Abstract

Post weld heat treatment is the most widely used technique to restore the strength of aluminum welds by recrystallization of precipitates and often requires cumbersome, energy intensive, and time-consuming heat treatments. Equal channel angular pressing (ECAP) is proposed for the first time as an alternative to the heat treatment of welded AA6061 samples, welded by the gas tungsten arc welding process, and processing was performed in two different orientations of the work piece with respect to the position of the weld bead. Both orientations of the ECAP process produce significant modifications to the mechanical and metallographic properties of the work piece. Characterization of the ECAPed specimens shows that usage of ECAP as an alternative to heat treatment is viable and the second variant of ECAP proves more effective than the first. ECAP restores the strength of the joints on par with heat treatment with better ductility and consumes very less time, and hence, it is very desirable than post weld heat treatment.

Similar content being viewed by others

References

Lakshminarayanan AK, Balasubramanian V, Elangovan K (2009) Effect of welding processes on tensile properties of AA6061 aluminium alloy joints. Int J Adv Manuf Technol 40(3–4):286–296

Dewan MW, Wahab MA, Okeil AM (2015) Influence of Weld Defects and Postweld Heat Treatment of Gas Tungsten Arc-Welded AA-6061-T651 Aluminum Alloy. Journal of Manufacturing Science and Engineering, Transactions of the ASME 137(5)

Menzemer CC, Hilty E, Morrison S, Minor R, Srivatsan TS (2016) Influence of post weld heat treatment on strength of three aluminum alloys used in light poles. Metals 6(3):52

Jannet S, Mathews K, Raja R (2014) Comparative investigation of friction stir welding and fusion welding of 6061 T6 - 5083 O aluminum alloy based on mechanical properties and microstructure. Bull Polish Acad Sci Tech Sci 62(4):791–795

Ipekoglu G, Erim S, Cam G (2014) Investigation into the influence of post-weld heat treatment on the friction stir welded AA6061 Al-alloy plates with different temper conditions. Metall Mater Trans A Phys Metall Mater Sci 45(2):864–877

Lee WB, Jang HS, Yeon YM, Jung SB (2004) Effect of PWHT on behaviors of precipitates and hardness distribution of 6061 Al alloy joints by friction stir welding method. Mater Sci Forum 449–452(I):601–604

Segal VM (1995) Materials processing by simple shear. Mater Sci Eng A 197(2):157–164

Raab GJ, Valiev RZ, Lowe TC, Zhu YT (2004) Continuous processing of ultrafine grained Al by ECAP-Conform. Mater Sci Eng A 382(1–2):30–34

Srinivasan R, Cherukuri B, Chaudhury PK (2006) Scaling up of equal channel angular pressing (ECAP) for the production of forging stock. Mater Sci Forum 503–504:371–378

Kamachi M, Furukawa M, Horita Z, Langdon TG (2003) Equal-channel angular pressing using plate samples. Mater Sci Eng A 361(1–2):258–266

Lienert T, Siewert T, Babu S, Acoff V, Specifications SWP (2011) ASM handbook, volume 6A: welding fundamentals and processes. ASM International Materials Park, OH

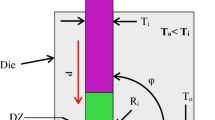

Patil Basavaraj V, Chakkingal U, Prasanna Kumar TS (2009) Study of channel angle influence on material flow and strain inhomogeneity in equal channel angular pressing using 3D finite element simulation. J Mater Process Technol 209(1):89–95

Wei W, Nagasekhar AV, Chen G, Tick-Hon Y, Wei KX (2006) Origin of inhomogenous behavior during equal channel angular pressing. Scr Mater 54(11):1865–1869

Xu C, Xia K, Langdon TG (2007) The role of back pressure in the processing of pure aluminum by equal-channel angular pressing. Acta Mater 55(7):2351–2360

Wang S, Liang W, Wang Y, Bian L, Chen K (2009) A modified die for equal channel angular pressing. J Mater Process Technol 209(7):3182–3186

Nagasekhar AV, Tick-Hon Y, Li S, Seow HP (2005) Effect of acute tool-angles on equal channel angular extrusion/pressing. Mater Sci Eng A 410–411:269–272

Sadasivan N, Balasubramanian M, Venkatesh R, Vigneshram S, Sunil T (2019) Influence of equal channel angular pressing in an acute angle die with a back pressure notch on grain refinement, torsion and mechanical properties of aluminium. Mater Werkst 50(2):155–164

Alhajeri SN, Gao N, Langdon TG (2011) Hardness homogeneity on longitudinal and transverse sections of an aluminum alloy processed by ECAP. Mater Sci Eng A 528(10–11):3833–3840

Fadaeifard F, Matori KA, Garavi F, Al-Falahi M, Sarrigani GV (2016) Effect of post weld heat treatment on microstructure and mechanical properties of gas tungsten arc welded AA6061-T6 alloy. Trans Nonferrous Met Soc China (English Ed) 26(12):3102–3114

Elangovan K, Balasubramanian V (2008) Influences of post-weld heat treatment on tensile properties of friction stir-welded AA6061 aluminum alloy joints. Mater Charact 59(9):1168–1177

Courtney TH (2005) Mechanical Behavior of Materials. Waveland Press, Illinois

Xu C, Furukawa M, Horita Z, Langdon TG (2003) Using ECAP to achieve grain refinement, precipitate fragmentation and high strain rate superplasticity in a spray-cast aluminum alloy. Acta Mater 51(20):6139–6149

Abd El Aal MI, Sadawy MM (2015) Influence of ECAP as grain refinement technique on microstructure evolution, mechanical properties and corrosion behavior of pure aluminum. Trans Nonferrous Met Soc China (English Ed) 25(12):3865–3876

Pérez JS, Ambriz RR, López FFC, Vigueras DJ (2016) Recovery of mechanical properties of a 6061-T6 aluminum weld by heat treatment after welding. Metall Mater Trans A Phys Metall Mater Sci 47(7):3412–3422

Lampman S (1997) Weld integrity and performance: a source book adapted from ASM international handbooks, conference proceedings, and technical books. Asm International, Materials Park, Ohio

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XVIII - Quality Management in Welding and Allied Processes

Rights and permissions

About this article

Cite this article

Sadasivan, N., Balasubramanian, M. Equal channel angular pressing of gas tungsten arc welded AA6061 alloy. Weld World 64, 1053–1064 (2020). https://doi.org/10.1007/s40194-020-00897-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00897-0