song J, Kostka A, Veehmayer M, Raabe D (2011) Hierarchical microstructure of explosive joints: example of titanium to steel cladding. Mater Sci Eng A 528(6):2641–2647

Zhou G, Xu J, Shen Z, Ma H (2019) Microstructure and mechanical properties of simultaneously explosively-welded Steel/Cu pipes and Al/Cu pipe/rod. J Manuf Process 47:244–253

Rajani HZ, Mousavi SA (2012) The effect of explosive welding parameters on metallurgical and mechanical interfacial features of Inconel 625/plain carbon steel bimetal plate. Mater Sci Eng A 556:454–464

Qin L, Wang J, Wu Q, Guo X, Tao J (2017) In-situ observation of crack initiation and propagation in Ti/Al composite laminates during tensile test. J Alloy Compd 712:69–75

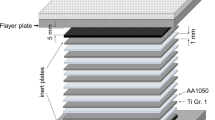

Bazarnik P, Adamczyk-Cieślak B, Gałka A, Płonka B, Snieżek L, Cantoni M, Lewandowska M (2016) Mechanical and microstructural characteristics of Ti6Al4V/AA2519 and Ti6Al4V/AA1050/AA2519 laminates manufactured by explosive welding. Mater Des 111:146–157

Durgutlu A, Okuyucu H, Gulenc B (2008) Investigation of effect of the stand-off distance on interface characteristics of explosively welded copper and stainless steel. Mater Des 29(7):1480–1484

Durgutlu A, Gülenç B, Findik F (2005) Examination of copper/stainless steel joints formed by explosive welding. Mater Des 26(6):497–507

Liu Y, Li C, Hu X, Yin C, Liu T (2019) Explosive welding of copper to high nitrogen austenitic stainless steel. Metals 9(3):339

Wang Y, Li X, Wang X, Yan H (2018) Fabrication of a thick copper-stainless steel clad plate for nuclear fusion equipment by explosive welding. Fusion Eng Des 137:91–96

Saravanan S, Raghukandan K (2012) Weldability windows for explosive cladding of dissimilar metals. In Advanced Materials Research (Vol. 445, pp. 729–734). Trans Tech Publications Ltd

Gladkovsky SV, Kuteneva SV, Sergeev SN (2019) Microstructure and mechanical properties of sandwich copper/steel composites produced by explosive welding. Mater Charact 154:294–303

Dyja H, Mróz S, Stradomski Z (2003) Properties of joint in the bimetallic rods Cu-Al and Cu-steel after explosive cladding and the process of rolling. Metalurgija 42(3):185–191

Dyja H, Mróz S, Milenin A (2004) Theoretical and experimental analysis of the rolling process of bimetallic rods Cu-steel and Cu-Al. J Mater Process Technol 153:100–107

Livne Z, Munitz A (1987) Characterization of explosively bonded iron and copper plates. J Mater Sci 22(4):1495–1500

Shiran MRKG, Khoshakhlagh A, Khalaj G, Bakhtiari H, Banihashemi AR (2018) Effect of postweld heat treatment on interface microstructure and metallurgical properties of explosively welded bronze—carbon steel. J Central South Univ 25(8):1849–1861

Shiran MRKG, Razazi M, Bakhtiari H, Tavira A (2018) Evaluation of welding parameter’s effects on corrosion behavior of bronze-carbon steel dual-layer explosion welded joint at salt environment. Mater Res 21(2):e20170619

Szulc W, Pietrzyk M, Dyja H, Pilarczyk JW (1994) Theoretical and experimental analysis of drawing of steel rods covered with copper. J Mater Process Technol 45(1–4):401–406

Karolczuk A, Kluger K, Derda S, Prażmowski M, Paul H (2020) Influence of impact velocity on the residual stress, tensile strength, and structural properties of an explosively welded composite plate. Materials 13(12):2686

Khaustov SV, Pai VV, Lukyanov YL, Lysak VI, Kuz'min SV (2022) Simulation and experimental determination of temperature in the joint zone during explosive welding. Therm Sci Eng Prog 30:101240

Émurlaeva YY, Bataev IA, Zhou Q, Lazurenko DV, Ivanov IV, Riabinkina PA, Tanaka S, Chen P (2019) Welding window: comparison of Deribas’ and Wittman’s approaches and SPH simulation results. Metals 9(12):1323

Zakharenko ID, Zlobin BS (1984) Effect of the hardness of welded materials on the position of the lower limit of explosive welding. Combust Explos Shock Waves (Engl Transl);(United States) 19(5):689–692

Zamani E, Liaghat GH (2012) Explosive welding of stainless steel–carbon steel coaxial pipes. J Mater Sci 47(2):685–695

De Rosset WS (2006) Analysis of explosive bonding parameters. Mater Manuf Process 21(6):634–638

Lysak VI, Kuzmin SV (2012) Lower boundary in metal explosive welding. Evolution of ideas. J Mater Process Technol 212(1):150–156

Walsh JM, Shreffler RG, Willig FJ (1953) Limiting conditions for jet formation in high velocity collisions. J Appl Phys 24(3):349–359

Cowan GR, Bergmann OR, Holtzman AH (1971) Mechanism of bond zone wave formation in explosion-clad metals. Metall Mater Trans B 2(11):3145–3155

Carton E (2004) Wave forming mechanisms in explosive welding. In Materials Science Forum (Vol. 465, pp. 219–224). Trans Tech Publications Ltd

Shiran MRKG, Khalaj G, Pouraliakbar H, Jandaghi M, Bakhtiari H, Shirazi M (2017) Effects of heat treatment on the intermetallic compounds and mechanical properties of the stainless steel 321–aluminum 1230 explosive-welding interface. Int J Miner Metall Mater 24(11):1267–1277

Jandaghi MR, Saboori A, Khalaj G, Shiran MRKG (2020) Microstructural evolutions and its impact on the corrosion behaviour of explosively welded Al/Cu bimetal. Metals 10(5):634

Shiran MRKG, Bakhtiari H, Mousavi SAAA, Khalaj G, Mirhashemi SM (2017) Effect of stand-off distance on the mechanical and metallurgical properties of explosively bonded 321 austenitic stainless steel-1230 aluminum alloy tubes. Mater Res 20:291–302

Chu Q, Xia T, Zhang L, Zhao P, Zhang M, Zheng J, Yan F, Cheng P, Yan C (2022) Structure-property correlation in weld metals and interface regions of titanium/steel dissimilar joints. J Mater Eng Perform 31(8):6509–6522

Shmorgun VG, Bogdanov AI, Arisova VN, Trykov YP (2016) Growth kinetics of the diffusion zone at the interface of the explosion-welded nickel–aluminium composite. Weld Int 30(8):625–629

Carvalho GHSFL, Galvão I, Mendes R, Leal RM, Loureiro A (2018) Formation of intermetallic structures at the interface of steel-to-aluminium explosive welds. Mater Charact 142:432–442

Kwiecien I, Bobrowski P, Janusz-Skuza M, Wierzbicka-Miernik A, Tarasek A, Szulc Z, Wojewoda-Budka J (2020) Interface characterization of Ni/Al bimetallic explosively welded plate manufactured with application of exceptionally high detonation speed. J Mater Eng Perform 29(10):6286–6294

Sherpa BB, Kumar PD, Upadhyay A, Kumar S, Agarwal A, Tyagi S (2021) Effect of explosive welding parameters on Al/LCS interface cladded by low velocity of detonation explosive welding (LVEW) process. Int J Adv Manuf Technol 113(11):3303–3317

Fu Y, Qiu Y, Li Y (2018) Experimental study and fractal analysis on the anisotropic performance of explosively welded interfaces of 304 stainless Steel/245 carbon steel. J Mater Eng Perform 27(5):2556–2565

Szachogluchowicz I, Sniezek L, Grzelak K, Sulym H, Turchyn I, Pasternak I (2019) The analytical model of stress zone formation of Ti6Al4V/AA1050/AA2519 laminate produced by explosive bonding. Metals 9(7):779

Fronczek DM, Saksl K, Chulist R, Michalik S, Wojewoda-Budka J, Sniezek L, Wachowski M, Torzewski J, Sulikova M, Sulova K, Lachova A (2018) Residual stresses distribution, correlated with bending tests, within explosively welded Ti gr. 2/A1050 bimetals. Mater Charact 144:461–468

Paul H, Chulist R, Lityńska-Dobrzyńska L, Prażmowski M, Faryna M, Mania I, Szulc Z, Miszczyk MM, Kurek A (2021) Interfacial reactions and microstructure related properties of explosively welded tantalum and steel sheets with copper interlayer. Mater Des 208:109873

Bataev IA, Tanaka S, Zhou Q, Lazurenko DV, Junior AJ, Bataev AA, Hokamoto K, Mori A, Chen P (2019) Towards better understanding of explosive welding by combination of numerical simulation and experimental study. Mater Des 169:107649

Greenberg BA, Ivanov MA, Pushkin MS, Inozemtsev AV, Patselov AM, Tankeyev AP, Kuzmin SV, Lysak VI (2016) Formation of intermetallic compounds during explosive welding. Metall and Mater Trans A 47(11):5461–5473

Borchers C, Arlt J, Nowak C, Gärtner F, Hammerschmidt M, Kreye H, Volkert CA, Kirchheim R (2021) Influence of element distribution on mechanical properties in the bonding zone of explosively welded steels. Scripta Mater 199:113860

Wu X, Kondo S, Yu H, Okuno Y, Ando M, Kurotaki H, Tanaka S, Hokamoto K, Ochiai R, Konishi S, Kasada R (2021) Bonding strength evaluation of explosive welding joint of tungsten to ferritic steel using ultra-small testing technologies. Mater Sci Eng, A 826:141995

Yang M, Ma H, Shen Z, Huang Z, Tian Q, Tian J (2020) Dissimilar material welding of tantalum foil and Q235 steel plate using improved explosive welding technique. Mater Des 186:108348

Atifeh SM, Rouzbeh A, Hashemi R, Sedighi M (2022) Effect of annealing on formability and mechanical properties of AA1050/Mg-AZ31B bilayer sheets fabricated by explosive welding method. Int J Adv Manuf Technol 118(3):775–784

Shmorgun VG, Arisova VN, Slautin OV, Taube AO, Bakuntseva VM (2017) Effect of heat treatment on the structure and properties of explosion welded bimetal Kh20N80+ AD1. Met Sci Heat Treat 59(1):106–109

Gurevich LM, Arisova VN, Trykov YP, Ponomareva IA, Trudov AF (2016) Special features of structure formation in an explosion-welded magnesium-aluminum composite under deformation and subsequent heat treatment. Met Sci Heat Treat 58(3):214–218

Pouraliakbar H, Khalaj G, Jandaghi MR, Fadaei A, Ghareh-Shiran MK, Shiran MRKG, Shim SH, Hong SI (2020) Three-layered SS321/AA1050/AA5083 explosive welds: effect of PWHT on the interface evolution and its mechanical strength. Int J Press Vessels Pip 188:104216

Shargh SF, Saadat A, Najafi A, Shiran MRKG, Khalaj G (2020) Investigating the effect of post weld heat treatment on corrosion properties of explosive bonded interface of AA5083/AA1050/SS 321 tubes. Mater Res Express 7(3):036529

Shiran MKG, Khalaj G, Pouraliakbar H, Jandaghi MR, Dehnavi AS, Bakhtiari H (2018) Multilayer Cu/Al/Cu explosive welded joints: characterizing heat treatment effect on the interface microstructure and mechanical properties. J Manuf Process 35:657–663

Tian Q, Yang M, Xu J, Ma H, Zhao Y, Shen Z, Ren Z, Zhou H, Tian J (2022) Microstructure evolution and mechanical property of W/Ta bimetal foil produced by a high wave impedance explosive welding technology. Int J Adv Manuf Technol 120(1–2):1023–1040

Wachowski M, Kosturek R, Śnieżek L, Mróz S, Stefanik A, Szota P (2020) The effect of post-weld hot-rolling on the properties of explosively welded Mg/Al/Ti multilayer composite. Materials 13(8):1930

Nan X, Lu C, Chen L, Sun W, Yu H, Liu L, Chen K, Xiong Z, Gao Z, Li J (2020) Preparation of laminated structure in AZ31 magnesium alloy by explosive welding. Mater Lett 268:127574

Yu Y, Xu P, Li K, Zhao J, Dai Y, Ma H, Yang M (2019) Study on modalities and microdefects of Al-Cu bimetallic tube by underwater explosive cladding. Arch Civil Mech Eng 19(4):1390–1398

Chen X, Li X, Inao D, Tanaka S, Hokamoto K (2021) Study of explosive welding of A6061/SUS821L1 using interlayers with different thicknesses and the air shockwave between plates. Int J Adv Manuf Technol 116(11):3779–3794

Author information

Authors and Affiliations

Contributions

Gholamreza Khalaj: supervision, project administration, resources, and writing—review and editing. Moein Moradi: investigation, methodology, and resources. Ebrahim Asadian: data curation and formal analysis.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III—Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khalaj, G., Moradi, M. & Asadian, E. Exploring the impact of rolling temperature on interface microstructure and mechanical properties of steel–bronze explosive welded bilayer composite sheets. Weld World 67, 1411–1425 (2023). https://doi.org/10.1007/s40194-023-01495-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-023-01495-6