Abstract

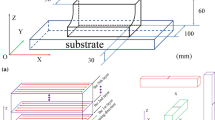

In this paper, the utilization of gas-metal-arc-welding additive manufacturing (GMAWAM) for the repurposing of components was explored. Herein, the GMAWAM process was used to build new low-carbon steel features on an existing low-carbon steel component to obtain a new part with new functionalities. To confirm the internal quality of the new part obtained by such a strategy that is adequate for real applications, its material properties were investigated. The obtained results reveal that the new features (i.e., thin walls) built by GMAWAM possess different microstructure types. The upper region of thin-walled features exhibits lamellar structures, whereas the middle region is characterized by granular structures, and mixed equiaxed and lamellar grains appear in the bottom region. Particularly, the new features have an excellent bonding strength with the existing part. The material properties of GMAWAM-repurposed parts also meet industrial requirements, confirming that the GMAWAM-repurposed parts are adequate with real applications.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Le VT, Paris H, Mandil G (2017) Environmental impact assessment of an innovative strategy based on an additive and subtractive manufacturing combination. J Clean Prod 164:508–523. https://doi.org/10.1016/j.jclepro.2017.06.204

Le VT, Paris H (2018) A life cycle assessment-based approach for evaluating the influence of total build height and batch size on the environmental performance of electron beam melting. Int J Adv Manuf Technol 98:275–288. https://doi.org/10.1007/s00170-018-2264-7

Huang S, Liu P, Mokasdar A, Hou L (2013) Additive manufacturing and its societal impact: a literature review. Int J Adv Manuf Technol 67:1191–1203. https://doi.org/10.1007/s00170-012-4558-5

Guo N, Leu M (2013) Additive manufacturing: technology, applications and research needs. Front Mech Eng 8:215–243. https://doi.org/10.1007/s11465-013-0248-8

Frazier WE (2014) Metal additive manufacturing: a review. J Mater Eng Perform 23:1917–1928. https://doi.org/10.1007/s11665-014-0958-z

Dutta B, Froes FH (2014) Additive manufacturing of titanium alloys. Adv Mater Process 172:18–23

Lu X, Zhou YF, Xing XL, Shao LY, Yang QX, Gao SY (2017) Open-source wire and arc additive manufacturing system: formability, microstructures, and mechanical properties. Int J Adv Manuf Technol 93:2145–2154. https://doi.org/10.1007/s00170-017-0636-z

Karunakaran KP, Suryakumar S, Pushpa V, Akula S (2010) Low cost integration of additive and subtractive processes for hybrid layered manufacturing. Robot Comput Integr Manuf 26:490–499. https://doi.org/10.1016/j.rcim.2010.03.008

Williams SW, Martina F, Addison AC, Ding J, Pardal G, Colegrove P (2016) Wire + arc additive manufacturing. Mater Sci Technol 32:641–647. https://doi.org/10.1179/1743284715Y.0000000073

Cunningham CR, Flynn JM, Shokrani A, Dhokia V, Newman ST (2018) Invited review article: strategies and processes for high quality wire arc additive manufacturing. Addit Manuf 22:672–686. https://doi.org/10.1016/j.addma.2018.06.020

Ding D, Pan Z, Cuiuri D, Li H (2015) Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int J Adv Manuf Technol 81:465–481. https://doi.org/10.1007/s00170-015-7077-3

Xiong J, Li Y, Li R, Yin Z (2018) Influences of process parameters on surface roughness of multi-layer single-pass thin-walled parts in GMAW-based additive manufacturing. J Mater Process Technol 252:128–136. https://doi.org/10.1016/j.jmatprotec.2017.09.020

Wu B, Pan Z, Ding D, Cuiuri D, Li H, Xu J, Norrish J (2018) A review of the wire arc additive manufacturing of metals: properties, defects and quality improvement. J Manuf Process 35:127–139. https://doi.org/10.1016/j.jmapro.2018.08.001

Ivántabernero PA, Álvarez P, Suárez A (2018) Study on arc welding processes for high deposition rate additive manufacturing. Procedia CIRP 68:358–362. https://doi.org/10.1016/j.procir.2017.12.095

Ortega AG, Corona Galvan L, Salem M, Moussaoui K, Segonds S, Rouquette S, Deschaux-Beaume F (2019) Characterisation of 4043 aluminium alloy deposits obtained by wire and arc additive manufacturing using a cold metal transfer process. Sci Technol Weld Join 24:538–547. https://doi.org/10.1080/13621718.2018.1564986

Gomez Ortega A, Corona Galvan L, Deschaux-Beaume F, Mezrag B, Rouquette S (2018) Effect of process parameters on the quality of aluminium alloy Al5Si deposits in wire and arc additive manufacturing using a cold metal transfer process. Sci Technol Weld Join 23:316–332. https://doi.org/10.1080/13621718.2017.1388995

Geng H, Li J, Xiong J, Lin X (2017) Optimisation of interpass temperature and heat input for wire and arc additive manufacturing 5A06 aluminium alloy. Sci Technol Weld Join 22:472–483. https://doi.org/10.1080/13621718.2016.1259031

Zhao H, Zhang G, Yin Z, Wu L (2013) Effects of interpass idle time on thermal stresses in multipass multilayer weld-based rapid prototyping. J Manuf Sci Eng 135:011016. https://doi.org/10.1115/1.4023363

Suryakumar S, Karunakaran K, Chandrasekhar U, Somashekara M (2013) A study of the mechanical properties of objects built through weld-deposition. Proc Inst Mech Eng Part B J Eng Manuf 227:1138–1147. https://doi.org/10.1177/0954405413482122

Liberini M, Astarita A, Campatelli G, Scippa A, Montevecchi F, Venturini G, Durante M, Boccarusso L, Minutolo FMC, Squillace A (2017) Selection of optimal process parameters for wire arc additive manufacturing. Procedia CIRP 62:470–474. https://doi.org/10.1016/j.procir.2016.06.124

Rafieazad M, Ghaffari M, Vahedi Nemani A, Nasiri A (2019) Microstructural evolution and mechanical properties of a low-carbon low-alloy steel produced by wire arc additive manufacturing. Int J Adv Manuf Technol 105:2121–2134. https://doi.org/10.1007/s00170-019-04393-8

ElMaraghy H, Moussa M (2019) Optimal platform design and process plan for managing variety using hybrid manufacturing. CIRP Ann 68:443–446. https://doi.org/10.1016/j.cirp.2019.03.025

Bauer T, Brissaud D, Zwolinski P (2017) Design for high added-value end-of-life strategies:113–128. https://doi.org/10.1007/978-3-319-48514-0_8

Le VT, Paris H, Mandil G (2018) The development of a strategy for direct part reuse using additive and subtractive manufacturing technologies. Addit Manuf 22:687–699. https://doi.org/10.1016/j.addma.2018.06.026

Le VT, Paris H, Mandil G, Brissaud D (2017) A direct material reuse approach based on additive and subtractive manufacturing technologies for manufacture of parts from existing components. Procedia CIRP 61:229–234. https://doi.org/10.1016/j.procir.2016.11.190

The Lincoln Electric Company: MIG (GMAW) WIRE n.d. https://lincolnelectric.com/assets/global/Products/Consumable_MIGGMAWWires-SuperArc-SuperArcG4Si1/c41025.pdf. Accessed 3 Sept 2020

Pham TH, Kim JJ, Kim SE (2014) Estimation of microstructural compositions in the weld zone of structural steel using nanoindentation. J Constr Steel Res 99:121–128. https://doi.org/10.1016/j.jcsr.2014.04.011

Montevecchi F, Venturini G, Grossi N, Scippa A, Campatelli G (2018) Idle time selection for wire-arc additive manufacturing: a finite element-based technique. Addit Manuf 21:479–486. https://doi.org/10.1016/j.addma.2018.01.007

Zhao H, Zhang G, Yin Z, Wu L (2011) A 3D dynamic analysis of thermal behavior during single-pass multi-layer weld-based rapid prototyping. J Mater Process Technol 211:488–495. https://doi.org/10.1016/j.jmatprotec.2010.11.002

Yang D, Wang G, Zhang G (2017) Thermal analysis for single-pass multi-layer GMAW based additive manufacturing using infrared thermography. J Mater Process Technol 244:215–224. https://doi.org/10.1016/j.jmatprotec.2017.01.024

Shassere B, Nycz A, Noakes MW, Masuo C, Sridharan N (2019) Correlation of microstructure and mechanical properties of metal big area additive manufacturing. Appl Sci 9. https://doi.org/10.3390/app9040787

Aldalur E, Veiga F, Suárez A, Bilbao J, Lamikiz A (2020) High deposition wire arc additive manufacturing of mild steel: strategies and heat input effect on microstructure and mechanical properties. J Manuf Process 58:615–626. https://doi.org/10.1016/j.jmapro.2020.08.060

Khalid FA, Farooque M, ul Haq A, Khan AQ (1999) Role of ferrite/pearlite banded structure and segregation on mechanical properties of microalloyed hot rolled steel. Mater Sci Technol 15:1209–1215. https://doi.org/10.1179/026708399101505121

Haden CV, Zeng G, Carter FM, Ruhl C, Krick BA, Harlow DG (2017) Wire and arc additive manufactured steel: tensile and wear properties. Addit Manuf 16:115–123. https://doi.org/10.1016/j.addma.2017.05.010

Yan JB, Liew JYR, Zhang MH, Wang JY (2014) Mechanical properties of normal strength mild steel and high strength steel S690 in low temperature relevant to Arctic environment. Mater Des 61:150–159. https://doi.org/10.1016/j.matdes.2014.04.057

Ghaffari M, Vahedi Nemani A, Rafieazad M, Nasiri A (2019) Effect of solidification defects and HAZ softening on the anisotropic mechanical properties of a wire arc additive-manufactured low-carbon low-alloy steel part. Jom 71:4215–4224. https://doi.org/10.1007/s11837-019-03773-5

ASTM A36 Steel, plate n.d. http://www.matweb.com/search/DataSheet.aspx?MatGUID=afc003f4fb40465fa3df05129f0e88e6&ckck=1. Accessed 30 Sept 2020

Funding

This research is funded by the Vietnam National Foundation for Science and Technology Development (NAFOSTED) under grant number 107.99-2019.18.

Author information

Authors and Affiliations

Contributions

Van Thao Le: Conceptualization, methodology, data analysis, writing—original draft preparation. Henri Paris: Methodology, reviewing, and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission I - Additive Manufacturing, Surfacing, and Thermal Cutting

Rights and permissions

About this article

Cite this article

Le, V.T., Paris, H. On the use of gas-metal-arc-welding additive manufacturing for repurposing of low-carbon steel components: microstructures and mechanical properties. Weld World 65, 157–166 (2021). https://doi.org/10.1007/s40194-020-01005-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-01005-y