Abstract

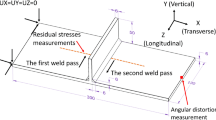

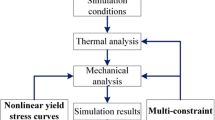

Prediction and minimisation of weld-induced distortion at the design stage incites pre and in-process mitigation techniques to improve the weld structure. As a result, it inhibits the need for post welding processes like line heating, straightening etc. In this work, to get more accurate results for distortion prediction, an effort has been made to improve the existing equivalent load method. In this method, the transient behaviour of plastic strain distribution was considered to analyse the large welded structure. Here, the actual transient phenomenon of a weld was considered, i.e. the effect of start, end and middle quasi-steady-state was considered. The separate average loads were applied at the start, middle and end regions of the welding line instead of the same average load throughout the weld length. This proposed method was validated with experimentally obtained results, which showed a perfect agreement and hence, confirmed its efficacy. This method was also validated for published results for different welding joints to assure its effectiveness. At last, a large weld structure was analysed for distortion prediction by using the proposed equivalent load-based technique.

Similar content being viewed by others

References

Patte FM (1975) 02235375-MIT.pdf, Massachusetts Institute of Technology

Murakawa H, Nomoto T, Terasaki T, Maeda K (1998) Critical conditions of plate buckling generated by welding. Trans. Japan Soc. Mech. Eng. Ser. A 64(625):2239–2244

Zhu XK, Chao YJ (2002) Effects of temperature-dependent material properties on welding simulation. Comput. Struct. 80(11):967–976

Goldak J, Bibby M, Moore J, House R, Patel B (1986) Computer modelling of heat flow in welds. Metall. Mater. Trans. B. 17(3):587–600

Goldak J, Bibby MJ, Downey D, Gu M (1990) Heat and fluid flow in welds. In: Advanced Joining Technologies. Springer, pp 69–82

Goldak J, Chakravarti A, Bibby M (1984) A new finite element model for welding heat sources. 15

Brown S, Song H (1992) Implications of three-dimensional numerical simulations of welding of large structures. Weld. J. 71(2):55–62

C. D. Jang, Y. T. Kim, Y. C. Jo, and H. S. Ryu, Welding distortion analysis of hull blocks using equivalent load method based on inherent strain, 2007.

Hidekazu Murakawa SS (2009) Dean Deng, Sharif Rashed, Prediction of distortion produced on welded structures during assembly using inherent deformation and interface element. Trans JWRI 38(1):63–69

Kim YC, Yuan MG, Ueda Y (1989) A predicting method of welding residual stress using source of residual stress. Trans JWRI 18(1):135–141

Wang J, Ma N, Murakawa H (2015) An efficient FE computation for predicting welding induced buckling in production of ship panel structure. Mar. Struct. 41:20–52

Wang R, Zhang J, Serizawa H, Murakawa H (2009) Study of welding inherent deformations in thin plates based on finite element analysis using interactive substructure method. Mater. Des 30(9):3474–3481

Adak M, Mandal NR (2009) Pseudolinear equivalent constant rigidity concept for analysing welding residual deformation. Appl. Math. Model. 33(4):2096–2108

Yusuke T, Sherif R, Yasuhisa O, Yasuo K (2007) Prediction of welding distortion and panel buckling of car carrier decks using database generated by FEA †. 36(1)

Biswas P, Mandal NR, Das S (2011) Prediction of welding deformations of large stiffened panels using average plastic strain method. Sci. Technol. Weld. Join. 16(3):227–231

Mochizuki M, Mikami Y, Yamasaki H, Toyoda M (2008) Elastic predicting method of weld distortion of large structures using numerical simulation results by thermal-elastic-plastic analysis of small components. Weld. Res. Abroad 54(6):42

Deng D, Murakawa H, Liang W (2007) Numerical simulation of welding distortion in large structures. Comput. Methods Appl. Mech. Eng. 196(45):4613–4627

Murakawa H, Deng D, Ma N, Wang J (2012) Applications of inherent strain and interface element to simulation of welding deformation in thin plate structures. Comput. Mater. Sci. 51(1):43–52

Wang J, Zhao H, Zou J, Zhou H, Wu Z (2017) Welding distortion prediction with elastic FE analysis and mitigation practice in the fabrication of cantilever beam component of jack-up drilling rig. Ocean Eng 130(December 2016):25–39

Choobi MS, Haghpanahi M, Sedighi M (2010) Investigation of the effect of clamping on residual stresses and distortions in butt-welded plates. 17(5):2010

Lu P, He LH, Lee HP, Lu C (2006) Thin plate theory including surface effects. Int. J. Solids Struct. 43(16):4631–4647

Canonsburg TD ANSYS Mechanical APDL Coupled-Field Analysis Guide, vol. 3304, no. November. 2013

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XV - Design, Analysis, and Fabrication of Welded Structures

Rights and permissions

About this article

Cite this article

Suman, S., Sridhar, P.V.S.S., Biswas, P. et al. Prediction of welding-induced distortions in large weld structure through improved equivalent load method based on average plastic strains. Weld World 64, 179–200 (2020). https://doi.org/10.1007/s40194-019-00805-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00805-1