Abstract

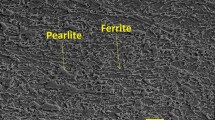

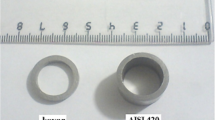

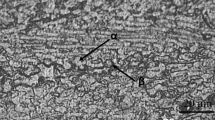

In the present investigation, titanium alloy Ti6Al4V of 1.4 mm thickness has been laser-welded in butt joint configuration using pulsed Nd:YAG laser system. The effects of heat input on weld bead shape, fusion zone width (top, middle, and bottom), heat-affected zone (HAZ) width (top, middle, and bottom), and fusion zone area have been studied. The microstructure and mechanical properties of laser-welded specimens at various heat inputs (43.7–103.5 J/mm) have also been investigated. Microstructures of the fusion zone, HAZ, and parent material have been compared at various heat inputs using optical microscope and field emission scanning electron microscope (FESEM). The mechanical properties such as microhardness and tensile strength of the welded joints at varying heat inputs have been studied. Tensile tests of the welded specimen and base metal have been conducted for analyzing ultimate tensile strength and percentage elongation. Surface topography of the tensile fractured specimen of the welded joints and base metal has been examined to analyze the ductile and brittle behavior. EDS analyses of base metal and fusion zone of the welded specimen have been studied. XRD of the as-received base metal and welded specimen have been measured in the range of 30 to 85° to study the crystallographic structure.

Similar content being viewed by others

References

Li Z, Gobbi SL, Norris I, Zolotovsky S, Richter KH (1997) Laser welding techniques for titanium alloy sheet. J Mater Process Technol 65:203–208

Elias CN, Lima JHC, Valiev R, Meyers MA (2008) Biomedical applications of titanium and its alloys. JOM 60:46–49

Balasubramanian TS, Balasubramanian V, Manickam MM (2011) Fatigue crack growth behaviour of gas tungsten arc, electron beam and laser beam welded Ti–6Al–4V alloy. Mater Des 32:4509–4520

Chen YC, Nakata K (2009) Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater Des 30:469–474

Yunlian Q, Ju D, Quan H, Liying Z (2000) Electron beam welding, laser beam welding and gas tungsten arc welding of titanium sheet. Mater Sci Eng A 280:177–181

Lima MSFD (2005) Laser beam welding of titanium nitride coated titanium using pulse-shaping. Mater Res 8:323–328

Bertrand C, Laplanche O, Rocca JP, Le Petitcorps Y, Nammour S (2007) Effect of the combination of different welding parameters on melting characteristics of grade 1 titanium with a pulsed Nd–Yag laser. Lasers Med Sci 22:237–244

Costa A, Miranda R, Quintino L, Yapp D (2007) Analysis of beam material interaction in welding of titanium with fiber lasers. Mater Manuf Process 22:798–803

Liu J, Watanabe I, Yoshida K, Atsuta M (2002) Joint strength of laser-welded titanium. Dent Mater 18:143–148

Colegrove P, Simiand PE, Varughese A, Williams S, Yapp D (2009) Evaluation of a drilling model approach to represent laser spot microwelding. In Trends in welding research, ASM Proceedings of the 8th International Conference 2008, pp. 303–312

Torkamany MJ, Hamedi MJ, Malek F, Sabbaghzadeh J (2006) The effect of process parameters on keyhole welding with a 400 W Nd: YAG pulsed laser. J Phys D Appl Phys 39(21):4563–4567

Chen Y, Chen S, Li L (2009) Effects of heat input on microstructure and mechanical property of Al/Ti joints by rectangular spot laser welding-brazing method. Int J Adv Manuf Technol 44(3–4):265–272

Torkamany MJ, Ghaini FM, Papan E, Dadras S (2012) Process optimization in titanium welding with pulsed Nd: YAG laser. Sci Adv Mater 4:489–496

Akman E, Demir A, Canel T, Sınmazçelik T (2009) Laser welding of Ti6Al4V titanium alloys. J Mater Process Technol 209:3705–3713

Gao XL, Zhang LJ, Liu J, Zhang JX (2014) Effects of weld cross-section profiles and microstructure on properties of pulsed Nd: YAG laser welding of Ti6Al4V sheet. Int J Adv Manuf Technol 72:895–903

Xu PQ (2012) Microstructure characterization of Ti–6Al–4V titanium laser weld and its deformation. Trans Nonferrous Metals Soc China 22:2118–2123

Gao XL, Liu J, Zhang LJ, Zhang JX (2014) Effect of the overlapping factor on the microstructure and mechanical properties of pulsed Nd: YAG laser welded Ti6Al4V sheets. Mater Charact 93:136–149

Gursel A (2017) Crack risk in Nd: YAG laser welding of Ti-6Al-4V alloy. Mater Lett 197:233–235

Caiazzo F, Alfieri V, Astarita A, Squillace A, Barbieri G (2016) Investigation on laser welding of Ti-6Al-4V plates in corner joint. Adv in Mech Eng 9:1687814016685546

Kumar C, Das M, Paul CP, Singh B (2017) Experimental investigation and metallographic characterization of fiber laser beam welding of Ti-6Al-4V alloy using response surface method. Opt Lasers Eng 95:52–68

Campanelli SL, Casalino G, Mortello M, Angelastro A, Ludovico AD (2015) Microstructural characteristics and mechanical properties of Ti6Al4V alloy fiber laser welds. Procedia CIRP 33:428–433

Caiazzo F, Alfieri V, Corrado G, Cardaropoli F, Sergi V (2013) Investigation and optimization of laser welding of Ti-6Al-4 V titanium alloy plates. J Manuf Sci Eng 135:061012

Akbari M, Saedodin S, Toghraie D, Shoja-Razavi R, Kowsari F (2014) Experimental and numerical investigation of temperature distribution and melt pool geometry during pulsed laser welding of Ti6Al4V alloy. Opt Laser Technol 59:52–59

Oliveira JP, Miranda RM, Fernandes FB (2017) Welding and joining of NiTi shape memory alloys: a review. Prog Mater Sci 88:412–466

Oliveira JP, Panton B, Zeng Z, Andrei CM, Zhou Y, Miranda RM, Fernandes FB (2016) Laser joining of NiTi to Ti6Al4V using a niobium interlayer. Acta Mater 105:9–15

Auwal ST, Ramesh S, Yusof F, Manladan SM (2018) A review on laser beam welding of titanium alloys. Int J Adv Manuf Technol 97:1071–1098

Sjögren G, Andersson M, Bergman M (1988) Laser welding of titanium in dentistry. Acta Odontol Scand 46:247–253

Palanivel R, Dinaharan I, Laubscher RF (2017) Microstructure evolution and mechanical characterization of Nd: YAG laser beam welded titanium tubes. Mater Charact 134:225–235

Gao XL, Liu J, Zhang LJ (2018) Effect of heat input on microstructure and mechanical properties of pulsed laser welded joints in Ti6Al4V/Nb dissimilar alloys. Int J Adv Manuf Technol 94:3937–3947

Standard ASTM (2011) E3 Standard guide for preparation of metallographic specimens. West Conshohocken (PA): ASTM International

ASTM E8/E8M (2013) Standard test methods for tension testing of metallic materials. West Conshohocken (PA): ASTM International

Hong KM, Shin YC (2016) Analysis of microstructure and mechanical properties change in laser welding of Ti6Al4V with a multiphysics prediction model. J Mater Process Technol 237:420–429

Squillace A, Prisco U, Ciliberto S, Astarita A (2012) Effect of welding parameters on morphology and mechanical properties of Ti–6Al–4V laser beam welded butt joints. J Mater Process Technol 212:427–436

Elmer JW, Palmer TA, Babu SS, Zhang W, DebRoy T (2004) Phase transformation dynamics during welding of Ti–6Al–4V. J Appl Phys 95:8327–8339

Huang JL, Warnken N, Gebelin JC, Strangwood M, Reed RC (2012) On the mechanism of porosity formation during welding of titanium alloys. Acta Mater 60:3215–3225

EN BS (2011) 4678 Aerospace series. Weldments and brazements for aerospace structures. Joints of metallic materials by laser beam welding. Quality of weldments BSI

Funding

The present research work was supported by Central Mechanical Engineering Research Institute (CMERI) Durgapur, India, and funded by the National Institute of Technology Patna, India. Many of the testing facilities have been carried out at IIT Kharagpur and IIT Kanpur.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IV - Power Beam Processes

Rights and permissions

About this article

Cite this article

Kumar, P., Sinha, A.N. Effect of heat input in pulsed Nd:YAG laser welding of titanium alloy (Ti6Al4V) on microstructure and mechanical properties. Weld World 63, 673–689 (2019). https://doi.org/10.1007/s40194-018-00694-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-00694-w