Abstract

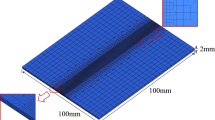

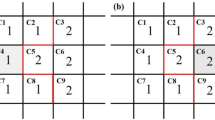

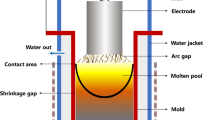

The purpose of this article is to investigate the influence of growth kinetic models and nucleation models on the grain structure predicted by cellular automata (CA) during bead on Cu30Ni thin plate. Temperature field is obtained with the computation of two-dimensional finite element model (FE). Based on these temperatures, a CA model simulates the evolution of the envelope of grains along the solidification front. It is shown that for the same temperature field, the grains structure is modified if the growth model changes. The influence of the nucleation law parameters is also discussed from a modelling point of view. Experimental size of the weld pool are compared with thermal results and EBSD maps are compared with grain structure prediction obtained with the CA algorithm.

Similar content being viewed by others

References

Kou S (2003) Welding metallurgy. Wiley

Pavlyk V, Dilthey U (2004) Simulation of weld solidification microstructure and its coupling to the macroscopic heat and fluid flow. Model Simul Mater Sci Eng 12:33–35

Farzadi A, Do-Quang M, Serajzadeh S, Kokabi A, Amberg G (2008) Phase field simulation of weld solidification microstructure in an Al Cu alloy. Model Simul Mater Sci Eng, 16. https://doi.org/10.1088/0965-0393/16/6/065005

Rodgers TM, Mitchell JA, Tikare V (2017) A Monte Carlo model for 3D grain evolution during welding. Modell Simul Mater Sci Eng 25(6). https://doi.org/10.1088/1361-651X/aa7f20

Chen S, Guillemot G, Gandin Ch-A (2014) 3D coupled cellular automaton- finite element modeling for solidification grain structures in gas tungsten arc welding. ISIJ Int 54:401–407

Kurz W, Giovanola B, Trivedi (1986) Theory of microstructural development during rapid solidification. Acta Metallur 34:p823–830

Chiocca A, Soulié F, Bordreuil C, Deschaux-Beaume F (2016) In situ observations and measurements during solidification of CuNi weld pools. Sci Technol Weld Join 21(7):578–584

Gandin Ch-A, Rappaz M (1994) A coupled finite element-cellular automaton model for the prediction of dendritic grain structures in solidification process. Acta Metallur Materiala 42:2233–2246

Hunt JD (1948) Steady state columnar and equiaxed growth of dendrites and eutectic. Material Sci Eng 25:65–75

Takatani H, Gandin Ch-A, Rappaz M (2000) EBSD characterisation and modelling of columnar dendritic grains growing in the presence of fluid flow. Acta Materiala 48:675–688

Vitek JM (2005) The effect of welding conditions on stray grain formation in single crystal welds. Acta Materiala 53:53–67

Villaret V, Deschaux-Beaume F, Bordreuil C (2016) A solidification model for the columnar to equiaxed transition in welding of a Cr-Mo ferritic stainless steel with Ti as inoculant. J Mater Process Technol 233:115–124

Dantzig G, Rappaz M (2009) Soldification. CRC Press

Bordreuil C, Niel A (2014) Modelling of hot cracking in welding with a cellular automaton combined with an intergranular fluid flow model. Comput Mater Sci 82:442–450

Rappaz M, Gandin Ch-A, Desbiolles J-L, Thevoz P (1996) Prediction of grain structures in various solidification processes. Metallur Mater Trans A 27:695–705

Miettinen J (2003) Thermodynamic description of the Cu–Ni–Sn system at the Cu–Ni side. Comput Coupling Phase Diagrams Thermochem 27:309–318

Hupf T, Cagran C, Kaschnitz E, Pottlacher G (2010) Thermophysical properties of five binary copper-nickel alloys. Int J Thermophys 31:966–974

Chiocca A (2016) Phd Thesis. Univerisité de Montpellier

Funding

All authors belong and were funded by the Université of Montpellier. Université de Montpellier is a university devoted to education and scientific research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Chiocca, A., Soulié, F., Deschaux-Beaume, F. et al. Study of the effect of growth kinetic and nucleation law on grain structure simulation during gas tungsten arc welding of Cu-Ni plate. Weld World 63, 887–901 (2019). https://doi.org/10.1007/s40194-019-00717-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00717-0