Abstract

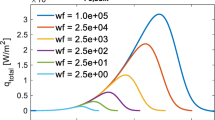

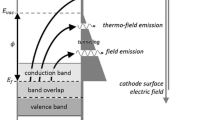

Currently used approaches for modeling the cathodic heat input in gas metal arc welding (GMAW) process simulation are usually based on very simplified approaches, either using a Rykalin-Rosenthal-distributed heat flux or a thermal conductivity approach, which do not reflect the deep physical processes involved. In this paper, a new approach for the calculation of the arc-cathode coupling in GMAW is presented, and the influence of the parameter variation on the formation of the weld pool is studied. The evaporation-determined model for arc-cathode coupling (EDACC) takes into account the recent findings on the plasma temperature in the GMAW arc, which is dominated by metal vapor, as well as the metal evaporation, which is readily ionized in the cathode region. It determines a relationship between the weld pool surface temperature and the heat flux as well as the current density distribution. As a result, the heat flux as well as the current density distribution is not axisymmetric. In this work, the model was coupled to a simplified weld pool simulation, and the influence of the model parameters like distribution of plasma temperature and welding velocity were investigated. Additionally, also the influence of the droplets on the weld pool surface temperature distribution and its effect on the arc-cathode attachment, as determined by the model, were studied.

Similar content being viewed by others

References

Mokrov O et al (2019) Arc-cathode attachment in GMA welding. J Phys D Appl Phys 52:36. https://doi.org/10.1088/1361-6463/ab2bd9

Rykalin NN (1957) Berechnung der Wärmevorgänge beim Schweißen (transl.). VEB Verlag Technik, Berlin

Jeong H, Park K, Baek S, Kim DY, Kang MJ, Cho J (2018) Three-dimensional numerical analysis of weld pool in GMAW with fillet joint. Int J Precis Eng Manuf 34(8):1171–1177. https://doi.org/10.1007/s12541-018-0138-4

Ogino Y, Asai S, Hirata Y (2018) Numerical simulation of WAAM process by a GMAW weld pool model. Welding in the World 62(2):393–401. https://doi.org/10.1007/s40194-018-0556-z

Xu G, Hu J, Tsai HL (2009) Three-dimensional modeling of arc plasma and metal transfer in gas metal arc welding. Int J Heat Mass Transf 52(7):1709–1724. https://doi.org/10.1016/j.ijheatmasstransfer.2008.09.018

Knight CJ (1979) Theoretical modelling of rapid surface vaporization with back pressure. AIAA J 17(5):519. https://doi.org/10.2514/3.61164

Kozakov R et al (2013) Weld pool temperatures of steel S235 while applying a controlled short-circuit gas metal arc welding process and various shielding gases. J Phys D Appl Phys 46:47. https://doi.org/10.1088/0022-3727/46/47/475501

Benilov MS, Marotta A (1995) A model of the cathode region of atmospheric pressure arcs. J Phys D Appl Phys 28(9):1869. https://doi.org/10.1088/0022-3727/28/9/015

Benilov MS (1993) Nonlinear heat structures and arc-discharge electrode spots. Phys Rev E 48:506. https://doi.org/10.1103/PhysRevE.48.506

Benilov MS (2008) Understanding and modelling plasma–electrode interaction in high-pressure arc discharges: a review. J Phys D Appl Phys 41(14):144001. https://doi.org/10.1088/0022-3727/41/14/144001

Zielinska S et al (2007) Investigations of GMAW plasma by optical emission spectroscopy. Plasma Sources Sci Technol 16:832. https://doi.org/10.1088/0963-0252/16/4/019

Valensi F et al (2010) Plasma diagnostics in gas metal arc welding by optical emission spectroscopy. J Phys D Appl Phys 43:43400. https://doi.org/10.1088/0022-3727/43/43/434002

Kozakov R et al (2013) Spatial structure of the arc in a pulsed GMAW process. J Phys D Appl Phys 46:224001. https://doi.org/10.1088/0022-3727/46/22/224001

Rouffet ME et al (2010) Spectroscopic investigation of the high-current phase of a pulsed GMAW process. J Phys D Appl Phys 45(43):189501. https://doi.org/10.1088/0022-3727/43/43/434003

Mokrov O et al (2017) Numerical investigation of droplet impact on the welding pool in gas metal arc welding. Mater Sci Eng Technol 48(12):1206–1212. https://doi.org/10.1002/mawe.201700147

Funding

The presented investigations were carried out at the RWTH Aachen University within the framework of the Collaborative Research Centre SFB1120 “Precision Melt Engineering” (project no. 236616214) and were funded by the German Research Foundation (DFG). Simulations were performed with computing resources granted by the RWTH Aachen University under project rwth0398.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Study Group 212 - The Physics of Welding

Rights and permissions

About this article

Cite this article

Mokrov, O., Simon, M., Sharma, R. et al. Effects of evaporation-determined model of arc-cathode coupling on weld pool formation in GMAW process simulation . Weld World 64, 847–856 (2020). https://doi.org/10.1007/s40194-020-00878-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00878-3