Abstract

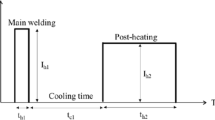

The possibility of creating local-designed variations in microstructure has the potential to radically change how advanced and ultra-high strength steels are used in vehicle components. Such local changes in the microstructure offer the potential for tailored combinations of strength and ductility, both reducing vehicle weight and improving structural performance. This study addresses development of a new technology for creating such local changes in microstructure. The process, termed direct resistance heat treatment (DHRT) is analogous to resistance welding with in situ tempering. Current impulses are used to first locally transform the microstructure (austenitize and quench to martensite) then temper the martensitic microstructure to achieve desired levels of performance. Work here was done on a 1-mm thick 10B21 steel. Practices were first developed to achieve fully martensitic microstructures, and then combinations of temper currents and times were used to achieve differing final hardnesses. Thermal analyses suggested that for the material studied, stable temperatures (during heating) could be achieved in about 50 ms, and the workpiece could effectively quenched in about 100 ms. Mechanical evaluations showed that the locally hardened areas were effective for diverting plastic deformation, even when using notched specimens.

Similar content being viewed by others

References

Davies RG, Magee CL (1979) Physical metallurgy of automotive high strength steels. Structure and Properties of Dual Phase Steels. Kot RA, Morris JW (eds) AIME

Bleck W (1996) Cold rolled, high-strength sheet steels for auto applications. J Metals 48(7):26–30

Hein P, Wilsius J (2009) Status and innovation trends in hot stamping of USIBOR 1500 P. Steel Res Int 79(2):85–91

Asadi M, Frommeyer G, Aghajani A, Timokhina I, Palkowski H (2012) Local laser heat treatment in dual phase steels. Metall Mater Trans A 43A(4):1244–1258

George R, Bardelcik A, Worswick MJ (2012) Hot forming of boron steels using heated and cooled tooling for tailored properties. J Mater Process Technol 212(11):2386–2399

Chuko W, Gould JE (2002) Development of appropriate resistance spot welding practice for transformation-hardened steels. AISI/DOE report TRP 9934. American Iron and Steel Institute Technology Roadmap Program Office, Pittsburgh, PA

Chuko W, Gould JE (2002) Development of appropriate resistance spot welding practice for transformation hardened steels. Weld J Res Suppl 81(1):1s–7s

Peterson W, Gould J (2004) Development of spike temper diagrams for a range of advanced high strength steels. Sheet Metal Welding Conference XI, AWS Detroit Section, Detroit, MI

(2011) Standard Specification for Quality Assurance Requirements for Carbon and Alloy Steel Wire, Rods, and Bars for Mechanical Fasteners. ASTM Standard F2282-03. Annual Book of ASTM Standards 01.08. ASTM. Conshohocken, PA, pp 592–606

Bhadeshia HKDH, Svensson LE (1993) Mathematical Modeling of Weld Phenomena. In Cerjack H, Easterling KE (eds) Institute of Metals, London, pp 109–180

(2000) Recommended Practices for Resistance Welding. AWS C1.1-2000. American Welding Society. Miami, FL

Gould JE (1987) An examination of nugget development during spot welding using both experimental and analytical techniques. Weld J Res Suppl 67(1):1s–10s

Holloman JH, Jaffee LD (1945) Time-temperature relations in the tempering of steel. Trans. AIME pp 162–223

Han Z, Indacochea JE, Chen CH, Bhat S (1993) Weld nugget development and integrity in resistance spot welding of high strength cold rolled sheet steels. Weld J Res Suppl 72(5):209s–216s

Gould JE, Workman D (1998) Fracture morphologies of resistance spot welds exhibiting hold time sensitivity behavior. Proceedings, Sheet Metal Welding Conference VII, AWS Detroit Section. Detroit, MI

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Select Committee AUTO - Automotive and Road Transport

Rights and permissions

About this article

Cite this article

Gould, J.E., Harris, M., Sakkinen, D. et al. Application of direct resistance treatment to localized areas on advanced high strength steel sheet. Weld World 60, 1109–1119 (2016). https://doi.org/10.1007/s40194-016-0361-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0361-5